- DL manuals

- TallyGenicom

- Printer

- LMPCHS

- Administrator's Manual

TallyGenicom LMPCHS Administrator's Manual

Summary of LMPCHS

Page 1

Administrator’s manual 6800 series printers.

Page 2

Read this software license agreement before using this printer software license agreement carefully read the following terms and conditions before using this printer. Using this printer indicates your acceptance of these terms and conditions. If you do not agree to these terms and conditions, prompt...

Page 3

Acknowledgement of terms and conditions you acknowledge that you have read this agreement, understand it, and agree to be bound by its terms and conditions. Neither party shall be bound by any statement or representation not contained in this agreement. No change in this agreement is effective unles...

Page 4

Table of contents introduction .................................................................... 9 printer overview .................................................................................................. 9 tallygenicom 6800 series cartridge ribbon printers (crp) ..........................

Page 5

Saving your new configuration .................................................................. 42 6800 crp main menu ....................................................................................... 48 quick setup .................................................................................

Page 6

How to program the security key ............................................................... 99 downloading firmware .............................................. 101 firmware file types (.Prg) and (.Exe) ............................................................. 102 webpanel download ..........

Page 7

Acoustic noise level ....................................................................................... 144 electrical characteristics ................................................................................. 145 interfaces ..................................................................

Page 9: Introduction

9 introduction printer overview this chapter provides a general overview of your printer and the conventions used within this manual. Tallygenicom 6800 series cartridge ribbon printers (crp) tallygenicom® is pleased to announce the tallygenicom 6800™ series line matrix printers, the latest generatio...

Page 10: Protocols And Emulations

10 five printer configurations are available: cabinet (68xxq) • the enclosed cabinet models provide for near silent operation, making these printers perfectly suitable for use in the quietest of office environments. • provides the best paper handling for large print runs. All paper input and output ...

Page 11: Conventions In This Manual

11 taking care of your printer your printer will produce high quality print jobs if it is well taken care of. Periodic cleaning, handling the printer properly, and using the correct printer supplies such as ribbon and paper ensures optimum performance. Chapter 8 explains how to clean the printer, an...

Page 12

12.

Page 13: Setting Up The Printer

13 setting up the printer before you begin read this chapter carefully before installing and operating the printer. The printer is easy to install. However, for your safety and to protect valuable equipment, perform all the procedures in this chapter in the order presented. Power requirements the pr...

Page 14: Printer Dimensions

14 table 2 maximum interface connection cable length interface type maximum cable length centronics parallel 5 meters (15 feet) ieee 1284 parallel 10 meters (32 feet) serial rs-232 15 meters (50 feet) usb 2.0 universal serial bus 5 meters (15 feet) twisted pair / type 3 300 meters (985 feet) etherne...

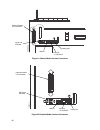

Page 15

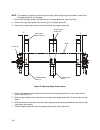

15 figure 2 pedestal model 54.0 in (137.2 cm) 11.36 in (28.9 cm) 29.5 in (74.93 cm) 29.1 in (73.9 cm) 19.1 in (48.5 cm) 25.92 in (65.8 cm).

Page 16

16 figure 3 zero tear pedestal mode 38.9 in (98.8 cm) 19.1 in (43.8 cm) 31.95 in (81.2 cm) 25.92 in (65.8 cm) 42.0 in (106.7 cm) 60.1 in (152.7 cm).

Page 17

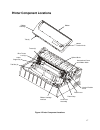

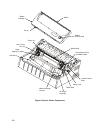

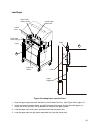

17 printer component locations figure 4 printer component locations ribbon cartridge tab (2) tractor (2) blue tractor lock (2) paper support (2) tab slot (2) ribbon cartridge interface air shroud assembly platen stop platen lever vertical position knob hammerbank cover and ribbon mask splined shaft ...

Page 18

18.

Page 19: Operating The Printer

19 operating the printer powering on the printer when you power on the printer, it executes a self-test. The default power-up state is offline. When the self-test completes and the software has initialized successfully, the status indicator light is off, indicating the printer is offline. When the p...

Page 20: The Control Panel

20 the control panel figure 5 shows the keys, displays, and indicators as they appear on the control panel. The following section provides the descriptions, and functions of the control panel keys. Key combinations are indicated with the plus (+) sign. For example, “press + ” means to press the key ...

Page 21

21 control panel keys online toggles the printer between online and offline modes. The key performs the following in online, offline, fault, and menu modes: • online mode – sets the printer to offline mode. • offline mode – sets the printer to online mode. • fault mode – causes the printer to rechec...

Page 22

22 note: use of this key will cause loss of data. Tof sets the top-of-form on the printer. This key is active only when the printer is offline and will not operate if the printer is in a fault condition. The paper moves down to the print position and aligns to the top-of-form. Refer to the user’s se...

Page 23: Operational Procedures

23 up + down ( + ) locks and unlocks the enter key. Prev or next ( or ) moves between the options on the current level of configuration menu. In the configuration menu, press to scroll backward or press to scroll forward through the menu selections on the same level. Prev + next ( + ) whe...

Page 24

24 figure 6 paper slot location 1. Raise the printer cover. Raise the platen lever as far as it will go. (see figure 4 on page 17 for the location of the lever.) note: do not open tractor doors or remove the existing paper. 2. Cabinet models: open the front door and align the paper supply with the l...

Page 25

25 figure 7 loading new paper into the printer 6. Pull the new paper above and behind the ribbon mask, but in front of the existing paper. See figure 4 on page 17 for the ribbon mask location. If necessary, gently press the existing paper back. 7. Align the top edge of the new paper with the top per...

Page 26

26 9. Turn the platen stop knob clockwise or counterclockwise to match the paper thickness. (the a-b-c scale corresponds approximately to 1-, 3-, and 6-part paper thickness). Note: if you are using the same thickness of paper, there is no need to readjust. 10. Lower the platen lever until it stops. ...

Page 27

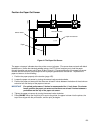

27 figure 10 positioning the left tractor to avoid damage caution to avoid damage to the printer caused by printing on the platen, always position the left tractor unit directly to the left of the “1” mark on the paper scale. 21. Normally, you should not need to adjust the position of the left tract...

Page 28

28 22. Unlock the right tractor. 23. Load the paper onto the sprockets and close the tractor door. If necessary, slide the right tractor to remove paper slack or to adjust for various paper widths. Then, lock the tractor. Figure 12 using the paper guide to orient the paper 24. Press advance several ...

Page 29

29 figure 13 aligning the perforation with the tof indicator 26. Align the top of the first print line with tof indicator on the tractor by rotating the vertical position knob. For best print quality, it is recommended that the top-of-form be set at least one print line or more below the perforation...

Page 30

30 27. Turn the platen stop knob clockwise or counterclockwise to match the paper thickness. (the a-b-c scale corresponds approximately to 1-, 3-, and 6-part paper thickness. Adjust until you have the desired print quality). Note: the platen stop allows you to set an optimum and consistent thickness...

Page 31

31 figure 16 completely removing the paper 8. To completely remove the paper from the printer: a. Raise the platen lever as far as it will go and open both tractor doors. Caution be careful when pulling any paper backward through the paper path, especially when using a label stock. If you are not ca...

Page 32

32 without losing data in the printer’s buffer. If a new ribbon is loaded, the system automatically detects the change, clears the condition when the platen is closed, and restarts the life at 100%. If a partially used ribbon is loaded, the system continues the life at the percentage indicated for t...

Page 33

33 figure 17 preparing to load the ribbon 1. Open the printer cover. 2. Raise the platen lever as far as it will go. 3. Ensure the tractor doors are closed. 4. Remove the old ribbon cartridge and discard properly. Blue tractor door (2) platen lever.

Page 34

34 figure 18 installing the ribbon cartridge 5. Remove the ribbon slack on the new ribbon cartridge by turning the ribbon tension knob clockwise. Caution do not turn the ribbon tension knob counterclockwise. This could damage the ribbon cartridge. 6. Hold the cartridge at an angle, so that the rear ...

Page 35

35 figure 19 the ribbon cartridge snapped in place 7. Rock the cartridge downward, making sure that the ribbon goes between the guide and the mask (see figure 19). You will feel it snap into place. Caution make sure that the ribbon does not twist or fold over. 8. Turn the ribbon tension knob clockwi...

Page 36

36.

Page 37: Configuration Menus

37 configuration menus configuration overview to print data, the printer must respond correctly to signals and commands received from the host computer. Configuration is the process of matching the printer's operating characteristics to those of the host computer and to specific tasks, such as print...

Page 38

38 navigating the menus to manipulate configurations review the following instructions about navigating through the menus. You must be offline to move within the menus. Press to toggle between online and offline. Press enter to enter menu mode. Menus are accessed only in menu mode. Scroll up, down, ...

Page 39: Top Level Menu Overview

39 press to return to offline mode. If changes were made, the user will be prompted to save or discard the configuration. To experiment with navigating the menus, use the example on the next page as a tutorial. Top level menu overview when entering menu mode, the user will see top level menus repres...

Page 40

40 changing parameters example a configuration consists of several parameters. The default factory configuration has a starting set of parameters. In the configuration menu above, and in all the configuration menus in this chapter, the factory default values are indicated by an asterisk (*). Your pr...

Page 41

41 step press lcd notes 5. 6. 7. The * indicates this choice is active. 8. Press until the desired selection or value displays. 9. The * indicates this choice is active. 10. Press enter to go back into the menus or press online again to go online. 11. Configuration changes were detected and you are ...

Page 42

42 auto save configuration if the user makes a menu change and attempts to place the printer online without saving the changes to a configuration, the following prompt displays: the active option is highlighted. Use the up and down keys to scroll through the different options; the keys will loop at ...

Page 43

43 example 1 this example shows how to save a configuration as a numbered configuration, then later print it. Step press lcd notes 1. Make sure the printer is on. 2. 3. Shows the top level icons. 4. 5. 6. 7. 8. Cycle through the choices. 9a. Configuration is in the process of being saved. Online ent...

Page 44

44 step press lcd notes 9b. The * indicates this choice is active. Note: we recommend that you print the configuration. To print the configuration go to step 10. To skip this procedure and resume printer operation, go to step 16. 10. The cancel key will return back one level. 11. 12. 13. 14. 15. The...

Page 45

45 step press lcd notes 17. 18. If you printed the configuration, store it in a safe place. The printer is ready for operation. Example 2 this example shows how to save a configuration as a named configuration. Step press lcd notes 1. Make sure the printer is on. 2. 3. Shows the top level icons. 4. ...

Page 46

46 step press lcd notes 8. 9. 10. You will rename config. 2. 11. The lcd flashes. 12. Press the left or right key to choose the character that is highlighted. 13. Press the up key to select the next character in the string. Press the down key to go back to the previous character and continue editing...

Page 47

47 step press lcd notes 17. 18. Test now appears as one of the configuration choices. 19a. 19b. Your configuration is saved as test. 20. Press enter to go back into the menus or press online again to go online. 21. Now you have the saved configuration for later use if needed. Until enter online onli...

Page 48: 6800 Crp Main Menu

48 6800 crp main menu figure 20 6800 crp main menu configuration pattern fault override diag offline host interface emulation ribbon configuration clear font forms vfu printer codes graphics configurations host interface usb i/o serial i/o parallel i/o 2 intellifilter main file mgmt sd file mgmt 3 c...

Page 49: Quick Setup

49 quick setup host interface the host interface menu enables you to select and configure interfaces between the printer and your host computer. Options include: • auto switching (default). This menu selects which host i/o is currently active (see page 75). Other selections include centronics, seria...

Page 50

50 emulation • ser/par emul. This parameter allows you to define which set of printer control commands will be emulated for data received on the serial and parallel ports. Tally ansi is the default selection. This menu also enables you to define the form length, characters per inch (cpi) and lines p...

Page 51: Operator Menu

51 • lpi. This parameter allows you to set the lines per inch (lpi). The possible selections are 1.5, 2, 3, 4, 5, 6, 8, 9, 10, and 12. The default setting is 6 lpi. Ribbon ribbon end point. This parameter adjusts the point at which the system will declare the ribbon as being expended. The life count...

Page 52

52 font submenu this submenu contains parameters that control how print looks on a page and the display language. The level 2 headings are as follows: dp* gothic courier ocr-a ocr-b download draft font (from page 51) us* german norwegian/dan french uk spanish swedish/finish italian japanese portugue...

Page 53

53 ser/par lang this option allows you to select the language used by emulations attached to the parallel, serial, and lan ports. The language selection defines the character substitutions in hex locations 23, 24, 40, 5b, 5c, 5d, 5e, 60, 7b, 7c, 7d, and 7e. The default is us. Refer to the 6800 emula...

Page 54

54 refer to the 6800 emulations manual for details on character sets. The possible selections are: latin1 8859-1 latin2 8859-2 latin9 8859-15 cyrillic 8859-5 greek 8859-7 turkish 8859-9 code page 437 code page 850 code page 851 code page 852 code page 855 code page 857 code page 863 code page 866 co...

Page 55

55 ser/par style this option allows you to select the font style for use by emulations attached to the parallel, serial, and lan port. For emulations that support downloaded fonts, you can use this parameter to select the download font. The default is dp. Style selections include: draft (high-speed)...

Page 56

56 • medium. Prints a normal bold text character. Although selecting this weight reduces print speed, it provides the best boldness appearance. • dark. Prints a thick bold character. This weight is best for 10 and 12 cpi characters and provides an increase in print speed over the medium weight. Ital...

Page 57

57 forms submenu this submenu is used for setting form specifics. The level 2 headings are as follows: 66* 1-255 forms (from page 51) * = factory default 1 2000 lpm printer only. 2 1000 lpm printer only. 3 default is 15 minutes for cabinet models. Bottom margin top margin lpi length (inches) 2 lengt...

Page 58

58 length (lines) to define the length of your form in lines, select a form length from 1 to 255. The default option is 66. Length (inches) to define the length of your form in inches, select a form length from 00.1 to 25.5 inches. The default is 11.0 inches. Lpi this allows you to set the lines per...

Page 59

59 quick access this option provides a way for a pedestal printer to position printed forms for quick tear-off access. When quick access is enabled, the paper is moved to the tear position by holding down the view key for one second for eject. The eject mode may be exited by pressing the view key. (...

Page 60

60 note: printing will only stop on the first occurrence of a ribbon low condition. Once the user clears the warning message, subsequent warnings will display the warning message, but printing will continue. Rbn end action this menu allows the user to override the normal ribbon low warning and ribbo...

Page 61

61 vertical format units (vfu) submenu this submenu is used for setting vfu specifics. The level 2 headings are as follows: vfu enable a vertical format unit is a means for loading sets of vertical tabs. These vertical tabs define various parameters of a form. This parameter applies only to the emul...

Page 62: Config Menu

62 config menu the following are explanations of each submenu and parameter. Printer submenu (see below) config menu (from page 48) * = factory default 1 if parallel installed. 2 if sf card is installed. Host interface configurations graphics codes printer usb i/o (see page 65) (see page 69) (see pa...

Page 63

63 ser/par emul this parameter allows you to define which set of printer control commands will be emulated for data received on the serial and parallel ports. The emulation settings are automatically saved in the powerup configuration. Tally ansi is the default selection. When a new emulation settin...

Page 64

64 dump mode dump mode is used to troubleshoot problems that may arise when processing data. It places the printer into a hex dump mode. You can select three styles of printouts for use as debugging tools. The standard selections are: • off (default). Dump mode is disabled. • style1. Two column outp...

Page 65

65 codes submenu auto lf (line feed) auto lf causes the printer to perform a line feed each time it receives a carriage return control code. This parameter is available for host systems that cannot send a line feed control code. Some computers automatically generate a line feed of their own at the r...

Page 66

66 line wrap if the printer gets to the right margin without receiving a paper movement command, the line wrap parameter dictates how the rest of the data will be treated. If line wrap is off, the excess characters are lost. If line wrap is on, printer response is determined by the wrap line feed pa...

Page 67

67 upper only this parameter allows you to set up your printer to print in uppercase characters only from the active character set. When this parameter is enabled, the lower-case characters in hex positions 61 through 7a are overwritten by the uppercase characters in positions 41 through 5a. The def...

Page 68

68 tof control (available when genicom ansi emulation is selected) when a new form is defined, the top-of-form position is left unchanged if this parameter is set to enable (the default). When a new form is defined, and this parameter is set to disable, the top-of-form position is reset to the top m...

Page 69

69 graphics submenu this submenu allows you to configure certain aspects of the graphic processing options on your printer. The level 2 headings are as follows: 94* 1-255 graphics (from page 62) * = factory default 1 if mtpl emulation is selected 2 if genicom ansi emulation is selected dark bar pn t...

Page 70

70 code v cmd char this parameter allows you to change the cvcc. The default for this parameter is the ascii caret ( ^ , decimal 94, hex 5e) character. Smooth size this parameter controls the size at which block characters are smoothed. The default is 3, which means that size 3 block characters will...

Page 71

71 version this parameter controls the version of code v the printer emulates. Version 2 is the default selection. Descender this parameter controls insertion of the character descender gap between print lines. • fixed (default). The descender gap is always inserted after the line whenever descender...

Page 72

72 us uk swedish/finnish norwegian/dan japanese german french italian spanish pgl language this parameter allows you to select the language character set that will be used for text output in printronix graphics mode. The default is ascii. The available selections are: ascii german swedish danish nor...

Page 73

73 pgl terminator determines whether or not a cr-lf terminator for pgl commands will cause a line feed to occur. • cr. Allows line feeds which follow the carriage return to be executed. Example: ~execute;test ~normal the above example would execute three line feeds following the job test. • cr-lf (d...

Page 74

74 save config. This option allows you to save up to eight configurations to meet different print job requirements. This eliminates the need to change the parameter settings for each new job. The configurations are stored in memory and will not be lost if you turn off the printer. The factory defaul...

Page 75

75 host interface submenu the host interface submenu enables you to select one of many types of interfaces between the printer and your host computer. The currently selected interface is indicated with an asterisk on the control panel message display. There are also submenus available to setup the h...

Page 76

76 trickle time when the printer is printing data from a host and a second job is received by the printer from a different host, trickle time prevents the second host from timing out while it is waiting for its data to be printed. To support this feature, the port has to be able to accept data from ...

Page 77

77 serial i/o submenu baud sets the baud rate of the serial interface in the printer. Baud rate is the speed at which serial data is transferred between the host computer and the printer. The choices for the rs-232 interface are 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, and 115200 baud. The ...

Page 78

78 8th bit if 8 bits per byte is selected under data bits above, use this parameter to determine how the 8th bit is to be used. If this bit is to be ignored, set the parameter to unused. If the bit is to be used, set the parameter to data. Data is the default, used for 8-bit characters. Protocol the...

Page 79

79 table 5 status enquiry response bit pattern bit meaning/value 7 parity if 7 bit data and parity enabled (msb) 6 always a 0 5 always a 1 4 always a 1 3 0 if parity error, data overrun, or buffer overflow 2 1 if offline 1 1 if busy (fault or buffer full) 0 1 if paper system error or platen open (ls...

Page 80

80 buffer size in k this option configures the amount of memory allocated for the serial port buffer. You may specify between 1 and 16 kbytes, in 1-kbyte increments. The default is 16k. Unsolicit rpt this option enables or disables printer device status reports to be sent to the host when a reportab...

Page 81

81 resp. Polarity the resp. Polarity parameter must be set to match the response polarity of your host computer. • standard (default). Does not invert the response signal. • inverted. Inverts the response signal sent to the host computer. Busy on strobe • enable (default). Asserts a busy signal afte...

Page 82

82 serial, parallel, lan • disable (default). The intellifilter will be disabled on the respective port. • enable. The intellifilter will be enabled on the respective port. File management • download. This selection will place the printer in the intellifilter download mode. • delete. This selection ...

Page 83

83 optimize&reboot reclaims flash space from deleted flash files. After pressing enter, wait for the printer to reboot. Note: when the optimize&reboot option is executed, the message, “optimizing flash files” does not display before printer rebooting takes place. Important do not turn the printer of...

Page 84: Tcp/ip Menu

84 erase qcmc erases the qcmc image stored on the sd card (see appendix d, quick change memory card (qcmc). Cst/paa submenu refer to the printnet enterprise suite user’s manual. Ptx_setup option submenu selects the special function control code for the ptx_setup command and functions. See appendix e...

Page 85

85 ethernet address ip address a numeric address such as 123.45.61.23 which identifies a printer or server in a lan or wan. Subnet mask a binary value used to divide ip networks into smaller networks or subnets. This mask is used to help determine whether ip packets need to be forwarded to other sub...

Page 86

86 ethernet params the ethernet params menu helps your printer communicate on a network. Ascii data port this option sets the port number for ascii print jobs. The data port number needs to match your host system setting. • 9100 (default) • 1023 - 65535 keep alive timer this is the time that the kee...

Page 87: Test Menu

87 • enhanced. The nic waits for the printer to finish receiving the current job before sending another job. The status line shows “done” when the job is fully printed. • fast standard. The eoj (end of job) packet is acknowledged immediately. Use this selection if the job is timed out due to a delay...

Page 88

88 pattern submenu the pattern submenu has a series of printer self-tests which have predefined patterns used to test the basic printer functions. Printer tests these tests are used to check the print quality and operation of the printer. Note: your authorized service representative will typically r...

Page 89

89 • novram err log. Prints detailed information about the most recent novram related failure that has occurred. It is useful when the front panel reports “bad nvm” or “ill nvm” error types. Contact the customer solutions center and provide this information if such an error occurs. • all characters....

Page 90

90 paper motion this parameter controls paper motion fault reporting status. This setting is saved in nvram so that it does not need to be set up on powerup each time. Shuttle off the amount of time the shuttle continues moving after no data is received. If your host is slow, setting the number to a...

Page 91: Interfaces

91 interfaces overview this chapter describes the host interfaces provided with the printer. The printer interface is the point where the data line from the host computer plugs into the printer. The interface processes all communications signals and data to and from the host computer. Plus, with the...

Page 92

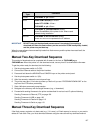

92 figure 21 cabinet model interface connectors figure 22 pedestal model interface connectors 1 2 3 4 5 6 7 8 9 1 8 4 9 5 1 a optional parallel i/o connection serial port (rs-232) usb 2.0 ethernet 10/100 baset debug port 1 8 4 9 5 2 a optional parallel i/o connection serial port (rs-232) usb 2.0 eth...

Page 93: Rs-232 Serial Interface

93 rs-232 serial interface note: the rs-232 serial interface circuit characteristics are compatible with the electronic industry association specifications eia-232-e and eia-422-b. The rs-232 serial interface enables the printer to operate with bit serial devices that are compatible with an rs-232 c...

Page 94: Usb

94 usb menus the universal serial bus (usb) port is part of auto switching and is active when the host interface menu is set to auto switching. It can also be selected as the only host interface under the host interface menu by selecting usb. A top level usb port menu with two submenus is also avail...

Page 95

95 centronics parallel interface signals data lines 1 through 8. Provides eight standard or inverted levels from the host that specify character data, plot data, or a control code. Data line 8 allows access to the extended ascii character set. You may enable or disable this line via the data bit 8 p...

Page 96

96 table 9 1284 signals pin source of data type of mode compatible nibble byte 1 host nstrobe hostclk host/clk 2 host/printer data 1 (lsb) 3 host/printer data 2 4 host/printer data 3 5 host/printer data 4 6 host/printer data 5 7 host/printer data 6 8 host/printer data 7 9 host/printer data 8 (msb) 1...

Page 97: Ethernet

97 table 9 1284 signals pin source of data type of mode compatible nibble byte 31 host ninit 32 printer nfault ndataavail adataavail 33 not defined 34 not defined 35 not defined 36 host nselectin 1284 active 1284 active note: the length of the data cable from the host computer to the printer should ...

Page 98

98.

Page 99: Reprogramming The Security

99 reprogramming the security key reprogramming the security key the security key on the psa3 controller board can be reprogrammed with a software program exchange (spx) module. The spx is an intelligent module that plugs into the debug port on the back of the 6800. The spx is used only once; it aut...

Page 100

100 4. Power on the printer. The printer will begin its boot-up sequence. 5. When the printer detects a valid spx, the control panel displays: “new spx detected press enter” note: if an error message displays, find the message in the message list in chapter 8 and follow the troubleshooting instructi...

Page 101: Downloading Firmware

101 downloading firmware the controller board contains 256 mb of flash memory. The printer firmware which includes the printer control languages (emulations), engine control, and printer operating system software are loaded into flash memory at the factory, but there are occasions when you may need ...

Page 102: Webpanel Download

102 table 10 firmware download methods firmware download method file type(s) user flash files webpanel (ethernet only) requirements: network option installed, a browser, and the ip address. Filename.Prg preserved automatic download (any host io) using the filename.Exe, firmware can be downloaded fro...

Page 103

103 5. Click “printer configuration”, “configuration management”, or “file management” as shown in figure 24. Figure 24 selecting printer, configuration, and file management options 6. Click the “system” link in the top header section (see figure 25). Figure 25 system configuration screen 7. Click “...

Page 104

104 figure 26 upgrading firmware 9. A warning message appears (figure 27). Click “ok”. Figure 27 firmware upgrade warning 10. Click “yes” to confirm reboot (figure 28). Figure 28 rebooting after downloading firmware upgrade 11. Wait until the printer finishes firmware upgrade and restarts (figure 29...

Page 105: Automatic Download (.Exe)

105 figure 29 printer reboot notification when the web page is redirected, download process is complete. Automatic download (.Exe) note: this method of download requires firmware in the form of filename.Exe. The firmware can be downloaded without manually putting the printer into download mode. 1. M...

Page 106

106 5. For usb connections, the printer must have a “share name” established. The “share name” will be required when executing the filename.Exe command. This should be accomplished during installation, but can be verified at any time. Select the driver, right-click the mouse button and select “print...

Page 107

107 connection type command parallel filename –a -pb serial mode com1:9600,n,8,1 mode lpt1=com1 filename –a -pb usb filename –a –pbsharedname where sharedname of the printer is the ‘share name’ entered during installation. Ethernet filename -n xxx.Xxx.Xxx.Xxx where xxx.Xxx.Xxx.Xxx represents the ip ...

Page 108

108 this can be completed with firmware in the form filename.Exe or filename.Prg. When the printer is in download mode, only usb or parallel can be used to download the firmware. 1. Set the printer power switch to o (off). 2. Connect the ethernet cable to the printer interface. 3. Usb download: pres...

Page 109

109 5. When download is complete, exit the ftp program by typing: quit important do not interrupt the download process once it has started. Interrupting a download will leave the flash memory on the controller pcba and nic incompletely loaded, and the printer may not boot up. When the new software h...

Page 110

110 b. Select “control panel”. C. Click “add hardware wizard”. For windows 7: a. Click the “start” menu. B. Select “control panel”. C. Click “hardware and sound”. D. Under “device and printers”, click “device manager”. E. Select your pc and start the “add legacy hardware” process from the “action” m...

Page 111

111 5. When prompted for hardware installed options, select “advanced” which that allows you to select the hardware from a list. Then click the “next”. 6. Select “network adaptor”, then click the “next”. 7. Select “microsoft loopback adapter”, then click the “next”..

Page 112

112 8. Click the “next” button. Installation is complete. Verify the proper installation in the following steps. 9. To verify installation, go back to the control panel and select “system” for winxp. Under the “hardware” tab, select “device manager”. For windows 7, select “device manager” directly f...

Page 113

113 10. Select the “network adaptors” and expand the selection if necessary. “microsoft loopback adaptor” is listed. Leave all settings as default. You are now finished and may proceed as outlined in sending firmware via usb on page 109. Sending firmware via parallel this method of download can be c...

Page 114

114 important some systems can only use the 9600 baud rate. The baud rate information entered in the above commands must match the baud rate setting saved in the power-up config. Important do not interrupt the download process once it has started. Interrupting a download will leave the flash memory ...

Page 115: Webpanel File Download

115 webpanel file download 1. Make sure the printer online and that the ethernet cable is connected. 2. Obtain the ip address from the front panel (under tcp/ip menu icon in the menus). 3. Enter the ip address of the printer in your browser (e.G., http://10.224.5.34). 4. When prompted for a user nam...

Page 116: Ptx_Setup Download

116 ptx_setup download ptx_setup can be used to load files into the main file system. See the ptx_setup commands on page 165. Example loading a font named arial.Ttf: !Ptx_setup file_io-capture;“arial.Ttf” ptx_end arial truetype font binary data note: do not add any lf/ff at the end of the binary dat...

Page 117: Demo Facility

117 the process is complete when the file has successfully loaded into flash memory and the printer resets itself. 7. Verify that the file is properly recognized and downloaded, look under the main file mgmt submenu of the config menu icon. One of the files should include file_name3. Downloading fil...

Page 118

118 configuring the printer to run a demo file this facility makes no attempts to identify which emulation a particular demo file is designed for. The user must configure the printer for the appropriate emulation before invoking the demo. The demo will inherit all menu configuration parameters when ...

Page 119: Troubleshooting

119 troubleshooting cleaning requirements clean the printer every six months or after every 1000 hours of operation, whichever occurs first. If the printer is located in a dusty area or is used for heavy duty printing, clean it more often. Warning disconnect the power source before cleaning the prin...

Page 120

120 figure 34 interior printer components ribbon cartridge tab (2) tractor (2) blue tractor lock (2) paper support (2) tab slot (2) ribbon cartridge interface air shroud assembly platen stop platen lever vertical position knob hammerbank cover and ribbon mask splined shaft ribbon tension knob ribbon.

Page 121: Diagnosing Problems

121 to clean the interior of the printer perform the following steps. 1. Power off the printer and unplug the printer power cord. 2. Open the printer cover. 3. Fully raise the platen lever. 4. Unload the paper. 5. Remove the ribbon cartridge. 6. Lift the ribbon out of the ribbon path. 7. Brush the p...

Page 122

122 printing a hex dump a hex code printout (or hex dump) is a translation of all host interface data to its hexadecimal equivalent, listing all ascii character data received from the host computer with their corresponding two-digit hexadecimal codes. Hex dumps are used to troubleshoot printer data ...

Page 123

123 the cd contains a utility called hexcode.Exe. This utility can be run from a dos window to convert an input file into a hexadecimal equivalent. The output from this utility can then be used to compare what is received when printing a hex dump. Usage: hexcode sample output: 412068657820636f646520...

Page 124

124 most frequent problems and solutions problem corrective action poor print quality • dark print • light print • light print on half of the page • missing dots or characters • smeared print • wavy vertical lines • adjust the forms thickness lever setting. Print quality can be affected if it is too...

Page 125

125 4. Verify that files ‘autodmp1’ or ‘autodmp2’ are present in the file list. 5. If present, use printnet enterprise suite to upload these files to your host computer. 6. Contact tallygenicom customer support center and send them the files along with the printer’s configuration printout. Refer to ...

Page 126

126 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution b20 status:00% download mode no status message informing the operator that software is being downloaded. Percentage figure indicates approximate amount loaded into the printer. No action is requir...

Page 127

127 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution bad nvm call 1 bad nvm call 2 bad nvm call 3 bad nvm call 4 bad nvm call a yes printer firmware code error with the novram module that stores configurations and statistics. 1. Cycle power. Run the...

Page 128

128 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution coil temp fail yes the coil temperature was never set or the attempt to set it did not result in correct numbers. Allow printer to cool completely, then set coil temperature. If message continues ...

Page 129

129 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution cartridge/ shuttle mismatch use correct cart yes this message displays when an extended life cartridge is mounted on a 500 lpm printer. Install standard life cartridge. Cartridge/ tipsize mismatch...

Page 130

130 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution e00 exe @ addr0 e01a type 0x40 e01b type 0x60 e02 machine chk e03a dsi hash l e03b dsi hash s e03c dsi bat pl e03d dsi bat ps e03e dsi cxiwx e03f dsi cxowx e03g dsi ecxiwx e03h dsi ecxowx e04a isi...

Page 131

131 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution error occurred flushing queues* yes an interim message that displays while the printer discards host data it cannot use because a fault condition exists. While this message displays, the asterisk ...

Page 132

132 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution error: wrong printer type no the spx inserted in the debug port is not intended for this model printer or this oem. Contact your authorized service representative. 1 ethernet detected n/a status m...

Page 133

133 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution flash: was not cleared no printer encountered an error while trying to program flash memory. Contact your authorized service representative. 1 flash: write error # 2 no printer encountered an erro...

Page 134

134 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution hammerbank not installed* no hammer bank not installed. Self-test routines do not detect hammer coils at printer start-up. Contact your authorized service representative. 1 hmr bank fan flt yes se...

Page 135

135 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution interrupt unused vector 00 no the controller board receives an interrupt it does not understand. The problem can be created by electrical noise, by a software problem, or by a hardware problem. Cy...

Page 136

136 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution pap fd drvr cir* see manual no paper feed driver circuit. The paper feed driver circuit on the controller board is drawing too much current. Contact your authorized service representative. 1 pap f...

Page 137

137 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution power supply hot yes power supply sensors report high temperatures. Check printer environment. If hot or dusty, relocate printer. Contact your authorized service representative if this occurs freq...

Page 138

138 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution ribbon under 2% change rbn soon yes status message indicating the integrated print management system is enabled and ribbon ink level is 2%. Install a new ribbon. Sd card error remove sd card yes t...

Page 139

139 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution sd write fail write protected check sd card yes a write operation to the sd has failed because the sd card is write protected. Ensure that the write protect tab on the sd card is not active. If th...

Page 140

140 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution shuttle stall yes the shuttle is not moving. Set the platen lever to match the thickness of paper, but not too tightly. Check and adjust the platen gap. Inspect the ribbon mask for deformation tha...

Page 141

141 table 13 lcd message troubleshooting table displayed message can user correct? Explanation solution weld not detect see user manual no the cartridge weld was not detected. Contact your authorized service representative. 1 weld snsr error see user manual no the cartridge sensor could not be calib...

Page 142

142.

Page 143: Printer Specifications

143 printer specifications ribbon cartridge specifications p/n europe, middle east, & africa north america, latin america (excludes brazil), canada asia pacific (excludes china and india) india and brazil extended life, 1 pack extended life, 4 pack -101 -401 -102 -402 -103 -403 -104 -104 standard li...

Page 144: Acoustic Noise Level

144 printer weight and dimensions cabinet type dimensions weight height (inches) width (inches) depth (inches) unpacked (pounds) packaged (pounds) cabinet 42.5 27 29 200 260 open pedestal 35 24.5 27 115 153 zero tear pedestal 42.04 25.75 19.48 150 195 environmental characteristics temperature: opera...

Page 145: Electrical Characteristics

145 electrical characteristics printer type configuration voltage (+/- 10%) freq (+/- 10%) amps watts btu/hr cabinet 6805q ac 100-240v 50/60 hz 5a 320w 1093 cabinet 6810q ac 100-240v 50/60 hz 5a 320w 1093 cabinet 6815q ac 100-240v 50/60 hz 9a 475w 1622 cabinet 6820q ac 100-240v 50/60 hz 9a 475w 1622...

Page 146

146.

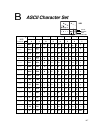

Page 147: Ascii Character Set

147 ascii character set b7 b6 b5 bits 0 0 0 0 0 1 0 1 0 0 1 1 1 0 0 1 0 1 1 1 0 1 1 1 column 0 1 2 3 4 5 6 7 b4 b3 b2 b1 row 0 0 0 0 0 nul 0 0 0 dle 20 16 10 sp 40 32 20 0 60 48 30 @ 100 64 40 p 120 80 50 140 96 60 p 160 112 70 0 0 0 1 1 soh 1 1 1 dc1 (xon) 21 17 11 ! 41 33 21 1 61 49 31 a 101 65 41...

Page 148

148.

Page 149: Overview

149 zero tear pedestal printer overview the p8000 zero tear pedestal (ztp) printer can print a form and present it for tear off without losing a form between print jobs. The printer automatically presents the current print line to the tear bar when it finishes printing and no data are being sent to ...

Page 150

150 note: this operation is typically done during initial setup. Before beginning the procedure, ensure that the paper guides are not damaged. 1. Remove the left paper guide knob and the left, front paper guide leaf. (see figure 36.) 2. Remove the right paper guide knob and the right, front paper gu...

Page 151

151 load paper figure 38 loading paper onto the printer 1. Align the paper supply box with the label on the left side of the floor. (see figure 38 on page 151.) 2. Unlock and open the tractor doors and slide the paper from below, through the black paper out sensor slot on the left side, and up betwe...

Page 152

152 figure 39 adjusting the horizontal paper tension 5. Adjust the paper web tightness by sliding the right tractor to remove slack or to adjust for various paper widths. (see figure 39.) 6. Lock the tractors in position by pressing down on the tractor locks. Figure 40 paper exiting the top of the p...

Page 153

153 position the paper out sensor figure 41 the paper out sensor the paper out sensor indicates when the printer runs out of paper. (the sensor does not work with black backed forms.) unlike the standard pedestal printer, the ztp printer requires you to load the paper through the paper out sensor sl...

Page 154

154 set the tear bar distance to set the tear bar distance, do the following steps: 1. Make sure the printer is offline. 2. Press enter key to enter menu mode. 3. Press the right arrow until the config menu icon is highlighted. 4. Press enter to go into config menu. 5. Press the down arrow until “zt...

Page 155

155 set the top of form figure 43 setting the tear off position the zt printer uses the tear bar as the reference point for setting the tear off position. To set the position of the forms perforation to the tear bar, use the tof button as follows: 1. Make sure the paper guides are adjusted correctly...

Page 156: Ztp Settings Menu

156 ztp settings menu the ztp settings menu includes the ability to enable and disable features unique to the zero tear printer (ztp), set the tear bar distance, set the auto present data time, and set the auto present wait time. This section defines these options. Ztp data time this option sets the...

Page 157: Performance Considerations

157 performance considerations forms type the paper feed tractors on the ztp printer push the paper up through the print station instead of pulling it through, as in the standard pedestal printer. This limits the variety of forms the ztp printer can use. If the forms do not fall within the range spe...

Page 158

158 clearing paper jams or removing paper 1. Raise the platen lever to open the platen. 2. Open the left and right tractor doors. 3. Pull the paper upward through the top of the printer. Note: do not pull the paper downwards from the bottom. This could cause the paper guides to bend. 4. Reload the p...

Page 159: Quick Change Memory Card

159 quick change memory card (qcmc) overview the qcmc provides the ability to duplicate an entire printer’s firmware, saved configurations, and custom files quickly through the printer’s control panel with a user friendly interface. No external host or files are needed to transfer this information t...

Page 160: Installing The Qcmc

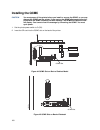

160 installing the qcmc caution you must power off the printer before you install or remove the qcmc, or you may damage the qcmc and the printer. If you remove the qcmc after powering on the printer with the qcmc installed, the fault message “sd removed reboot printer” will display. You cannot clear...

Page 161

161 saving the printer’s configuration to the qcmc note: the mac address residing on the qcmc will be used in place of the mac assigned to the printer’s own network card whenever the qcmc is installed. If you do not want to identify the printer with this mac address, make sure the qcmc is removed fr...

Page 162: Printer

162 if there is not enough space on the sd to save the entire flash image, you will be prompted with the following message. This is a fatal error and requires user intervention. Cycle power on the printer, when prompted to save the qcmc select to skip. The printer will boot online and allow access t...

Page 163

163 this means that the qcmc is not compatible with the printer’s software. A software upgrade is required, or a different configured qcmc will be needed. A qcmc validation check will be performed to ensure the data stored on the sd is not corrupted. If the test fails the following fault message wil...

Page 164

164.

Page 165: Ptx_Setup Commands

165 ptx_setup commands overview the ptx_setup commands are a superset of commands which allow the printer to perform several tasks by parsing commands either stored in flash or sent to the printer by the host. Commands range from printer configuration operations to file system operations. This appen...

Page 166

166 table 16 lists all the command, sub-command, and parameter combinations and gives a brief description of the command. Table 16 ptx_setup commands (non-platform specific) command sub-command parameter description config load cfg cfg can be 0-8. The ptx_setup will load configuration cfg. If config...

Page 167

167 table 16 ptx_setup commands (non-platform specific) command sub-command parameter description config overlay cfg this command overlays the configuration data that follows on existing configuration cfg. Cfg must be 1-8 (or end). If cfg does not exist then command is treated the same as download. ...

Page 168

168 table 16 ptx_setup commands (non-platform specific) command sub-command parameter description config pne_port_num port number this command sets the port number the pne uses to communicate to the printer if the pne port was set to ethernet. This command causes the printer to automatically reboot....

Page 169

169 table 16 ptx_setup commands (non-platform specific) command sub-command parameter description file_io (disk_io) upload file;port reads the file named file out of the flash file system and sends it to a host computer via the port i/o port. Port is either 1284 (for reverse nibble or byte mode tran...

Page 170

170 due to the nature of writing to flash, any data intended to be stored permanently in flash must first be copied into ram. As a result, the ability to manipulate files in the flash file system is dependent upon the printer having sufficient ram. None of the captured file data will be committed to...

Page 171: Customer Support

171 customer support tallygenicom customer support center important please have the following information available prior to calling the tallygenicom customer support center: • model number • serial number (located on the back of the printer) • installed options (i.E., interface and host type if app...

Page 172

172 corporate offices printronix, llc. 6440 oak canyon rd, suite 200 irvine, ca 92618 u.S.A. Phone: (714) 368-2300 fax: (714) 368-2600 printronix llc. C/o printronix nederland bv bijsterhuizen 11-38 6546 as nijmegen the netherlands phone: (31) 24 6489489 fax: (31) 24 6489499 printronix schweiz gmbh ...

Page 173: Communication Notices

173 communication notices notices tallygenicom brand is owned by printronix, llc this information was developed for products and services offered in the u.S.A. Tallygenicom may or may not offer the products, services, or features discussed in this document in other countries. Consult your tallygenic...

Page 174: Communication Statements

174 non-tallygenicom products. Questions on the capabilities of non- tallygenicom products should be addressed to the suppliers of those products. Tallygenicom encourages owners of information technology (it) equipment to responsibly recycle their equipment when it is no longer needed. Tallygenicom ...

Page 175

175 tallygenicom cannot accept responsibility for any failure to satisfy the protection requirements resulting from a non-recommended modification of the product, including the fitting of non-tallygenicom option cards. This product has been tested and found to comply with the limits for class a info...

Page 176

176 en 55024 hinweis: wird dieses gerät in einer industriellen umgebung betrieben (wie in en 55024 festgelegt), dann kann es dabei eventuell gestört werden. In solch einem fall ist der abstand bzw. Die abschirmung zu der industriellen störquelle zu öergrvßern. Anmerkung: um die einhaltung des emvg s...

Page 177

177 為保護您的安全,使用本設備時,請遵循下列安全注意事項: • 請依照設備上所有的警告與說明進行操作。 • 請確定電源的電壓與頻率符合設備的電氣等級標籤上指定的電壓與頻率。 • 請不要將任何物件塞入設備的開口。導電的異物可能會導致短路,引起火 災、電擊、或設備損傷。 • 不要對本設備進行機械或電氣修改。對經過修改的產品的安全與法規符合 性,不負任何責任。 • 不要阻礙或覆蓋產品的開口。永遠不要將產品放在靠近輻射來源或熱源的 地方。未能依照這些指引, 將可能導致過熱情況,影響產品的可靠性。 • 產品是設計來配合有中性地線的電源系統使用。為降低電擊風險,請不要 將產品插入任何其他類型的 電源系...

Page 178

178 taiwan warning: this is a class a product. In a domestic environment this product may cause radio interference in which case the user will be required to take adequate measures. Korea class a (broadcasting communication equipment for office use) as an electromagnetic wave equipment for office us...

Page 179: Software License Agreement

179 software license agreement your printer contains, among other software, tallygenicom operating software including, but not limited to the embedded configurable operating system (the “ecos software”) as embedded software. The terms of this agreement apply only to the ecos software, and all other ...

Page 180

180 to the extent applicable law prohibits such limitation. Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages so that exclusion and limitation may not apply to you. 6. U.S. Government users the embedded software is a “commercial item,” as that term is...

Page 181

181 this software is provided by the regents and contributors “as is'' and any express or implied warranties, including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose are disclaimed. In no event shall the regents or contributors be liable for any ...