- DL manuals

- Taylor

- Ice Cream Maker

- 8751

- Operating Instructions Manual

Taylor 8751 Operating Instructions Manual

Summary of 8751

Page 1

Models 8751/8754 pump style soft serve freezers operating instructions 056485--m 2/01/02.

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e february,...

Page 3: Table Of Contents

Table of contents models 8751/8754 table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Water connections (water cooled units only) 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air cooled units 1 . . . . ....

Page 4

Models 8751/8754 table of contents table of contents -- page 2 section 6 operating procedures 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Assembly 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5: Section 1

1 models 8751/8754 to the installer 050415 section 1 to the installer this machine is designed for indoor use only. Do not install the machine in an area where a water jet could be used to clean or rinse the machine. Failure to follow this instruction may result in serious electrical shock. Water co...

Page 6: Section 2

2 models 8751/8754 to the operator 050818 section 2 to the operator the freezer you have purchased has been carefully engineered and manufactured to give you dependable operation. The taylor company soft-serve models covered in this manual consist of the 8751 and 8754. These units, when properly ope...

Page 7: Section 3

3 models 8751/8754 safety 050415 section 3 safety we at taylor company are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built-in safety features to protect both you and the serv...

Page 8: Section 4

4 models 8751/8754 operator parts identification section 4 operator parts identification model 8751 item description part no. 1 cover a.-hopper x38458 2 gasket-hopper cover 038375 3 louver-side 017471 4 panel·a.-front x33237 5 stud-nose cone 022822 6 panel-upper side 024426 7 panel a.-side-lower-lou...

Page 9

5 models 8751/8754 operator parts identification model 8754 item description part no. 1 cover a.-hopper x38458 2 gasket-hopper cover 038375 3 pan-drip 17-1/4”long 027504 4 panel-upper side l 028822 5 stud-nose cone 022822 6 panel a.-front x32956 7 panel a.-side *lower l x46447 8 shield-splash 022766...

Page 10

6 models 8751/8754 operator parts identification model 8751 single spout door and beater assembly item description part no. 1 handle a.-draw-adj. X55096 1a handle-adjustable 028804 1b screw-adjustment 055092 1c o-ring-1/4 od x .070w 50 015872 1d nut-jam 029639-blk 2 nut-stud 021508 3 door a.-1 spout...

Page 11

7 models 8751/8754 operator parts identification model 8754 three spout door and beater assembly item description part no. 1 handle a.- draw x55096 1a draw handle 028804 1b screw-adjust 055092 1c o-ring 1/4od x .070w 015872 1d nut-jam 029639-blk 2 nut-stud flat long 034382 3 nut-stud flat short 0343...

Page 12

8 models 8751/8754 operator parts identification air/mix pump item description part no. 1 tube a.--mix inlet--hopper x45318 2 seal--air inlet fitting 045327 3 spring--tapered 1--7/8 022456 4 poppet--rubber black 022473 5 body a.--coax valve x46860-b 6 o--ring 2-1/8 od x .139 w 020051 7 o--ring 1-3/8...

Page 13

9 models 8751/8754 operator parts identification accessories item description part no. 1 brush--mix pump body 023316 2 brush--double ended 013072 3 brush--rear bearing 013071 4 brush--draw valve 013073 5 lubricant--taylor 4 oz. 047518 item description part no. 6 sanitizer--kay 5 (125 pkts) 041082 7 ...

Page 14: Section 5

10 models 8751/8754 important: to the operator section 5 important: to the operator 8751 8754 item description 1 mix low indicator light 2 mix refrigeration key 3 standby key 4 wash key 5 auto key item description 6 pump key 7 power on/off (toggle) 8 reset button -- beater motor 9 reset button -- pu...

Page 15

11 models 8751/8754 important: to the operator symbol definitions to better communicate in the international arena, symbols have replaced words on many of our operator switches, function, and fault indicators. Your taylor equipment is designed with these international symbols. The following chart id...

Page 16

12 models 8751/8754 important: to the operator wash key when the wash key is pressed, the light comes on. This indicates beater motor operation. The standby or auto modes must be cancelled first to activate the wash mode. Auto key when the auto key is pressed, the light comes on. This indicates that...

Page 17

13 models 8751/8754 important: to the operator 050201 feed tube (back--up option) if the air/mix pump has become inoperable because of a missing or damaged part, the operator can temporarily operate the unit using the feed tube. The product ejection rate will be slower when the feed tube is used ins...

Page 18: Section 6

14 models 8751/8754 operating procedures 050201 section 6 operating procedures the model 8751 has been selected to illustrate the step-by-step operating procedures for both models contained in this manual. These models, for all practical purposes of operation, are the same. Each unit stores mix in a...

Page 19

15 models 8751/8754 operating procedures step 2 install the beater assembly. First check the scraper blades for any nicks or signs of wear. If any nicks are present, or if the blades are worn, replace both blades. If the blades are in good condition, install the scraper blade clips on the scraper bl...

Page 20

16 models 8751/8754 operating procedures slide the two o-rings into the grooves on the prime plug(s). Apply an even coat of taylor lube to the o-rings and shaft(s). Figure 9 note: there are two prime plugs for the model 8754 door, one for each freezing cylinder. Insert the prime plug(s) into the hol...

Page 21

17 models 8751/8754 operating procedures step 6 install the adjustable draw handle(s). Slide the o-ring into the groove on the pivot pin, and lubricate. Figure 14 slide the fork over the bar in the slot of the draw valve. Secure with pivot pin. Note: the model 8754 has three draw handles. Slide the ...

Page 22

18 models 8751/8754 operating procedures air/mix pump assembly the purpose of the air/mix pump is to meter a specific amount of air and mix, and to transfer this combination to the freezing cylinder. Refer to the illustration on page 8 for identification of parts during assembly. Step 1 assemble the...

Page 23

19 models 8751/8754 operating procedures step 4 apply a small amount of lubricant to the lower inside diameter of the pump cylinder to a depth equivalent to the length of your index finger. Once applied, the amount of lubricant should be equal to a paper-thin film. Figure 23 insert the assembled pis...

Page 24

20 models 8751/8754 operating procedures insert the assembled mix inlet tube into the hole in the base of the liquid valve body. Figure 27 secure the pump parts in position by sliding the retaining pin through the cross holes located at the bottom of the pump cylinder. Figure 28 note: when the pump ...

Page 25

21 models 8751/8754 operating procedures install the hex end of the drive shaft into the drive hub at the rear wall of the mix hopper. Figure 31 note: for ease in installing the pump, position the ball crank of the drive shaft in the 3 o’clock position. Step 9 lay the pump assembly, pump clip, mix f...

Page 26

22 models 8751/8754 operating procedures step 4 install the pump assembly. To position the pump on the drive hub at the rear of the mix hopper, align the drive hole in the piston with the drive crank of the drive shaft. Secure the pump in place by slipping the pump clip over the collar of the pump, ...

Page 27

23 models 8751/8754 operating procedures 050201 step 9 when a steady stream of sanitizing solution is flowing from the prime plug opening in the bottom of the freezer door, pull the draw handle down. Draw off all of the sanitizing solution. (note: on the model 8754, momentarily pull the center draw ...

Page 28

24 models 8751/8754 operating procedures step 2 once a steady stream of mix starts to flow from the prime plug opening in the bottom of the freezer door, push down the prime plug. Figure 41 step 3 when the mix stops bubbling down into the freezing cylinder, insert the mix feed tube. Remove the locki...

Page 29

25 models 8751/8754 operating procedures draining product from the freezing cylinder step 1 press the auto key, cancelling compressor and beater motor operation. Press the mix ref key, cancelling the mix hopper refrigeration system. Step 2 remove the hopper cover and gasket. Take these parts to the ...

Page 30

26 models 8751/8754 operating procedures step 7 once the cleaning solution stops flowing from the door spout, raise the draw handle and press the wash key, cancelling the wash mode. Repeat steps 1 through 7 for the other side of the freezer on the model 8754. Disassembly step 1 be sure the power swi...

Page 31: Section 7

27 models 8751/8754 important: operator checklist 051215 section 7 important: operator checklist during cleaning and sanitizing cleaning and sanitizing schedules are governed by your state or local regulatory agencies and must be followed accordingly. The following check points should be stressed du...

Page 32

28 models 8751/8754 important: operator checklist j 7. If your machine is equipped with an auxiliary refrigeration system, check the auxiliary condenser for accumulation of dirt and lint. Dirty condensers will reduce the refrigeration capacity of the mix hopper. Condensers must be cleaned monthly wi...

Page 33: Section 8

29 models 8751/8754 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product is being dispensed with draw valve open and the machine in the auto mode. A. Freeze-up in mix inlet hole. A. Call service technician to adjust the mix hopper temperature. -...

Page 34

30 models 8751/8754 troubleshooting guide problem probable cause remedy page ref. 5. The mix in the mix hopper is too warm. A. The temperature is out of adjustment. A. Call service technician to adjust the mix hopper temperature. ------ b. Missing or defective mix hopper gasket. B. Replace/install t...

Page 35

31 models 8751/8754 troubleshooting guide problem probable cause remedy page ref. 11. Product is not feeding into the freezing cylinder. A. Inadequate level of mix in the mix hopper. A. Fill the mix hopper with mix. 24 b. The mix inlet hole is frozen up. B. The mix hopper temperature needs adjustmen...

Page 36

32 models 8751/8754 troubleshooting guide problem probable cause remedy page ref. 14. The piston travels back and forth, but product is not being pumped. A. Inspect the check bands. A. Check bands must be installed correctly, fit tightly, and not have any holes or lubrication. Make sure check bands ...

Page 37: Section 9

33 models 8751/8754 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually drive shaft seal x scraper blade x freezer door gasket x front bearing x beater shoes x draw valve o-ring x pivot pin o-ring x prime plug o-ring x air tube o-ri...

Page 38: Section 10

Section 10 parts list + available separately 34 parts list models 8751/8754 h p 62 r e fr ig er an t: 8751 - j6080596, 8754 - j 6080465/u p de s cri p t io n part num be r 8751 qty . 8754 qty . W arr. Cl as s re m arks part s up da t e ad apt o r a. --c aster x 18915 4 4 103 bear in g --f r o n t 05...

Page 39

35 + available separately models 8751/8754 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 8754 qty . 8751 qty . Part num be r b rus h --b la ck (1 ” x 2” ) 013071 1 1 000 b rus h --d oub le e nd 013072 1 1 000 b rus h --w hi t e (1 ” x 2” ) 013073 1 1 000 b rus h --w hi t e (...

Page 40

+ available separately 36 parts list models 8751/8754 de s cri p t io n part s up da t e re m arks w arr. Cl as s 8754 qty . 8751 qty . Part num be r de ca l- -d e c ora t iv e 033231 1 000 de ca l- -d e c ora t iv e 033232 1 000 de ca l- -p ow e r s w it ch -- on/ o f f (ol d ) 032484 1 000 p r io ...

Page 41

37 + available separately models 8751/8754 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 8754 qty . 8751 qty . Part num be r hood x 41996 1 103 hood 013667 1 103 k it a .-- t une --up x 49463 --9 1 000 ban d --c h e c k (l iq u id v al ve bo d y ) 020050 2 000 ban d --c h e ...

Page 42

+ available separately 38 parts list models 8751/8754 de s cri p t io n part s up da t e re m arks w arr. Cl as s 8754 qty . 8751 qty . Part num be r o --r in g (l iq u id v a lv e b o d y & p ist o n ) 020051 6 000 o --r in g (m ix in let tu be) 015835 2 000 o --r in g (m ix f eed tu be) 016132 4 0...

Page 43

39 + available separately models 8751/8754 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 8754 qty . 8751 qty . Part num be r nut --s t ud (s hor t ) 034383 2 103 sh o r t o r ific e --a ir 022465 --100 1 2 103 o- -r in g 016137 1 2 000 pa il 013163 1 1 000 10 q t. /9 .5 li t...

Page 44

+ available separately 40 parts list models 8751/8754 de s cri p t io n part s up da t e re m arks w arr. Cl as s 8754 qty . 8751 qty . Part num be r pr o b e a .-- t h e r m ist o r -- h o pper x 50717 1 1 103 p r ob e a .-- t he rm is to r -- b a rre l x 31602 1 2 103 pu ll e y (bea ter m o to r )...

Page 45

41 + available separately models 8751/8754 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 8754 qty . 8751 qty . Part num be r sh iel d --spl ash 022766 1 103 sl eeve a. --m ix p u m p x 45012 1 2 103 +n u t --pu m p sl eeve 036933 1 2 103 st ar ter --bea ter lin e 041950 -- 1...

Page 46

+ available separately 42 parts list models 8751/8754 de s cri p t io n part s up da t e re m arks w arr. Cl as s 8754 qty . 8751 qty . Part num be r t r im --l e f t re a r corne r 013761 1 103 t r im --ri ght r e a r corne r 020883 1 103 t r im --ri ght r e a r corne r 013663 1 103 tu be a. --m ix...

Page 47

43 + available separately models 8751/8754 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 8754 qty . 8751 qty . Part num be r opt ional f e a t ures w a ter c ooled bl o w er 012796 -- 1 1 103 +g ua rd --b low e r 022505 1 1 103 conde ns e r 048287 1 2 103 p a n e l a .-- lo ...

Page 48

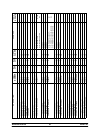

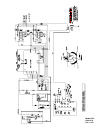

Model 8751 052613-27 rev. 11/02.

Page 49

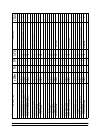

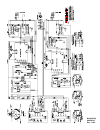

Model 8751 052613-33 rev. 11/02.

Page 50

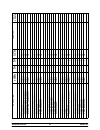

Model 8751 052613-40 rev. 11/02.

Page 51

Model 8751 052613-58 rev. 11/02.

Page 52

Model 8754 046585--27 rev. 11/02.

Page 53

Model 8754 046585--33 rev. 11/02.