- DL manuals

- Taskman

- Pressure Washer

- Pressure Washer

- Operator's Handbook Manual

Taskman Pressure Washer Operator's Handbook Manual

Summary of Pressure Washer

Page 1

Operators handbook taskman pressure washers taskman po box 41 plodder lane bolton lancs bl4 0lr tel: + 44 (0) 845 2304860 fax: + 44 (0) 1204 854620 www.Taskman-uk.Co.Uk issue 6 2013.

Page 2: Contents

Contents 1 introduction 2 declaration of conformity 4 identification 5 warranty terms & conditions 7 safe working 12 operation 18 maintenance and service 24 technical information.

Page 3: Valve Is Closed.

Addendum starting procedure for taskman pressure washers fitted with easystart valve please ensure that you stand clear of the water outlet on the pump. Water will spray from the pump until the valve is closed. Prior to starting engine turn valve to open position (figure 1) start engine as per engin...

Page 4: Without Notice.

Introduction 1 the contents of this handbook although correct at the time of publication, may be subject to alteration by the manufacturers without notice. Taskman operate a policy of continuous product development. Therefore, some illustrations or text within this publication may differ from your m...

Page 5: Declaration

Seddons plant & engineers limited declaration of conformity we: seddons plant & engineers limited, of p.O. Box 41, plodder lane, bolton, lancs, england bl4 0lr declare that the following taskman pressure washers:- models:- pw100ph10/11/12, pw140ph12, pw150ph8/11/12/14, pw170ph13/15 pw170dy15, pw200p...

Page 6: Pw100Ph10 104Db

We guarantee under the provisions of the above directive (2000/14/ec) that the sound power levels for these equipment models will not exceed:- pw100ph10 104db pw100ph11 99db pw100ph12 104db pw140ph12 107db pw150ph8 104db p w 150ph11 1 03db pw150ph12 107db pw150ph14 106db pw170ph13 106db pw170ph15 10...

Page 7: Pw90Ph12

Identification 4 pw90ph12 pw100ph11 pw140ph12 pw100ph12 pw140ph12t pw100ph10gc pw170ph15 pw150ph12gc pw200ph13 pw150ph14 pw200ph15 pw200dy15e pw200dy15es pw200ph21.

Page 8: Warranty Repairs

Warranty terms & conditions 5 taskman assures you that if any of the parts identified within the parts section of this manual become defective due to faulty manufacture or materials within 12 months from the date of purchase, the part will be repaired or replaced under warranty free of charge by any...

Page 9: Claims Are Reimbursed.

Warranty terms & conditions 6 are used to effect a repair, or if lubricants other than those recommended by taskman and the engine manufacturers are used. The equipment must be serviced and maintained in accordance with the service schedules laid down in this handbook. Evidence that these have been ...

Page 10: Read and Remember The

Safe working 7 safety is the responsibility of all persons working with and around this machine. Think “safety” at all times. Read and remember the contents of this and the engine operators handbook. Any modifications to the machine will affect its working parameters and reduce built in safety facto...

Page 11: Always

Safe working 8 always be aware of the lance reaction force when operating this machine. Always know how to stop the machine and bleed the water pressure quickly. Never over reach or stand on unstable supports, keep your footing and balance at all times. Never operate this machine from ladders or ste...

Page 12: Never

Safe working 9 never smoke whilst filling the fuel tank, mop up any fuel spills immediately and in any event before running the engine and allow time for any vapours from the spilled fuel to disperse before starting the engine. Never run the engine in an enclosed or confined area, exhaust fumes in e...

Page 13: Many

Safe working 10 many liquids used in this machine are harmful if taken internally or splashed into the eyes. In the event of accidentally swallowing oils or fuels, seek qualified medical assistance and advice. Always dispose of waste oils and fuels into designated waste oil storage tanks. If storage...

Page 14: Never

Safe working 11 electrical starting systems (continued) never remove any electrical cable while the battery is connected in the circuit. Only disconnect the battery with the engine stopped and all switches in the off position always ensure that cables are fitted to their correct terminal, a short ci...

Page 15: Operation

Operation 12 never commence work until the daily service checks have been carried out. Water supply connection high speed pumps can be fed from mains water tap pressure (positive pressure) or draw from a tank or sump via suction (negative pressure) however if used on suction (negative pressure) for ...

Page 16: Never

Operation 13 never commence work until the daily service checks have been carried out. Priming the water pump each time the machine is put into operation the water pump will require priming before it will operate correctly. Priming the pump and hoses removes any air which may be trapped in the syste...

Page 17: Never

Operation 14 never commence work until the daily service checks have been carried out. Low pressure chemical application the low pressure chemical application facility is an optional extra and may/may not be available on the machine. Totally immerse the filter on the chemical suction hose in the che...

Page 18: Never

Operation 15 never commence work until the daily service checks have been carried out. Starting the engine petrol driven units read the engine operators manual before attempting to start the engine. Connect the inlet/suction hose to a suitable tap or completely immerse the inlet filter in the tank o...

Page 19: Never

Operation 16 gun is operated the easystart valve will close and the water will stop discharging. Each time the trigger gun is closed water will discharge through the easystart valve again. This is a built in safety feature of this unit to avoid overheating the pump and to ease starting. The easystar...

Page 20: Periods of Time.

Operation 17 to avoid damage to the water pump and gearbox (if fitted) never allow the diesel engine to run on idle/tick over speed for prolonged periods of time. Model pw200 only as water enters the pump it will discharge through the easystart valve in the pump to atmosphere, this is correct. When ...

Page 21: Daily Service Checks

Maintenance and service 18 daily service checks read the engine operators manual for items in addition to those listed below. Check condition of suction and pressure hose and lance. Check suction filter, (if fitted) check the fuel level. Check condition of air filter element, and clean replace as ne...

Page 22: Weekly Service Checks

Maintenance and service 19 check all controls for correct operation. Report any faults or missing equipment or damage immediately. Weekly service checks read the engine operators manual for items in addition to those listed below. All the daily service checks plus check condition of water filter and...

Page 23: Inlet Filters-Identification

Maintenance and service 20 inlet filters-identification clean or replace inlet filters frequently filter type a filter type b.

Page 24

Maintenance and service 21 fault cause remedy pump running normally but pressure low on installation inlet filter blocked or dirty pump sucking air valves sticking unloader valve seat faulty check & clean inlet filter check water supply & possibility of air ingress. Check & clean or replace. Check &...

Page 25

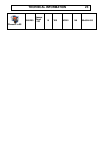

Technical information 22 model pressure psi/bar engine flow ltr/min gearbox type pump type weight (kg) dimensions hxwxl(mm) pw90ph12 1350/90 honda petrol gx120 12 n/a w1210 30 440x340x520 pw100ph11 pw100ph12 pw150ph8 1500/100 1500/100 2250/150 honda petrol gx120 gx160 gx160 11 12 8 n/a ww909 ww909 t...

Page 26

Technical information 23 pw200dy15es 3000/200 yanmar diesel l100 15 yes ws201 148 850x600x100

Page 27: Water Pumps

Technical information 24 water pumps sae10w/30 engine oil gearbox sae90 gear oil engines yanmar l100 diesel:- 10w30 or 20w40 api classification cd honda petrol engines:- 10w30, 10w40, 15w40 api classification sf or sh lubricants.

Page 28: California

California proposition 65 warning diesel engine exhaust and some of its constituents are known to the state of california to cause cancer, birth defects and other reproductive harm.