- DL manuals

- TapFlo

- Water Pump

- T125

- Manual

TapFlo T125 Manual

Summary of T125

Page 1

Sanitary series diaphragm pumps edition 2016 rev 2 read this instruction manual carefully, before you install and operate the pump pump models: t/tx30 t/tx80 t/tx125 t/tx225 t/tx425 t825.

Page 2: Contents

Contents 0. General ......................................................................................................................................... 6 0.1. Introduction..............................................................................................................................

Page 3: Contents

Contents 3.1.1. Performance test .............................................................................................................. 15 3.2. Routine inspection ................................................................................................................... 15 3.3. Compl...

Page 4: Contents

Contents 6.1. Capacity curves......................................................................................................................... 39 6.2. Capacity changes ...................................................................................................................... 39 6....

Page 5: Ce Certificate

Ce certificate ec declaration of conformity machinery directive 2006/42/ec pressure equipment directive 97/23/ec, category i tapflo ab declares that: product name: air operated diaphragm pumps models: t… is in conformity with the essential health and safety requirements and technical construction fi...

Page 6: 0. General

0. General iom manual tapflo sanitary series pumps 6 0. General 0.1. Introduction the tapflo air operated diaphragm pump range is a complete series of pumps for industrial applications. The pumps are designed to be safe, simple and easy to use and maintain. The construction is seal-less and without ...

Page 7: 1. Intstallation

1. Intstallation 1. Installation 1.1. Operation principle the tapflo diaphragm pump is driven by compressed air. The two diaphragms are connected by a diaphragm shaft and pushed back and forth by alternately pressurising the air chambers behind the diaphragms using an automatically cycling air valve...

Page 8: 1. Intstallation

1. Intstallation 1.3. Storage if the equipment is to be stored prior to installation, place it in a clean location. The pump should be stored in an ambient temperature of 15°c (59°f) to 25°c (77°f) and relative humidity below 65%. It should not be exposed to any heat source e.G. Radiator, sun as thi...

Page 9: 1. Intstallation

1. Intstallation 1.6. Health and safety the pump must be installed according to local and national safety rules. The pumps are constructed for particular applications. Do not use the pump on applications different from that for which it was sold without consulting us to ascertain its suitability. 1....

Page 10: 1. Intstallation

1. Intstallation 1.6.4. Noise level at tests, the noise level from a tapflo pump has not exceeded 80 db(a). Under some circumstances, for example if the pump is operating under high air pressure at low discharge head, the noise can be inconvenient or hazardous for personnel staying for long periods ...

Page 11: 1. Intstallation

1. Intstallation 2) manometer to read the actual pressure; 3) needle valve to adjust the air flow (especially when operating the pump in the lower range of performance); 4) filter. These components are included in tapflo’s air treatment system which can be ordered from us. 1.8. Example of installati...

Page 12: 2. Operation

2. Operation iom manual tapflo sanitary series pumps 12 2. Operation 2.1. Before starting the pump make sure the pump is installed according to the installation instruction (chapter 1). Filling of the pump with liquid before start is not necessary. When installation is new or reinstalled, a test run...

Page 13: 2. Operation

2. Operation if there is possibility of freezing at the air exhaust, it is good to pre-heat the air before it reaches the air intake in order to raise the dew point of the air. Note! Make sure that the air temperature does not exceed 50°c (122°f). If icing / freezing is still a problem with the stan...

Page 14: 2. Operation

2. Operation 2.4.1.1. Drainage of the pump (t80 – t825) after the cip procedure, the pump usually has to be drained from the cip fluid. The tapflo sanitary series is supplied with a hygienic stand, enabling 360° rotation of the pump unit. 1) disconnect the pump from the piping. 2) simply loosen the ...

Page 15: 3. Maintenance

3. Maintenance iom manual tapflo sanitary series pumps 15 3. Maintenance 3.1. When the pump is new or reassembled if the pump is new or reassembled after maintenance it is important to retighten the pump housing nuts (pos. 37) after a few days of operation. Make sure to use the right torque – see ch...

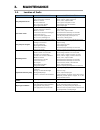

Page 16: 3. Maintenance

3. Maintenance 3.4. Location of faults problem possible fault possible solution the pump does not run the air pressure is to low increase air pressure via a filter-regulator the air connection is blocked check / clean air supply connection muffler is blocked check / clean / replace muffler air valve...

Page 17: 3. Maintenance

3. Maintenance 3.5. T30 – disassembly of the pump the numbers put in brackets, refer to the part numbers in the spare part drawings and spare part lists in chapter 5 “spare parts”. 3.5.1. Before the disassembly procedure be sure to drain all liquid from the pump. Cleanse or neutralize the pump thoro...

Page 18: 3. Maintenance

3. Maintenance fig. 3.5.5 unscrew the domed nuts [37] and remove the housing [11] from one side of the pump. Fig 3.5.6 unscrew the diaphragm [15]. Fig 3.5.7 turn the pump over, remove the domed nuts [37] and washers [38]. Take off the second housing [11]. Fig 3.5.8 take out the pin screws [14] and u...

Page 19: 3. Maintenance

3. Maintenance fig 3.5.10 press out the air valve [61] by means of a pressing device. Be careful not to damage the brass edges of the air valve. The pump is now completely disassembled. Check all components for wear or damage and replace if necessary. When air valve is removed from the centre body c...

Page 20: 3. Maintenance

3. Maintenance fig. 3.6.4 during assembly of the housings [11] make sure they are in the correct position – the inlet pipe has a valve ball stopper. Fig. 3.6.5 when fastening the domed nuts, remember to do it according to the tightening procedure and with the appropriate torque. Note! After a few we...

Page 21: 3. Maintenance

3. Maintenance iom manual tapflo sanitary series pumps 21 3.7. T80-t425 – disassembly of the pump the numbers put in brackets, refer to the part numbers in the spare part drawings and spare part lists in chapter 5 “spare parts”. 3.7.1. Before the disassembly procedure be sure to drain all liquid fro...

Page 22: 3. Maintenance

3. Maintenance fig. 3.7.3 unscrew and remove two tri-clamps [138] connecting the second manifold [131] to the housings [11]. Fig. 3.7.4 remove the valve balls [23] and sealing [18]. Loosen the socket head cap screws [174] and take off the pump from the stand [17]. Fig. 3.7.5 unscrew the domed nuts [...

Page 23: 3. Maintenance

3. Maintenance fig. 3.7.8 take out the second diaphragm [15] along with the shaft [16]. A) circlip mounted air valve – t/tx80, t125 fig. 3.7.9 using pliers remove both circlips [27] from the centre block [12]. Attention! While doing this, cover yourself with your other hand, as the circlip easily fl...

Page 24: 3. Maintenance

3. Maintenance c) threaded air valve – t225 from s/n 0803-… until 1105-… and t425 from s/n 0801-… until 1105-… fig. 3.7.13 carefully unscrew both air valve end caps by means of a mounting tool. Fig. 3.7.14 push out by hand the air valve shaft and piston. Fig. 3.7.15 to push out the cylinder, use the...

Page 25: 3. Maintenance

3. Maintenance fig. 3.8.1 when putting the air valve [61] into the centre block [12], apply some water or alcohol on the o-rings to provide smooth insertion of the air valve. It is recommended to use a pressing device for this operation. Fig. 3.8.2 when there is need to replace the diaphragm pin scr...

Page 26: 4. Options

4. Options 4. Options 4.1. Valve options in t225, t425 and t825 pump sizes flap valves or heavy duty valve cups (not available in t825) are available as an option instead of standard valves. 4.1.1. Flap valves it is a great option when the product we intend to pump has high viscosity, contains big s...

Page 27: 4. Options

4. Options 4.1.2. Ball cup valves this option is a perfect solution when there is risk of damage to the valve seats from the product. If such situation is to occur there is no need to replace the whole manifolds or housings, just the valve cup what drastically reduces the spare parts cost. Just like...

Page 28: 4. Options

4. Options 4.3. Magnetic ball lifters new magnetic ball lifters have been implemented in pump sizes t125 – t425. They are implemented to enable pump emptying when no other draining option is available. Rotating the pump is no longer needed. The balls are lifted by simply attaching the magnets to the...

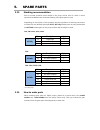

Page 29: 5. Spare Parts

5. Spare parts iom manual tapflo sanitary series pumps 29 5. Spare parts 5.1. T30 – spare parts drawing 5.2. T30 – spare parts list pos. Q-ty description material kit liq kit air 11 2 housing aisi 316l 12 1 centre block pp, conductive pp 131 1 manifold inlet and stand aisi 316l 132 1 manifold outlet...

Page 30: 5. Spare Parts

5. Spare parts 5.3. T80-t125 – spare parts drawing 5.4. T80-t125 – spare parts list pos. Q-ty description material kit liq kit air 11 2 housing aisi 316l 12 1 centre block pp, pp conductive 131 1 manifold inlet aisi 316l 132 1 manifold outlet aisi 316l 138 4 3-clamp aisi 304 14 6 pin screw a4-80 15 ...

Page 31: 5. Spare Parts

5. Spare parts 5.5. T80 – t125 – spare parts options air valve reinforcement (t125 only) – std on tx125 122 1 center block pp, pp cond. 271 1 set of 2 reinforcement plates aisi 316l 2711 8 screws a4-70 external control – built on solenoid valve 125 1 center block pp, pp cond. 97 1 solenoid valve - 9...

Page 32: 5. Spare Parts

5. Spare parts 5.6. T225-t425 – spare parts drawing 5.7. T225-t425 – spare parts list pos. Q-ty description material kit liq kit air 11 2 housing aisi 316l 122 1 centre block pp, pp conductive 131 1 manifold inlet aisi 316l 132 1 manifold outlet aisi 316l 138 4/8* 3-clamp aisi 304 14 8 pin screw a4-...

Page 33: 5. Spare Parts

5. Spare parts 5.8. T225 – t425 – spare parts options external control – built on solenoid valve 125 1 center block pp, pp cond. 97 1 solenoid valve - 971 2 threaded insert aisi 316l 972 2 screw a4-70 magnetic ball lifters 23-15 4 valve ball ptfe/ss core 23-59 4 valve ball aisi420 95m 4 magnetic bal...

Page 34: 5. Spare Parts

5. Spare parts flap valves 11h 2 housing aisi316l 131h 1 inlet manifold aisi316l 132h 1 outlet manifold aisi316l 138 8 tri-clamp aisi304 17v 1 stand aisi304 18h 8 sealing ptfe, epdm 241h 4 flap valve seat aisi316l 242h 4 flap aisi316l 24h 4 flap valve complete (241h+242h) aisi316l ball cup valves 11...

Page 35: 5. Spare Parts

5. Spare parts 5.9. T825 – spare parts drawing 5.10. T825 – spare parts list pos. Q-ty description material 11 2 housing aisi 316l 12 1 centre block pp 131 1 manifold inlet aisi 316l 132 1 manifold outlet aisi 316l 14 8 pin screw a4-80 141 32 manifold screw a4-70 15 2 diaphragm epdm, ptfe, nbr 16 1 ...

Page 36: 5. Spare Parts

5. Spare parts 36 2 centre block seal pe 37 16 pin screw nut a4-70 371 32 manifold screw nut a4-70 38 16 pin screw washer a4-80 381 32 manifold screw washer a4-70 47 2 o-ring (back up for 36) nbr 61 1 air valve complete pet/nbr (standard); aisi 316/fkm, brass/nbr, brass/epdm, aisi 316/fkm, pet/fkm 5...

Page 37: 5. Spare Parts

5. Spare parts 5.12. Stocking recommendation even at normal operation some details in the pump will be worn. In order to avoid expensive breakdowns we recommend having a few spare parts in stock. Depending on the severity of the operation and the importance of assuring continuous work we offer two d...

Page 38: 5. Spare Parts

5. Spare parts 5.14. Pump code the model number on the pump and on the front page of this instruction manual tells the pump size and materials of the pump. I. Tapflo diaphragm pump iv. Material of wetted metal parts ii. Basic options v. Material of diaphragms iii. Max capacity [l/min] vi. Material o...

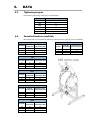

Page 39: 6. Data

6. Data iom manual tapflo sanitary series pumps 39 6. Data 6.1. Capacity curves the performance curves are based on water at 20°c.Other circumstances might change the performance. See below how the capacity will change at different viscosities and suction lifts. Example (see the red line below): a f...

Page 40: 6. Data

6. Data 6.3. Dimensions dimensions in mm (where other is not indicated) dimensions in inch (where other is not indicated) general dimensions only, ask us for detailed drawings. Changes reserved without notice. Dimension pump size t30 t80 t125 t225 t425 t825 a 168 303 328 412 476 760 6.6 11.9 12.9 16...

Page 41: 6. Data

6. Data 6.4. Technical data technical data pump size t30 t80 t125 t225 t425 t825 max capacity [l/min] / [us gpm] 30 / 7.9 80 / 21 125 / 33 225 / 59 425 / 112 825 / 218 volume per stroke* [ml] / [cu in] 120 / 7.3 320 / 19.5 515 / 31.4 1415 / 86.4 2600 / 158 4500 / 275 max discharge pressure [bar] / [...

Page 42: 6. Data

6. Data 6.5. Tightening torques the following tightening torques are recommended. Pump size mounting torque [nm] t30 5.5 t80 8 t125 16 t225 20 t425 23 t825 30 (housing) / 35 (manifolds) 6.6. Permitted loads on manifolds we recommend not to exceed the following loads and forces reacting on the manifo...

Page 43: 7. Warranty

7. Warranty iom manual tapflo sanitary series pumps 43 7. Warranty 7.1. Warranty form company: telephone: fax: address: country: contact name: e-mail: delivery date: date of pump installation: pump type: serial no (see name plate or stamped on pump housing): description of the fault: the installatio...

Page 44: 7. Warranty

7. Warranty 7.2. Returning parts when returning parts to tapflo please follow this procedure: consult tapflo for shipping instructions. Cleanse or neutralize and rinse the part/pump. Make sure the part/pump is completely empty from liquid. Pack the return articles carefully to prevent any damage dur...

Page 45: 7. Warranty

7. Warranty b.3. Accidents or any cause beyond the control of tapflo, including but not limited to lightning, water, fire, earthquake, and public disturbances, etc.; 4. The warrantee shall cover the replacement or repairing of any parts, which is documented faulty due to construction or assembling, ...

Page 46: Tapflo Ab

Tapflo group companies austria tapflo austria tel: +43 732 27292910 sales@tapflo.At azerbaijan tapflo azerbaijan llc tel: +994 502660799 sales@tapflo.Az baltic states tapflo latvia tel: +371 67472205 sales@tapflo.Lv belarus tapflo belarus tel: +375 17 3934609 sales@tapflo.By bulgaria tapflo eood tel...