Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 bonus plus model 30 installation and operations manual wood-fired central heating boiler report #236-s-09-2 ul 2523-2009 (r2013) “solid fuel-fired hydronic heating appliances, water heaters, and boilers.”.

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 3 table of contents section ..................................................................................................................................... Page 1.0 introduction ................................................

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 4 table of contents section ..................................................................................................................................... Page 3.4.11 electrical connections ...................................

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 5 1.0 introduction 1.1 foreword save this instruction manual for future reference congratulations on your purchase of the hs tarm bonus plus log wood boiler from tarm biomass! The bonus plus boiler is produced using the highest q...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 6 this product is provided with a limited warranty which is described in section 7.0 of this manual. The warranty is contingent upon the successful and legal installation of the boiler. At a minimum, the in- stallation, adjustmen...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 7 2.0 product description and requirements for safe operation 2.1 boiler overview 2.1.1 boiler cut-away product description and requirements for safe operation > boiler overview 8 1 2 4 5 6 7 1. Control panel 2. Loading door 3. F...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 8 2.2 boiler function 2.2.1 general operation a generalized discussion of the operation of the bonus plus follows. Please refer to the cut-away views of the boiler in fig 2.0 and 2.1. The bonus plus boiler is an induced draft woo...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 9 the induced draft fan (16) pulls combustion air into the boiler via the primary and secondary air con- trols and pulls gases from combustion through the heat exchanger and exhausts them out of the boiler. The flue gas turbulato...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 10 2.2.3 safety systems the bonus plus comes with safety systems to prevent the following: pressure in the boiler exceeding 30 psi (2 bars) (over pressure) boiler water temperature exceeding 212 ºf (100 ºc) to prevent an over-pre...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 11 2.1.5 boiler fabrication and testing your boiler was manufactured by hs tarm , a world leader in hot water (hydronic) heating for over 80 years. The hs tarm bonus plus series boiler conforms to traditional high standards for q...

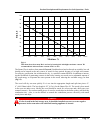

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 12 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% 90 80 70 60 50 40 30 20 10 100 moisture % btu/lb product description and requirements for safe operation > fuels fig 2.2 this chart shows how many btu’s are lost by burning fuel with...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 13 2.4 building requirements the boiler must be connected to a tile-lined masonry chimney or to a factory-built type ul 103 ht approved chimney in good condition. See the details in section 3.2 a dedicated supply of fresh combust...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 14 3.0 boiler installation & start-up this section is directed at the installer. 3.1 planning 3.1.1 sizing the boiler it is critical to size the boiler properly. A proper, up to date heat load calculation is advised. An accu- rat...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 15 the boiler must be installed with the minimum installation clearances to combustible materials out- lined below. Clearances may only be reduced by means approved by the regulatory authorities. Recommended distances in the boil...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 16 3.1.4 plumbing and mechanical the boiler must be connected to a suitable chimney. Chimney requirements are discussed in section 3.2. A dedicated supply of fresh combustion air should be provided near the boiler for efficient a...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 17 3.1.5 electrical for the bonus plus boiler a 120 vac, 60 hertz, 3-wire power supply is required. This electrical connection should be from a dedicated 15 amp circuit breaker. A master service switch for the boiler, mounted on ...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 18 fig 3.1 the smoke pipe connecting the boiler to the chimney flue must be black or stainless, have a minimum thickness of 24 gauge, and rise a minimum of ¼” per foot of run toward the chimney (fig3.1). Smoke pipe sections must ...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 19 3.2.1 outside combustion air provision for outside combustion air may be necessary to ensure that fuel-burning appliances do not discharge products of combustion into the house. Guidelines to determine the need for additional ...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 20 3.3.2 temporary storage if the boiler installation is going to take place at a later date the boiler and components need to be stored in a safe, dust-free, dry location. Moisture can damage the insulation, electrical component...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 21 boiler installation & start-up > connections to the boiler the chimney connector sections must be attached to the boiler and to each other with the crimped (male) end pointing away from the boiler. All joints, including the co...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 22 3.4.3 system plumbing there are numerous possibilities for connecting your bonus plus and thermal storage system to your home heating system. Tarm biomass provides diagrams as concept diagrams only. Final design, in- stallatio...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 23 3.4.9 installing the overheat aquastat the honeywell l4008b aquastat provided with this boiler must be installed and wired in parallel with the thermostat on the zone with the most heating capacity in the main living area (dum...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 24 3.4.10 installing the 339n probe thermometer the 339n probe thermometer (part # 339n) is to be installed just downstream of the boiler’s flue collar. Drill a ¼” hole in the side of the pipe and insert the probe all the way in ...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 25 boiler installation & start-up > commissioning the boiler a thermostatic mixing valve or loading unit, and boiler circulator (included with the loading unit ) should be incorporated into the heating system piping as shown in f...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 26 4.0 boiler operation, maintenance, and service 4.1 control panel orientation letters in brackets () in this section refer to the button with the corresponding letter on the control panel. All temperature values are in degrees ...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 27 the lo-limit thermostat sensor location. The sensor should be inserted into the sensor well at a depth equal to the width of the cleanout opening. The lo-limit thermostat (i) should only be adjusted by a qualified user only. ...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 28 when might an adjustment of these aquastats become necessary? It may be desirable to lower the boiler aquastat setting to 80 °c (176 °f) if you experience tripping of the thermal fuse or if the pressure relief valve has let go...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 29 4.2 items to check before using 1. Check the heating system water pressure before using the system. 2. Ensure that the chimney connector pipe is connected to the chimney, properly sealed and screwed together, and that the chim...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 30 note if wood is stored in the boiler room, ensure that it is not stored within the clearances to combustibles or in a way that will impede daily firing or maintenance. 4.4 adding wood to an already established fire it is very ...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 31 from the thermal storage system. An added benefit is that domestic hot water can also be created in the reservoir. Keep in mind that the amount of wood placed in the boiler’s filling chamber depends on the size and the tempera...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 32 boiler operation, maintenance, and service > cleaning and maintenance warning before performing any cleaning or maintenance on the boiler, allow boiler to completely burn through all fuel and to normally cool down and shut off...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 33 boiler operation, maintenance, and service > cleaning and maintenance ash removal from the tunnel stone ash removal from the secondary combustion tun- nel must be done regularly (daily in winter). The tunnel must not be obstru...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 34 boiler operation, maintenance, and service > cleaning and maintenance warning solid-fuel burning appliances need to be cleaned frequently because soot, creosote and ash may accumulate. If there is a soot or creosote fire, plea...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 35 boiler operation, maintenance, and service > cleaning and maintenance note please inspect the draft fan carefully – even a thin coating of ash significantly reduces the air flow and must be removed. Note if the fan motor is bl...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 36 loosen nuts 8mm x 4 clean the fan blades, fan housing. Clean the flue gas sensor well (pipe) located in the fan housing. 3 4 fig. 4.14 fig. 4.15 boiler operation, maintenance, and service > cleaning and maintenance.

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 37 4.10.3 maintaining door seals check the loading door and ash door gaskets regularly to insure that they are sealing well and that there is no unwanted air leakage into the boiler. Poor seals can result in air leakage into the ...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 38 how to clean the primary air channels : 1. Remove primary air cover plates (a) (fig. 4.12). (the right plate has already been removed). 2. Brush and vacuum channel if needed. Fig. 4.12 a how to clean the secondary air channels...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 39 note chimney inspection and maintenance is a critical part of any wood-burning maintenance sched- ule. Make sure that the chimney connection is secure and airtight. The chimney connector and chimney should be inspected at leas...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 40 4.10.7 checking the barometric damper annually check the barometric damper flap for ease of operation. The barometric damper flap should operate freely and maintain a chimney draft between -0.04 to -0.06 inches water column. 4...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 41 5.0 troubleshooting 5.1 troubleshooting guide troubleshooting > troubleshooting guide bonus plus troubleshooting guide problem root cause solution no heat in the system thermostat (h) set too low set thermostat higher fan cut ...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 42 problem root cause solution boiler stops before the fuel load is consumed and the storage tank is not yet fully charged. Flue gas thermostat the flue gas thermostat is not in place, incorrect temperature (default 90º c) or it ...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 43 6.0 data and drawings 6.1 measurement data data and drawings > measurement data description units 30 1. Return connection inches 1 2. Supply connection inches 1 3. Overheat/pressure relief connection inches 1 4. Side connectio...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 44 6.2 positioning data data and drawings > positioning data clearances to combustibles measurement units bonus plus 30 a-minimum clearance for blower maintenance inches 21 b-minimum clearance to combustibles inches 12 c-minimum ...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 45 6.3 specification data *6” with flue collar adaptor. Specifications subject to change. Data and drawings > specification data technical data units 30 measurements depth- boiler -total inches 43 width- boiler -total inches 23 h...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 46 6.4 electrical diagrams 6.4.1 wiring diagram a (boiler circuit ladder diagram) data and drawings > electrical diagrams.

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 47 6.4.2 circulator and overheat aquastat wiring connections data and drawings > electrical diagrams l6006a aquastat junction box incoming power circulator power suggested wiring layout mount over round knockouts overheat aquasta...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 48 7.0 warranty information 7.1 hs-tarm bonus plus wood boiler warranty limited warranty - for use only in united states tarm biomass warrants the steel boiler identified below and its component hot water tank or coil and cast ir...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 49 tarm biomass’ limited express warranty is only extended to and covers the tarm usa product’s end user who owns the building in which the tarm usa product is installed, and covers only repairs or replacements resulting from def...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 50 8.0 installation report for boiler system installation performed by:_________________________________________ bonus plus model / serial no. ____________________/_________________ boiler system installed and adjusted: _________...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 51 appendix a- temperature conversion temperature conversion table appendix a > temperature conversion table °c °f °c °f °c °f °c °f 40 104 80 176 135 275 220 428 45 113 82 179.6 140 284 225 437 50 122 84 183.2 145 293 230 446 52...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 52 appendix b - contact information manufacturer importer local dealer appendix b > contact information hs tarm a/s smedevej 2 tarm denmark phone +45 9737 1511 e-mail info@hstarm.Dk www.Hstarm.Dk tarm biomass 4 britton lane lyme,...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 53 appendix c - quick start guide appendix c > quick start guide how much fuel? See next page. Adjust air supply. See next page. Cover the bottom with kindling. Add crumpled newspaper. Add some more kindling. Leave upper door cra...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 54 appendix c > quick start guide the wood log: 18” long logs, which are 4”-6” in diameter. The logs shall have a moisture content keep always the next load in the boiler room – this will help dry the fuel for the next firing. Co...

Bonus plus instructions tarm biomass 1-800-782-9927 version 11/14 page 55.