- DL manuals

- Target

- Saw

- MC18

- Operating Instructions And Parts List Manual

Target MC18 Operating Instructions And Parts List Manual

1

OPERATING INSTRUCTIONS AND PARTS LIST

INSTRUCCIONES DE OPERACIÓN Y LISTA DE PIEZAS

0A7859

Copyright © July 11, 2002 DBInc.

Printed in U.S.A.

MC18

Concrete Saw

Model:

Serial Number:

Engine Serial No.:

Purchase Date:

MODELS: MC1809R (9 HP ROBIN)

MC1809H (9 HP HONDA)

MC1813R (13.5 HP ROBIN)

MC1813H (13 HP HONDA)

MC1805G (5 HP GAST)

MC1805B (5 HP BALDOR)

17400 West 119th Street

Olathe, Kansas 66061

Customer Service ..... 800-288-5040

Corp. Office ............... 913-928-1000

Cust. Service FAX .... 800-825-0028

Corp. Office FAX ....... 913-438-7951

Int’l. FAX .................... 913-438-7938

Internet www.targetblue.com

Summary of MC18

Page 1

1 operating instructions and parts list instrucciones de operaciÓn y lista de piezas 0a7859 copyright © july 11, 2002 dbinc. Printed in u.S.A. Mc18 concrete saw model: serial number: engine serial no.: purchase date: models: mc1809r (9 hp robin) mc1809h (9 hp honda) mc1813r (13.5 hp robin) mc1813h (...

Page 2

2 every machine is thoroughly tested before leaving the factory. Each machine is supplied with a copy of this manual. Operators of this equipment must read and be familiar with the safety warnings. Failure to obey warnings may result in injury or death. Follow instructions strictly to ensure long se...

Page 3

3 note: nota:.

Page 4: Symbol Definitions

4 symbol definitions definición de simbolos • please read the instructions for use prior to operating the machine for the first time. • antes de la puesta en marcha, lea detenidamente las instrucciones y familiaricese con la máquina. • mandatory • obligatorio • indication • indicación • prohibition ...

Page 5

5 • do not use in flammable areas • no usar in Áreas inflamables • machinery hazard, keep hands and feet clear • máquina peligrosa - mantenga manos y pies alejados de la máquina • danger, poison exhaust gas • peligro, gas de escape venenoso • no non-working personnel in area • prohibido para persona...

Page 6: Warning

6 • repairs are to be done by an authorized dealer only • las reparaciones deben ser efectuadas Únicamente por un distribuidor autorizado • diamond blade • sierra diamantada • blade diameter • diámetro de la hoja • pulley diameter • diámetro de la correa • number of revolutions per minute, rotationa...

Page 7

7 decal descriptions and locations decripciÓn de calcamonias y ubicaciones p/n 189732 location: front of frame (all models) quantity: 1 p/n 189731 location: blade guard (all models) quantity: 1 p/n 174993 location: belt guard (all models) quantity: 1 p/n 187691 location: frame (all models) quantity:...

Page 8

8 note: nota:.

Page 9

9 power source pneumatic electric mc 18 model mc 18 9r mc 18 9h mc 18 13.5r mc 18 13h mc 18 5a mc 18 5e horsepower 9 hp 9 hp 13.5 hp 13 hp 5 hp 5 hp (230 v) standard model c00094 c00084 c00098 c00086 c00088 c00090 screw feed model c00095 c00085 c00099 c00087 c00089 c00091 max. Blade cap. In. (mm) 18...

Page 10: Warning:

10 do warning: failure to comply with these warnings and operating instructions could result in death or serious bodily injury. Safety first! Warnings do’s and do not’s do read this entire operator’s manual before operating this machine. Understand all warnings, instructions, and controls. Do keep a...

Page 11: Safety First!

11 safety first! Warnings do’s and do not’s warning: failure to comply with these warnings and operating instructions could result in death or serious bodily injury. Do not do not operate this machine unless you have read and understood this operator’s manual. Do not operate this machine without the...

Page 12

12 figure 2 2a. Blade shaft nut: use to tighten the outer flange against the diamond blade. 2b. Outer flange: use to hold the diamond blade in position. 2c. Not used 2d. Locking pin: use to prevent the diamond blade from rotating on the shaft during operation. 2e. Diamond blade: use as the cutting t...

Page 13

13 pre operation checklist before leaving our factory, every machine is thoroughly tested. Follow our instructions strictly and your machine will give you long service in normal operating conditions. Before starting up the machine, make sure you read this entire operations manual and are familiar wi...

Page 14

14 • the handle must be attached. Place handle in position and securely tighten knobs. • check the engine oil level. Service before using. Refer to the engine operation manual for detailed information. These signs will give advice for your safety before leaving our factory every machine is thoroughl...

Page 15

15 always pay extreme care and attention to the preparation of the machine before starting. Remove all wrenches and tools from the floor and the machine. Always keep blade guard and transmission guard in place. (see fig. 1 and 2) always set the engine switch (1d) to the "off" position before mountin...

Page 16: Warnings!!!

16 • screw feed version: raise the blade out of the cut by pulling up on the depth control lock and slowly turning the hand wheel clockwise. Raise the blade (2e) high enough out of the cut to clear the pavement when maneuvering the saw. • e-z tilt version: raise the blade out of the cut by loosening...

Page 17

17 special outer flange assy 1/2" (12.7mm) wide cut (p/n 167963) • a special outer flange assembly is available as a field installed accessory. It enables the mc 18 to cut 7/16" - 1/2" (11-12.7mm) wide. Warning: this special outer flange assembly is for use with blade width stacks of 7/16" - 1/2" (1...

Page 18

18 it is critical that the governor and throttle on all internal combustion engines be adjusted properly. The engine speed is preset at the factory for the proper sawing speed. It is not normally necessary to change this setting. It should be periodically verified after the saw is placed into servic...

Page 19

19 note: nota:.

Page 20

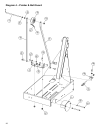

20 diagram 1 – frame & axle.

Page 21

21 diagram 1 – frame & axle (rev july 11, 2002) bill of material index p/n description qty 1 174939 frame weldment, mc18 1 2 174942 axle, front 1 3 174975 axle, pivot 1 4 020768 washer, flat .75 sae 4 5 040091 wheel assy, 5 inch dia 2 6 041160 lock collar, .750 id (w/ss) 2 7 020551 screw, set soc cu...

Page 22

22 diagram 2 – depth control (screw feed).

Page 23

23 diagram 2 – depth control (screw feed) bill of material index p/n description qty 1 174997 adj nut wldmnt w/ grease fit 1 2 049924 fitting, grease 1/8 npt x 90° 1 3 177915 screw, adj., .625-8 acme 1 4 040141 bearing, flange, .50 inch id 1 5 174944 bracket, screw feed 1 6 020764 washer, flat .375 ...

Page 24

24 diagram 3 – depth control (lock bar).

Page 25

25 diagram 3 – depth control (lock bar) bill of material index p/n description qty 1 139560 bar, lock 1 2 049513 washer, friction .531 id 2 3 139562 washer 2 4 139556 stud, depth control 1 5 174679 lever, adjustment 1 6 160164 pin, clevis .50 dia x 1.13 lg 1 7 020540 screw, set soc cup pt .250-20unc...

Page 26

26 diagram 4 – pointer & belt guard.

Page 27

27 diagram 4 – pointer & belt guard bill of material index p/n description qty 1 174328 guard, shaft - weldment 1 2 020785 lockwasher, split .313 2 3 020399 capscrew, hex hd .312-18unc x 3.25 2 4 174977 bracket, pointer mount 1 5 167908 bar, pointer - offset 1 6 167906 bar, pointer - straight 1 7 04...

Page 28

28 diagram 5 – guards & water distribution.

Page 29

29 diagram 5 – guards & water distribution bill of material index p/n description qty 1 174953 guard, belt 1 2 020785 lockwasher, split .313 4 3 020313 capscrew, hex hd .312-18unc x .75 4 4 174992 water valve assy, mc18 1 5 139021 water valve 1 6 169196 elbow, 1/2npt male x 90° brass 1 7 040270 hose...

Page 30

30 diagram 6 – blade guard.

Page 31

31 diagram 6 – blade guard (rev july 11, 2002) bill of material index p/n description qty 1 ------ rear guard weldment - 18 inch 1 2 139075 hinge (note a) 1 2a 195127 hinge (note a) 1 3 139596 front guard weldment, 18 inch (note a) 1 3a 195120 front guard weldment, 18 inch (note a) 1 4 020762 washer...

Page 32

32 diagram 7 – engine & bladeshaft.

Page 33

33 diagram 7 – engine & bladeshaft bill of material index p/n description qty 1 174973 group, bladeshaft r&l 4.5 (9h,13h,13r) 1 - 196003 group, bladeshaft r&l 4.5 (9r only) 1 2 177569 bladeshaft assy, complete (9h,13h,13r) 1 - 196004 bladeshaft assy, complete (9r only) 1 3 167185 collar, inner 4.50 ...

Page 34

34 diagram 8 – electric motor.

Page 35

35 diagram 8 – electric motor bill of material index p/n description qty 1 060143 pulley, 2g3v 2.65 x .875 bore 1 2 020550 screw, set soc cup pt .312-18unc x .375 2 3 139612 v-belt, 3vx280 (set of 2) 1 4 058020 v-belt, 3vx280 2 5 139306 motor, 5hp 230/60 alt wiring 1 - 000923 motor, 5hp 3450 208-230...

Page 36

36 diagram 9 – air motor.

Page 37

37 diagram 9 – air motor bill of material index p/n description qty 1 139644 air motor mount 1 2 139624 air motor 1 3 020785 lockwasher, split .313 4 4 020313 capscrew, hex hd .312-18unc x .75 4 5 020293 nipple, close 1/2 npt 4 6 020730 tee, female, 1/2 npt, galvanized 1 7 020810 elbow, street, 90° ...

Page 38

38 diagram 10 – kit, water tank (174957) bill of material index p/n description qty 1 196035 bracket, water tank 1 2 174648 water tank (w/cap), 7 gallon 1 3 020764 washer, flat .375 sae 4 4 020509 capscrew, hex hd .375-16unc x 2.00 2 5 020199 locknut, fiber .375-16unc 4 6 020322 capscrew, hex hd .37...

Page 39

39 note: nota:.

Page 40

22 warning the engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects or other reproductive harm. ! ! Target corporate office customer service...………………….... 800-288-5040 corp. Office...………………………..... 913-928-1000 cust. Service fax ……………………...