- DL manuals

- Tanaka

- Trimmer

- professional brushcutter TBC-600

- Service Manual

Tanaka professional brushcutter TBC-600 Service Manual

Summary of professional brushcutter TBC-600

Page 1

Service manual • trouble shooting • service / torque limits • technical data grass trimmers / brush cutters 1028 4th street s.W. • building b • auburn, wa 98001 • ph: 253-333-1200 • f: 253-333-1212 • tanakapowerequipment.Com.

Page 2: Introduction

This service manual is arranged for quick, easy reference when replacement parts are required, use only approved and is divided into numbered sections. Parts. Failure to do somayresult in products malfunction a nd possible injury to operator and/or bystander. Note: read all information for servicing...

Page 3: Safety Precautions

The following safety notations are used throughout this manual to call attention to special information or operating caution: a caution identifies safe operating procedures. Understand the message in each notation practices or indicates unsafe conditions that could and be alert to unsafe conditions ...

Page 4

Contents page special tools 1 technical data 2 service limits 4 torque limits 5 general components & inspections 6 1. Crankcase 6 2. Cylinder 6 3. Piston 6 4. Piston pin bore 6 5. Piston ring end gap 6 6. Piston ring side clearance 7 7. Piston pin 7 8. Crankshaft journal 7 9. Connecting rod/big end ...

Page 5

Www.Tanakapowerequipment.Com custsvc@nikko-tanaka-usa.Com 1. Special tool list ref.# description parts# tbc-230/2501 tbc-290 tbc-340 tbc-4200dx tbc-4200d tbc-550dx tbc-550/600 tbc-250pf/260pf tbc-340pf tbc-4200dlv tbc-270 tbc-420pf tbc-430pflv 2 fly-wheel remover 006-29326-00 x x x x x x 3 center bo...

Page 6

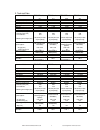

2. Technical data model tbc-230b series tbc-230 series tbc-250pf series tbc-2501 series displacement (cc) 21.1 21.1 23.9 25.0 bore x stroke (mm) 31 x 28 31 x 28 33 x 28 34 x 27 compression ratio 6.0 : 1 6.0 : 1 7.3 : 1 7.2 : 1 max. Kw/rpm 0.63/7500 0.63/7500 0.82/8000 0.90/7500 max. Kg e m/rpm 0.086...

Page 7

2. Technical data model tbc-420pf tbc-4200d tbc-550 series tbc-600 430pf series series displacement (cc) 39.8 39.8 46.5 46.5 bore x stroke (mm) 39.8 x 32 39.8 x 32 43 x 32 43 x 32 compression ratio 7.2 : 1 6.95:1 7.0 : 1 7.0 : 1 max. Ps/rpm 1.7/6500 1.78/7000 2.38/7000 2.38/7000 max. Kw/rpm 1.25/600...

Page 8

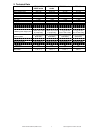

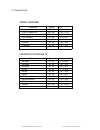

3. Service limit cyl inder bor e p iston / sk ir t outer d ia . P is t on p in b o r e p is t on p in outer d ia . C on -r o d b ig en d s ide clearanc e c on -r o d small en d s ide clearanc e crankshaf t eccentr ic it y crankshaf t jou r na l d ia . (pt o ) crankshaf t jou r na l d ia . (st ar te ...

Page 9

4. Torque limits special fasteners reference kg-cm in-lb flywheel nut 200 - 230 173.6 - 199.6 clutch or special nut 200 - 250 173.6 - 217.0 spark plug 150 - 200 130.2 - 173.6 carb. Insulator 50 - 60 43.4 - 52.1 cyiinder 45 - 50 39.1 - 43.4 crankcase 40 - 50 34.7 - 43.4 ordinary nuts and bolts refere...

Page 10

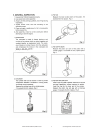

6 www.Tanakapowerequipment.Com custsvc@nikko-tanaka-usa.Com sealing is essential. Fig. 1.

Page 11

7 www.Tanakapowerequipment.Com custsvc@nikko-tanaka-usa.Com.

Page 12

8 www.Tanakapowerequipment.Com custsvc@nikko-tanaka-usa.Com.

Page 13

9 www.Tanakapowerequipment.Com custsvc@nikko-tanaka-usa.Com.

Page 14

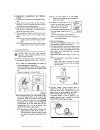

Www.Tanakapowerequipment.Com custsvc@nikko-tanaka-usa.Com 10 6. Engine side 6-1 recoil starter system 1) remove recoil starter body assy from unit. 2) pull starter handle, then hold rope reel and pull starter rope out from ropoe reel. Fig. 15 3) while holding rope reel, let recoil spring unwind slow...

Page 15

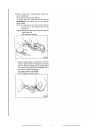

11 www.Tanakapowerequipment.Com custsvc@nikko-tanaka-usa.Com needle pin.

Page 16

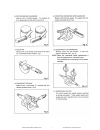

To maintain carburetor performance, it is recommended that c. Rubber parts be inspected periodically or whenever disassembled. Check diaphragm for deterioration or damage, valve hinge for deformation and needle valve for wear. Always use fresh fuel. Fuel which has been stored for an extended periods...

Page 17

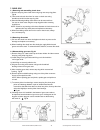

Www.Tanakapowerequipment.Com custsvc@nikko-tanaka-usa.Com 13 4) remove the screws securing cylinder and pull cylinder off of the crankcase, before installing cylinder apply a thin coat of oil to the piston. Align each piston ring with the locator pin, slowly insert piston into cylinder while compres...

Page 18

Www.Tanakapowerequipment.Com custsvc@nikko-tanaka-usa.Com 14.

Page 19

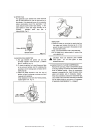

7. Drive side 7-1 removing and assembling clutch drum 1) remove stop ring from clutch drum using long nose snap ring pliers. Fig.33 2) then remove clutch drum from fan case or clutch case using handle bar 8x120 from the stop ring side. 3) some ball bearing holding clutch drums can be removed from fa...

Page 20

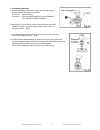

7- 4 assembling gear case 1) install ball bearing into the bottom of gear case using the proper daimeter installer. See below for diameters. Dia. 20mm ----- tbc-230 series dia. 24mm ----- tbc-2501/250pf/260pf/270 series, tbc420pf tbc-4200d/dlv/430pflv/550/600 2) apply grease on gear shaft and insert...

Page 21

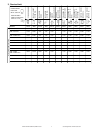

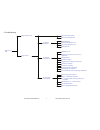

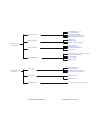

4. Trouble shooting engine doesn't crank check recoil starter system check internal engine parts check spark plug no spark or bad connection/ignition coil weak spark incorrect air gap/ignition coil bad ignition coil engine won't start clogged fuel filter clogged or incorrect of air vent valve on eng...

Page 22

Carbon deposits in muffler poor cylinder pressure power is low or poor dirty air cleaner element incorrect carburetor adjustment worn or damaged internal parts bad spark plug runs inconstantly bad ignition coil incorrect carburetor adjustment engine doesn't run properly air leak at intake air leak f...