- DL manuals

- Tanaka

- Lawn and Garden Equipment

- TIA-340

- Owner's Manual

Tanaka TIA-340 Owner's Manual

Summary of TIA-340

Page 1

Owner's manual manuel d'utilisation manuale uso e manutenzione bedienungsanleitung manual del propietario instruktionsbok (en, fr, it, ge, sp, sw) tia-340/ 350s 970-42465-212 2005. 07.

Page 2: Warning

The engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects and other reproductive harm. It is important that you read, fully understand and observe the following safety precautions and warnings. Careless or improper use of the unit may cau...

Page 3

En fr i t ge sp sw explains choke position. Upper sign indicates choke closed and the lower fully open. Explique la position du starter. La figure supérieure indique que le starter est fermé et la marque inférieure qu'il est complètement ouvert. Spiega la posizione della valvola dell'aria. Ii segno ...

Page 4

Ge what is what? Warnings and safety instructions assembly procedures operating procedures maintenance specifications en 1 2 8 9 13 21 index read the operator's manual carefully. Check that the cutting equipment is correctly assembled and adjusted. Start the unit and check the carburetor adjustment....

Page 5

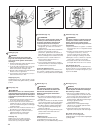

4 2 12 11 5 8 6 1 3 10 9 7 1. What is what? 1. Handle 2. Plug cap 3. Ignition switch 4. Muffler 5. Drive shaft 6. Throttle trigger 7. Recoil starter 8. Gear case 9. Fuel tank cap 10. Fuel tank 11. Grease hole 12. Air cleaner 1 en since this manual covers several models, there may be some difference ...

Page 6

Always wear a safety face shield or goggles. Always wear heavy, long pants, boots and gloves. Do not wear loose clothing, jewelry, short pants, sandals or go barefoot. Secure hair so it is above shoulder length. Do not operate this tool when you are tired, ill or under the influence of alcohol, drug...

Page 7

I t ge sw 3. Assembly procedures 8 en assembling (fig. 1-1) connect the bit to drive shaft (1) of the power head and fix it with the snap pins (2) after setting the fixing pins (3) and washers (2 pcs. Each). Selection of a suitable bit choose an auger bit according to material to be bored. In case o...

Page 8

I t the power auger is equipped with a two- stroke engine. Always run the engine on fuel, which is mixed with oil. Provide good ventilation, when fueling or handling fuel. Fuel always use branded 89 octane unleaded gasoline. Use tanaka two-cycle oil or a quality twocycle oil at mixing ratio of 25-50...

Page 9

11 i t ge sw en starting 1. Set ignition switch (1) to (run) position. (fig. 2-2) *push priming bulb (1) several times so that fuel flows through the bulb or return pipe. (if so equipped) (fig. 2-3) 2. If throttle lock (3) is equipped, pull the throttle trigger (2) and keep pushing the throttle lock...

Page 10

I t sw 1 run stop t perforazione (fig. 2-5) attenzione! Non toccare la punta quando il motore é in funzione per evitare incidenti imprevisti. Accertarsi di disattivare l'interruttore di accensione prima di toccare la punta. 1. Serrate saldamente con entrambe le mani le impugnature, per evitare che l...

Page 11

I t maintenance, replacement or repair of the emission control devices and systems may be performed by any nonroad engine repair establishment or individual. Carburetor adjustment (fig. 3-1, 1b) warning! The bit may be spinning during carburetor adjustments. Warning! Never start the engine without t...

Page 12

15 fig.3-2b fig.3-2 i t ge sw filtre à air (fig. 3-2, 2b) nettoyer le filtre à air régulièrement pour éviter: les troubles de fonctionnement du carburateur. Les problèmes de démarrage. Les pertes de puissance. L'usure prématurée des organes du moteur. Une consommation anormalement élevée. Nettoyer l...

Page 13

Spark plug (fig. 3-3) the spark plug condition is influenced by: an incorrect carburetor setting. Wrong fuel mixture (too much oil in the gasoline) a dirty air filter. Hard running conditions (such as cold weather) these factors cause deposits on the spark plug electrodes, which may result in malfun...

Page 14

17 fig.3-5 fig.3-4 i t ge sw transmission (fig. 3-4) vérifier le niveau de graisse du réducteur et de l'embrayage toutes les 50 heures d'utilisation en retirant le bouchon de l'orifice de remplissage de la graisse qui se trouve sur le côté du boîtier de réducteur. Si on ne peut pas voir de graisse s...

Page 15

Cleaning the cylinder fins (fig. 3-6) when wood chips are caught between cylinder fins (1), the engine may overheat, resulting in lower output. To avoid this, always keep cylinder fins and fan case clean. Every 100 operating hours, or once a year, (more often if conditions require) clean fins and ex...

Page 16

Cleaning the muffler (fig. 3-7, 3b) remove the muffler and spark arrestor (if so equipped), and clean out any excess carbon from the exhaust port or muffler inlet every 100 hours of operation. For long-term storage drain all fuel from the fuel tank. Start and let engine run until it stops. Repair an...

Page 17

Maintenance schedule below you will find some general maintenance instructions. For further information please contact your service dealer. Daily maintenance clean the exterior of the unit. Check that the drilling attachment is properly centred, sharp, and without cracks. An off- centred bit induces...

Page 18

Engine size (cm 3 ) ................................................. Spark plug ............................................................ Fuel tank capacity (litre)....................................... Dry weight (kg)...................................................... Drive shaft diameter (...

Page 19

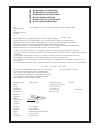

Seiji tanaka ge en sp fr i t sw declaration of conformity déclaration de conformité dichiarazione di conformità konformitätserklärung declaración de conformidad konformitetsdeklaration we, tanaka kogyo co., ltd., 3-4-29 tsudanuma, narashino, chiba, japan nous,soussignés, noi, der unterzeichnete, nos...