- DL manuals

- TARAL

- Tractor

- 850

- Instruction Manual

TARAL 850 Instruction Manual

Summary of 850

Page 3: Introduction

Introduction we would like to thank you, our valuable customers, for purchasing this taral product. This instruction manual contains information on the operation, lubrication and maintenance of your tractor. The information contained is comprehensive and essential, and is designed to assist you, eve...

Page 4

Tractor type information tractor brand: taral tractor type: 800d tractor variant: 850d 4wd swb Ör 855d 4wd swb Ör 860d 4wd swb Ör 856d 4wd swb Ör 850g 4wd swb Ör 855g 4wd swb Ör 860g 4wd swb Ör 856g 4wd swb Ör 850g 4wd lwb Ör 855g 4wd lwb Ör 860g 4wd lwb Ör 856g 4wd lwb Ör 850g 4wd lwb ar 855g 4wd l...

Page 5

Taking delivery of the tractor when your tractor is delivered, ask your dealer to perform the first operation and provide you information on instruction and maintenance. If you have further questions, please contact the factory. Make sure all components are installed and in perfect working condition...

Page 6

Treatment of a new tractor all components of your tractor are subject to stringent checking during assembly in the factory. However, a new tractor should be carefully checked over by the operator himself for the first 25—50 hours operation, heavy duty work should be avoided. If heavy duty work is un...

Page 8

Contents section 1. Safety warnings ...................................................................................................... 1 safety precautions .................................................................................................................. 2 general operating safet...

Page 9

Tire mounting............................................................................................................................ 35 weights ......................................................................................................................................... 36 section 4 ...

Page 10

Hydraulic control adjustment ..................................................................................... 58 grease locations .................................................................................................................... 59 injection nozzle inspection ....................

Page 11

Cooling system ........................................................................................................................ 78 air cleaner ................................................................................................................................. 78 fuel system .......

Page 13

Section 1. Safety warnings safety and warning signs and instructions this symbol means be careful and aware; your safety is in danger. The symbol above describes significant safety warnings when it is used in this manual. Please pay particular attention when you see this warning and follow subsequen...

Page 14: Safety Precautions

Safety precautions remember: "safety" is only a word until it is put into practice improper handling of the tractor could lead to an accident. Prior to the operation of the tractor, be sure to read this manual carefully and have a thorough understanding of all of the contents. In particular, the ins...

Page 15

Basic safety requirements for maintenance always follow these maintenance instructions before operating the tractor: immediately repair the head lights and work lamps required to conform to traffic regulations where the tractor is operated. Keep tractor steps clean to avoid accidents due to slippage...

Page 16

Before starting any work on electrical equipment or work that may cause you to touch the electrical part accidentally, first disconnect the battery cables. Never remove the rubber cap cover at the positive terminal of the battery cable end. Before connecting the battery to the charger, make sure tha...

Page 17

Starting and driving the tractor always operate the tractor at the proper speed which enables you to keep the tractor under your complete control. To start travelling, lower the engine speed and release the clutch pedal slowly. Abrupt releasing causes the tractor to jump off. Before leaving the trac...

Page 18

If rops is folded, level it down, fasten the seat belt before using the tractor and keep it fastened while in operation. It is not recommended to use tractors without rops. Travelling on roads and streets: prior to the operation of the tractor, be sure that all functions described in this manual per...

Page 19

Safety frame must always be rolled out (unfolded) and in undamaged condition. Do not perform any modifications on the safety frame for any purposes. Always fasten your seat belts when using the tractor. Always operate and stop the tractor while you are seated. When safety frame (rops) is open, be ca...

Page 20

Steering and turning the tractor slow down your tractor and disengage the differential lock before going into a turn, being careful to prevent any attachment mounted on the front or rear from hitting anyone or anything. Note that the turning radius may be higher especially with large implements. Tow...

Page 21

Driving forward out of a ditch or mired condition or up a steep slope could cause tractor to tip over rearward. Back out of such situation if possible. If the situation does not permit you to back out, use the front wheel weight or the chassis weight for balancing the tractor lengthwise. Also in cas...

Page 22

Preventing side rollover • adjust thread to the widest range suitable for the desired work. • lock brake pedals together prior to driving at carrying speed. • lower the speed according to working conditions. • make wide and slow turns at low speed. Do not allow tractor to shake, you may lose steerin...

Page 23

Sound levels according to 2009/63/ec, the noise level measured is 79,1db(a), and as per 2006/26/ec the noise exposed by the operator is 85,9db(a). These values can vary depending on models, refer to product values. According to the niosh criteria, the maximum exposure must be limited to 8 hours for ...

Page 24

12.

Page 25

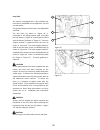

Location of warning labels 7106128 7106261 7106126 7106262 7106123 7106130 7106127 7106125 7106263 7106124 7106122 7106122 on the left side of the service sheet. Caution: before leaving the tractor, apply hand brake and lower the equipment to the ground. Stop the engine and remove the ignition key. ...

Page 26

7106128 on the right side of the safety frame. Danger: hold the steering tightly in case the tractor rolls over, protection bar protects the driver unless he attempts to stand up and leave the tractor. 7106126 on the left fender. Caution: do not carry any other passengers on the fender or any other ...

Page 27

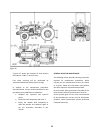

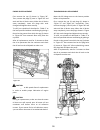

Figure 1 figure 2 section 2. External view and nomenclature of each part front dashboard controls 1. Ignition key 2. Rotating beacon lamp control 3. Work light control 4. Instrument panel 5. Hazard warning light control 6. Differential lock control 7. Illumination, flasher and horn control tractor c...

Page 28

16.

Page 29

Section 3. Functions and usage of parts instrument panel s1: fuel meter. Indicates the rate of remaining fuel in the tank. When the pointer comes over the red zone, you have about 4lt fuel in the tank, fill fuel as soon as possible. S2: engine rpm gauge. Indicates one percent of the engine speed in ...

Page 30

L1: battery not charging warning light. It lights in red. When the engine starts to run, the warning light should normally go off. L2: air cleaner warning light. It lights in red. It lights up when the air cleaner is jammed. L3: power take off warning light. It lights in red. It lights up when the p...

Page 31

Usage of front dashboard controls 1. Ignition controls 2. Rotating beacon lamp 3. Working light 5. Hazard warning light 6. Differential lock control off position: power supply to the tractor is off and the engine is not operating. In order to stop the engine while running and shut down the controls,...

Page 32

7. Illumination, flasher and horn control usage of tractor controls 8. Operator’s seat tractor is equipped with a seat that provides maximum operator comfort. Vibration levels of the seat measured for lightweight and heavy operators as per 78/764/ec are 1.24m/s 2 and 1.16m/s 2 , respectively. In ord...

Page 33

In order to adjust your seat up or down, loosen the screw (2) at both sides as seen in “figure 5”, after you place the seat to the desired position, secure it by tightening the screws at both sides by hand ensuring they are fully secured. In order the adjust the suspension of the seat, loosen and ti...

Page 34

14. Right brake pedal when depressed, it engages the right brake and brakes the right wheel. When released, automatically returns to its original position and braking effect also disappears. Normally, the play of the pedal should be 1-2 cm. 15. Left brake pedal when depressed, it engages the left br...

Page 35

Remember that when the wheel is in movement position, while the tractor moves backwards the pto will also rotate in opposite direction. This situation may constitute a problem when using certain equipment. When required, disengage and deactivate the pto by using the pto lever. 1 wheel rotation = 11....

Page 36

24. 4-wheel drive lever when lever (2) shown in “figure 10” is in lower position, the four wheel drive function activates, and when it is taken to the upper position, the function deactivates. When the four wheel drive is active, roadholding and braking ability improves on muddy and slippery surface...

Page 37

Lever (1) shown in “figure 11”, directs the pressure fluid from the outlets shown in “figure 12” to outlets (1a) and (1b) respectively according to “a” or “b” position, to which it is taken. Lever (2) shown in “figure 11”, directs the pressure fluid from the outlets shown in “figure 12” to outlets (...

Page 38

Toe-in adjustment on the front axle is carried out at the factory and it is set to max 6.5°. This angle is important for steerability at high speeds, easier control of the tractor on bends, and simple turning. You are not recommended to alter this value. To make this adjustment, after centering the ...

Page 39

3 point linkage system the tractor is equipped with a 3 point (3p) linkage system, category 2 (cat-ii). To make sure that the tractor runs smoothly, check if the equipment is suitable for three point linkage and hydraulic lift. 3p linkage system consists of the parts shown in "figure 17". 1. Center ...

Page 40

Implement mounting 1. Move the three point linkage system to the lowest position. 2. Slacken the stabilizer chain with a certain amount, so you can mount the drawbars to the linkage point of the equipment easily. 3. Approach the tractor to the implement by driving it backward slowly. 4. Raise the ar...

Page 41

Hitch connections front hitch the front hitch is supplied with the tractor. It is possible to link the front hitch, the part (1) shown in “figure 19”, to the weights on the chassis as well as it is possible to link it to the chassis directly. To link the front hitch to the weights, the front hitch (...

Page 42

Rear hitch the tractor is equipped with a iso certified rear hitch that is compatible to link implement, one and two axle trailer. The ground clearance of the hitch is non-adjustable and fixed. The rear hitch (1) shown in “figure 22” is connected to the lifting brackets with 4 pcs Ø18 pins (4) shown...

Page 43

Power take-off housing there are parts on and around of the pto outlet for your safety. 1. For extra safety, in every operation be sure to install the pto guard (1) shown in “figure 24” 2. For your safety, at the portion where the pto shaft is installed there is a safety zone (2) shown in “figure 24...

Page 44

Hydraulic circuit the hydraulic circuit diagram of the working principle indication of the steering wheel, 3 point linkage system and external power outputs and the description of the elements are provided below. Descriptions of the parts in the circuit: 1. Steering cylinder. 2. Pump. 3. Hydraulic f...

Page 45

Electrical circuit the electric circuit diagram and the elements of the tractor are provided below. Figure 26 33.

Page 46

Tires and rims you can find the tires on the tractor and the rims, tire pressures, axle loads, tracks and mounting types suitable to these tires in the following table. The bold measurements shown in the table 1 shows the factory defaults. There may be variations in these values up to ±20mm dependin...

Page 47

The axle loads specified in table 2 are the total axle loads for the axle which the tire is mounted on and the tire pressure for driving on the road is taken as reference. The carrying capacities are lower with lower tire pressures. Tire pressure should be checked frequently. Either too high or too ...

Page 48

Weights providing road handling and decreasing the slipping are important for the life of tire and fuel economy. While working with the heavy implements on the 3 point linkage system, to counterbalance the tractor it is necessary to attach the front-end weights. 4 x 25kg weights can be attached to t...

Page 49

In table 3, additive and solution amount per tire is shown. Use the weights based on the requirement of the work to be done. The weights increase the fuel consumption and tire wear, remove the weights if it is not necessary to use. While filling the tires with water, never use only water. Especially...

Page 50

38.

Page 51

Section 4 - operation before operating the tractor 1. Check the fuel level in fuel tank and replenish as necessary. 2. Check the levels of engine oil, transmission oil, and front drive differential. 3. Check the lubrication at every specified point on the chassis. 4. Check each bolt and nut for tigh...

Page 52

After the engine is started 1. Check the oil pressure and battery charge warning lamps to see they went off. If the lamp "does not go off, immediately pull the throttle lever all the way backward and turn the starter key counter clockwise to shut down the engine, and locate the cause to correct. Par...

Page 53

If any implement is mounted, turn the tractor slowly paying particular care for the space. Do not make a sharp turn at high speed. Be sure to lower the engine speed before turning. Before starting the operation on slope, check for the existence of stone, irregularity or other dangerous factors which...

Page 54

42.

Page 55

Section 5. Periodic and preventive maintenance symbos and related procedures check and/or replenish clean/wash adjust procedures to be performed only by the dealer periodic inspection must be performed when necessary to keep your tractor operating in the top condition is indispensable. First service...

Page 56

"figure 29" shows the locations of each position described in “table 4” on the tractor. First three servicing will be performed by authorized distiributor dealers free of charge. In addition to the maintenance procedures described above, visit you authorized dealer for the procedures every 1000 hour...

Page 57

Air cleaner the air cleaner element, when remarkably stained or clogged, may prevent smooth start of the engine or deteriorate its performance, preventing normal operation. Keep the element always clean to ensure full performance of engine. As known the air cleaner filters the intake air. Air cleane...

Page 58

Radiator it has a critical function for engine cooling, performance and life. To ensure proper functioning, radiator grill and the grilles of the tractor must be kept clean and open. Level of the radiator coolant must be check daily. Turn the cap no (1) as shown in “figure 32” counterclockwise, loos...

Page 59

When adding or replacing antifreeze solution, the following rules should be observed, otherwise, the cylinder block will rust. 1. This tractor's engine is of a diesel type and its cylinder block is made of cast iron. Therefore, suitable anti-freeze solution for such a cast engine block must be used....

Page 60

Engine oil filter to replace the engine oil filter, first drain all the engine oil and turn the filter housing (1) shown in “figure 35” with a filter wrench counterclockwise to remove it. Replace and tighten the filter element. Engine oil level place the tractor on a level ground to check the engine...

Page 61

Brake fluid the tractor has hydraulic brakes which use hydraulic pressure to function. If the amount of brake fluid decreases due to some reasons, it must be topped up. The hydraulic brake reservoir shown in “figure 38” has two lines; this represents the range for normal brake fluid level. If the fl...

Page 62

Engine oil replacement first remove the cap (3) shown in "figure 36". Then, remove the plugs (1) seen in “figure 39” and wait until the oil drains away. When the oil drains away completely, insert the plugs with seals changed and tighten them securely. To refill, use suitable oil described in “table...

Page 63

Run the tractor at idle speed after oil replacement in order to enable proper lubrication of transmission parts. Replacing the oil of front axle first remove the plugs (1) shown in "figure 42". Then, remove the plugs (2) shown in "figure 42" and (1) in “figure 43” and let the oil flow out. After the...

Page 64

Table 6: lubrication table l u b r ic a t io n t a b l e – r e c o m m e n d e d l u b r ic a n t s s h e ll h e li x h x 5 g d o n a x t d s p ir a x 8 5 w -1 4 0 s p ir a x 8 5 w -1 4 0 d o n a x y b d o t 4 m o b il d e lv a c m x m o b il fl u id 4 2 2 m o b il lu b e h d 8 5 w -1 4 0 m o b il l...

Page 65

Refuelling when the fuel warning light goes on or the pointer comes over the red zone, you must refuel your tractor as soon as possible. For refueling, remove the tank cap (1) seen in “figure 44”. Tank cap is locked with a key code and has to be locked/unlocked with the ignition key. To unlock the t...

Page 66

Adjustment of clutch pedal foot clutch foot clutch free play must be check on a daily basis. The play of the foot clutch is appropriate if it is between 2 to 3 cm. The free play must be adjusted if not appropriate. To adjust free play, loosen the nut (1) seen in “figure 47”; twist the part (2) clock...

Page 67

Brake adjustment foot brake foot clutch free play must be check on a daily basis. The play of the foot clutch is appropriate if it is between 1 to 2 cm. The free play must be adjusted if not appropriate. To adjust free play, open the bonnet first and loosen the nut (1) seen in “figure 49”; twist the...

Page 68

Hand brake parking brake operates independently from the brake pedal, yet squeezes brake discs through the same mechanism. When the brake disc is adjusted, it also applies to the hand brake. Adjust the distance between stoppers and nuts (1) seen in “figure 51” and “figure 52” in a way to leave 2 cli...

Page 69

Adjusting toe-in on front axle tire toe-in on the front axle is adjusted for driving comfort and easier steering control. Front side of the front tires is a bit more turned in (75-90mm) than the rear side; this alignment is called front axle toe-in. If this alignment is not proper, it should be read...

Page 70

Safety start control the tractor is equipped with a safety starter switch to protect the operator and the persons around him from potential dangers caused the abrupt starting of the engine with gear applied or an implement mounted. This safety system prevents tractor from starting before shuttle lev...

Page 71

Greasing locations certain moving mechanisms of the tractor are lubricated with grease oil. This oil may diminish or lose its function in time due to use. If these parts are stuck during the operation or any other problem occurs, the following locations should be greased. For greasing, use general p...

Page 72

Injection nozzle inspection inspection of injection nozzles requires expertise and special equipment; the inspection must be performed only at authorized service centers. Operator instructions provided in this section are only for information purpose. When the injection pressure of the nozzle is low...

Page 73

Valve clearance adjustment inspection and adjustment of valve clearance requires expertise and special equipment; the inspection must be performed only at authorized service centers. Operator instructions provided in this section are only for information purpose. Adjust the valve clearances when the...

Page 74

Setting injection pump timing adjustment of injection pump requires expertise and special equipment; the inspection must be performed only at authorized service centers. Operator instructions provided in this section are only for information purpose. A certain amount of variation can apply to the in...

Page 75

12. If the fuel does not increase, it is exhaust time. Therefore, turn the crankshaft 360° and repeat the procedures above to find the compression time. 13. Mark the injection timing measured from the timing window and measure the interval between your mark and "1, 4 az'. Note this measurement; it w...

Page 76

Electrical system battery the tractor is equipped with a maintenance free battery which normally does not require special maintenance. The specific gravity of battery electrolyte is 11280kg/m 3 ± 0.01 at 20°c. Keeping clean and servicing the battery, increase the service life. To reach the battery, ...

Page 77

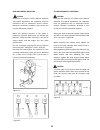

Booster connection in case the battery has run down making it impossible to start the engine, the booster is used for starting the engine using good battery of the other vehicle (12v vehicle) as power source. 1. Select a booster cable with as large a capacity as possible. It must resist a 200a curre...

Page 78

Proper battery service and tips for safety table 7 66.

Page 79

Headlamps perform periodic maintenance in order not to disturb other drivers when using the front head lamps of the tractor on roads, and to comply with the laws and regulations. Your tractor is equipped with a proper head lamp in accordance with the local and country laws and provides suitable head...

Page 80

Fuses the tractor is equipped with a fuse in the circuit to protect the electrical system against jump starts and overloads. Fuses installed in the tractor is shown in “figure 77”. 1. Main fuse (80a) 2. Fuse box to replace the damaged fuse, remove the covers by hand to reach the fuses. Glow plug the...

Page 81

Relays relays in the electrical circuit of the tractors are shown in “figure 79” and “figure 80”. The functions of the relays are listed below: 1. Buzzer 2. Flasher 3. Front head lamp low beam relay 4. Front head lamp high beam relay 5. Shut-off solenoid relay 6. Timer 7. Starter relay 8. Glow relay...

Page 82

Starter motor starter motor is a maintenance free motor. In case of failure, contact your dealer. Stretch and check the tightness of the cable connections on the starter motor by hand; if loose, tighten. Always remove the (-) terminal before performing any procedures on the electrical system. When y...

Page 83

Instrument panel wiring diagram description polarization s1: fuel meter ohm s2: engine rpm gauge. Hz s3: hour meter hz s4: engine water temperature gauge ohm j1: battery charge warning lamp negative j2: air cleaner negative j3: background illumination positive j4: pto warning light negative j5: (+) ...

Page 84

Opening the bonnet to open the bonnet, pull the arm (1) seen in "figure 81" to the right side of the tractor; this will release the latch. After unlocking, pull the bonnet up by holding it appropriately from split point on the seal. Simply push down the bonnet to close it back. The bonnet will be lo...

Page 85

Section 6. Storing storage a tractor should be stored in a dry and protected place when it is left without use for some period. Leaving a tractor outdoors will result in shortened life of the tractor. For storing the tractor please follow the procedures described below: 1. After washing and cleaning...

Page 86

74.

Page 87

Section 7. Technical specifications figure 83 table 8: technical specs 75.

Page 88

Note: the table above indicates forward speeds. For reverse speeds, multiply the speeds on the table by 0.988. Table 10: speeds via tires. Table 9: engine specs 76.

Page 89

Figure 84 table 11: turning radius 77.

Page 90

Engine lubrication system lubrication pump trochoid gear pump filter cartridge type, paper oil pressure 0.4 kgf/cm 2 (at idle) engine speed governor speed governor type mechanical, centrifuge transmission gear range 12 forward 12 reverse main shifting synchromesh shuttle shifting synchromesh maximum...

Page 91

Fuel system fuel diesel fuel filter cartridge type, paper fuel pump sequential fuel tank material pe fuel tank capacity 32 liters hydraulic pump pump type gear pump number of sections 2 pump 1 flow rate 7.2cc/rev (18.7 l/d @2600) pump 1 pressure 120 bar pump 2 flow rate 12cc/rev (31.2 l/d @2600) pum...

Page 92

Maximum axle loads front axle 1000 kg rear axle 1750 kg note: maximum front axle load is 975 kg when 7.00-12 front tire is used. Power take-off measure 1-3/8” 6spline (iso500) engine-driven pto rpm 540 540 @ 2540 engine-driven pto rpm 750 750 @ 2600 wheel driven pto rpm 11.076 x wheel rot. Hydraulic...

Page 93

Unit conversion table length 1 inch 0.0254 m 30.48 cm 0.3048 m 0.91 m 0.9144 m 1 statute miles 1,609 m 1 nautical miles 1,852 m volume 1 us ounces 29,574 cm 3 1 imperial ounces 28,413 cm 3 1 us gallons 3785.43 cm 3 1 imperial gallons 4546.09 cm 3 1 us pints 473.17 cm 3 1 imperial pints 568,261 cm 3 ...

Page 94

82.

Page 95

Section 8. Troubleshooting engine starts difficult possible cause remedy increased fuel thickness or viscosity. - check fuel tank and fuel filter. - remove water, dust and other dirt. - as the filter is used to clean the entire fuel, replace the filter if there is water or foreign matter on it. Air ...

Page 96

Bad exhaust colour possible cause remedy deteriorated injector pump - consult your dealer for repair. Low fuel quality - use high quality fuel. O diesel no.2 for over 10°c o diesel no 1 for below 10°c deteriorated injector nozzle - replace with a new part if necessary. Combustion interrupted - this ...

Page 97

Tractor is not starting possible cause remedy no sound from starter motor - safety switches may be on. Move the pto shaft and shuttle shift lever to neutral and depress clutch pedal all the way. - one or more of fuses may be damaged; check the fuses and replaced damaged ones. - ignition or starter c...

Page 98

Battery problems possible cause remedy low electrolyte level - add treated water and recharge for a long time. The battery does not recharge - as the current of the alternator is very high, the plates are displaced or short-circuit occurred. Reduce the charging current of the alternator and replace ...

Page 99

For conditions that are not described in the instruction manual, please consult your dealer. In case of failure to use the machine properly as instructed in this book, all responsbility must be undertaken by the user. Caution 87.

Page 100

88.

Page 102

Dealer taral tarım makina ve aletleri sanayi a. Ş . Maltepe mah. Hastane yolu sok. No:1 p.K. 34010 zeytinburnu/ İ stanbul tel: +90 212 5679550 (pbx) fax: +90 212 6740679 1 +90 212 6121239 e-mail: info@taral.Com web site: http://www.Taral.Com taral reserves the right to change tractor design and spec...