- DL manuals

- Taylor

- Ice Cream Maker

- 142

- Operator's Manual

Taylor 142 Operator's Manual

Summary of 142

Page 1

Operator’s manual model 142 soft serve freezer original operating instructions 039709- m 3/00 (original publication) (updated 7/18/14).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e 2000 carr...

Page 3: Table Of Contents

Table of contents model 142 table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Site p...

Page 4

Table of contents model 142 table of contents - page 2 cleaning 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Disassembly 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5: Section 1

1 model 142 to the installer 131122 section 1 to the installer the following information has been included in the manual as safety and regulatory guidelines. For complete installation instructions, please see the installation checklist. Installer safety in all areas of the world, equipment should be...

Page 6

2 model 142 to the installer 101111 electrical connections in the united states, this equipment is intended to be installed in accordance with the national electrical code (nec), ansi/nfpa 70-1987. The purpose of the nec code is the practical safeguarding of persons and property from hazards arising...

Page 7

3 model 142 to the installer 130809 electrical hook- up installation for 60 cycle, 1 ph, supplied with cord and plug this equipment is supplied with a 3- wire cord and grounding type plug for connection to a single phase, 60 cycle, branch circuit supply. This unit must be plugged into a properly gro...

Page 8: Section 2

4 model 142 to the operator 131122 section 2 to the operator your freezer has been carefully engineered and manufactured to give you dependable operation. If the taylor model 142 is properly operated and cared for, it will produce a consistent, quality product. Like all mechanical products, this mac...

Page 9: Section 3

5 model 142 safety 130211 section 3 safety we, at taylor company, are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built- in safety features to protect both you and the service ...

Page 10

6 model 142 safety 130211 s do not allow untrained personnel to operate this machine. S do not operate the freezer unless all service panels and access doors are restrained with screws. S do not remove any internal operating parts (examples: freezer door, beater, scraper blades, etc.) unless all con...

Page 11: Section 4

7 model 142 operator parts identification 140407 section 4 operator parts identification item description part no. 1 cover a.- hopper x49633 2 float a.- mix level x39690 3 tube- feed- .166 hole- ss 035819 4 shield- splash- plastic 039444 5 pan a.- white front drip x43474 6 seal- u- cup 080534 7 beat...

Page 12: Section 5

8 model 142 important: to the operator section 5 important: to the operator figure 1 item description 1 power switch 2 indicator light - mix low 3 standby switch symbol definitions to better communicate in the international arena, the words on many of our operator switches and buttons have symbols t...

Page 13

9 model 142 important: to the operator 130702 standby switch this push button switch determines which mode of operation the freezing cylinder is operating in. If the center button of this switch is in the “out” position and it is not illuminated, the unit will operate in the normal product dispensin...

Page 14: Section 6

10 model 142 operating procedures 120501 section 6 operating procedures the model 142 has a 1.5 quart (1.4 liter) capacity freezing cylinder. The mix flows from the hopper to the freezing cylinder through a feed tube. The mix flow is controlled by gravity. We begin our instructions at the point wher...

Page 15

11 model 142 operating procedures 120501 step 4 slide the front bearing over the baffle rod so the flanged edge is against the door. Place the white plastic guide bearing on the end of the baffle rod. Do not lubricate the front bearing or guide bearing. Figure 8 step 5 insert the handscrews into the...

Page 16

12 model 142 operating procedures note: the draw valve is installed correctly when the slotted opening in the draw valve is visible through the “window” of the freezer door. Figure 12 step 8 install the draw valve handle. Insert the valve lifter arm through the slotted opening in the draw valve and ...

Page 17

13 model 142 operating procedures 090421 the illustration below shows the draw valve assembled on the left side. Figure 16 step 9 snap the design cap over the bottom of the freezer door spout. Figure 17 step 10 lay the feed tube and mix level float in the bottom of the mix hopper. Sanitizing step 1 ...

Page 18

14 model 142 operating procedures figure 20 figure 21 step 4 place the toggle switch in the wash position. This will cause the sanitizing solution in the freezing cylinder to be agitated. Allow to agitate for five minutes. Step 5 place an empty pail beneath the door spout and open the draw valve. Dr...

Page 19

15 model 142 operating procedures priming prime the machine as close as possible to the time of first product draw. Step 1 with a pail beneath the door spout, open the draw valve. Fill the mix hopper with fresh mix and allow it to flow into the freezing cylinder. This will force out any remaining sa...

Page 20

16 model 142 operating procedures standby this unit is equipped with a standby feature. If product is not dispensed for long periods of time (i.E.; early morning hours), the standby feature will maintain the hopper and freezing cylinder product at safe temperatures and prevent product breakdown. To ...

Page 21

17 model 142 operating procedures 140718 draining product from the freezing cylinder step 1 place the toggle switch in the off position as far ahead of cleaning time as possible to allow frozen product to soften for easier cleaning. Step 2 lift the hopper cover, remove the feed tube and the mix leve...

Page 22

18 model 142 operating procedures 120529 brush cleaning step 1 prepare a sink with an approved cleaning solution (ex- amples: kay- 5r or stera- sheenr). Use warm water and follow the manufacturer’s specifications. (important: follow the label directions. A strong solution can cause parts dam- age. A...

Page 23: Section 7

19 model 142 important: operator checklist 080110 section 7 important: operator checklist during cleaning and sanitizing: cleaning and sanitizing schedules are governed by federal, state, or local regulatory agencies, and must be followed accordingly. If the unit has a “standby mode”, it must not be...

Page 24

20 model 142 important: operator checklist winter storage if the place of business is to be closed during the winter months, it is important to protect the freezer by following certain precautions, particularly if the building is subject to freezing conditions. Disconnect the freezer from the main p...

Page 25: Section 8

21 model 142 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product being dispensed. A. Toggle switch in off position. A. Place toggle switch in the auto position. 15 b. Inadequate level of mix in mix hopper. B. Fill mix hopper with mix. 15 c. Bea...

Page 26

22 model 142 troubleshooting guide problem probable cause remedy page ref. 4. Product is too soft. A. The temperature control is set too warm. A. Call service technician. - - - b. The feed tube is not installed. B. Install the feed tube in mix inlet hole at bottom of the mix hopper. (the metering ho...

Page 27: Section 9

23 model 142 parts replacement schedule 120430 section 9 parts replacement schedule part description every 3 months every 6 months annually quantities to be replaced beater drive shaft cup seal x 1 freezer door o- ring x 1 freezer door front bearing x 1 freezer door guide bearing x 1 draw valve o- r...

Page 28

24 model 142 limited warranty on equipment 131122 section 10 limited warranty on equipment taylor company limited warranty on freezers taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor-branded freezer equipment a...

Page 29

25 model 142 limited warranty on equipment 3. Replacement of wear items designated as class “000” parts in the taylor operator’s manual. 4. External hoses, electrical power supplies, and machine grounding. 5. Parts not supplied or designated by taylor, or damages resulting from their use. 6. Return ...

Page 30: Section 11

26 model 142 limited warranty on parts 131122 section 11 limited warranty on parts taylor company limited warranty on taylor genuine parts taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor genuine replacement com...

Page 31

27 model 142 limited warranty on parts limited warranty exceptions this limited warranty does not cover: 1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of defective parts, replacement parts, or new parts. 2. Normal maintenance, clean...

Page 32

28 model 142 limited warranty on parts limitation of warranty this limited warranty is exclusive and is in lieu of all other warranties, conditions and/or remedies under the law, including any implied warranties or conditions of merchantability or fitness for a particular purpose. The original owner...

Page 33: Section 12

Section 12 parts list 29 + available separately model 142 parts list 014212h000 - 115v 60hz 1 ph - 014227h000 - 208- 230v 60hz 1 ph - a /c -t ecum seh- (r 404a) de s cri p t io n p art num be r 142 qty . W arr. Cl as s re m arks beari n g- front 023262 4 000 beari n g- gui d e 014496 4 000 beari n g...

Page 34

+ available separately 30 parts list model 142 de s cri p t io n re m arks w arr. Cl as s 142 qty . P art num be r co rd- po w e r- 250v- 15a- 95" l 042936- 27 1 103 208- 230v 60hz 1 ph cover a. -h opper x49633 1 103 decal- clean in st. -hopper 019029 1 000 decal- mag- flavor pads 039713 1 000 decal...

Page 35

31 + available separately model 142 parts list de s cri p t io n re m arks w arr. Cl as s 142 qty . P art num be r label- s w -w ash/ o ff/ auto- symbol 014502 1 000 label- w arn- condenser- s harp 059287 1 000 label- w arn- cover 051433 4 000 leg- 4" -3 /8 -1 6 s tud- plasti c 024755 4 103 li ght- ...

Page 36

+ available separately 32 parts list model 142 de s cri p t io n re m arks w arr. Cl as s 142 qty . P art num be r shell a .- in sulated *142* ho o d x49175- ser 1 512 stud- no se co ne *142* 042168 2 103 shi e ld- splash- p lasti c 039444 1 103 shro ud- fan *142* 048877 1 103 sw it ch a. -draw *142...

Page 37

33 + available separately model 142 parts list de s cri p t io n re m arks w arr. Cl as s 142 qty . P art num be r 014212h879 - canada - 115v 60hz 1 ph - a/ c- tecum seh- (r 404a) man- oper- c ond 142 romance 039709rm 1 000 card- checkout f reezer french 033941- f 1 000 label- a ttn svc eng- french ...

Page 38

+ available separately 34 parts list model 142 de s cri p t io n re m arks w arr. Cl as s 142 qty . P art num be r 014240hw 6 5 - 220- 240v 50hz 1 ph - a/ c- tecum seh- (r 404a) - r o h s c o m pli ant france belt- v- 4l380 007098 1 000 card- checkout f reezer french 033941- f 1 000 compressor - tec...

Page 39

35 + available separately model 142 parts list de s cri p t io n re m arks w arr. Cl as s 142 qty . P art num be r 014240hw 7 0 - 220- 240v 50hz 1 ph - a/ c- tecum seh- (r 404a) - r o h s c o m pli ant *g ermany* belt- v- 4l380 007098 1 000 card- checkout f reezer german 033941- g 1 000 compressor -...

Page 40

+ available separately 36 parts list model 142 de s cri p t io n re m arks w arr. Cl as s 142 qty . P art num be r 014240hw 5 0 - 220- 240v 50hz 1 ph - a/ c- tecum seh- (r 404a) - r o h s c o m pli ant *n ew zealand* belt- v- 4l380 007098 1 000 compressor - tecumseh 049302- 40 1 512 +capaci t or- ru...

Page 41

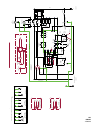

142 049264 11/21/13 red/wht compressor start time dealy-2sec dom input (115 v only) load red/wht grn/yel grn/yel grn/yel stdby switch barrel suction solenoid hopper thermistor barrel thermistor mix low unreg light switch com 1 lamp- n.O 2 com 2 lamp+ n.C. 1 - - + + blk yel alarm l2 l1 beater hopper ...