- DL manuals

- TARAL

- Lawn Mower

- VST 818

- User Instruction Manual

TARAL VST 818 User Instruction Manual

TARAL

- VST 818

TRACTOR

USER

INSTRUCTION MANUAL

Taral Tarım Makina ve

Aletleri Sanayi

A.

Ş

.

Maltepe Mah. Hastane

Yolu Sok. No:1 P.K. 34010 Zeytinburnu/

İ

STANBUL

Tel: +90 212 5679550 (Pbx) Fax: +90 212 6740679 / +90 212 6121239

e-mail: info@taral.com website: http://www.taral.com

Form No: KBK-7205207 Revision No: 0

Publish Date: 01.08.2012

Summary of VST 818

Page 1

Taral - vst 818 tractor user instruction manual taral tarım makina ve aletleri sanayi a. Ş . Maltepe mah. Hastane yolu sok. No:1 p.K. 34010 zeytinburnu/ İ stanbul tel: +90 212 5679550 (pbx) fax: +90 212 6740679 / +90 212 6121239 e-mail: info@taral.Com website: http://www.Taral.Com form no: kbk-72052...

Page 3

Introduction we would like to thank you, our valuable customers, for purchasing this taral product. This instruction manual contains information on the operation, lubrication and maintenance of your tractor. The information contained is comprehensive and essential, and is designed to assist you, eve...

Page 4

Tractor type information tractor brand: taral tractor type: 818d tractor variant: 818d 4wd ar tractor category: t2 tractor trade name: taral - vst 818 manufacturer of tractor: taral tarım makine ve aletleri sanayi a. Ş . Address: maltepe mah. Hastane yolu sok. No:1, 34010, zeytinburnu, İ stanbul tel...

Page 5

Taking delivery of the tractor when your tractor is delivered, ask your dealer to perform the first operation and provide you information on instruction and ma- intenance. If you have further questions, please contact the fac- tory. Make sure all components are installed and in perfect working condi...

Page 6

Do not try to pass over cars on road. If the traffic behind becomes busy, pull over at an appropriate place and give way to the vehicles behind. This tractor is compatible for both rh traffic and lh traffic drive. Check, and ask dealer if necessary to adjust, front lamps and mirror regarding local r...

Page 7

Contents section 1. Safety precautions a. General operating safety precaution ................................................................................ 1 b. Basic safety requirements for maintenance ...................................................................... 1 c. Operation of the t...

Page 8

Operator's seat ........................................................................................................................ 19 external outlet valve .............................................................................................................. 19 front axle steering adju...

Page 9

Air cleaner .............................................................................................................................. 32 fan belt tension adjustment .................................................................................................. 33 battery........................

Page 10

Clutch ...................................................................................................................................... 45 transmission............................................................................................................................ 45 power take off ...

Page 11

Section 1 - safety precautions remember: "safety" is only a word until it is put into practice improper handling of the tractor could lead to an accident. Prior to the operation of the tractor, be sure to read this manual carefully and have a thorough understanding of all of the contents. In particu...

Page 12

9. Before starting any work on electrical equipment or work that may cause you to touch the electrical part accidentally, first disconnect the battery cables. Never remove the rubber cap cover at the positive terminal of the battery cable end. Before connecting the battery to the charger, make sure ...

Page 13

Low never attempt to jump on or off a moving tractor. High to start travelling, lower the engine speed and release the clutch pedal slowly. Abrupt releasing causes the tractor to jump off. Before leaving the tractor, stop the engine, remove the key, apply the parking brake and make sure that the eng...

Page 14

If rops is folded, level it down, fasten the seat belt before using the tractor and keep it fastened while in operation. Never operate the differential lock while driving at high speed or travelling on the road. For driving the 4-wd tractor on the road, be sure to place the 4-wd shift lever in off p...

Page 15

For towing, be sure to use the drawbar only. Set the hitch point below the center line of the rear axle. When using a chain, never try to move forward abruptly. When using a long chain or cable to hitch the tractor to the load, drive the tractor forward slowly until all slack is taken out. When towi...

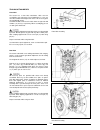

Page 16: Section 2. External

Section 2. External view and nomenclature of each part the above photos show taral-vst 818. 6.

Page 17

1 2 3 6 4 5 1. Battery 2. Radiator cap 3. Air cleaner 4. Engine oil filler cap 5. Fuel tank cap 6. Alternator 2 4 3 1. Nozzle 2. Fuel injection pump 3. Air cleaner inlet 4. Radiator hose for opening the bonnet, remove backward the hook on the rear side of the bonnet. When closing the bonnet, be sure...

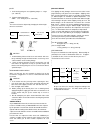

Page 18: Section 3. Instruments

Section 3. Instruments and controls 5 1 7 2 3 6 1. Fuel meter 2. Tachometer 3. Water temperature gauge 4. Combination switch indicators 5. Stop switch 6. Head lamp and horn switch 7. Ignition key 2 1 1. Throttle lever 2. Fuse box 8 4 5 2 7.

Page 19

Tachometer and warning lamps tachometer fuel meter water temperature indicator alternator charging indicator glow plug indicator battery low warning lamp oil low pressure warning lamp hour counter heat position………………… power applied to the glow plug off position ........................ Engine and al...

Page 20

Water temperature indicator when the temperature of the cooling water exceeds 110°c (230°f). When this occurs, lower the engine speed to about 900 rpm immediately and wait until the warning lamp goes off. Then stop the engine and check the amount of cooling water, the fan belt tension, the wiring, t...

Page 21

When disengaging clutch you are advised also to lower the engine speed. The life of the clutch depends on the operating habit of the user. The clutch works in combination with the pto. Foot speed control pedal caution lowering the speed, when the tractor is overloaded, by half engaging the clutch or...

Page 22

By operating the pto shift lever located on left hand side of the transmission case, the three pto speeds can be selected. When shifting the pto shift lever, lower the engine speed , depress the clutch pedal fully to interrupt the power from the engine and make sure the machine is brought to a compl...

Page 23

8-speed transmission the gear shift positions are as shown in the diagram below. By combination of the main and high-low shift levers, six for- ward speeds and two reverse speeds can be obtained. The first, second, and third forward speeds and first reverse speed can be obtained with high-low shift ...

Page 24

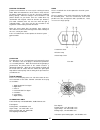

Front hitch assembly rear hitch assembly trailing attachments front hitch the tractor has a front hitch attachment. Hitch must be assembled as per side picture. To assemble hitch (“1”) first, user must disassemble front weights from chasis. All necessary parts are provided with tractor. Use m10 x30 ...

Page 25

Section 4 - operation before operating the tractor before operating the tractor, read this instruction manual care- fully and learn it correctly. The manual has been prepared for achieving tractor's maximum performance and safety for your work with this tractor employed. 1. Check the fuel level in f...

Page 26

16 rules to avoid toppling to the side • adjust tread to maximum permitted fort he work being performed • lock pedal brakes to eachother before driving on the road. • drive at a suitable speed depending ont he land and the work being performed. • turn slowly and with big radiuses. Avoid tractor from...

Page 27

Warning for travelling at high speed, interlocking the left and right brakes is particularly essential. Be sure not to travel at high speed with left and right brakes being independent to each other (not being interlocked). 7. Do not attempt to stop tractor using brakes, which may cause failure of t...

Page 28

Note 1. Axle housing and gear case tightening torque: 6 ~ 7 kgm ( 43 ~ 50 ft.Lb ) 2. Front tire tightening torque 4-wd 8.5 – 9.5 kg.M ( 61.4 ~ 68.6 ft-lb ) rear: the rear tread can be adjusted by changing the left and right wheels to each other. Standard thread max. Thread ballast weight the slippin...

Page 29

Operator's seat 3-point linkage it is cushioned seat with spring support for maximum operator comfort. Vibration levels of the seat measured for lightweight and heavy operators as per 78/764/eec are 1.24m/s 2 and 1.16m/s 2 , respectively. In order to reduce the vibration levels: 1. Try to keep the v...

Page 30

Position control stopper a stopper b position control lever position control is provided for determining and holding the position of an implement as desired by means of a lever. To use the position control, operate the control lever in the following manner: pulling the lever backward will cause an i...

Page 31

External hydraulic service the hydraulic pressure can be used to control the implement installed to the tractor. Relief valve cover note when taking out the hydraulic pressure, be watchful of oil level in the transmission case and sticking of the pump to be caused by oil shortage. Power take off for...

Page 32

Section 5 regular maintenance guide to keep your tractor operating in the top condition and to assure its proper performance and reliability for a long period of time, periodic inspection is indispensable. If your tractor is not periodically serviced, the result will be such that its perfor- mance a...

Page 33

* after completing the first 450 hours of operation, repeat the service schedule given in the above chart. * usually the service is carried out in every 100 hours. For new tractor, however, 1st service should be carried out the time of 50 hours of run. Daily inspection 1. Check for leakage of oil, w...

Page 34

Note in cold weather, check the specific gravity of the antifreeze water mixture, if necessary replenish to the required level. 4. Tightening nuts and bolts tighten all nuts and bolts because vibration is always noticed when the tractor is operated. At the same time, check the ballast weight bolts f...

Page 35

25.

Page 36

Greasing diagram greasing nipple greasing nipple greasing nipple 26.

Page 37

These photos showing the greasing points note: photos are from the bottom of tractor greasing nipple drag link grease nipple 27.

Page 38

Section 6. Preventive service instruction this section provides servicing instruction required for regular maintenance and adjustment and its procedures. Note when carrying out the maintenance services or adjust- ments, place the tractor on as open and level ground as possible. Before removing caps,...

Page 39

5. Treat antifreeze carefully so that it may not remove paint from the cylinder block. 6. Any antifreeze solution (antifreeze and water), even if it is permanent antifreeze, should not be used for more than 2 years. 7. Confirm that there are no leak from the hose connections or cylinder head gasket....

Page 40

Fuel filter element replacement fuel filter element is inserted in the filter body in the cup. To replace the element, close the filter body cock, loosen the ring nut and remove the cup. After removing the element, clean it or replace it, as necessary. After installing the cleaned or new filter to t...

Page 41

Filler cap approx. 4* fill with new oil from filler port. Make sure that the filler cap is tightened securely before starting the engine. Engine oil filter replacement when necessary, the cartridge type engine oil filter should be removed with the special tool, and replaced with a new filter. Note 1...

Page 42

Valve clearance adjustment adjust the valve clearances when the sound of the tappets is loud or when the engine does not run smoothly. Adjust the valve clearances by loosening the lock nut (b), the adjusting screw (a) using a screwdriver and then applying a thickness gauge (c). When locking the adju...

Page 43

Note 1. When operating in extremely dusty conditions, service the filter more frequently than specified. 2. Clean the element with compressed air below 7 kg/cm 2 (100 psi). Fan belt tension adjustment hose outlet proper fan belt tension is for 10 ~ 12 mm ( 0.4 ~ 0.5 in.) deflec- tion with a thumb pr...

Page 44

Booster connection in case the battery has run down making it impossible to start the engine, the booster is used for starting the engine using good battery of the other vehicle (12v specification vehicle) as power source. Following procedure should be observed in such case: proper procedure for boo...

Page 45

Proper battery maintenance and tips for safety 35.

Page 46

Warning during battery inspection, watch for fire and be careful not to touch the electrolyte with clothing or part of your body. See "tips for safety" in safety precautions. Battery recharging 1. For charging the battery on this tractor, a slow charging operation should be carried out at 4.5 amp. 2...

Page 47

Cleaning the hydraulic oil filter final case (right) note 1. If the transmission oil drained has to be reused, wipe clean the surrounding surfaces of the drain plug before draining, so that dust or dirt will not get into oil. 2. Oil replacement should be carried out in every 200 hours under normal o...

Page 48

Filter 2. Blow with clean water to wash away remaining dust or straw. Caution be careful not to damage the radiator since damaged or deformed radiator will reduce the cooling efficiency. Drain 1. Remove drain plugs (3 locations) and let the oil flow out. 2. Wrap the drain plugs with sealing tape and...

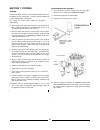

Page 49

Clutch pedal adjustment differential lock pedal adjustment brake pedal free play of the brake pedal must be maintained within the cor- rect range, otherwise, accident may occur or power will be lost. Before the brake on one side becomes unadjustable even by means of the rod, caused by earlier wear o...

Page 50

Hydraulic control adjustment the hydraulic control link has been carefully adjusted in the factory, so that adjustment is hardly ever necessary. However, if it is not working correctly, adjust it in the following manner: when carrying out this adjustment, stop and start the engine as required. Posit...

Page 51

Starting the engine facilities and instruments are necessary for servicing the starter motor. When the rotational force of the motor is weak, measure the battery voltage because it may be caused by insufficient battery capacity. When the voltage is correct and there is still inferior rotation, let y...

Page 52

Section 7- storing storing a tractor should be stored in a dry and protected place when it is left without use for some period. Leaving a tractor outdoors will result in shortened life of the tractor. For storing the tractor please follow the procedures shown below: 1. After washing and cleaning the...

Page 53

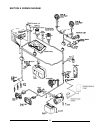

Section 8. Wiring diagram 43.

Page 54

Section 9. Specifications and data engine model ...................................................... Type ........................................................ In line diesel engine ................................ Number of cylinder .................................. Piston displacement .........

Page 55

Chassis dimensions model ...................................................... Overall length .......................................... Overall width .......................................... Overall height .......................................... Wheelbase ........................................

Page 56

Hydraulic system (mitsubishi live hydraulic system) control .................................................... Position (lift and lower), down speed control and lock cylinder type .......................................... Single acting cylinder pressure of relief valve .......................... ...

Page 57

Travelling speed tire size 7.50-18 at engine speed 2700 rpm 1.2 0.3 0.8 1.8 0.5 1.1 3.1 0.9 2.0 5.3 1.5 3.3 8.1 2.2 5.0 13.8 3.8 8.6 1.2 0.3 0.8 5.3 1.5 3.3 capacities engine oil ................................................ 3.0 lit (3/4 gal. 1/3 pt.) fuel tank ......................................

Page 60

Taral reserves the right to change tractor design and specifications shown in this instruction manual at any time without prior notice. Dealer taral tarım makina ve aletleri sanayi a. Ş . Maltepe mah. Hastane yolu sok. No:1 p.K. 34010 zeytinburnu/ İ stanbul tel: +90 212 5679550 (pbx) fax: +90 212 67...