- DL manuals

- TANDBERG

- Telephone

- SLR AUTOLOADER - SERVICE AND

- Service And Repair Manual

TANDBERG SLR AUTOLOADER - SERVICE AND Service And Repair Manual

Summary of SLR AUTOLOADER - SERVICE AND

Page 1

Tandberg slr autoloader service and repair manual tandberg data asa p.O. Box 134 kjelsås n-0411 oslo, norway phone + 47 22 18 90 90 telefax + 47 22 18 95 50 © tandberg data asa part no. 43 20 72 – 03 december 2003.

Page 2

Related publications available from our marketing department: part no. Title 43 21 77 – 03 tandberg slr autoloader installation and user manual 43 20 73 – 03 tandberg slr autoloader scsi interface manual 43 20 74 – 01 tandberg slr autoloader product verification report 43 04 44 - 11 tandberg slr 7-1...

Page 3: Table of Contents

Table of contents chapter 1 – introduction..............................................................1 models.......................................................................................2 capacity................................................................................2 data tran...

Page 4

Tandberg data table of contents default setup options..............................................................50 setting a password .................................................................51 chapter 5 – maintenance...........................................................53 using the ...

Page 5: Chapter 1 – Introduction

Chapter 1 – introduction tandberg data’s slr autoloader is a compact tape cartridge loader designed for secure, reliable unattended system backup. Based on advanced scalable linear recording (slr) technology, the slr autoloader occupies only one half of the shelf space in a standard 19” rack yet del...

Page 6: Models

Tandberg data chapter 1 - introduction models there are tree models of the slr autoloader. The model number for each is identical except for the last two/three digits which represent the maximum compressed data capacity gigabytes (gb) for each cartridge used in a particular model. See tables 1-1 and...

Page 7: Product Description

Media compatibility the slr140, slr100, slr75 and slr60 autoloader models can perform the following operations with the indicated media drives tape type slr140 slr100 slr75 slr60 slrtape140 r/w - - - slrtape100 r/w r/w - - slrtape75 r/w r/w r/w - slrtape60 r/w r/w r/w r/w slrtape50 r/w r/w r/w r/w s...

Page 8

Tandberg data chapter 1 - introduction front panel the front panel includes the user control panel with lcd display and control buttons, led indicators, and the front door panel. Control panel the control panel presents: • a backlit green lcd matrix display • four control buttons • two led indicator...

Page 9

Lcd display in various modes of operation, the display panel screens can show you: • drive and loader status • menu choices, and • error messages. Through most of its operation, the backlit screen displays four 20-character lines of information. This manual refers to the four text lines of the scree...

Page 10

Tandberg data chapter 1 - introduction front panel door the door is opened by a control panel button, with the door latch being released by the autoloader robotic mechanism. In order to operate the front door ac power must be applied. The hinged door swings open to the left, permitting access to the...

Page 11

Tape cartridge magazine the 8-cartridge magazine is accessible through the front panel door. The rugged polymer magazine fits into an alignment guide, which assures precise cartridge positioning with respect to the loader robotics. The only correct insertion orientation for the magazine is shown in ...

Page 12

Tandberg data chapter 1 - introduction loading view #1 front view proper alignment of magazine prior to loading it into its bay in the slr autoloader. Loading view #2 diagonal side view better view of the front end of the magazine entering its bay of slr autoloader. Loading view #3 front view view o...

Page 13

Bar code reader an integrated bar code reader is installed as standard equipment in the slr autoloader. It is an integral part of the robot shuttle assembly and moves with it. At power up, the loader automatically pulls each cartridge into the robot shuttle to scan the bar code, and replaces it in t...

Page 14

Tandberg data chapter 1 - introduction bar code label the bar code label is encoded with a code 3 of 9 standard bar code format. The label for all cartridges consists of six alphanumeric characters: three alpha characters and three numeric characters. The cleaning cartridge uses cln as the alpha cha...

Page 15

Calibrating the bar code reader to calibrate the bar code reader, do the following: 1. Insert a cartridge in slot 2 of the slr autoloader. Make sure the cartridge has a bar code label that is: • tandberg approved for slr autoloader • clean • properly positioned on the cartridge. 2. Power up the auto...

Page 16

Tandberg data chapter 1 - introduction rear panel the rear panel includes eight mechanical devices that relate to bus communication, firmware upgrading and troubleshooting, device cooling, and line power. Bus communication between the scsi bus connector and the host adapter occurs through scsi bus c...

Page 17

Power switch the power switch is located on the upper right corner of the rear panel. It is a two- position rocker switch that controls the supply of ac power to the unit: • to turn the power on, depress the switch on the 1 side. The lcd display illuminates. • to turn the power off, depress the swit...

Page 18

Tandberg data chapter 1 - introduction scsi interface connectors the scsi interface connectors link the internal scsi bus devices (scsi drive and robotic controllers) to the external host adapter. The bi-directional scsi bus transfers the scsi commands and data. To provide this function, there are t...

Page 19

This page intentionally left blank tandberg slr autoloader service and repair manual 15.

Page 20: Chapter 2 – Installation

Chapter 2 – installation tandberg data has installed a locking pin as a precautionary safety mechanism to prevent damage to the slr autoloader during shipment from the factory. Inserted from underneath the loader floor, the pin prohibits any lateral movement of the shuttle assembly by locking it dow...

Page 21: Removing The Locking Pin

Tandberg data chapter 2 - installation removing the locking pin to remove the locking pin (also called lockdown mechanism), do the following: 1. Make sure that the power cord is disconnected from line power. 2. Place the unit on a table at waist height. 3. Position the unit so that the front panel d...

Page 22: Reinstalling The Locking Pin

Reinstalling the locking pin note: the locking pin must be reinstalled to prevent damage to the cartridge shuttle mechanism during transportation. 1. Make sure that the power cord is disconnected from line power. 2. Make sure the shuttle is parked in the home position. (see the description of the ut...

Page 23

Tandberg data chapter 2 - installation mounting tabletop units tabletop units require no mechanical assembly. Place the unit on a desk, table, server top, or other stable, horizontal surface with at least 2-inch (5 cm) clearance behind it to allow free flow of cooling air from the fan. Caution: make...

Page 24

Installation of slr autoloader rack chassis into rack 1. Attach the left support bracket to the left rear rail surface side using two 10- 32x1/2” screws and two 10-32 nut plates. 2. Attach the right support bracket to the right rear rail surface side using two 10- 32x1/2 screws and two 10-32 nut pla...

Page 25

Tandberg data chapter 2 - installation cabling and interface connections before the slr autoloader can be powered up or communicate with the host device or user applications, the following connections must be made (see the diagram of the rear panel’s connectors on the next page): • ac line power • s...

Page 26

There are two types of power cables supplied with the slr autoloader. They differ in their cable connectors and length. Each cable has a different terminal ending for connecting to local line power. The cable length of the usa version is 6.5 feet (2.0 m); the european one is 2.5 m. To maintain produ...

Page 27

Tandberg data chapter 2 - installation interface cable specifications the slr autoloader is a high-performance system. To avoid degradation of performance, any additional or replacement cables you use should likewise be of the highest quality. The detailed requirements for scsi cables are set forth ...

Page 28

68-pin high density male connector thumb screw pole led light 4. If the slr autoloader is the only scsi device you want to connect to the interface card, connect the cable from the interface card to the incoming scsi connector, attach the terminator to the outgoing scsi connector, then skip to step ...

Page 29: Software Installation

Tandberg data chapter 2 - installation 7. Be sure not to exceed the maximum bus length of the entire scsi bus. The internal scsi bus length for the slr autoloader is 5.0 feet (1.54 m) including all cabling and trace lengths. Refer to the manuals for the other scsi devices to determine their internal...

Page 30: Chapter 3 – Operation

Chapter 3 – operation system power-up with mechanical installation and electrical connection complete, turn on the ac power switch. At power-up, for the first three seconds, the unit performs a sequence of diagnostic tests called power-on self tests (post). These include: a rom crc check, a ram test...

Page 31

Tandberg data chapter 3 - operation selecting the control panel display modes after normal startup, the default screen appears without operator or host intervention. Several display modes appear on the display panel screen. To view the main menu, press the menu (top right) control button on the cont...

Page 32

Navigating through the menu map from the main menu screen, you can access three submenus: system data, setup, and utilities. Access the main menu screen from the default screen. Entering the menu mode while viewing the default screen, press the upper right control button labeled menu to change the d...

Page 33

Tandberg data chapter 3 - operation autoloader options the number of possible values for each autoloader option setting varies among the entire autoloader option list. All of these values for each menu option of the autoloader options menu are provided on the next page. Unload mode [= implicit] (2) ...

Page 34

Scsi options the number of possible values for each scsi option setting varies among the entire scsi option list. Here is a list of all of them for each menu option of the scsi options menu: loader scsi id [= scsi id 4] (16) scsi id 0 to scsi id 15 drive scsi id [= scsi id 5] (16) scsi id 0 to scsi ...

Page 35

Tandberg data chapter 3 - operation cartridge map when this option is selected, the operator may schroll through a list of all 8 magazine slots and the drive. For each slot and for the drive, line 3 on the display will indicate if the slot / drive has a cartridge or not. If the barcode scan is enabl...

Page 36

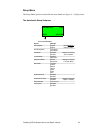

Setup menu the setup menu options are described in more detail in chapter 4 – configuration. The autoloader setup submenu system data exit setup utilities a utoloader s ubmenu option settings unload mode implicit explicit default settings display in italics numbering base one based zero based autocl...

Page 37

Tandberg data chapter 3 - operation the scsi setup submenu system data exit setup utilities scsi s ubmenu option settings loader scsi id scsi id 0 to scsi id 15 scsi id 4 default settings display in italics drive scsi id scsi id 0 to scsi id 15 scsi id 5 loader parity disabled enabled product id slr...

Page 38

Utilities menu the utilities menu options are described in detail in chapter 4 – configuration. The utility menues system data exit setup utilities m aintenance s ubmenu option settings park select this option select next or exit clean drive select this option select next or exit displays if cleanin...

Page 39: Autoloader Operation Modes

Tandberg data chapter 3 - operation autoloader operation modes the autoloader has two operating modes, random mode and sequential mode. Random mode is the factory default operation mode. Random mode when the loader is operating in random mode, the host computer controls the drive and the loader robo...

Page 40

Sequential operation a sequential operation is started when a cartridge from a set is loaded into the drive using the front panel load button. Any cartridge in a set can be selected as the first cartridge and the sequential operation will run until the last cartridge in the set has been unloaded fro...

Page 41

Tandberg data chapter 3 - operation setting the write-protect switch before loading cartridges into magazines, you should set the write-protect switch of each cartridge to enable or disable data recording. • to enable data recording, rotate the write-protect switch until it points to the unlocked ic...

Page 42: Cartridge Handling

Cartridge handling inserting cartridges into the magazine insert cartridges so that access door is facing up and located at the magazine front. After you insert your cartridges, position the magazine so that the cartridges face forward and the handle is toward you. Make sure the cartridges latch. Lo...

Page 43

Tandberg data chapter 3 - operation to unload a cartridge: 1. Press the unload button. The following screen appears, displaying the slot number of one of the available, empty cartridge slots on line two: ▲ cancel slot 1 ▼ select 2. Select the cartridge slot number of your choice. Press the ▲ button ...

Page 44: Magazine Handling

Magazine handling you must remove the magazine from the unit in order to insert or remove cartridges. When inserting cartridges, be sure that the slot you intend to use is not already reserved in the system map for a cartridge in a drive. The best way to avoid conflicts is to unload the drive, eithe...

Page 45

Tandberg data chapter 3 - operation warning ! Do not push on display panel when pulling out the magazine. Using your thumb for leverage can crack the display panel. Such damage can lead to injury or electrical shock. The following illustration shows the correct way to remove the magazine from its co...

Page 46: Chapter 4 – Configuration

Chapter 4 – configuration this chapter describes: • setting up initial system configuration parameters with individual setup and utility options • entering characters into a menu option using the control panel • protecting the system with a password. Before using the slr autoloader for the first tim...

Page 47

Tandberg data chapter 4 - configuration auto clean mode — enables autoclean mode. This option does not display unless you have selected a cleaning slot. Loader mode — allows the loader to be used as either a random access device or as a sequential loader device. When set to random, the host has full...

Page 48

Sequential mode — applies when the loader mode is set to sequential. When normal is selected, sequential operation terminates after the last cartridge in the sequence has been unloaded. A cartridge sequence ends at an empty slot or when the cartridge in slot 8 has been unloaded. (slot 7 if cleaning ...

Page 49

Tandberg data chapter 4 - configuration scsi options loader scsi id — sets the scsi id of the loader. Legal values range from 0 – 15. Drive scsi id — sets the scsi id of the drive. Legal values range from 0 – 15. Loader parity — enables/disables the parity checking for the loader scsi bus. Vendor id...

Page 50: Utilities Options

Utilities options maintenance submenu clean drive — enables running an installed cleaning cartridge. (cleaning slot must also be enabled in the setup menu.) park — enables moving the shuttle assembly to the home position. This option must be executed before the loader is prepared for transport by in...

Page 51

Tandberg data chapter 4 - configuration security submenu set password — allows you to set a password that can restrict access to the system through the front panel. If you set the password to a non-zero value, and press the load, unload, or open door buttons, the system prompts you for the password....

Page 52

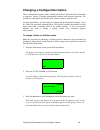

Changing a configuration option these configuration options (such as setup and utilities) allow the slr autoloader to support a variety of storage management software and network platforms. The settings for each option are stored in non-volatile memory inside the unit. For most applications, you do ...

Page 53

Tandberg data chapter 4 - configuration 4. From the option you want, press the select button. ▲ a sc re e n sim ila r to th e fo llo w in g a p p e a rs, sh o w in g th e c u rre n t v a lu e fo r th e se le c te d o p tio n : ▲ cancel u nload m ode = im p lic it ▼ accept 5. Press the ▼ or ▲ button ...

Page 54: Default Setup Options

Default setup options setup option default autoloader unload mode implicit numbering base one based auto clean disabled loader mode random sequential mode normal baud rate 115,200 enable bar code disabled enable check char enabled cleaning slot disabled set serial number _ _ _ _ _ _ _ _ _ _ _ _ (12 ...

Page 55: Setting A Password

Tandberg data chapter 4 - configuration setting a password you can restrict access to the system by setting a password in the setup options. When these access codes are set, the load, unload, or open door buttons will cause an entry prompt to appear on the screen. The password also restricts access ...

Page 56

This page intentionally left blank tandberg slr autoloader service and repair manual 52.

Page 57: Chapter 5 – Maintenance

Chapter 5 – maintenance this chapter shows you how to: • use the cleaning cartridge • install firmware upgrades. Using the cleaning cartridge the cleaning cartridge is similar in size and shape to the regular slr data cartridge. There are three procedures for using the cleaning cartridge: two manual...

Page 58

Tandberg data chapter 5 - maintenance running an installed cleaning cartridge manual method 1 this method can be used if the cleaning slot is disabled in the setup menu. 1. Install a cleaning cartridge in slot #8. 2. Use the load button to load the cleaning cartridge into the drive. 3. When the disp...

Page 59: Installing Firmware Upgrades

Installing firmware upgrades the loader fw can be upgraded via the rs232 diagnostic port on the back of the loader or via the scsi interface. Before attempting this upgrade, make sure you have access to a fw upgrade utility program for loading the new firmware into the slr autoloader. Tandberg data ...

Page 60

Tandberg data chapter 5 - maintenance 7. When all sectors of the flash has been erased and programmed, the slr autoloader will display the following messages. After firmware is downloaded: flash firmware scsi update checking crc when programming is complete and the autoloader reboots: flash firmware...

Page 61: The Fault Screen

Chapter 6 – troubleshooting the fault screen when the slr autoloader detects a fault condition, the red/amber fault led illuminates and one of the fault screens, shown below, appears on the control panel: fault code: 3013 drive fetch failed reboot pass thru fault code: 2912 unknown tape type exit pa...

Page 62

Tandberg data chapter 6 - trobleshooting error codes the error codes are listed in numerical sequence by their fault symptom code (fsc) in the tables that follow. If a persistent error condition prompts you to call your technical support representative, be sure to furnish the code information to hel...

Page 63

Scsi error codes fsc display message description source of failure suggested action 1001 scsi firmware error scsi process detected an unexpected error condition. Robotics assembly 1002 scsi fifo empty scsi controller fifo is empty. 1003 scsi fifo error scsi controller fifo should be empty. 1004 scsi...

Page 64

Tandberg data chapter 6 - trobleshooting control process error codes fsc display message description source of failure suggested action 2001 ctl invalid command an invalid command was received by the control process. Robotics assembly contact tandberg data for new firmware. Flash with new firm- ware...

Page 65

Control process error codes (continued) 2050 no free queues the system could not allocate a free queue. 2610 break detected 2611 daci locked 2612 daci busy 2613 drive busy 2614 illegal cdb 2615 illegal parameters 2617 unknown command 2618 daci poll error 2619 illegal data unexpected status returned ...

Page 66

Tandberg data chapter 6 - trobleshooting motor process error codes, continued fsc display message description source of failure suggested action 301 1 slot fetch failed a problem was encountered while trying to fetch a cartridge from a slot. 301 2 slot stow failed a problem was encountered while try...

Page 67

Boot firmware error codes fsc display message description source of failure suggested action b001 boot rom crc error b002 code rom crc error b003 boot ram test failed b004 boot cpu test failed b005 boot enc test failed b006 boot uart error b007 boot comm open error a power-up error was detected. Rob...

Page 68

Tandberg data chapter 6 - trobleshooting this page intentionally left blank 64 tandberg slr autoloader service and repair manual.

Page 69: Replacement

Chapter 7 – parts removal and replacement this chapter provides procedures for the removal and replacement of the tape drive module and the robot shuttle assembly. The slr autoloader has two field replaceable units (frus) that you can order: the add-on replacement drive and the complete autoloader u...

Page 70: The Drive

Tandberg data chapter 7 – parts removal and replacement the drive to remove the drive 1. Press the open door button. The robot shuttle moves over to operate the door latch, and the door swings open. Note: if the door does not open, refer to appendix c – emergency magazine removal. 2. Turn off the po...

Page 71

5. Remove the four m3 button socket head screws from the underside of the painted cover. 6. Turn the unit back upright so that it is resting on its feet. 7. Slide the painted cover off toward the back of the unit. 8. Remove the four flat-head screws that hold the door panel assembly to the chassis. ...

Page 72

Tandberg data chapter 7 – parts removal and replacement to replace the drive 1. Turn off the power. 2. Insert the four m3 x 6mm pan head screws to fasten the drive to the mounting plate. 3. Following the guide channels molded into the chassis, slide the drive into position, between the pairs of lanc...

Page 73

6. Insert the four flat-head screws that hold the door panel assembly to the chassis. 7. Slide the painted cover on from the back of the unit. 8. Facing the door panel, gently place the unit on its left side. 9. Insert the four m3 button socket head screws into the underside of the painted cover. 10...

Page 74: The Robot Shuttle Assembly

Tandberg data chapter 7 – parts removal and replacement the robot shuttle assembly cleaning the bar code reader 1. Press the open door button. The robot shuttle moves over to operate the door latch, and the door swings open. Note: if the door does not open, refer to appendix c – emergency magazine r...

Page 75

6. Turn the unit back upright so that it is resting on its feet. 7. Slide the painted cover off toward the back of the unit. 8. Facing the front, gently place the unit on its left side. 9. Remove the 10 m3 x 6mm flat-head phillips screws that fasten the right side panel of the unit, and remove the p...

Page 76

Tandberg data chapter 7 – parts removal and replacement shuttle bar code reader re-assembly after bar code reader cleaning 1. Replace the right side panel and fasten with 10 m3 x 6mm flat-head phillips screws. 2. Turn the unit upright so that it is resting on its feet. 3. Starting from the back, sli...

Page 77

5. Insert the four m3 button socket head screws to fasten the underside of the painted cover. 6. Turn the unit upright again so that it is resting on its feet. 7. Apply power to the unit, and unlock the door. 8. Insert a magazine, close the door, and test the operation of the unit. To remove the rob...

Page 78

Tandberg data chapter 7 – parts removal and replacement 6. Turn the unit back upright so that it is resting on its feet. 7. Slide the painted cover off toward the back of the unit. 8. Facing the front, gently place the unit on its left side. 9. Remove the 10 m3 x 6mm flat-head phillips screws that f...

Page 79

11. Remove the cable retainer and unplug the ribbon cable from the main printed wiring board (pwb). 12. Reach in through the front of the chassis past the forward bulkhead, and place your hand under the shuttle assembly. 13. Applying a slow uniform pressure, gently lift the shuttle assembly upward. ...

Page 80

Tandberg data chapter 7 – parts removal and replacement to replace the robot shuttle assembly 1. Make sure electrical power to the unit is off. 2. Place the unit on its left side, with the bottom toward you, and the painted cover and right side panel removed. 3. Holding the shuttle assemble with bot...

Page 81

5. Tilt the shuttle assembly down to engage the other pair of pinion gears with their racks. 6. Reach in through the front of the chassis past the forward bulkhead, and place your hand under the shuttle assembly to assist in lowering it. Note: for proper operation, the assembly should move through t...

Page 82

Tandberg data chapter 7 – parts removal and replacement 10. Continue gently pushing until the assembly is at the bottom of its travel. 11. Insert the four m3 x 6mm flathead phillips screws that fasten the lower magazine guide assembly. 12. Attach the ribbon cable to the main pwb and replace the reta...

Page 83

14. Turn the unit upright so that it is resting on its feet. 15. Starting from the back, slide the painted cover over the unit. 16. Turn the unit over on its left side. 17. Insert the four m3 button socket head screws to fasten the underside of the painted cover. 18. Turn the unit upright again so t...

Page 84

Tandberg data chapter 7 – parts removal and replacement this page intentionally left blank 80 tandberg slr autoloader service and repair manual.

Page 85

Appendix a – specifications operational performance specifications host interfaces: fast/wide scsi, single-ended ultra-2, low voltage differential number of cartridges, full magazine 8 media compatibility: read operations slr140 slr7, slr50, slr60, slr75, slr140 cartridges slr100 slr7, slr24, slr40,...

Page 86

Tandberg data appendix a - specifications notice this product complies with the requirements for an it power system. Mechanical specifications height 6.84 in (17.4 cm) width 8.80 in (22.4 cm) depth 22.75 in (57.8 cm) weight 30 lbs (13.6 kg) shipping weight 32 lbs (14.6 kg) shipping size height 12.4 ...

Page 87

Electromagnetic emission notice this equipment has been tested using double shielded cables and terminators for emi compliance. The use of unshielded cables, terminators, or modifications requires system testing for emi testing for compliance to the standard. Industry of canada this class b digital ...

Page 88

Tandberg data appendix a - specifications this page intentionally left blank 84 tandberg slr autoloader service and repair manual.

Page 89

Appendix b – spares/accessories type description p/n spares complete unit ps/2 grey black 006294 006295 add-on/replacement drive slr140 slr100 slr75 slr60 006784 006137 006840 006560 loader assembly ps/2 grey black 006449 006450 accessories data cartridge 431891 cleaning cartridge 005678-2 bar code ...

Page 90

Tandberg data appendix b – spares/accessories this page intentionally left blank 86 tandberg slr autoloader installation and user manual.

Page 91: Removal

Appendix c – emergency magazine removal if a fault occurs that prevents the normal removal of the magazine, you can still remove it using the emergency procedure described below: 1. Turn the power off. 2. Facing the front panel, gently turn the slr autoloader on its right side so you can access its ...

Page 92

Tandberg data appendix c – emergency magazine removal this page intentionally left blank 88 tandberg slr autoloader installation and user manual.