- DL manuals

- Tatung

- Washer

- TAW-A70FD

- Service Manual

Tatung TAW-A70FD Service Manual

Service Manual

Auto Washer

Model : TAW-A70FD

TATUNG CO.

Update date : Aug, 2002

TA

TUNG

✔

Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information,please refer to PPL(Parts Price List) in

Service Information Center (http://svc.dwe.co.kr).

Summary of TAW-A70FD

Page 1

Service manual auto washer model : taw-a70fd tatung co. Update date : aug, 2002 ta tung ✔ caution : in this manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the latest parts information,please refer to ppl(parts price list) in servi...

Page 2: Ashing Machine

Auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer auto washer ...

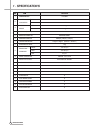

Page 3: 1. Specifications

1. Specifications 2 specifications no. Item 1 power source 110v, 60hz 2 power 340w consumption 220w 3 machine 28.5kg weight 32kg 4 dimension (wxhxd) 525x948x535 5 material of internal tub stainless steel 6 water level selector high(55 l ), mid(45 l ), low(31 l ) 7 operating water pressure 0.3kgf/cm ...

Page 4

2. Structure of the washing machine 3 structure • ground wire in case of 3-wire power cord, ground wire will not be provided • power cord • drain hose • lint filter • cold water tap after using the washer, close the water tap • detergent case • adjustable leg • softener inlet • bleach inlet • contro...

Page 5

3. Functions of the control panel 4 control panel • press this switch to turn the power on or off. • it can be used to adjust amount of water according to the size of the load to be washed. • as the button is pressed, water level is selected by mid → high → low • it can be used to pre-engage time fo...

Page 6

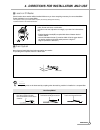

4. Directions for installation and use 5 directions the opening must not be obstructed by carpeting when the washing machine is installed on a carpeted floor. " " location of washer check location where washer will be installed. Make sure you have everything necessary for correct installation. Prope...

Page 7

6 connection for ordinary tap 6 connect the inlet hose adapter of the hose to the water inlet of the washer by turning it clock- wise to be fixed tightly. • please check the rubber packing inside the inlet hose adapter of the hose. 1 pull down the collar of the inlet hose to separate it from the wat...

Page 8

7 convenience " " how to clean the filter 4 remove the dirt from the inlet filter with a brush. 1 pull the power plug out before cleaning it. 2 turn off the water supply to the washer and separate the inlet hose. 3 pull the inlet filter out. Cleaning the lint filter cleaning the water inlet filter •...

Page 9

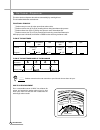

5. Feature and technical explanation 8 explanation wash drain spin fill rinse 1 drain spin fill rinse 2 drain ••• motor c.W singal c.C.W time(sec.) 0.4 0.4 0.4 0.4 0.4 0.4 • • • • • • • 40 sec. (about 25 times) * when the water level is “high” feature of the washing machine 1 the first air bubble wa...

Page 10

9 explanation functional principle 1 the micom can remember the time from the begining of drain to reset point when the pressure switch reaches to “off” point 2 in case of continuous draining, residual drain time is determined by micom. Draining time as a whole = d + 40 residual drain time. The time...

Page 11

10 explanation this is the device to dispense the softener automatically by centrifugal force. This is installed inside the auto-balancer. Functional principle 1 softener stays in room (a) when poured into softener inlet. 2 softener moves from (a) to (b) by centrifugal force during intermittent spin...

Page 12

11 explanation automatic unbalance adjustment circulating-water the alarm finished when you close the lid after opening it. Check the unbalance of the wash load and the installation condition. Notes filter tub outer tub water channel pulsator this system is to prevent abnormal vibration during inter...

Page 13

12 explanation much lint may be obtained according to the kind of clothes to be washed and some of the lint may also sticks to the clothes. To minimize this possibility a lint filter is provided on the upper part of the tub to filter the wash water as it is discharged from the water channel. It is g...

Page 14

13 explanation the proper water currents is made by the rotation of pulsator at a low speed to prevent the damage to the small sized clothes. Structure pulsator shaft one way clutch bearing brake lever spin shaft gear unit as clutch spring clutch boss gear pulley planetary gear sun gear internal gea...

Page 15

14 explanation principle of intake & outlet of the air intake : armature moves up, and bellows inhales the air. At the same time, protector b is open and a is close. Outlet : armature moves down, and bellows exhausts the air. At the same time, protector b is close and a is opend. Functional principl...

Page 16

6. Directions for disassembly and adjustment 15 directions # raise the top plate on the outer cabinet. # remove outer tub cover from the tub ass’y. # remove the spinner shaft flange nut by using ‘t’ type box wrench. # loosen the pulsator mounting screw and remove the pulsator. # remove the tub ass’y...

Page 17

16 directions # lay the front of the washer on the floor. # remove four bolts mounting the plate-gear protect by using a box wrench and remove plate-gear protect. # remove the v-belt. # remove four bolts mounting the gear mechanism ass’y by using a box wrench. # pull out the gear mechanism assy..

Page 18

17 directions # loosen the adjustment bolt and turn the adjust- ment bolt until the end of the bolt touches to the brake lever. # tighten the lock nut and apply a small amount of paint-lock. Adjustment bolt clutch lever gear mechanism ass'y brake lever notes: 1. The brake adjustment has been made at...

Page 19

7. The repair method of gear mechanism for clutch spring problem 18 the repair # tool for replacing the clutch boss assemble # tool name specification q’ty fixing jig 1 ratchet handle 1 socket and extension bar socket : 10mm, 17mm per each some cotton yarn some the structure of gear mechanism bearin...

Page 20

19 the repair no. Parts name specification code q’ty 1 spring clutch swp-a 1.5x1.2 4505e37073 1 2 clutch boss pp 3619301300 1 3 cllitch grease himonax ws 443 2291131420 3g packing packing the clutch boss ass’y 1 method by using vinyl pack 1) the laundary is in the spin tub unevenly when just startin...

Page 21

20 the repair no. Process notice disassemble 1 1 2 3 4 release screws marked 4-point remove the protector remove the v-belt loosen the fastening nut disassemble the spring washer use wrench or driver - ratchet handle - extension bar - socket : 10mm use fixing jig for pulley as to see fig 1. And 17mm...

Page 22

21 the repair no. Process notice disassemble 2 5 6 7 8 disassemble the pulley disassemble the clutch boss assembly separate coupling from clutch boss ass’y cleaning catch the boss and pull upward with spiral rotate in the clockwise direction clean the drum plate, coupling surface and contact face be...

Page 23

22 the repair no. Process notice assemble 1 1 2 3 4 assemble the coupling assemble the new clutch boss ass’y assemble the pulley assemble the spring washer check the uneven face of cou- pling is assembled upward - push in the clutch boss ass’y with rotating on the clockwise direction. - after assemb...

Page 24

23 the repair no. Process notice assemble 2 5 6 7 8 assemble the fastening nut assemble the belt assemble the protector final checking - use fixing jig and 17mm socket wrench as if disassembling, as fastening torque about 100~200kgf-cm. - check the end-play, up and downward and check the bind- ing f...

Page 25: 8. Trouble Shooting Guide

8. Trouble shooting guide 24 trouble shooting problem water is not sup- plied. Check point do you open the water tap? Is the filter of the water inlet valve clogged with dirt? Is the water pressure sufficient? (0.3~8 kgf/cm 2 ) does the water inlet valve make operating sound? Is the connector or the...

Page 26

25 trouble shooting problem water sup- ply is not stopped. Check point does the water supply continue while the power is turned off? Does the water supply start as soon as you press the power switch? Operate the washer after setting the water level to “high” does the water supply continue after the ...

Page 27

26 trouble shooting problem the washer does not drain. Check point do you install the drain hose proper- ly? Is the foreign matter accumulated inside the pump housing? Is the output voltage of the drain pump normal? Cause solution install the drain hose properly. Remove the foreign mat- ter from the...

Page 28

27 trouble shooting problem the washer does not spin. Check point is the lid open? Does the safety switch operate normally? Does the pulsator rotate while the tub does not rotate? Is the connector of p.C.B ass‘y connected properly? Is the input voltage of the drain motor normal? Is the v-belt worn o...

Page 29

28 trouble shooting no no problem the indica- tor lamps(l.E.D) do not light up when the power but- ton is pressed. Progress lamps(led) do not light up. Motor rotates when start/hold button is not pressed. Abnormal noise dur- ing wash process. Check point is the plug connect-ed to electric outlet? Is...

Page 30

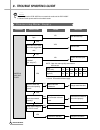

9. Presentation of the p.C.B ass’y 29 pcb ass’y message cause solution improper installation of drain hose. The drain hose is blocked up by foreign matter. Drain motor is inferior. The water tap is closed. The water inlet filter clogged. It passes over the 30 minutes, yet it doesn’t come to assigned...

Page 31: Appendix

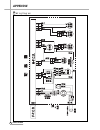

Appendix 30 wiring diagram " " wiring diagram.

Page 32

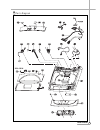

31 parts diagram " " parts diagram.

Page 33

32 parts diagram "" parts list no. Part name part code specification remark a01 plate t 3614521500 pp a02 door b as 3611797600 abs option : a03 door f as 3611797700 abs transparent a04 spring plate lever 3615111801 hsw 3 d=1.0 since feb, 2002 a05 plate lever 3614521400 pp a06 spring door 3615112101 ...

Page 34

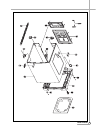

33 parts diagram.

Page 35

34 parts diagram "" parts list no. Part name part code specification remark b01 cabinet 3610809600 painted steel sheet 0.6t b02 handle cabinet 3612603300 pp b03 plate upper 3614521600 pp b04 base u 3610389200 pp high h=135 dwf-752/755/758/802/805/808 b05 leg adjust as 3617702120 screw (4x14) b06 leg...

Page 36

35 parts diagram.

Page 37

36 parts diagram "" parts list no. Part name part code specification remark c01 balancer as 3616104700 dwf-6010 c02 tub 3618808501 sus 0.5t since april, 2001 c03 tub u 3618808601 pp c04 guide filter as 3612507000 dwf-6010np c05 special screw 3616003700 sus 5.5x16 c06 pulsator as 3719706700 dwf-800wn...

Page 38

37 parts diagram.

Page 39

38 parts diagram "" parts list no. Part name part code specification remark d01 cover tub o 3611414600 pp d02 tub o 3618817600 pp d03 suspension as f 3619804200 front d04 suspension as b 3619804300 rear d05 valve drain as 3615408500 dwf-750m d06 hose drain i as 3613227000 ldpe+eva dwf-752mn d07 clam...

Page 40

39 circuit diagram " " circuit diagram.

Page 41

S/m no. :.