- DL manuals

- Tally

- Printer

- T2155

- Maintenance Manual

Tally T2155 Maintenance Manual

Summary of T2155

Page 1

Maintenance manual matrix printer t2265 sprintpro ® t2280 sprintpro t2155 t2170

Page 2

This page intentionally left blank.

Page 3: Table of Contents

Table of contents chapter 1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 chapter 2 specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 2.1 printer specifications . . . . . . . . . . . . . . . ....

Page 4

3.3.14 paper thickness motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32 3.3.15 function select motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33 3.3.16 paper thickness sensor (aga) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34...

Page 5

5.3.3 dismount main electronic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9 5.3.4 replacing the aga assy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10 5.3.5 replacing carriage adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10 5...

Page 6

Chapter 7 spare parts and schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 7.1 housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 7.2 basic printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 7

Chapter 10 rear tractor (option, 2t model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1 10.1 specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1 10.2 tractor complete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 8

This page intentionally left blank.

Page 9: Introduction

1 introduction the matrix printers have been developed for professional applications in all environments. They meet the highest possible technical standards, and with proper use, they should provide many years of trouble-free operation. High-performance print qualities as well as operation with fanf...

Page 10

This page intentionally left blank.

Page 11: Specifications

2 specifications 2.1 printer specifications printer system serial impact matrix printer 1800 hz printhead with 24 needles ∅ 0.25 mm bidirectional printing print speed and character matrices t2155 t2170 t2265 t2280 cps cps cps cps cpi matrix hsq (high speed quality) 650 800 10,0 12 x 10 720 880 12,0 ...

Page 12

Fonts standard print qualities: hsq (t2265/t2280 only), (draft), cpq (copy draft) near letter quality (nlq), letter quality (lq); fonts: courier, roman, sanserif, ocr a + b (all resident in nlq und lq); dll is standard, but not battery-buffered barcodes (standard) a 2/5 matrix (default) b 2/5 indust...

Page 13

Paper feed feed speed 10"/sec 1/6" (line feed) 35 ms view position 10"/sec reverse motion up to max. Form length (22 inch), max. 1/6 inch for automatic single sheet feeder printhead gap standard automatic gap adjustment paper transport t2155/t2265 t2170/t2280 standard – tractor 1 with parking – trac...

Page 14

Dimensions width 623 mm (25.52 inches) height 277 mm (10.9 inches) depth 430 mm (16.92 inches) weight 19 kg (38 pounds) environmental conditions operation temperature +10° to +35°c rel. Humidity 16 to 73% climate iec 721-3-7, class 7k1 storage temperature -5° to +45°c rel. Humidity 5 to 95% climate ...

Page 15

2.2 interface specifications parallel interface bidirectional type of data transmission 8-bit parallel interface (centronics compatible) ieee-1284; nibble mode transmission rate max. 30 khz signal status low: 0.0 v to +0.4 v high: +2.4 v to +5.0 v connection cable material awg no. 28 at least length...

Page 16

2.3 paper specifications continuous paper tractor 1, single part forms weight 60 to 120 g/m 2 width 3 to 16.5 inches 76 to 420 mm form length 3 to 22 inches 76 to 559 mm continuous paper, multi part forms, tractor 1 (to be tested individually) number of copies 1 + 6 weight of original 45 to 65 g/m 2...

Page 17

Multi part forms (to be tested individually!) number of copies standard printer 2t model 1 + 6 1 + 1 weight of original 50 to 60 g/m 2 weight of copies 45 to 56 g/m 2 weight of bottom sheet 50 to 60 g/m 2 thickness (max.) 0.024 inches 0.6 mm width 3 to 16.5 inches 76 to 420 mm form length 3 to 12 in...

Page 18

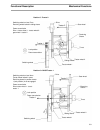

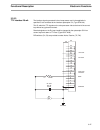

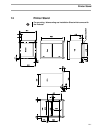

2.4 printer dimensions 623 36.5 128 432 3.5 280 42 ±5 49 ±5 42 ±5 62 ±5 60 110 377 376 509 183 189 522.5 30 30 430 45 (out max) (out max) 426 94 389 (2 in) (2 in) 406 (1 in) (1 in) 420 (out 1) (out 1) 420 (3 in) (3 in) 406 front buttom rear side t2155/t2265, t2170/t2280 outline drawing t2155/t2265, ...

Page 19: Functional Description

3 functional description 3.1 general 3.1.1 printhead the printhead is rated to more than 300.000 standard pages. The printer is economical too: 12.000 standard letters are printed with one ribbon. With our own word-wide patented 24 needle technology the printer also in speed reaches the top region o...

Page 20

3.1.4 data transfer the main difference between the serial and parallel interface is the form in which the data bytes are transfered. The serial interface transfers bits in a row, one after the other. Theoretically you only need three connections for this form of data transfer. In the parallel inter...

Page 21

3.2 mechanical functions 3.2.1 head/platen clearance the worm gear (see principle drawing) determine the basic head distance. You can imagine the worm gear as a mechanical memory. During initialisation (power up) of the printer the head distance stepper moves the toothed segment on block at the worm...

Page 22

Mechanic rotation platen mean point carriage axle bearing point ca. 1.4 mm movement of carriage 26° mechanical functions functional description 3-4.

Page 23

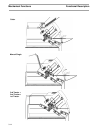

3.2.2 shift friction ➜ tractor the function of the tractor and the friction drive is controlled by a stepper motor. By changing from friction to tractor drive the wheels are moving as shown in the schematic below. Gear function select description explosion view function unit toothing (connects tract...

Page 24

Principle 1. The sliding sleeve is pushed by turning of the switching gear over the tractor gear on the revolving sleeve 2. The revolving gear is pushed over the guide line of the turret 3. The pressure spring, the slope at the sliding sleeve and the revolving sleeve, the revolving sleeve is turned ...

Page 25

Position 1 intermediate position 2 / tractor 2 tractor 2 drive tractor wheel 2 tractor wheel 1 sliding sleeve switching wheel switching wheel is turned on level 7mm, sliding sleeve and revolving sleeve are turned in intermediate position. Tractor wheel 1 and revolving sleeve are not locked in the tu...

Page 26

Position 3 / asf position 4 / intermediate tractor 2 drive tractor wheel 2 tractor wheel 1 sliding sleeve switching wheel switching wheel turned back; tractor wheels, sliding sleeve and revolving sleeve are pushed back by means of a spring until the revolving sleeve is engaged in the turret. No powe...

Page 27

Position 5 / tractor 2 position 6 = base tractor 1 tractor 2 drive tractor wheel 2 tractor wheel 1 sliding sleeve switching wheel switching wheel on level 7mm revolving wheel locked in sliding sleeve power transmission drive - tractor wheel 1 - tractor wheel 2 - gear wheel - tractor 2 revolving slee...

Page 28

3.2.3 monitoring light barrier ,,path selection“ fss1 fss2 description 0 5 tractor 1 (front) 5 0 tractor 2 (optional front) 5 5 tractor 3 (rear) or single (front) values in volt mechanical functions functional description 3-10

Page 29

3.2.4 position of the wheels to make sure that the printer works without any problems the wheels, curves, dampers and eccenters have to be mounted in the correct positions (marks). There are several marks on both side walls and the corresponding wheels and dampers. See the following drawing for furt...

Page 30

Right mark mark mark mechanical functions functional description 3-12.

Page 31

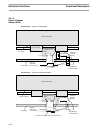

3.2.5 paperways standard printer 1st tractor asf-r functional description mechanical functions 3-13.

Page 32

Cutter manual single 3rd tractor + 2nd tractor + 1st tractor mechanical functions functional description 3-14.

Page 33

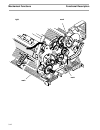

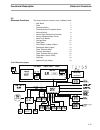

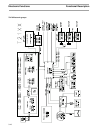

3.3 electronic functions the control electronic consists of up to 19 different units: – main board 1 – panel 2 – connection board 4 – printhead sensor/timing belt station 5 – interlock sensor 6 – sensor paper position/front insertion 7 – sensor sheetfeeder/rear tractor 8 – motor driver boards 9 – ca...

Page 34

T2170 electronic groups electronic functions functional description 3-16.

Page 35

T2265/t2280 electronic groups functional description electronic functions 3-17.

Page 36

3.3.1 main board the main board can be deviced into the following parts. – mains input/power supply – driver section – needle drivers – printhead thermo control – logic part 3.3.1.1 description of the switching power supply to switch over from e.G. 120 v to 230 v the user only has to move the power ...

Page 37

How to test the printer’s function without mains input there is the possibility to run a test procedure without line voltage. To perform this run following steps: – disconnect printer from outlet and switch printer off – give dc voltage (33 v) to jumpers connector x4 on the main board. – if you supp...

Page 38

Relation of the voltage/current needle magnet u 64v 36v 0v t i electronic functions functional description 3-20

Page 39

3.3.2 panel the panel consists of 2 function keys (online, setup) and 4 situation dependent softkeys. It will be plugged in via x6 connection board online trac1 tear online setup 2 1 3 4 10 9 8 7 6 5 4 2 3 1 gnd scli txd0 rxd0 vcc ct50 en pln rs gnd x6 functional description electronic functions 3-2...

Page 40

3.3.3 bidirectional centronics interface 1. Overview this sidm printer is equipped with a parallel centronics interface which is located on the main electronic pcb. The data transfer handshake (with some smaller exceptions) has been implemented according ieee1284 standard. Up to now (13.12.95) only ...

Page 41

2.2 phase 2, data transmission phase this phase is activated even after phase 1. A string of characters is transferred from the printer to the pc, which immediately describes the printer type, the manufacturer, the device class and some sort of compatibility. Procedure – selectin and autofeed are se...

Page 42

3.3.3.1 interface board option/modular there are several i/o boards available as option. They are designed as modules and easily changed within few seconds. It is plugged in at the main board x5. Input/output wired to gnd with 1nf. Gnd gnd if3 gnd vcc if4 gnd gnd if5 gnd c12 b12 a12 c11 b11 a11 c10 ...

Page 43

General infomation about external interfaces this printer has a bi-directional parallel centronics type interface (according ieee1284) which is mounted on the printer’s main board. As an option, the plug-in interfaces of other pay be used. E.G. If someone wants to use an (optional) rs232 (v24) i/o h...

Page 44

3.3.3.2 shared interface your printer can be configured in such a way, so that it uses only one interface or both alternatively. If only one interface is used, this is only monitored by the printer. If the printer is configured in such a way that both interfaces are used simultaneously, it alternate...

Page 45

3.3.3.3 tty interface 20 ma the interface signals generated in the microprocessor and in the application’s specified ic are connected to the interface optocoupler ic1 (type sfh 618). This ic switch the ttl-signals on the microprocessor side to the level of the current loop without any galvanical con...

Page 46

3.3.3.4 rs422/v11, ss97 rs422 the interface signals generated in the microprocessor and in the application’s specified ic are connected to the driver ic1. This ic converts the ttl signals on the microprocessor side to the rs422 / v.11 levels on the i/o side and vice versa. On the i/o side the signal...

Page 47

3.3.4 connection board the connection board has the task to interface the main logic to sensors and actuators. Therefore it owns no logic or active elements. More details about this board you will find in chapter 7.5 and 7.11. A fuse for “un” is built in : 5at “slow blow”. Asf/cutter carriage adapte...

Page 48

3.3.5 printhead sensor board this board is mounted inside the carriage. It contains connectors for fan (x1) and aga-sensor connector (x2). X3 and x4 will take the printhead cables. X7 is provided for the clock station. Details in chapter 7.25 3.3.6 interlock switch this switch is necessary to preven...

Page 49

3.3.9 motor driver these boards are controlling: – multi color option – sheetfeeder option (mounted in gear block) they are connected to the connector board via x12 (color) and x10 (asf). Stepper controller: connector bord out driver board out color motor sheetfeeder motor + cutting device principle...

Page 50

3.3.10 carriage motor this motor is directly connected to the connector board via x15. The dc-motor is controlled by the main logic (ic7, l6203) and the signals from the timing station. Horizontal motor 3.3.11 vertical motor this motor is controlled by driver circuit l 298 (ic18) on the main board a...

Page 51

3.3.15 function select motor this motor switches from fanfold paper (tractor) to single sheet (friction) and vice versa. It is controlled by ic26 (l 6219) on the main board. The motor is plugged directly in x4 on the connection board. Remark: for testing it’s possible to exchange the – sf motor (3.2...

Page 52

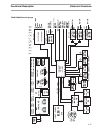

3.3.16 paper thickness sensor (aga) h l l h main friction roll friction roller l h h l clock band light barrier 1 light barrier 2 thickness test mask no paper of clock station clock pulses test gate signals: main friction roll thickness test mask light barrier 1 light barrier 2 of clock station cloc...

Page 53

3.3.17 optional rear tractor this connector leads to the external driver board. For standard assembly this connector (x16) is not mounted. 3.3.18 paper motion sensor 3.3.19 function select sensor this sensor monitors the position of the ,,function select gears“. It is connected to x3 of interconnect...

Page 54

3.3.20 option recognition whether an 2nd front tractor, a asf-front or no front option is mounted is monitored by this sensor. It is connected to x17 of the connection board. Table option recognition 48022 out value description tsfr 2.5 no option tsfr 0 tractor 2 mounted tsfr 5 sheet feeder front va...

Page 55

3.3.22 printhead there are two different printheads available: – ndk9/24 (approx. 1800 hz max) – ndk11/24 (approx. 2400 hz max) this modern ballistic printhead is driven by the needle driver section on the main board (ft5763m, signals n1x–n24x). The needle control is performed by the ppu96 (47537). ...

Page 56

3.3.23 additional fonts at the main board there is a possibility to load additional fonts (up to 8 mb depending on printer type). They are accessable by means of esc-sequences and by using the printer’s menu. It makes sense to put different fonts together in one eprom. The following list includes al...

Page 57

High draft sans character set id 1) speed draft copy roman serif courier 2) ocr-b ocr-a prestige script orator gothic souvenir cp737 greek 93 x x x – x – – – – – – – – cp850 latin 1 82 x x x x x x x x x x x x x cp851 greek 88 x x x – x – – – – – – – – cp852 latin 2 87 x x x – x x – – – – – – – cp857...

Page 58

3.3.23.2 scalable fonts character set roman roman t sans serif sans serif h iso usa – – – – iso uk – – – – iso france – – – – iso germany – – – – iso italy – – – – iso sweden – – – – iso norway – – – – iso spain – – – – iso portugal – – – – epson usa x x x x epson france x x x x epson germany x x x ...

Page 59

Character set roman roman t sans serif sans serif h cp857 turkish – – – – cp858 (ibm with ) x x x x cp860 portugal x x x x cp861 icelandic x x x x cp863 french canada x x x x cp864 arabic – – – – cp864 arab. Extended – – – – cp865 nordic x x x x cp866 cyrillic – – – – siemens turkish – – – – dec tur...

Page 60

3.3.23.3 barcodes resident barcodes 1 code 2/5 matrix (default) 2 code 2/5 industrial 3 code 2/5 interleaved 4 code 11 5 code bcd matrix 6 code 39 7 codabar 8 code ean 8 with clear text line 9 code ean 8 without clear text line 10 code ean 13 (with hri) 11 code ean 13 (without hri) 12 code msi/modif...

Page 61

3.3.24 theory of adjusting print- head temperature t2170 and t2280 only the resistance of each coil of the printhead is proportional to its internal temperature. The temperature will change almost linear to the measured coil resistance. The resistance is measured continuously. Therefore it is possib...

Page 62

3.4 loading firmware (principle) in the very first beginning a firmware is released by development. After that the alpha test will check the firmware in a flash controller. Since eprom controller are not supported only the flash version will be checked and released by alpha test department. Afterwar...

Page 63

4 testmodes and troubleshooting the following internal printer tests are available: ascii tree 8 inch ascii tree 13.6 inch hex-dump capability monitoring function for better understanding it is recommended to read also chapter 3 “functional description”. 4.1 test functions in order to test whether y...

Page 64

Note: the printer is equipped with the option of locking the menu, for example to prevent others from accessing it. You can do this using the menlock parameter from within the menu itself. (the menlock parameter is described in detail in the menu description table of the operators manual). You can a...

Page 65

4.2 troubleshooting many errors and problems that occur during printer operation have a simple cause and can be easily solved. So if you have a few problems with your printer, you do not need to phone the manufacturer right away. The following chapter will help you to differentiate between real prin...

Page 66

Error message cause removing the error load error the printer cannot draw in the loaded paper. Check: whether the paper path is blocked by an object. Whether the paper is damaged. Whether the tractors were properly closed and locked into position. Whether the paper is subjected to sufficient/insuffi...

Page 67

Error message cause removing the error check if new options are built in previously. Wrong board wrong logic board remove logic board or assy. Replace it with correct one. Wrong head wrong head mounted remove head. Replace it with correct head. Motor hot motor overload let printer cool down. Ths err...

Page 68

4.2.2 further messages in the lcd display the messages in the table below are not error messages, but operating steps to be mentioned. Message meaning head hot the printhead is hot. The printer reports that the temperature of the printhead is becoming too high and that print speed is being reduced f...

Page 69

4.2.3 printer malfunctions without any message at the lcd display this table deals with possible errors not reported in the lcd display. Problem possible causes printer has been switched on but nothing happens. The lcd display remains blank. Check whether the power cord is properly connected to the ...

Page 70

Problem possible causes paper jam (fanfold paper) open upper flap. Switch printer off. Close upper flap. Remove the jammed paper by tearing it off on the tearing edge and then open the tractors and pull out the paper in your direction (to the front). Pay attention to the following points: do not til...

Page 71

Problem possible causes the printed image is too dark or smudged the printhead distance is too small. Increase printhead distance (aga: go to plus direction). Check/adjust aga option. Install ribbon correctly (correct fitting). Check the thickness of the used paper (inhomogeneous?). Use built in cha...

Page 72

4.2.4 failure analysis are you sure the printer is the problem? Selftest (ascii test) ok? Panel function ok ? – buttons ok? – ability to enter the printer menu ? – check panel cable horizontal sstem ok ? – check cr motor – check horizontal belt – whether the carriage is blocked – firmware new? Print...

Page 73

4.3 monitoring functions to get the actual values (4 digits) of head/platen clearance printhead and cr motor temperature horizontal carriage position position of aga-flag during normal online condition, a special monitoring function has been implemented. The head/platen clearance will be displayed i...

Page 74

– control the display. A head/platen clearance b do not care c head temperature x if ,,m“ is displayed, cr motor is too hot d horizontal position cr e horizontal position aga-flag examples – to leave the monitoring (show) function, set printer offline and switch printer off. Dddd xaaabccc eeee lf/ff...

Page 75

4.4 caring, lubrication and maintenance the printer needs only very little cleaning maintenance. When cleaning the printer, observe the following points: – before cleaning, turn off the printer and disconnect the power cable. Never use strong detergents or alcohol-based cleaners. – clean the outside...

Page 76

4.5 monitoring of thermo-asic and printhead after power on the thermo-asic will be tested. Is there a asic bug the display will show a bitcoded message ths error xxx (xxx = failure number from 1 trough 16). The message is active approx. 20 s and will be deleted by pressing any key. Bit 1 = 1 (xxx = ...

Page 77

4.6 display message “hardware alarm” to analyse failures much more easier, an extended failure report has been implemented. The messages described below will only occur in “hardware alarm” state. If this message occures the printer must be repaired before switching on again. Please take care about t...

Page 78

6. Task control codes task control code meaning / description 1 horizontal task – active 2 horizontal task – motor is accelerating 4 horizontal task – motor break on 8 vertical movement – active 16 color motor – active 32 motor function select – active 64 motor sheetfeeder – active 128 adjustment pr...

Page 79

Phenomena countermeasure no clocks from incremental stripe – check whether the stripe positiones in the barrier – check whether the stripe is damaged or lose – check whether the barrier is plugged in correctly – substitute the sensor (light barrier) missing clocks from incremental stripe intermitten...

Page 80

4.8 printing without top cover sometimes it is usefull to look into the printer while the printer is working. (normally this is prevented by means of an interlock sensor.) caution: take care when the printer is operating: danger of injury! – open top cover – install the magnet at the interlock hall ...

Page 81

4.9 loading optional firmware or character generator if you download new firmware as described below, all menu settings will be overwritten. For this reason you should print a menu dump in order to be able to reestablish the previous settings if necessary (see menu description table). To load new fi...

Page 82

Download ok is displayed briefly when the procedure has been completed successfully. The printer then runs through its initialisation routine, after which it is ready for use. It is possible to repeat the download separately, e.G. Firmware followed by character generator. Loading the operating syste...

Page 83

5 instructions for disassembly and assembly this chapter provides the necessary information about disassembly and assembly 1) of the printer components and parts. Caution: switch off the printer, wait a few seconds and remove the power cord. Attention: give special attention on how the printer parts...

Page 84

5.1 replacing casing 5.1.1 replacing top case – first remove noise preventer “a”. – remove top cover “b” and rear cover “c”. – remove the front cover ,,a“. – remove the bottom cover tractor 1 ,,b“. A b c b a replacing casing instructions for disassembly and assembly 5-2.

Page 85

– use a screwdriver to unlock the casing aperture as shown in the illustration and remove it. Caution: be carefull while doing the above mentioned step. You may damage the panel cable. – disconnect the panel cable by pulling it out of the plug. Take caution. – use a screwdriver to unlock the casing ...

Page 86

– use a screwdriver to unlock the upper casing as shown in the illustration, lift it upward and remove it. Caution: be carefull about the panel cable. Assembly: for reassembling the top case run the procedure backwards. Use a screwdriver to make sure that the snap lock on the rear side engages corre...

Page 87

5.1.2 replacing bottom case – for first steps see section 5.1.1 – disconnect panel – remove optional interface board if present (see section 5.3) – remove main electronic “a” (see section 5.3.3) – release the 4 rubber snaps “b” (c: hook 395 850) – lift the printer mechanic with both hands straight u...

Page 88

5.2 printhead 5.2.1 removing the printhead – remove the top cover – lift upper friction – unlock the screws “a” at the printhead – now lift the printhead carefully. A printhead instructions for disassembly and assembly 5-6.

Page 89

5.2.2 installing the printhead – install the printhead by pressing it carefully downwards. – be sure the head connector fits correctly. – lock the printhead “c”. Caution (t2170/t2280 only): after installing printhead make sure to calibrate the temperature of the head. For further details see chapter...

Page 90

5.3 replacing electronic parts 5.3.1 replacing optional interface – push lever “a” in right direction (view from the rear) – take the interface cover and pull it in left direction “b” attention: do not buckle the spring inside the board space of the bottom case when you assemble the interface board ...

Page 91

5.3.2 replacing main board – disconnect mains voltage. – run steps 5.3.1 and 5.3.2. – remove top case (see section 5.1.1). – turn the lock “a” on the back of the printer indicated by the arrow. – pull slightly the board half out of the bottom case. – disconnect mains voltage connector “b”. – remove ...

Page 92

5.3.4 replacing the aga* assy – unplug aga cable “a” – unplug aga unit “b” by prying the hooks “c” outwards. Attention when installing aga you must run an adjustment procedure (see chapter 6, “adjustments”) 5.3.5 replacing carriage adapter – remove the upper housing (section 5.1.1) – remove main boa...

Page 93

– push cable holder “f” into the left direction. – release cable holder to upper direction. – remove cable cover “a” by pulling downwards. – release the flat cable out of the given cable guide “b” (front) and cable holder “c” (back). – unlock the two printhead cables “d” on the connection board by r...

Page 94

5.3.6 replacing motor driver (color option) – remove top case (section 5.1.1) – unplug the two cables “a” – release the board by pressing the snap in clamps up - and downwards “b” 5.3.7 replacing connector board – remove top case (section 5.1.1) – remove main board (section 5.3.3) – remove bottom ca...

Page 95

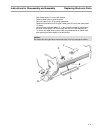

5.4 replacing motors 5.4.1 replacing carriage (dc) motor – remove top and bottom case as seen in section 5.1 – release the tension of the horizontal belt by turning the tightener in upward direction “a” – unlock both screws “b” – disconnect the motor from the connector board “c” – press down the mot...

Page 96

5.5 replacing sensor parts 5.5.1 replacing double sensor: front insertion / paper position and paper motion sensor – remove upper part of casing (section 5.1) – remove upper friction (section 5.9) – remove carriage system (section 5.8) – remove transverse paper guide (section 5.6) – remove sensor “a...

Page 97

5.5.2 replacing sheetfeeder sensor – remove optional interface (section 5.3.1). – remove main board (section 5.3.2). – remove housing (section 5.1). – remove sensor “a” at the bottom side of the printer’s chassis. A instructions for disassembly and assembly replacing sensor parts 5-15.

Page 98

5.5.3 replacing interlock sensor – remove housing (section 5.1) – remove main board (section 5.3.3) – unplug x8 from connector board – unplug the two hall sensors “a” by prying the catches a replacing sensor parts instructions for disassembly and assembly 5-16.

Page 99

5.6 replace transverse paper guide – remove the housing (section 5.1) – remove upper friction assy (section 5.9) – remove carriage system (section 5.8) – remove platen (section 5.16) – pry the two hooks (on both side walls) to inner direction “a” and move the whole transverse paper guide “b” into th...

Page 100

5.7 ribbon drive 5.7.1 replacing ribbon drive – remove the upper part of casing (section 5.1.9) – remove the color ribbon if installed – remove the lid “a” – remove the circlip above the toothed wheel in the middle “b” – replace desired toothed wheel caution: take care about the washers located at w...

Page 101

5.7.2 installing ribbon drive set – remove old ribbon drive. – put the washer “a” on the axle and the two other washers “b” and “c” on the toothed wheel “d”. – lubricate the shown positions. – put axle and wheel into correct position on transverse connector; put spring, washer and circlip onto axle....

Page 102

5.8 remove carriage system – remove the casing (section 5.1) – remove upper friction drive (section 5.9) – release the belt thightener on the left side “a” – unlock carriage motor. Place it on a safe position not to damage the cables. – remove drive wheel (section 5.15) – remove hindering toothed wh...

Page 103

5.9 replacing upper friction drive – remove upper part of casing (section 5.1.1) – unlock the friction by moving the colored lever “a” to the left and lift the friction upwards. – first spread the right side wall outward “b”. Simultaneously lift the right side of the friction. – run the same procedu...

Page 104

5.10 replacing the tractor assy – remove casing (section 5.1) – remove 2nd tractor drive “a” – remove support “b” by pressing the two notches ,,b1" – spread part “c” of the side wall outwards and pry the catch “d”. Simultaneously pull the tractor assy carefully outwards. – run the same procedure on ...

Page 105

5.11 replacing lower friction drive – remove the casing (section 5.1) – remove upper friction drive (section 5.9) – remove carriage system (section 5.8) – remove transverse paper guide (section 5.6) – unhook the two springs by prying with a screw driver “a”. – carefully lift the indicator axle “b” a...

Page 106

5.12 remove incremental stripe – open top cover – open front cover – remove color ribbon if neccessary – guide a small screw driver through the hole in the back at the right side from the bottom “a”. – pry the lower edge of the spring and press it in upper direction – if neccessary do the same proce...

Page 107

5.13 replacing side walls – remove all parts as described in sections 5.1 to 5.13 – unlock the screws – unlock hook “a” – press hook “b” – press hook “c” – remove side wall instructions for disassembly and assembly replacing side walls 5-25.

Page 108

5.14 mounting drive wheel – remove housing as described in section 5.1 – release circlip “a” – move drive wheel “b” outwards b a mounting drive wheel instructions for disassembly and assembly 5-26.

Page 109

5.15 remove platen – remove casing (section 5.1) – remove upper friction assy (section 5.9) – remove carriage system (section 5.8) – release clip “a” by means of a screwdriver – move platen to the front as shown in the picture “b” – take care about the position of the esd spring; detail “c” instruct...

Page 110

This page intentionally left blank.

Page 111: Adjustments

6 adjustments depending on the actual state of the printer, you have to carry out the following adjustments: mechanical adjustments gap printhead/platen parallelism between printhead and platen tension of the horizontal drive toothed belt ➜ must be carried out if replacing carriage system or toothed...

Page 112

– loose the belt by turning the eccentric pulley in upward direction. Tension the belt by turning the pulley downwards. Caution: do not bend the cables “a” while turning the eccentric pulley. – the point of measure is within the range of 150 mm to 200 mm from the left side wall. – the scale should b...

Page 113

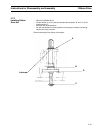

– remove the transparent paper guide from carriage. – adjust a clearance printhead (d)/platen (e) of ∆ x = 1.4 mm by means of a feeler gauge. Use your hand to move the toothed segment (c). – adjust worm gear (a) by moving gear on block at the toothed segment (b). – after adjusting you need not to fa...

Page 114

6.1.3 adjusting parallelism printhead/platen you must adjust parallism of printhead and platen if the printout is not satisfactory (one side of the printed matter is smudged or too light) or in case of changing/replacing the horizontal system (carriage etc.) necessary tool: feeder gauge 0.05 -1.5 mm...

Page 115

Adjustments mechanical adjustments 6-5.

Page 116

6.2 electrical adjustments 6.2.1 interface jumper settings 6.2.1.1 shared interface (option) (046 752) serial interface open closed s1 – 3 s1 – 4 s1 – 5 s1 – 6 – – * – – ready on pin 19 * ready on pin 25 ready on pin 11 * ready on pin 10 * b1 b3 meaning open closed closed open serial interface with ...

Page 117

S1 default of f 654321 on adjustments electrical adjustments 6-7.

Page 118

6.2.1.2 tty-interface 20 ma current loop (option) (046 755) tx jumper open close connector female x2 passive b11 x +txloop b12 x b13 x –txloop via switch tx b14 x active b11 x +txloop b12 x b13 x –txloop via switch tx to gndli b14 x rx jumper open close connector female x2 passive b15 x +rxloop via ...

Page 119

6.2.1.3 interface rs422 (047 144) ss 97 (047 145) (option) open closed function * b1 b8 chassis/gnd via r11//c1 and l5 on logic/gnd b1/b8 chassis/gnd via l5 on logic/gnd * b2 x2/pin 1 potential-free b2 chassis/gnd on x2/pin 1 * b3 b4 b7 b5 b6 b9 txd to interface txd on b txd/rdy txd on a txd/rdy b5 ...

Page 120

6.2.1.4 main controller jumper settings jumper on closed off open function 1 b18 x dtr → on pin 4 b23 x 2 b19/b23 x rdy → on pin 4 b18/b20/b22 x 3 b20/b23 x rdy → on pin 4 b18/b19/b22 x 4 b21 x txd → on pin 2 b22 x 5 b19/b22 x rdy → on pin 2 b20/b21 x 6 b20/b22 x rdy → on pin 2 b19/b21 x 7 b24 x cts...

Page 121

6.2.1.5 firmware name t2155 t2170 t2265 t2280 class. Spare depot qty. Firmware standard 048 042 048 042 048 431 048 431 — — 1 korea na 048 063 na 048 513 — — 1 china mainland 048 061 048 061 048 512 048 512 — — 1 taiwan 048 334 048 060 048 511 048 511 — — 1 6.2.1.6 non standard controller name t2155...

Page 122

6.3 soft adjustments 6.3.1 setting of head temperature (reference value) (t2170/t2280 only) necessary tools: thermometer caution: make sure the printhead has room temperature. – make sure the printhead has room temperature – keep top cover closed – press keys online and setup simulaneously while pow...

Page 123

6.3.2 adjustment of aga there is no special adjustment procedure necessary. The printer has to be powered on once without paper. This has to be performed after replacing of the carriage system and after substituting of the aga itself. Also after replacing of the main logic the printer has to be swit...

Page 124

This page intentionally left blank.

Page 125: Spare Parts and Schematics

7 spare parts and schematics the spare parts lists show: 1. The position of the part in the explosion drawing. 2. The name of the part. 3. The part number. 4. The type of the machine. Stand. Means standard machine w/o color color means color printer 5. The classification of parts. 6. Recommended loc...

Page 126

7.1 housing housing spare parts and schematics 7-2.

Page 127

1 front flap assy 061 293 061 293 061 293 061 293 b t 1 1 front flap assy (us version) 061 091 061 091 061 091 061 091 b t 1 2 panel assy 060 014 060 009 061 619 a s 1 2 panel assy /neutral 061 575 061 575 061 575 061 575 b c 1 3 screen left 060 003 060 003 060 003 060 003 b c 1 4 screen tractor tra...

Page 128

7.2 basic printer 133 1/3 basic printer spare parts and schematics 7-4.

Page 129

Basic printer 2/3 spare parts and schematics basic printer 7-5.

Page 130

Basic printer 3/3 basic printer spare parts and schematics 7-6.

Page 131

Electronic parts / main board complete standard spare assy 048 232 048 240 048 576 048 502 a s 1 / connection pcb 448 006 448 006 448 006 448 006 a s 1 62 carriage adapter 447 575 447 575 447 575 447 575 a s 1 84 sensor papermotion/end 061 312 061 312 061 312 061 312 a s 1 112 sensor asf/3rd tractor...

Page 132

Mechanical parts ii / leaf spring indicator axle 054 974 054 974 054 974 054 974 b t 3 5 belt tightener 060 740 060 740 060 740 060 740 b t 1 8 lever, parallelity 053 213 053 213 053 213 053 213 b t 1 9 bearing platen 052 042 052 042 052 042 052 042 b t 2 10 foot 053 229 053 229 053 229 053 229 b s ...

Page 133

This page intentionally left blank.

Page 134

7.3 standard tractor assy standard tractor assy spare parts and schematics 7-10

Page 135

Standard tractor parts / tractor assy complete 460 037 460 037 460 037 460 037 b t 1 17 tractor le/ri complete 061 064 061 064 061 064 061 064 a s 1 132 sensor option recognition 061 523 061 523 061 523 061 523 a s 1 / support na na na na 1 3 side panel tractor 1 right na na na na 1 4 bearing na na ...

Page 136

7.4 aga spare item name part no class depot qty. Aga 1 aga assy 048 030 a s 1 2 aga flag 054 616 a s 1 3 indicator axle 054 765 b c 1 / aga sensor holder 054 614 b c 1 “/”: no item number available. Please see details in according chapters; “na”: no spare part 7.5 connection board/cables 3 2 1 aga s...

Page 137

Spare item name t2155 t2170 t2265 t2280 class. Depot qty. Remark / connection board 448 006 448 006 448 006 448 006 a s 1 1 carriage adapter i 047 575 047 575 047 575 047 575 a s 1 2 carriage adapter ii 047 575 047 575 047 575 047 575 a s 1 3 asf/cutter cable 046 807 046 807 046 807 046 807 b t 1 4 ...

Page 138

“/”: no item number available. Please see details in according chapters; “na”: no spare part part id-no class. Qty power switch assy 047 526 a 1 part id-no class. Qty cable power supply 047 522 b 1 connection board/cables spare parts and schematics 7-14.

Page 139

7.6 electronic parts and sensors 7.6.1 mainboard complete standard spare assy spare item name t2155 t2170 t2265 t2280 class. Depot qty. Remark / main board complete standard spare assy 048 232 048 240 048 576 048 502 a s 1 spare parts and schematics electronic parts and sensors 7-15.

Page 140

7.6.2 carriage adapter assy spare item name t2155 t2170 t2265 t2280 class. Depot qty. Remark / carriage adapter 447 575 447 575 447 575 447 575 a s 1 a1 b-seite darstellung ohne a2/a3/a4 kabelführung a4 kabel l-seite a2 l-seite (a1) b-seite (ohne bestückung) kabel b-seite a3 x2 c1 x7 x1 electronic p...

Page 141

7.6.3 sensor papermotion/end spare item name t2155 t2170 t2265 t2280 class. Depot qty. Remark / sensor papermotion/end 061 312 061 312 061 312 061 312 a s 1 7.6.4 sensor asf/3rd tractor spare item name t2155 t2170 t2265 t2280 class. Depot qty. Remark / sensor asf/3rd tractor 048 025 048 025 048 025 ...

Page 142

7.6.6 sensor funciton selection spare item name t2155 t2170 t2265 t2280 class. Depot qty. Remark / sensor function selection 061 523 061 523 061 523 061 523 a s 1 kit 7.6.7 aga sensor spare item name t2155 t2170 t2265 t2280 class. Depot qty. Remark / aga sensor 447 540 447 540 447 540 447 540 a s 1 ...

Page 143

7.7 panel spare item name t2155 t2170 t2265 t2280 class. Depot qty. Remark 1 panel complete 060 014 060 009 061 618 061 619 a s 1 2 switch unit 070 109 070 109 070 109 070 109 b c 1 3 panel logic na na na na b 1 4 clamp 054 589 054 589 054 589 054 589 b c 1 “/”: no item number available. Please see ...

Page 144

7.8 pms + double sensor pms mechanic pms + double sensor spare parts and schematics 7-20

Page 145

7.9 sensor sheet feeder and rear tractor 2 1 3 4 gp2s07c x1 2 1 3 4 1 2 3 4 x1 (1b) (1a) 1 2 3 4 2 2 spare parts and schematics sensor sheet feeder and rear tractor 7-21.

Page 146

7.10 option recogition option recogition spare parts and schematics 7-22.

Page 147

7.11 sens function select spare parts and schematics sens function select 7-23.

Page 148

7.12 afi automatic front insertion afi automatic front insertion spare parts and schematics 7-24.

Page 149

7.13 modular interfaces 7.13.1 shared interface cx/rs232 (option) part. No.: 046 752 spare parts and schematics modular interfaces 7-25.

Page 150

Modular interfaces spare parts and schematics 7-26.

Page 151

7.13.2 current loop interface 20 ma (option 046 755) spare parts and schematics modular interfaces 7-27.

Page 152

7.14 serial interface rs422/v11 interface (option) part no.: 047 144 ss97 interface (option) part no.: 047 145 serial interface spare parts and schematics 7-28.

Page 153: Sheet Feeder Mechanic

8 sheet feeder mechanic this chapter provides the necessary information on disassembly of the different sheet feeder components and elements. Note: asf will not fit on t2170-2t and t2280-2t. 8.1 specifications dimensions hight of printer with sheet feeder installed: 350 mm weight autom. Sheet feeder...

Page 154

Paper specifications single sheet paper weight: 60 - 90 g/m 2 (for sheets with the paper weight beyond this range a functional test should be performed) paper width: 100 - 369 mm (format selection range) paper length: 100 - 356 mm multilayer forms paper weight: original: 52 - 65 g/m 2 first sheet: 6...

Page 155

8.2 assembly/ disassembly 8.2.1 sheetfeeder the sheetfeeder is easily disassembled by unhooking the four snaplocks as shown in the picture “a”. 8.2.2 mounting gear block – guide the gear block carefully in direction to the left side wall till the electrical contact is automatically performed. – to r...

Page 156

8.3 spare parts and schematics sheet feeder mechanic spare parts and schematics 8-4.

Page 157

1 file support 053 492 053 492 053 492 053 492 b c 1 2 toothed wheel z35 053 489 053 489 053 489 053 489 b c 2 3 cover left 053 491 053 491 053 491 053 491 b c 1 4 marginal stopp right 060 361 060 361 060 361 060 361 b c 2 5 swing plate left 053 486 053 486 053 486 053 486 b c 2 6 support paper 053 ...

Page 158

8.4 asf/sheetfeeder, gear block 1 2 3 4 5 (3x) 6 7 (2x) 8 (2x) sheet feeder mechanic asf/sheetfeeder, gear block 8-6.

Page 159

/ asf gear block assy 054 484 054 484 054 484 054 484 a t 1 1 gear cover na na na na 1 2 motor asf na na na na 1 3 logic motor control na na na na 1 4 gear housing na na na na 1 5 toothed wheel z33 na na na na 3 6 toothed wheel z33 na na na na 1 7 washer a3 din 137 na na na na 2 8 screw ejot-pt-ka30...

Page 160

This page intentionally left blank.

Page 161: Face Down (Option)

9 face down (option) 9.1 specification please see section 8.1 9.2 functional description the face down option is an additional module which can be used in connection with the automatic sheet feeder as well as with the manual paper insertion at the front of the printer. It offers the advantage that s...

Page 162

9.3 spare parts / face down assy 054 807 054 807 054 807 054 807 b c 1 1 carrier plate assy na na na na 1 2 paper guide na na na na 1 3 bearing left na na na na 1 4 pressure foil na na na na 1 5 axle shaft na na na na 1 6 bearing right na na na na 1 7 toothed wheel z25 na na na na 1 8 toothed wheel ...

Page 163

10 rear tractor (option, 2t model) (not field montable) paper feed for fanfold paper is either – from the front via the tractor 1 or – from the rear via the tractor 3 – optional feed from tractor 2 (front) paper feed for single sheets is from the front via manual single sheet feed. This chapter prov...

Page 164

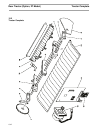

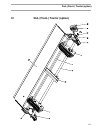

10.2 tractor complete 14 rear tractor (option, 2t model) tractor complete 10-2.

Page 165

1 drive wheel na na na na 1 in 453 986 4 side plate na na na na 2 in 453 986 5 tractor set assy na na na na 1 in 453 986 6 paper guide 1 na na na na 1 in 453 986 6 paper guide 1 na na na na 1 7 axle, round na na na na 1 in 453 986 8 tractor axle, square na na na na 1 in 453 986 9 adapter plate na na...

Page 166

This page intentionally left blank.

Page 167: Cutting Device (Option)

11 cutting device (option) safety notes: – if you have any short pieces of paper remaining in the device, turn off the printer first. – do not stick unsuitable materials or tools – such as screw drivers etc. – into the device openings as this may damage the mechanical system. – replace the protectiv...

Page 168

14 6 4 12 1 5 6 11 7 13 7 8 17 2 9 3 16 15 4 cutting device (option) specifications 11-2.

Page 169

11.2 spare parts and schematics 11.2.1 mechanical components 1 connection cable 395 076 395 076 395 076 395 076 b c 1 2 controller pcb 395 077 395 077 395 077 395 077 b c 1 3 motor incl. Gears 395 078 395 078 395 078 395 078 b c 1 4 housing upper part 395 079 395 079 395 079 395 079 b c 1 5 drive be...

Page 170

This page intentionally left blank.

Page 171

12 2nd- (front-) tractor (option) 2nd- (front-) tractor (option) 12-1.

Page 172

/ 2nd supplemental tractor assy 061 218 061 218 061 218 061 218 b t 1 1 tractor le/ri complete 061 064 061 064 061 064 061 064 a s 1 3 bearing na na na na 1 4 toothed wheel z=50 m=0.7 na na na na 1 set 5 side panel tractor 2 right na na na na 1 set 6 side panel tractor 2 left na na na na 1 7 axle tr...

Page 173: Color Option

13 color option color option 13-1.

Page 174

Color parts standard color 1 motor controller na 046 760 c 1 2 colormotor cable na 046 809 c 1 3 motor color na 053 510 c 1 4 switch shaft na 053 315 c 1 5 bearing na 053 314 c 1 6/7/8 ribbon carrier + 2x springs na 054 471 c 1 9 curve (inner) na 053 321 c 1 10 toothed wheel z40 na 053 318 c 1 11 to...

Page 175: Printer Stand

14 printer stand for mounting / dismounting see installation sheet which comes with the pedestal printer stand 14-1.

Page 176

This page intentionally left blank.

Page 177

“all rights reserved. Translations, reprinting or copying by any means of this manual complete or in part or in any different form requires our explicit approval. The manufacturer reserves the right to make changes to this manual without notice. All care has been taken to ensure accuracy of informat...

Page 178

© december 2001 tally computerdrucker gmbh 379 615b tally representatives france tally s.A. 19 avenue de l’lle saint martin f-92237 nanterre cedex france tél.: +33 1 41 30 11 00 fax: +33 1 41 30 11 10 http://www.Tally.Fr austria tally ges.M.B.H. Eduard-kittenberger-gasse 95 b a-1232 wien austria tel...