- DL manuals

- Taylor

- Freezer

- 430 Torque

- Operator's Manual

Taylor 430 Torque Operator's Manual

Summary of 430 Torque

Page 1

Operator's manual model 430 torque shake/slush freezer original operating instructions 051430-m 3/97 original publication (updated 9/2/14).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on data plate: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: amps minimum wire ampacity: amps part numb...

Page 3: Table Of Contents

Model 430 torque table of contents table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

Model 430 torque table of contents table of contents - page 2 ______________________________________________________________________________ section 7 important: operator checklist 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . During cleaning and sanitizing: 18 . . . . . . . . . . ....

Page 5: Section 1

1 model 430 torque to the installer 131202 section 1 to the installer the following information has been included in the manual as safety and regulatory guidelines. For complete installation instructions, please see the installation checklist. Installer safety in all areas of the world, equipment sh...

Page 6

2 to the installer model 430 torque 130930 air cooled units do not obstruct air intake and discharge openings: air cooled units require a minimum of 3” (76.2 mm) of clearance around all sides of the freezer to allow for adequate air flow across condenser. Failure to allow adequate clearance can redu...

Page 7

3 model 430 torque to the installer 130816 beater rotation beater rotation must be clockwise as viewed looking into the freezing cylinder. Note: the following procedure must be performed by an authorized taylor service technician. To correct rotation on a single- phase unit, change the leads inside ...

Page 8: Section 2

4 to the operator model 430 torque 131202 section 2 to the operator the freezer you have purchased has been carefully engineered and manufactured to give you dependable operation. The taylor model 430 torque, when properly operated and cared for, will produce a consistent quality product. Like all m...

Page 9: Section 3

5 model 430 torque safety 130930 section 3 safety we, at taylor company, are concerned about the safety of the operator at all times when they are coming in contact with the unit and its parts. Taylor makes every effort to design and manufacture built- in safety features to protect both operators an...

Page 10

6 safety model 430 torque 130930 this unit is provided with an equipotential grounding lug that is to be properly attached to the rear of the frame by the authorized installer. The installation location is marked by the equipotential bonding symbol (5021 of iec 60417-1) on both the removable panel a...

Page 11: Section 4

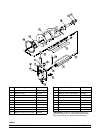

7 model 430 torque operator parts identification 070104 section 4 operator parts identification auto off wash 1 6 12 7 8 10 11 2 3 4 5 9 item description part number 1 shield- splash 049320 2 tray- drip 049319 3 pan- drip 17- 1/4” long 027504 4 gasket- base pan 049420 5 panel a.- front x50678 6 stud...

Page 12

8 operator parts identification model 430 torque 130816 item description part number *1 door a.- partial x39248- ser 2 handle a.- draw x47384 3 valve- draw 047734 4 valve a.- handle pin x25929 5 o- ring - 1” od x .139 w 032504 6 buster- ice 047735 7 o- ring - .291 id x .080 w 018550 8 torque assembl...

Page 13

9 model 430 torque operator parts identification 140102 item description part number 1 brush- 3” x 7” white 023316 2 brush- double ended 013072 3 brush- draw valve 014753 item description part number 4 brush- rear bearing 013071 5 lubricant- taylor 047518 *6 video- training m430torque 050987- dvd *n...

Page 14: Section 5

10 important: to the operator model 430 torque section 5 important: to the operator viscosity adjustment the viscosity (thickness) of the slush can be adjusted by turning the viscosity adjustment screw on the upper right side of the front panel. Turn the viscosity adjustment screw clockwise for a th...

Page 15: Section 6

11 model 430 torque operating procedures section 6 operating procedures the model 430 freezer is designed to produce shake or slush product at the desired thickness. This unit has a 4 quart freezing cylinder. We begin our instructions at the point where we enter the store in the morning and find the...

Page 16

12 operating procedures model 430 torque holding the beater securely, slide the beater into the freezing cylinder and align the hole at the rear of the beater with the flats on the end of the drive shaft. Slide the beater the remainder of the way into the freezing cylinder and over the end of the dr...

Page 17

13 model 430 torque operating procedures rotate the draw valve so the flats on the top of the draw valve are perpendicular to the door face. Figure 12 insert the ice buster through the door spout and into the slot located just above the lower o- ring. Figure 13 with the ice buster in place, rotate t...

Page 18

14 operating procedures model 430 torque 090114 step 7 install the front drip pan. Slide the long drip pan into the hole in the front panel. Figure 17 step 8 install the front drip tray and splash shield beneath the door spout. Figure 18 step 9 lay the air/mix feed tube (optional) in the bottom of t...

Page 19

15 model 430 torque operating procedures 140804 step 5 place an empty pail beneath the door spout and move the draw handle to the right. Draw off all the sanitizing solution. When the sanitizer stops flowing from the door spout, move the draw handle to the left and place the control switch in the “o...

Page 20

16 operating procedures model 430 torque 140804 step 4 place the mix hopper cover in position. Periodically, during the day’s operation, check to be sure there is a substantial amount of mix in the hopper. Figure 26 closing procedure to disassemble this unit, the following items will be needed: s tw...

Page 21

17 model 430 torque operating procedures 090114 cleaning step 1 prepare a pail of an approved 100 ppm cleaning solution (examples: 2- 1/2 gal. [9.5 liters] of kay- 5r or 2 gal. [7.6 liters] of stera- sheenr). Use warm water and follow the manufacturer’s specifications. Step 2 pour the cleaning solut...

Page 22: Section 7

18 important: operator checklist model 430 torque 071205 section 7 important: operator checklist during cleaning and sanitizing: always follow local health codes cleaning and sanitizing schedules are governed by federal, state, or local regulatory agencies, and must be followed accordingly. If the u...

Page 23

19 model 430 torque important: operator checklist winter storage if the place of business is to be closed during the winter months, it is important to protect the freezer by following certain precautions, particularly if the building is to be left unheated and subject to freezing conditions. Disconn...

Page 24: Section 8

20 troubleshooting guide model 430 torque section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product being dispensed. A. Power switch is in the “off” position. A. Place power switch in the “auto” position. 15 b. Improper mixing of product. B. Carefully follow directions fo...

Page 25

21 model 430 torque troubleshooting guide problem probable cause remedy page ref. 5. Product too thin. A. Missing, incorrectly installed, or bad scraper blade. A. Install or replace scraper blade. 11 b. Improper mixing of product. B. Carefully follow directions for mixing product. - - - c. The visco...

Page 26: Section 9

22 parts replacement schedule model 430 torque section 9 parts replacement schedule part description every 3 months every 6 months annually quantities to be replaced drive shaft seal x 1 drive shaft o- ring x 1 scraper blade x 1 freezer door gasket x 1 front bearing x 1 draw valve o- rings x 2 black...

Page 27

23 model 430 torque limited warranty on equipment 131202 section 10 limited warranty on equipment taylor company limited warranty on freezers taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor-branded freezer equi...

Page 28

24 limited warranty on equipment model 430 torque 3. Replacement of wear items designated as class “000” parts in the taylor operator’s manual. 4. External hoses, electrical power supplies, and machine grounding. 5. Parts not supplied or designated by taylor, or damages resulting from their use. 6. ...

Page 29: Section 11

25 model 430 torque limited warranty on parts 131202 section 11 limited warranty on parts taylor company limited warranty on taylor genuine parts taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor genuine replacem...

Page 30

26 limited warranty on parts model 430 torque limited warranty exceptions this limited warranty does not cover: 1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of defective parts, replacement parts, or new parts. 2. Normal maintenance...

Page 31

27 model 430 torque limited warranty on parts limitation of warranty this limited warranty is exclusive and is in lieu of all other warranties, conditions and/or remedies under the law, including any implied warranties or conditions of merchantability or fitness for a particular purpose. The origina...

Page 32

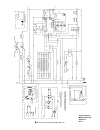

Model 430 torque 050367-12 08/14 taylor company 2014 carrier commercial refrigeration, inc. C w1 mix out sensitivity: remove jumper to reduce sensitivity. Yes w2 mix low sensitivity: remove jumper to reduce sensitivity. Yes grn/yel wht blk blk blk blk ground frame securely m t2 compressor l2 l1 t1 c...

Page 33

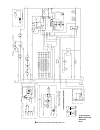

Model 430 torque 050367-27 08/14 taylor company 2014 carrier commercial refrigeration, inc. C grn/yel wht blk blk blk blk ground frame securely m t2 compressor l2 l1 t1 compressor contactor condenser fan motor beater motor overload switch compressor high pressure limit switch (see fig 1) blk blk com...