- DL manuals

- TallyGenicom

- Printer

- T6200 Series

- Operator's Manual

TallyGenicom T6200 Series Operator's Manual

Summary of T6200 Series

Page 1

T6200 series line printer operator manual serial • parallel • twinax • coax • tcp/ip including ipds a product from tallygenicom.

Page 2

This manual is published by tally printer corporation for use with the computer printer described herein. Transla- tions, reprinting or copying by any means of this manual, complete or in part, in any different form requires our explicit approval. Tally printer corporation reserves the right to revi...

Page 3: Table of Contents

Toc–1 table of contents table of contents preface................................................................... Preface–1 introduction.................................................................................... Preface–1 about this manual ...................................................

Page 4

Operator manual toc–2 tractor sets ...................................................................................................... 1–8 figure 1–9. Opening, locking, and unlocking tractors ................... 1–8 platen gap wheel and lever..........................................................

Page 5

Toc–3 table of contents chapter 3 ......................................................................... 3–1 introduction................................................................................................3–1 control panel menus ...........................................................

Page 6

Operator manual toc–4 ribnmon thresh .............................................................................................. 3–13 ribbon monitor operation .................................................................... 3–14 vertical format units (vfu) category ..............................

Page 7

Toc–5 table of contents tof control .................................................................................................... 3–22 dc3 operation ............................................................................................... 3–22 siso overszbar ...............................

Page 8

Operator manual toc–6 protocol .......................................................................................................... 3–29 status enquiry ................................................................................................. 3–30 dtr function .............................

Page 9

Toc–7 table of contents pattern category .................................................................................. 3–40 print ................................................................................................................ 3–40 fault override category ..........................

Page 10

Operator manual toc–8 blank page.

Page 11: Introduction

Pref–1 preface introduction the t6200 series offers the following i/o configurations (modules): • standard serial/parallel • fourplex (standard plus twinax/coax) • fourplex ipds • lanplex (standard plus ethernet 10/100 base-t) • lanplex ipds in less than five minutes you can add other configurations...

Page 12: About This Manual

Operator manual pref–2 about this manual chapter 1: setting up your printer in chapter 1, you are instructed on how to set up your printer. You will find criteria for site selection, instructions for removing the protective shipping hardware from your printer, and locations of connectors for printer...

Page 13

1–1 chapter 1: setting up your printer site preparation choosing a site for your printer is important because the environment affects your print quality. The best site for your printer is one that is protected from dirt and heavy dust, and has a moderate temperature and humidity range. In addition, ...

Page 14

Operator manual 1–2 unpacking your printer instructions for unpacking your printer are located on the outside of the shipping container. After you have removed your printer from its container, store the shipping materials for possible later use. Repacking repacking your printer for storage or shippi...

Page 15

1–3 chapter 1: setting up your printer figure 1–2. Shipping screw locations setting up paper stacking chains paper exits the print area through a set of passive paper stacking chains that help fold and stack printed forms uniformly. Proper loading of the paper in the tractors improves paper stacking...

Page 16

Operator manual 1–4 interface connections and powering up interface connectors properly secure the cable to the printer interface using the correct connectors. Shielded i/o cables must be used on all installations to comply with fcc regulations. Maximum interface cable length serial/parallel only yo...

Page 17

1–5 chapter 1: setting up your printer connecting the i/o after connecting each interface to your printer, run a print job from the host computer to verify proper function of the printer. Serial/parallel the serial interface operates up to 38.4 kbaud and uses a standard db 25 serial cable connector ...

Page 18

Operator manual 1–6 your twinax hookup is now complete and it is time to test your printer to verify its operation. Load your printer with paper and an ink ribbon. Run the ibm printer verification test. If the test is successful, your installation is complete. Twinax trouble checklist if the printer...

Page 19

1–7 chapter 1: setting up your printer powering up the power switch is located on the left side of the printer, and the power and interface connectors are inside the printer housing, accessible through the back door. Figure 1–7. Printer (rear view) step 1. Make sure the power is off. Connect the pow...

Page 20

Operator manual 1–8 paper system paper system components the tractors, platen, paper iron and ribbon cartridge are all parts of the paper system. The first two assemblies are involved in how the paper moves past the print mechanism and through the printer. Figure 1–8. Paper system components tractor...

Page 21

1–9 chapter 1: setting up your printer platen gap wheel and lever the platen gap lever opens and closes the platen gap for loading paper and ribbon. The wheel rotates to let the platen accommodate different thicknesses of paper. The higher the letter, the wider the platen gap. Once it's set, you don...

Page 22

Operator manual 1–10 platen gap sensing the t6300 has a mechanism that senses the platen gap, used in conjunction with the paper weight and impact parameters to control paper movement and hammer impact force. This is explained in chapter 3. When the platen is open, the position is sensed, printing i...

Page 23

1–11 chapter 1: setting up your printer step 1. Make sure the printer is offline or power is off. Open the printer lid and open the platen gap using the lever, then remove the old ribbon by lifting it straight up off of the ribbon platform. Step 2. Remove slack in the new ribbon by turning the knob ...

Page 24

Operator manual 1–12 loading paper for regular printing your printer is designed to use a continuous sheet, sprocket-fed paper. It can handle: • six-part forms (1 original and 5 copies) with a maximum thickness of .025" (0.6 mm). • page widths of 2.5" to 18" (6.4 cm to 45.7 cm). Figure 1–14. Paper s...

Page 25

1–13 chapter 1: setting up your printer step 1. Make sure the printer is offline or printer power is off. Step 2. Open the new box of paper. Remove the box top so that the paper can be pulled out freely, then place the new box of paper under the printer. Figure 1–15. Paper box placement and paper pa...

Page 26

Operator manual 1–14 careful! The left end of the scale (5 & 10 cpi) on the ribbon platform marks the position of column 1. Before printing, make sure that this marker is aligned with the desired position on the form. To align the paper on the column marker, unlock the tractor and slide it to the de...

Page 27

1–15 chapter 1: setting up your printer let’s check before beginning a print job, check the following items: • all tractor locking levers are locked. • the upper tractor sprocket pins are snug against the top of each paper hole. The bottom tractor sprocket pins are snug against the bottom of each pa...

Page 28

Operator manual 1–16 blank page.

Page 29: Introduction

2–1 chapter 2: printer control panel introduction in this chapter you will learn about the printer control panel and how it is used to control printer functions. Control panel components the control panel is located on the top cover. You can use it to program and direct most printer functions. Chapt...

Page 30

Operator manual 2–2 lcd (liquid crystal display) the lcd is located at the left of the control panel. It shows printer status, menu selections, and normal, fault, and error messages. The lcd is divided into four main areas. Each area displays one of the following: current state, paper indicators, op...

Page 31

2–3 chapter 2: printer control panel paper indicators the paper indicators occupy position 16 of the first line of the display. Table 2-1 shows the meaning of each indicator. Indicator paper weight impact (blank) the platen is in the light the platen is in the normal weight zone when paper impact zo...

Page 32

Operator manual 2–4 key functions online/offline key this key toggles the printer between online and offline states, or exits from the menu directly to an online state. When the printer is online, the indicator will light, and the printer is ready to accept data from the host. When it's offline, it ...

Page 33

2–5 chapter 2: printer control panel tof key (top of form) when you load paper, you line the top of your form (usually the perforation) with the indicated position on the tractor (see figure 2-3). Once the paper is loaded, pressing this key moves the paper so that printing commences at the proper po...

Page 34

Operator manual 2–6 menu/back key pressing this key allows you to access menu selections, which you can scroll through using the up and down arrow keys. Pressing the menu/back key returns you to a previous selection. This key command is only available when the printer is in an offline mode. Enter ke...

Page 35

2–7 chapter 2: printer control panel clear reset the printer controller performs a hardware reset. You may use this in lieu of cycling power to the printer. As with cycling power, the powerup configuration is loaded as the current configuration (see chapter 3). Clear cancel (twinax and coax only) al...

Page 36

Operator manual 2–8 blank page.

Page 37: Chapter 3

3–1 chapter 3: printer menus and configuring your printer introduction in this chapter you will learn about the printer’s modes, multilevel menus, parameters, parameter values, and how to select and store parameter values as part of a configuration. You will also learn how to obtain printouts that s...

Page 38

Operator manual 3–2 categories, parameters and selections within the operator, config, and test menus, there are a number of catego- ries. Within each category is a list of parameters. In some cases, a param- eter can execute a function upon pressing enter, or in other cases, it displays yet another...

Page 39

3–3 chapter 3: printer menus and configuring your printer in the offline state, pressing the menu key gives you access to the first level of the menu system. Upon doing this, the display reads: offline operator menu now, in the offline state, you may access one of four available menus (opera- tor, c...

Page 40

Operator manual 3–4 5. Press the enter key. Your display then reads: forms form length 6. Form length is the selection you want, so press the enter key. The display reads: form length 66* (the asterisk means that 66 is the current selection.) 7. You want to change this to 65. Press the down arrow on...

Page 41

3–5 chapter 3: printer menus and configuring your printer operator menu following are explanations of each menu category and parameter. Font category this category contains parameters that control how print looks on a page and the display language. The level 2 headings are as follows: ser/par langua...

Page 42

Operator manual 3–6 ipds language (displays only if ipds is installed) this defines the language used by the ipds emulation. The default is us. The details of the character sets can be found in the line printer applications manual. The possible selections are: internat'l 500 english us 037 aus/germa...

Page 43

3–7 chapter 3: printer menus and configuring your printer matrix there are two font modes available on your printer. One mode is called en- hanced and the other is called constant density. Enhanced fonts include draft and data processing, near letter quality (gothic and courier), and optical charact...

Page 44

Operator manual 3–8 tx/cx style this allows you to select the default font style used by emulations attached to the twinax and coax ports (except ipds). Style selections draft (high-speed) dp (data processing, default selection) gothic (sans serif nlq) courier (serif nlq) ocr-a (optical character re...

Page 45

3–9 chapter 3: printer menus and configuring your printer forms category this category is used for setting form specifics. Length (lines) if you wish to define the length of your form in lines, you may select a form length from 1 to 255. The default option is 66. Length (inches) if you wish to defin...

Page 46

Operator manual 3–10 ipds in the ipds emulation, the margin settings are absolute in regards to column number, so that changing the cpi also changes the physical location of the margin. Right margin you can place the right margin at any column number across the page. As with left margin, the range o...

Page 47

3–11 chapter 3: printer menus and configuring your printer sure the paper is feeding correctly. When you are ready, depress the clear key to clear the fault condition, then place the printer online and continue printing. If print to eof is off, you have two options: option 1: load a new supply of pa...

Page 48

Operator manual 3–12 impact impact is the relative energy level of the hammer impact on the form being printed. On auto (the default), the printer senses the thickness of the form by the platen gap and varies the setting automatically from normal to high. If you want to override it, you can set it t...

Page 49

3–13 chapter 3: printer menus and configuring your printer fast slew slew refers to the high speed paper motion that occurs whenever the printer moves paper more than one line. If your forms are thin or fragile such that output stacking is a problem, you can decrease the printer's slew speed by sett...

Page 50

Operator manual 3–14 ribbon monitor operation when the number of characters printed reaches the ribbon life threshold, the current print job will stop, the fault indicator will light, and the replace ribbon message will appear. When this situation occurs: clear the fault with the clear key. The faul...

Page 51

3–15 chapter 3: printer menus and configuring your printer vertical format units (vfu) category vfu enable a vertical format unit is a means for loading sets of vertical tabs. These vertical tabs define various parameters of a form. This parameter applies only to the emulations which make explicit u...

Page 52

Operator manual 3–16 configuration menu following are explanations of each menu category and parameter. For all available selections under each parameter below, consult the help menu printout. Printer category powerup this parameter sets the printer either online or offline when the power switch is ...

Page 53

3–17 chapter 3: printer menus and configuring your printer lan emulation (lan interface only) used to select the emulation attached to the ethernet port when using the lanplex interface. The possible selection are the same as the ser/par emul option. Twinax emul (twinax/coax only) used to select the...

Page 54

Operator manual 3–18 report you can use this parameter to print or display a report. Current config this selection produces a printed report of the current printer configuration. The report contains a header which identifies the installed software and interface, any options that are installed, and s...

Page 55

3–19 chapter 3: printer menus and configuring your printer codes category in this category are parameters that allow you to determine the printer’s re- sponse to certain conditions and to assign values to parameters that are used by other commands or escape sequences. For the ipds emulation, these o...

Page 56

Operator manual 3–20 print on cr this parameter is intended for use by customers whose applications embolden characters by using a cr-only method to selectively reprint all or parts of a line. Off: ignore bolding, print as regular text (default setting) double strike: print line, then backup to repr...

Page 57

3–21 chapter 3: printer menus and configuring your printer code 7f this parameter allows you to dictate how the printer will react when it receives a hexadecimal code 7f. The default value depends on the emulation. (see the emulation parameter, presented earlier in this chapter.) ignore: the code is...

Page 58

Operator manual 3–22 tof control (available when genicom ansi emulation is selected) when a new form is defined, the top-of-form position is left unchanged if this parameter is enabled (the default). When a new form is defined, and this param- eter is disabled, the top-of-form position is reset to t...

Page 59

3–23 chapter 3: printer menus and configuring your printer graphics category this category allows you to configure certain aspects of the graphic process- ing options on your printer. Code v cmd char this parameter allows you to change the cvcc. The default for this parameter is the ascii caret ( ^ ...

Page 60

Operator manual 3–24 table 3–1. Bar code dot density darkbar selection "normal" mode "dark" mode low 60 x 72 60 (120) x 144 medium (default) 60(120) x 144 120 x 144 high 120 x 144 120 x 144 modplot this parameter eliminates the need to send an align to line boundary command (mt660) or an extra line ...

Page 61

3–25 chapter 3: printer menus and configuring your printer vertical scale this parameter determines whether vertical block characters will be scaled to the same dimensions as horizontal block characters. Style 1 is the default selection. Style 1: adds intercharacter gap after the character has been ...

Page 62

Operator manual 3–26 automatic py if automatic py is enabled, the printer is automatically in code v graphics mode, and a ^py command is not needed in the file being sent to the printer to begin code v graphics. The default is disabled. Mtpl bar setting this parameter will print out barcodes for mtp...

Page 63

3–27 chapter 3: printer menus and configuring your printer ignore term determines whether or not a line feed following the cr terminator, an sfoff, or an igoff command will cause a line feed to occur. There are two options: en- abled (usually the default), and disabled (the default for genicom ansi)...

Page 64

Operator manual 3–28 load you will use this parameter to load any of your saved configurations into the current configuration. Use the load parameter to choose the configurations you've previously saved. Powerup config you will use this parameter to designate any of the saved configurations as the c...

Page 65

3–29 chapter 3: printer menus and configuring your printer serial i/o category serial interface is a style of host computer-to-printer i/o communications. It requires certain parameters to be properly set in order for the printer and host computer to communicate. Baud the baud parameter allows the u...

Page 66

Operator manual 3–30 status enquiry when this option is enabled, the host may send an enquiry packet to the printer requesting status. The printer will then send back a 1 byte packet denoting the status of the printer. If this option is set to off (the default), no packet will be sent back. The stat...

Page 67

3–31 chapter 3: printer menus and configuring your printer dtr function this parameter allows the user to change the operation of the data terminal ready (dtr) line on the printer interface. The dtr line is used to indicate printer status to the host computer. Busy (default selection) in this mode t...

Page 68

Operator manual 3–32 parallel i/o category the parallel category on your printer has three parameters that can be changed according to user needs. Popc (print on paper command) the popc parameter can be set up so that each time a paper advance com- mand is received (such as a line feed, form feed, o...

Page 69

3–33 chapter 3: printer menus and configuring your printer intellifilter category intellifilter is a programmable feature, standard on tallygenicom line printers. Without having to touch an otherwise well-working host system, intellifilter permits users to free their systems from hard coded dependen...

Page 70

Operator manual 3–34 twinax/coax category send pa (coax only) there are two options for this category, pa1 and pa2. These options only have meaning when the printer is in the scs mode. If they are selected while the printer is in non scs mode, the invalid key error message will display briefly. Thes...

Page 71

3–35 chapter 3: printer menus and configuring your printer host font style (twinax only) when you set this parameter to disabled, the host page presentation media command is ignored. This is used when you want to prevent the host from overriding control panel font style settings. The default is enab...

Page 72

Operator manual 3–36 comp switch 5 this switch determines the printer response to formatted print lines composed entirely of unprintable characters (such as control and format commands). If off, and the ignore bit in the pcia is on, the line is not printed and no nl function is performed. If on, the...

Page 73

3–37 chapter 3: printer menus and configuring your printer epc the early print complete parameter allows you to set up the printer data buffering scheme to emulate the 4234 data-handling characteristics. When this parameter is set to off (the default), the printer emulates the buffering scheme of th...

Page 74

Operator manual 3–38 ipds category (ipds only) address (twinax only) this parameter sets the twinax ipds device address for the printer. This feature allows the ipds emulation to reside at a different address than the standard twinax scs emulation, hence providing two virtual twinax printers. The de...

Page 75

3–39 chapter 3: printer menus and configuring your printer tcp/ip menu - lan interface only the tcp/ip menu only appears if a tcp/ip lan network interface card is installed in the printer. Ip addr this option allows you to set up the four octets of the ip address. Category parameter ip octet 1 0-255...

Page 76

Operator manual 3–40 test menu in test menu you will find diagnostic test print patterns used to check printer functions and a parameter that allows you to control paper motion sensing. Use the up and down arrow keys to scroll to the desired selection. To move down in the menu use the up arrow key. ...

Page 77

3–41 chapter 3: printer menus and configuring your printer diag category this is a diagnostics and calibration category. Cal-paper (calibrate paper out) this parameter allows users to calibrate the paper-out detection sensor if the factory default settings fail to detect when the paper really is out...

Page 78

Operator manual 3–42 blank page.

Page 79: Introduction

A–1 appendix a: troubleshooting introduction this chapter deals with troubleshooting problems on a t6200 series printer. Messages that indicate printer faults and errors are explained and corrective action given. The few paper handling and print quality problems that may occur are also explained. Me...

Page 80

Operator manual a–2 table a–1. Display messages message explanation and corrective action attention explanation: the host has sent the bell command corrective action: corrective action depends on the reason the bell command was sent. Contact your system operator. Bad vfu channel explanation: a vfu c...

Page 81

A–3 appendix a: troubleshooting key disabled explanation: key has no function for this printer model or mode of operation. Corrective action: no corrective action. Lost adrs (27) explanation: certain communication signals have been lost between the printer and the host computer. Corrective action: c...

Page 82

Operator manual a–4 hammer voltage explanation: one of the hammer drive circuits was turned on when it shouldn't have been, so all printing has been disabled. The usual cause is a failed drive transistor. Corrective action: call your customer service representative for repair. Paper motion flt expla...

Page 83

A–5 appendix a: troubleshooting and the fault does not clear, call your customer service representative for repair. Setup address explanation: the printer address has not been set up or a configuration with address set to undefin has been loaded. Corrective action: set up the printer address using t...

Page 84

Operator manual a–6 table a–2. Paper/printing corrective action problem cause corrective action the paper holes are wider than normal after passing through the tractors. Horizontal paper tension is too tight. Unlock and readjust the tractors. Printed characters on heavy- weight or multi-part paper a...

Page 85: Specifications

S–1 specifications emulations the emulations available on your printer are: mt660, printronix p600, printronix p6000, printronix p5000, epson fx-1180, ibm proprinter iii xl, ibm 4234 (twinax and coax), ibm 4210 and 5225 (twinax only), dec lg01, hp2564c, mtpl, genicom ansi, pjl, code v, pgl, ipds. Ty...

Page 86

Operator manual s–2 table s–1 text performance text throughput - lines per minute t6218 t6215 t6212 upper case / lower case draft 10 cpi 1800/1500 1500/1285 1200/1000 15 cpi 1800/1500 1500/1285 1200/1000 17.14 cpi 1800/1500 1500/1285 1200/1000 data processing 10 cpi 1350/1080 1125/900 900/720 15 cpi...

Page 87

S–3 specifications lines per inch ten lines per inch (lpi) settings are available through the control panel. They include 1.5, 2, 3, 4, 5, 6, 8, 9, 10, and 12 lpi. In some emulations the availability of certain lpis is restricted. Paper movement speed your printer has a normal slew speed of 36 inche...

Page 88

Operator manual s–4 power supply the printer requires single phase, 47 to 63 hz. 90 to 264 vac input power. The printer’s universal power supply automatically adjusts to the correct values. A fuse is provided to interrupt power to the power supply. The follow- ing table gives typical current values....

Page 89

S–5 specifications environment operating temperature dry bulb: 50°f to 104°f (10°c to 40°c) humidity: 10 to 90% noncondensing with a maximum wet bulb temperature of 82°f (28°c) and a minimum dew point of 36°f (2°c ) altitude: to 8,000 ft. (2438 meters) nonoperating temperature: boxed: -40°f to 151°f...

Page 90

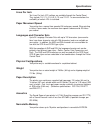

Operator manual s–6 28.8 in. (731.5 mm) 40.0 in. (1016.0 mm) 28.3 in. (718.8 mm) 62.2 in. (1579.9 mm) back (and front) view top view side view printer dimensions figure s-1. Physical dimensions.

Page 91

S–7 specifications industry and agency standards. The t6200 series is designed to meet the requirements of several industry and government agency standards. Electro-magnetic emissions emi: fcc part 15, subpart j, class a and en55022 class b harmonics: en 61000-3-2 flicker: en 61000-3-3 electro-magne...

Page 92

Operator manual s–8 blank page.