- DL manuals

- TASKalfa

- Copier

- 3500i

- Troubleshooting Manual

TASKalfa 3500i Troubleshooting Manual

Summary of 3500i

Page 1

2012.3. 8 revised 3.16revised 3.19revised 3.21revised 4. 6 revised 8.30 revised 2013.11.18 3rd edition 3500i/4500i/5500i/6500i/8000i troubleshooting guide 1.

Page 2

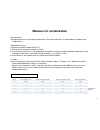

Content 2 item phenomeno 3500i/4500i/5500i 6500i/8000i pages image toner color dot / color mark ○ ○ 4-5 void line / white band ○ ○ 6-9 void line / black band ( vertical black stripes ) ○ ○ 10 image smudges ○ ○ 11-23 light image ○ ○ 24 edge part background ○ ○ 25 measure for condensation ○ ○ 26 dp-77...

Page 3

Content 3 item phenomeno 3500i/4500i/5500i 6500i/8000i pages c-call c0640 ○ ○ 78 c2101 ○ ○ 79 c2201 ○ ○ 80 c510x ○ ○ 81 c6000/c6030/c6050/c6200/c6230/c6250 ○ 82 c6020/c6220 ○ 83 c6020/c6030/fixing roller fusing, poor fixing ○ 84 c6030/c6050 ○ 85 c6600/c6720/fixing belt damage ○ 86-90 c6620 ○ 91 c673...

Page 4

4 black dot / black marks image sample 1 1. 126mm interval black dots (drum) if one of several 126mm interval black dots appears randomly at sub scanning direction, take the following measure. (image sample 1) (*there is the case that the black dots appearance becomes vertical line.) a.Replace the d...

Page 5

Black dot / black mark 2. 45mm interval black dots if 45mm interval paper appears at image in the sub scanning direction, take the following measure. A. Check whether the foreign substance are attached on the developing roller surface. B. If the foreign substance attached, wipe off by the clean clot...

Page 6

A. If the void image appear at solid part of prints out on u089 color belt, refer to below “b” * if the vertical streak image appears at the halftone, replace the developing unit. B. Execute u140 ac calib high altitude c. Select “altitude” and find the setting which the leak image does not appear. *...

Page 7

A. If the void image appear at solid part of prints out on u089 color belt, refer to below “b” * if the vertical streak image appears at the halftone, replace the developing unit. B. Check the value of u140 sleeve ac (1) c. U140 execute ac calib ( 2 ) set “ k” off to on ( 3 ) execute ( 4 ) start d. ...

Page 8

Void line / white band 2. Horizontal white streaks (image sample 1) if 1.2mm interval horizontal streaks occur at the gray image in the main scanning direction, take the following measure. *in case of this appearance at the machine’s rear side is more noticeable than at front. A. Replace the lsu. Im...

Page 9

Void line / white band 3.Vertical white streaks (image sample 1) if vertical white streaks appears continuously and linearly in the sub scanning direction, take the following measure. A. Clean the cover glass on the lsu. Image sample 1 vertical white streaks image sample 2 4. Vertical white lines (v...

Page 10

1. Vertical black streaks (image sample 1) it occurs continuously and linearly toward the paper feeding direction. Please remove the transfer belt unit and check whether the transfer belt is cracked. 1. When the transfer belt is torn or cracked, please replace the drum unit and the transfer belt uni...

Page 11

Image smudges (1/13) image sample 2 view from bottom part of ejected paper 2.Image smudges (image sample 2) the smudges appears at the leading edge of ejected paper. Clean the duct at inside if machine and the developing unit. Refer to “3.Cleaning procedure” for cleaning. 1.Image smudges (image samp...

Page 12

(stains on the conveying guide) the stains occur at the outside of paper path. 3. Cleaning procedure image smudges (2/13) a. Preparation before cleaning remove the lower rear cover and toner box ( fig.1) remove the developing unit and drum unit after detaching the inner unit . Remove the toner box. ...

Page 13

Image smudges (3/13) c. Clean the toner exhaust duct at inside of machine while the developing unit is taken out and the conveying guide is removed, suction the toner exhaust part at inside the machine where the toner exhaust duct of the developing unit connected with a cleaner. (fig.4) note) clean ...

Page 14

Image smudges (4/13) e. Clean the duct toner unit ( in case of 2012 feb. Production machine) clean the duct toner unit with the vacuum cleaner. Procedure 1) clean and suction the outlet of duct with cleaner for 1 min. A cleaner tip is put in and attracted from this direction. (if a opening is covere...

Page 15

Image smudges (5/13) procedure 2) remove the 302lf33012/duct fan toner from the machine and clean, suction it with the vacuum cleaner. Reattaching the seal after cleaning and cut the part of duct. 302lf33012/duct fan toner remove the duct with 2 screws lift up this part if it is detached. Clean the ...

Page 16

Re-attach with 302lf33201/seal toner duct a (change with 5mm thick sponge) cut the rib (claw) of the duct. Procedure 3) peel off the film of 302lf33012/duct fan toner and replace with 302lf94410/parts lid toner fan assy(zg) sp 302lf94410/parts lid toner fan assy(zg) sp film 302lf94410 is re-usable. ...

Page 17

F. Clean the duct toner unit (in case of 2012 mar and after production machine) clean suction the duct toner unit with the vacuum cleaner. Procedure 1) clean suction the duct outlet for 1 min with the vacuum cleaner. A cleaner tip is put in and attracted from this direction. (if a opening is covered...

Page 18

Procedure 2) remove the 302lf33830/lid toner fan from the machine and clean suction it with the vacuum cleaner. ( before cleaning ) toner is accumulating. Lid toner fan remove it after releasing 3 pcs of snap-fit return the lid toner fan at original position after cleaning image smudges (8/13) 18.

Page 19

(-->) g. Replace the disposal toner unit. - replace the following disposal toner unit. 302lf94400 parts disposal unit(zg) sp - clean suction the accumulating toner at the disposal toner unit inside or the filter. Refer to the right figure for the cleaning procedure. ( filter ) 302lc33240/filter opti...

Page 20

Filter 2 filter 2 6500i/8000i 3500i/4500i/5500i at cleaning the filter, the filter can be detached after removing the df rear cover without releasing df from the main body. After removing, clean or replace it. H. Clean the filter ( filter ) 302lc33370/filter left side image smudges (10/13) 20

Page 21

I. Clean the developing unit clean the toner stain on the removed developing unit. (-->) absorb the inside toner while fitting the nozzle of the vacuum cleaner to the toner waste aperture of the duct. Clean the accumulating toner on the toner receiver of the developing unit. At rear side of the deve...

Page 22

Image sample4 image sample3 4.Image smudges (image sample 4) toner smudges at the 1st cassette (image sample3) toner smudges by the feed pulley when feeding the paper from the 1st cassette (image sample4) a. Clean the duct at inside if machine and the developing unit. *refer to “3.Cleaning procedure...

Page 23

128mm 118mm toner stain ・ bottom edge toner stain 5. Toner stain occurs at the position shown in the right fig, please take the following measure. (image sample a) 2. When toner stain occurs at about 20mm position from paper bottom edge, please take the following measure. (image sample b) a. Replace...

Page 24

Light image if the copy image becomes out of focus, take the following measure in order. (sample1) 1. Replace the isu_lens unit (parts image scanner l sp : 302k993082) 2. Execute the scanner auto adjustment. 2-1. Place the designated adjustment original (part no.: 7505000005) on the contact glass. 2...

Page 25

Edge part background 1. if paper edge background occurs, you will be required of the following as below. ■ case of failure during the continuous output, event does not occur until a few sheet of papers, but it may occur in the middle. The uneven density appears periodically at background image with ...

Page 26: Measure For Condensation

Measure for condensation flowing image occurs at printing after power on if the inside machine is in cold condition. (condensation image occurs) 1.Update the firmware above pack.3.07 2.Change refresh frequency (mode) of u148 3.If the condensation occurs easily depends on installation environment (th...

Page 27: 37 Mm Bottom Edge

Dp-770 character blur at 50mm leading edge, 37 mm bottom edge text character is extended around 50mm from original leading edge and 37mm from bottom edge. Change the front and rear nip pressure at scanning the original during dp conveying and stabilizing the original conveying speed. 1.Change of the...

Page 28: 37 Mm Bottom Edge

Dp-770 character blur at 50mm leading edge, 37 mm bottom edge 1. Detach the original mat and remove 6 screws (1screw for front cover left lower, 1screw for left cover, 4screws for scan rear sprint mount plate) 2. All of 5pcs springs at rear original scan are cut two and a half coils. 1 2 3. Remove t...

Page 29: ( Misfeed)

J0501 to 7 / j0523 to 7 (misfeed jam) if above code display, take an action as referring to below procedure. A. If jam paper or printout paper is like a fig.1, replace the roller of the primary feed. * the maintenance cycle for primary feed is 150k.* b. Please adjust the pressure of the retard pulle...

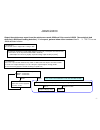

Page 30: ( Misfeed)

[procedures for adjusting the pressure of the retard pulley (flow chart)] refer to the service bulletin no. 2lf-0015(c191) for the detail information j0501 to 7 / j0523 to 7 ( misfeed) 30

Page 31

J051x continuous feeding jam if j051x occurs, take an action as referring to below procedure. A. Check the paper size (fig.1) check whether the size of paper is set at the cassette and stated on the jam log of the even log is same or not. If the paper size is different at “a” b. Check whether the po...

Page 32

Check the firmware version. ( engine ) ・ 8000i/6500i : 2lf_1000.002.005 ・ 5500i/4500i/3500i : 2lf_1000.002.005 j05x8/j44xx(jam during duplex printing) jam during duplex printing a. If the version is older than the righthand, upgrade the firmware to the latest version. B. After above “a” action, if j...

Page 33

J0545 (misfeeding jam pf-770) j0545 (no paper feeding jam pf-770) if j0545 occurs, take an action as referring to below procedure. A. If jam paper or printout paper is like a fig.1, replace the roller of the primary feed. (image sample 1) b. Replace with 303ng94011 parts feed unit sp if the producti...

Page 34

Pf-770 check & recovery for slating of tray paper 1. Remove the stopper deck. 2. Check the right and left slanting condition of the tray paper surface. Turn the shaft lift and adjust the top part of stay deck side becomes the same flat surface level with the tray paper at the feed unit side. In that...

Page 35

1. If j1313/j1314 occurs, take the measure as referring to the following. A. Check whether installing 302k994130 parts guide feed middle assy sp is proper. The unit is not set properly, reinstall it. B. Check whether 302k994430 parts roller feed low sp is rotating without power on the clutch. * refe...

Page 36

J150x/j1904 【 phenomenon 】 the paper conveying actuator is scraped for a long usage, j1904 and j150x occurs due to sensor detection failure depending on the paper. 【 how to respond 】 replace the actuator (actuator feed low 302n706500) when the problem occurred. 【 service bulletin 】 2lc-0123 ( d148 )...

Page 37

J1512 【 phenomenon 】 the cassette 4 paper may not stop before the feed sensor (middle sensor at vertical conveying) and the sensor may be turned on while the cassette 2 paper stays at the registration for duplex feed. 【 change 】 paper waiting position for the next feeding paper after feeding paper f...

Page 38

Pf-780 if j341x occurs, take the measure as referring to the following. If the actueator of smpcs1 is slow to return to the home position, it occurs. A. Replace the actuator spring with 303nl06510 spring actueator pi b. If pf-730 for the 6 th /7 th cassette is installed and after replacing the above...

Page 39: J4103/4104

J4103/4104 check whether a corner of a4 paper runs on the bump with a step of 11x8.5 size. When paper runs on, set paper correctly. Please adhesive the regulation sheet: parts sheet stopper a4 sp(303nf94170) as needed. *if paper seriously runs on, c1100/1110 may occur. 1. when j4103/4104 occur at th...

Page 40

Abnormal sound/j42xx/j40xx ( add intermediate motor cover ) 【 phenomenon 】 the abnormal noise may be heard or the jam (j42xx / j40xx) may occur if the gear of the middle roller drive motor is worn with toner spillage. Model : tasaalfa8000i / 6500i 【 how to respond 】 the cover (302n724020 : cover mot...

Page 41

J42xx/ the separation claw cracks or comes off j42xx occurred frequently, replace with the new claws or new parts when the separation claw cracks or comes off. Single item : 302ft20120 separator assy assembly : 302lh94370 parts separator assy sp if the claw is broken in half, please change to the ne...

Page 42

If j421x/j460x/j470x occurs. 1. In case of jam at the shift guide of the exit unit part, take the following measure. A. Increase the clearance between the housing and the shift guide, attach the following spacers (no.1: 3pcs in one set) on the driving plate. *302lc94660(parts film spacer exit set sp...

Page 43

■ removal procedure for the exit drive unit 3500i/4500i/5500i/6500i/8000i b. When the entire paper is not damaged at jam. Since there is a possibility of incorrect detection of the sensor, please replace the sensor in the inside of the eject unit, or the eject unit. * sensor : 7nxgp1a73lch01(sensor ...

Page 44

J421x(fuser exit sensor stay jam) 【 service bulletin 】 2k9-0021(c155) 【 permanent support 】 exit guide rib shape change + fixing cover ribs added sept 2013 - production: corresponding time item number item name 302k994c40 parts cut-washer 6 set sp * set bundling 2 pcs of the cut washer in the case o...

Page 45: From Bottom Edge

Paper tear, j430x/431x/440x/471x, horizontal line at 60mm from bottom edge ( phenomenon1 ) if the leading edge of the actuator switching the switchback sensor is hooked with the center hole of 3-hole pre-punched paper when the paper is turned over with the duplex printing, the paper may be torn or t...

Page 46

1. Check whether the positioning of bridge conveying-in unit is inserted into the positioning hole of the drive unit. If it is not inserted into the positioning hole. a .While being careful not to contact with the tray in following fig, insert the positioning boss of ak conveying-in unit into the po...

Page 47

3. Check the positioning cutout part (red circle at below fig.) at the left slider section of the bridge conveying unit is fitted to red round mark on the slider section. ■ affected machine’s serial number is below № old new parts no parts name q’ty 1 302lf28770 2lf28770 sheet hinge stopper 2 (right...

Page 48

■ the film attached procedure j49xx / j50xx / j51xx / j600x (3/9) 48.

Page 49

5. Check the material of roller at the bridge conveying-in unit (fig.1) if it is old type shown in right fig, replace the roller. Fig 1 № old new item number parts name q’ty 1 302lf94010 2lf94010 parts roller relay middle sp 3 2 302lf94030 2lf94030 parts roller relay exit sp 1 ■ affected machine’s s...

Page 50

7. Check whether the screw fixed boss, positioning boss of the rail installing section at the bridge relay exit unit is broken. If it is broken, replace the relay exit unit. No. Old new parts no parts name q’ty 1 303nb94174 3nb94174 parts relay exit sp 1 6. Check there is any breakage at the hook ha...

Page 51

8. Check the bushing of the bridge exit unit (fig.1) if it is old type shown in right fig, replace the bushing according to the replacement procedure (refer to the next page). Fig 1 № old new item number parts name q’ty 1 302k324450 2k324450 bush 6 6 ■ affected machine’s serial number is below 【 ser...

Page 52

■ replacement procedure for the bushing j49xx / j50xx / j51xx / j600x (7/9) 52.

Page 53

9. Check whether the check whether the paper conveying guide fulcrum for the bridge exit unit has separated or not. (fig.1). If it is separated, install the following parts ( fig 2) a. Install it to the front and rear stay while holding the upper cover of exit unit. B. Check whether the paper convey...

Page 54

10.Check whether the rib (blue color round mark on the right fig) of the conveying guide of the bridge exit unit is broken or not. In case of breakage, replace the below part no.1 to 3 as referring to the service bulletin “2lc-0068(c076) 11. After performing above items 1 to 10, jam still occurs, re...

Page 55

1. Add the films to the holes (2 locations )on the conveying unit. (fig.1) affix the film (no.1) to the designated location at fig after cleaning where to affix it on the conveying unit. (fig.2) no. Old new parts no parts name q’ty 1 302lf28820 2lf28820 sheet reray lower 2 sample1 fig 1 fig 2 【 serv...

Page 56

56 j6100 / j6110 (df) (2/6) ■ affected machine’s serial number is below № old new parts no parts name q’ty 1 302lf28770 2lf28770 sheet hinge stopper 2 2. Check whether the leverage of upper conveying guide on the bridge conveying unit is not detached. If it is detached, add the below parts as referr...

Page 57

■ the film attached procedure j6100 / j6110 (df) (3/6) 57.

Page 58

2. Replace the guide feed lower with the no.1 parts guide feed assy which the no.3 pet film is attached on. No. Old parts no. New parts no parts name q’ty 1 303nb94250 parts guide feed assy sp 1 2 303nb07020 303nb07021 +guide feed lower 1 3 303nb07190 +sheet feed in c 2 2 1 3. Check whether the pape...

Page 59

J6100 / j6110 (df) (5/6) 4 、 if the paper stop before the conveying-in roller and there is no damage on paper, check whether the paper is caught by the stay punch. A. Add the pet films on the middle part of cutout of the stay punch. Stay punch № old parts item new parts items parts name q’ty 1 303nb...

Page 60

J6100/j6110 (df) ( 6/6 ) 5. When select a4 paper size at the manual bypass tray, be careful below item. If the actual direction of a4(letter)size paper set on the manual bypass tray is not same as setting the direction by the operation panel, jam6110 may occur after feeding is started . Therefore, p...

Page 61

J631x / j641x / j650x (1/3) 1. Corner folding at paper leading edge or curling jam (image sample 1) – it occurs since lower curled paper is caught by the cursor. A. Replace the cursor. 2. Paper trail end folding jam (image sample 2) it occurs since the opening of the bundle discharge unit is (b) sla...

Page 62

4.Curling jam at paper leading edge (image sample 3) due to paper downward curl, the leading edge of paper is round at the inner part of the process tray and jam occurs. A. Please affix the films. Image sample3 inside of process tray ( paper tray leading side) (a)affix the films 303nc24050 sheet con...

Page 63

J631x/j641x/j650x (df) (3/3) 【 service bulletin 】 3nc-0002 (c179) 【 phenomenon 】 when ejecting 45 to 50 sheets of paper bundle of a4r or letter-r, it may bound and the 1st sheet of the next bundle may be caught up at the paper guide. Then, the j6311 jam may occur. 【 hot to respond 】 the tension of t...

Page 64

J6510 ( df-790 caution of manual staple) 【 notes 】 when inserting the paper, please make sure that the paper hold hand is away from the paper during staple operation. When you perform the manual staple operations when they hold the paper by hand, paper jam (j6510) will occur. Please do not perform t...

Page 65

J6600 (df-770/790) 1. Jam after paper stops at the paper conveying path (a) the leading edge of paper is caught by the feedshift guide 1 (b)paper is fed to the direction2 instead of the direction1. (a) check the assembling condition of the feedshift guide1. Check the shaft of feedshift guide 1 is fi...

Page 66

J6710/j7710 ( bf) bf lock lever DF fix pin 1. J6710/7710 occurs, take the following measure. A. The jam paper is stopped before reaching the bf. No. Old new parts no parts name q’ty 1 303nd02280 303nd02281 fulcrum plate release 2 2 303nd02360 pin hook booklet 2 old → new 2. Df hook pin old → new 1. ...

Page 67

J9020/j9030 the function can be stopped after setting is off. If the user request below demand, keep u460 set on and do not stop this detection function. A. Reduce the original damage in case of setting the stapled originals wrongly on dp. B. Prevent missing page due to multi feeding (except df-771)...

Page 68

Check the maintenance report or u903 (jam counter), check whether below counter are counted up. 8000i/6500i//dp-771 : j9010 j9011 j9110 j9300 j9310 j9400 j9600 dp-770 : j9010 j9110 j9600 j9610 check the dp firmware version at u019 8000i/6500i//dp-771:3m4_9500.007.002 dp-770 : 3nv_9500.005.001 ok no ...

Page 69

1.If it occurs at lower tray ejecting, perform below a, b. (at df-770 install: a tray eject/ at df-790 installed: a, b tray eject) a. Add the films to the holes (2 locations )on the conveying unit. (fig.1) affix the film (no.1) to the designated location at fig after cleaning where to affix it on th...

Page 70

■ affected machine’s serial number is below no. Old new parts no parts name q’ty 1 302lf28770 2lf28770 sheet hinge stopper 2 b. Check whether the leverage of upper conveying guide on the bridge conveying unit is not detached. If it is detached, add the below parts as referring the procedure mentioni...

Page 71

■ the film attached procedure corner folding (3/6) 71.

Page 72

2. If it occurs at ejecting paper to upper tray (at df-770 install: b tray eject/ at df-790 installed: c tray eject), replace with new guide (no.1) which is affixed the films or the relay exit unit (no,2). No. Old new parts no parts name q’ty 1 303nb94190 3nb94190 parts guide relay exit sheft sp 1 2...

Page 73

Corner folding (5/6) 73.

Page 74

Corner folding (6/6) 74.

Page 75

75 no perform above service bulletin measurement contents. If the paper creasing like a below image occurs frequently, check as referring to below procedure. Paper creasing (1/2) ref.No. 2lc-0013(b213) on the image sample of creased paper, spread out the creased part and check if toner is not transf...

Page 76

[the procedures to install the guide] 1. Remove the conveying unit. 2. Remove 2 of the screws that fix the middle feed plate. 3. Remove the middle feed plate after rotating it downward as in the figure right. 4. Overlay the film (a) bundled in the parts set (no.1) on the film ( x ) affixed on the pa...

Page 77

Bf-730/720/710 measure for paper creasing when a sheet of paper is fed after middle folding 【 phenomenon 】 when center-folding or tri-folding one sheet of paper with the downward bending (toward the cf blade side) at its central part, the paper center part of paper may be creased or damaged due to t...

Page 78

C0640 ( hdd error ) c0640 display on the operation panel lcd at turning on the main sw. Check the cable, connecter between hdd and main pcb. (check poor connection, break, damage 5500i/4500i/3500i : yc1 、 yc27 replace the cable check abnormal sound (rattling sound) during driving hdd initialize hdd:...

Page 79

1. In case of abnormal sound occurs a. Replace the dlp unit . B. Re-assemble it as referring to below attention 1. 2. In case of no abnormal sound (developing drive possible) a. Remove the inner unit. B. Check the cass shutter of the dlp unit. C. If the parts is broken, replace the dlp unit. ( fig.1...

Page 80

C22xx ( drum motor error ) if c22xx(drum motor error) occurs, take the following measure. A. Remove the drum unit from machine. B. Check the drum rotation (refer to fig1) in case of no rotation, replace the drum unit skip to “e”. C. Check rotation of the drum spiral roller (refer to fig2) in case of...

Page 81

1. C510x main hvt error check the firmware version and version up to above fw pack v3.07. Please check the following a-f, when a problem is not solved. A. Remove the drum unit from machine. B. Check the drum rotation (refer to fig1) in case of no rotation, replace the drum unit c. Check rotation of ...

Page 82

C6000 ( fuser heater broken ) ,c6030 ( fuser thermistor1 broken ) , c6050 ( fuser thermistor1 low temp error ) c6200 ( fuser edge heater broken ) , c6230 ( fuser thermistor2 broken ) , c6250 ( fuser thermistor2 low temp error ) check whether the contact of fuser unit connection connector is removed....

Page 83

C6020/c6220 ( abnormal high temperature detected by fuser thermistor ) check whether the version of engine firmware is [2lf_1000.003.083] or after. Version up firmware n g o k ok n g o k yc26 c6020 c6220 302h746191 if c6020/c6220 occurs, take the following measure. Check the poor connection on the e...

Page 84

C6020 (abnormally high fuser thermistor 1 temperature)/c6030 ( broken fuser thermistor 1 wire ) /the fuser press roller may melt and stick./poor fusing please be required following the below cases such as c6030/c6020/the fuser press roller may fuse and stick./the fuser failure. 1. please upgrade the...

Page 85

C6030(fuser thermsitor 1 broken), c6050 (abnormal low temperature detected by fuser thermistor 1) check whether the engine firmware is above [upgrade pack ver. V3.06] firm version up ng c6030 replace the fuser unit replace the engine pcb c6050 ok replace ih pcb ok ok replace the ih coil ok replace t...

Page 86

No c6600/c6720 check whether the fuser belt is broken. Yes judge the fuser belt slackness as referring to content of right fig. (fig.1) “take a measure for “a.” (refer to next page) error take a measure for “a.” ”b.” (refer to next page) normal “take a measure for “c.” (refer to next page) front rea...

Page 87

B. Check the machine’s serial number whether its number is before taking the measure (use the jig to adjust the fuser position plate) during the production. If the machine’s serial number is before affected number, perform the corrective measure as referring to the service bulletin no. 2lf-0003 (b34...

Page 88

【 how to check the unexecuted machine in the production line of the belt edge at failure 】 c6600 ( fuser belt rotation error ) /c6720 ( fuser ih belt rotation error ) /fuser belt failure no ( a or later) yes no whether the machine serial number is less than a ? Yes (less than a ) whether the fuser b...

Page 89

C6600 ( fuser belt rotation error ) /c6720 ( fuser ih belt rotation error ) /fuser belt failure step checking contents 1 detach the fuser unit and then check whether the flange keys of the machine front and rear side do not get under the inside heat roller and whether the flange key is not raised du...

Page 90

Yc26 ( engine pcb ) c6720 occurs due to poor connection identify the measured fuser unit (pi poor contact ) method 1: change “2” for part of serial no. Method2 : even above number is 1, if the connector color of pi is white on fuser unit, it has been modified. White: modified, black: not modified kx...

Page 91

C6620(ih core motor rotation error) ih core motor ok check whether updated with measured engine firmware. (refer to right colum) install updated firmware ok ng ok ng ng ok ok ok ok replace exit pcb (only 6500i/8000i) ok ok ng ok ok ng ok ng ng replace the front pcb ok ok ng ok ok replace the harness...

Page 92

C6730 【 phenomenon 】 cooling fan of ihpwb is clogged by dust, cooling efficiency is reduced, c6730 (fuser ih substrate temperature error 1) is generated. 【 how to respond 】 clean the cooling fan with a vacuum cleaner. After before (with clogging) fan position for 6500i/8000i 92.

Page 93

C6770 ( ih fuser low power error ) check whether engine firmware version is after the right colum. Replace fuser unit. Ng ok ok replace ih pcb ng ok ok ok ok ok firmware ver up ng c6770 ng replace ih coil unit ok ok check connection of fuser unit connector (right fig.) ok ok ng check the firmware ve...

Page 94

C6910(engine firmware ready error) u019 firmware version c6910 check the version of the firmware on the machine. If the version is older than the following, upgrade the firmware to the latest version. Engine venus : 2lc_1000.007.0xx mercury : 2k9_1000.005.0xx zeus/gaia : 2lf_1000.004.0xx check the e...

Page 95

1.In case of abnormal sound occurs a. Replace the dlp unit . B. Re-assemble it as referring to below attention 1. 2. In case of no abnormal sound (developing drive possible) a. Check the firmware ver.And version up with most updated one and replace the dlp unit. B. Re-assemble it as referring to bel...

Page 96

C9500/c9510/c9520/c0630/c0640/cf245 sata cable contact failure the sata cable (no.1 to 4) may have contact failure or may be broken if the service call error below appears. Perform the corrective action below when it arises. 1) check and perform the corrective action for each checkpoint as described...

Page 97

“welcome” screen lock checking method solution welcome screen lock (the screen is not changed more than 3 and half min.) check the connection condition of harness and connector between the panel and main pcb, between main pcb and hdd. 1.Check the contact of ddr memory (detach and attach). (if possib...

Page 98

Cf040 ( communication error between the main pcb and engine pcb ) whether aging drive is starts or not after closing the cover. Check the short circuit of harness for 5v or 3.3v connected to the engine pcb and recover the fault wire. Replace engine pcb main pcb yc3 re-insert the ffc connector re-ins...

Page 99

1. When cf182/cf186 occur after every printing. 1) check connection of the harness (engine - main board) and connectors and check function. *[main ⇔ engine interface] main board:yc3 engine board:yc46 or yc50 2) format the hdd and check function. (u024 full formatting) 3) execute the u021 memory init...

Page 100

A. Replace the dlp unit . B. Re-assemble it as referring to below attention 1. Abnormal sound from developing section when pushing in the cass lock release lever at the inner unit, there is a case not to push in smoothly. In that case, without pushing in by force, re-install the inner unit while shi...

Page 101

Abnormal sound from the fuser section (1/5) match with cycle abnormal sound from fuser check the sound by driving the fuser motor ( u030>fuser), check whether the sound occur at the following cycle during driving. 5500i:0.4sec cycle/4500i: 0.5sec cycle/3500i:0.6sec cycle (refer to sound file) not ma...

Page 102

■ procedure ■ affected machine’s serial number abnormal sound from the fuser section (2/5) for 3500i/4500i/5500i 102.

Page 103

Abnormal sound from the fuser section (3/5) for 3500i/4500i/5500i 103.

Page 104

Abnormal sound from the fuser section (4/5) for 3500i/4500i/5500i 104.

Page 105

23.Install the fuser unit and drive it to check if the abnormal ticking sound is heard. The latch of the bearing to the frame may still not be released in case any abnormal sound is heard. Perform the procedures no.1 and after again. Move the frame in the procedures no 6- 10 cycles note) move the fr...

Page 106

Reducing dp motor driving sound if the driving sound of dp is large, perform below measure 1 and 2. Note : both measure 1 and 2 is not needed to perform together. Eject motor driving sound can be reduced by changing motor drive control. Download dp firmware check dp firmware version by u019 ver.3m4_...

Page 107

Dp size detection error set 1 sheet of a4r (or letter r) on dp original tray, check the original size displayed on the operation panel. When the size detection error occurs at dp, check below item and take measure. Check below after detaching 6 location of claws at fig1, if finding the problem, clea...

Page 108

Waste toner bottle 1. When full of the waste toner bottle is detected earlier incorrectly, check the following. A. If turning the waste toner (toner entrance) down or it is accidentally dropped, while the waste toner is in the wt-860 or vibration is added, *toner will adhere to remaining toner amoun...

Page 109: Time For Maintenance.(T)

Time for maintenance.(t) 1. Time for maintenance.(t) when “time for maintenance.(t)" was displayed on a status bar (refer to attachment picture), please take the following measure. A. Performs resetting partial operation control in sim.906. B. Set up the present time from a system menu. C. When can ...

Page 110

The cassette rails damage (1/2) ● note the parts to use and the direction to install differ between before and after the damage. ① : may contact the pulley a in the figure left and may be broken if pulled out just before full open and the downward force is applied to the cassette. ② : may contact th...

Page 111

The cassette rails damage (1/2) ● note the parts to use and the direction to install differ between before and after the damage. 1 st rib: may contact the pulley a in the figure left and may be broken if pulled out just before full open and the downward force is applied to the cassette. 5 th rib: ma...

Page 112

The cassette rails damage (2/2) ● for strengthening the rail ( before the damage, the resin portion and deformation is whitening rail section. ) 【 service bulletin 】: 2lc-0117 ( d113 ) 302k909690 parts b rail cassette sp for strengthening the rail---install before broken and where is deformed or whi...