- DL manuals

- Taylor

- Freezer

- 8752

- Operator's Manual

Taylor 8752 Operator's Manual

Summary of 8752

Page 1

Operator's manual model 8752, 8756, & 8757 soft serve freezers original operating instructions 028752- m 8/99 (original publication) (updated 8/14/14).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: amps minimum wire ampacity: amps part ...

Page 3: Table Of Contents

Table of contents models 8752, 8756, & 8757 table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 2 to the operator 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section...

Page 4

Table of contents models 8752, 8756, & 8757 table of contents - page 2 rinsing 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cleaning 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5: Section 1

1 models 8752, 8756, 8757 to the installer 131210 section 1 to the installer the following information has been included in the manual as safety and regulatory guidelines. For complete installation instructions, please see the installation checklist. Installer safety in all areas of the world, equip...

Page 6

2 models 8752, 8756, 8757 to the installer 101122 water connections (water cooled units only) an adequate cold water supply must be provided with a hand shut- off valve. On the underside rear of the base pan, two 3/8” i.P.S. (for single- head units) or two 1/2” i.P.S. (for double- head units) water ...

Page 7

3 models 8752, 8756, 8757 to the installer 130819 supply cords used with this unit shall be oil-resistant, sheathed flexible cable not lighter than ordinary polychloroprene or other equivalent synthetic elastomer-sheathed cord (code designation 60245 iec 57) installed with the proper cord anchorage ...

Page 8: Section 2

4 models 8752, 8756, 8757 to the operator 131210 section 2 to the operator the freezer you have purchased has been carefully engineered and manufactured to give you dependable operation. The taylor models 8752, 8756, and 8757 are highly sophisticated pieces of equipment, and when properly operated a...

Page 9: Section 3

5 models 8752, 8756, 8757 safety 130211 section 3 safety we, at taylor company, are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built- in safety features to protect both you an...

Page 10

6 models 8752, 8756, 8757 safety 130819 s supply cords used with this unit shall be oil-resistant, sheathed flexible cable not lighter than ordinary polychloroprene or other equivalent synthetic elastomer-sheathed cord (code designation 60245 iec 57) installed with the proper cord anchorage to relie...

Page 11: Section 4

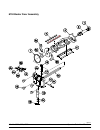

7 models 8752, 8756, 8757 operator parts identification 130117 section 4 operator parts identification model 8752.

Page 12

8 models 8752, 8756, 8757 operator parts identification 111129 8752 parts identification item description part no. 1 panel a.- front x22997 2 stud- nose cone 022822 3 bolt- carriage 012347 4 panel a.- lower side (r & l) x23956 5 panel- upper side left 028599 6 hood 050464 7 panel- upper rear 022074 ...

Page 13

9 models 8752, 8756, 8757 operator parts identification 130116 8752 beater door assembly.

Page 14

10 models 8752, 8756, 8757 operator parts identification 130116 8752 beater door parts identification item description part no. 1 seal- drive shaft 032560 2 shaft- beater 032564 3 beater a.- 3.4 qt. 1 pin x46231 4 clip- scraper blade 046236 5 blade- scraper- plastic 046235 6 kit a.- beater- front sh...

Page 15

11 models 8752, 8756, 8757 operator parts identification 111129 model 8756.

Page 16

12 models 8752, 8756, 8757 operator parts identification 111129 8756 parts identification item description part no. 1 panel a.- front x22879 2 stud- nose cone 022822 3 bolt- carriage 012347 4 panel a.- lower side (r & l) x23956 5 panel- upper side left 028599 6 hood 048526 7 panel- upper rear 022015...

Page 17

13 models 8752, 8756, 8757 operator parts identification model 8757.

Page 18

14 models 8752, 8756, 8757 operator parts identification 111129 8757 parts identification item description part no. 1 panel a.- front x36711 2 stud- nose cone 022822 3 bolt- carriage 1/4- 20 x 3/4 012347 4 panel a.- lower side- l/r x36741 5 panel- upper side left 028599 6 hood 048526 7 panel- upper ...

Page 19

15 models 8752, 8756, 8757 operator parts identification 8756 & 8757 beater door assembly item description part no. 1 seal- drive shaft 032560 2 shaft- beater 032564 3 beater a.- 3.4 qt. 1 pin x46231 4 clip- scraper blade 046236 5 blade- scraper- plastic 046235 *6a bearing- front 050348 *6b shoe- fr...

Page 20

16 models 8752, 8756, 8757 operator parts identification 140814 accessories item description part no. 1 brush- mix pump body 023316 2 brush- pressure switch 027647 3 brush- feed tube 021101 4 brush- double ended 013072 5 brush- rear bearing 013071 6 brush- draw valve 013073 7 lubricant- taylor 4 oz....

Page 21: Section 5

17 models 8752, 8756, 8757 important: to the operator section 5 important: to the operator model 8752 model 8756 model 8757.

Page 22

18 models 8752, 8756, 8757 important: to the operator parts identification for 8752, 8756, & 8757 item description 1 power switch (toggle) 2 reset switch 3 mix refrigeration control 4 standby key 5 wash key 6 auto key 7 pump key 8 mix low indicator 9 mix out indicator 10 heater switch symbol definit...

Page 23

19 models 8752, 8756, 8757 important: to the operator 091030 standby during long “no sale” periods it becomes necessary to warm the product in the freezing cylinder to approximately 35_ to 40_f (1.7_to 4.4_c) to prevent overbeating and product breakdown. When the standby key is pressed, the light co...

Page 24: Section 6

20 models 8752, 8756, 8757 operating procedures 071017 section 6 operating procedures the model 8752 has been selected to show you the pictured step- by- step operating procedures for both models contained in this manual. These models, for all practical purposes of operation, are the same. The size ...

Page 25

21 models 8752, 8756, 8757 operating procedures install the drive shaft through the rear shell bearing in the freezing cylinder and engage the hex end firmly into the gear box coupling. Be sure the drive shaft fits into the drive coupling without binding. Figure 2 step 2 install the beater assembly....

Page 26

22 models 8752, 8756, 8757 operating procedures step 3 assemble the freezer door. Place the large rubber gasket(s) in the groove(s) on the back side of the freezer door. Slide the white plastic front bearing(s) over the baffle rod(s), making certain that the flanged end of the bearing is resting aga...

Page 27

23 models 8752, 8756, 8757 operating procedures step 5 install the draw valve(s). Slide the two o- rings into the grooves on the draw valve(s) and lubricate. Figure 10 note: the models 8756 and 8757 have three draw valves. Lubricate the inside of the freezer door spout(s), top and bottom, and insert...

Page 28

24 models 8752, 8756, 8757 operating procedures step 7 snap the design cap over the bottom of each door spout. Figure 14 step 8 install the rear drip pan. Slide the rear drip pan into the hole in the side panel. Figure 15 step 9 install the front drip tray and the splash shield beneath the door spou...

Page 29

25 models 8752, 8756, 8757 operating procedures note: check bands have two smooth surfaces. A concave shape indicates an incorrect assembly. Turn the check band inside out to correctly expose the flat surface. Figure 19 step 3 put a small amount of lubricant inside the piston and insert the liquid v...

Page 30

26 models 8752, 8756, 8757 operating procedures insert the mix inlet fitting into the hole in the base of the liquid valve body. Figure 24 secure the pump parts in position by sliding the retaining pin through the cross holes located at the bottom of the pump cylinder. Figure 25 step 5 assemble the ...

Page 31

27 models 8752, 8756, 8757 operating procedures 140306 step 6 secure the air/mix pump. Place the pump collar over the pump cylinder. (the cross holes of the pump collar should be on top.) figure 28 align the drive hole in the piston to the ball crank of the motor reducer. At the same time, align the...

Page 32

28 models 8752, 8756, 8757 operating procedures air/mix pump assembly exploded view item description part no. 1 cap- pump (model 8752) 023324 cap- pump (models 8756/8757) 021276- 9 2 pin- retaining 021276- 8 3 pump assembly x36201 3a cylinder a.- pump 022345- 1 3b pin- retaining 021276- 8 3c piston ...

Page 33

29 models 8752, 8756, 8757 operating procedures 080820 sanitizing step 1 prepare a pail of approved 100 ppm sanitizing solution (examples: 2- 1/2 gal. [9.5 liters] of kay- 5r or 2 gal. [7.6 liters] of stera- sheenr). Use warm water and follow the manufacturer’s specific- ations. Place the pail of sa...

Page 34

30 models 8752, 8756, 8757 operating procedures step 7 press the pump key. A light will come on, indicating the air/mix pump is operating. This action will cause the sanitizing solution to be pumped through the air/mix pump and out through the pressure line. After approximately 15 seconds, press the...

Page 35

31 models 8752, 8756, 8757 operating procedures 071017 step 10 after 5 minutes, open the prime plug. Press the pump key. Pull the draw handle down and draw off the remaining sanitizer. Figure 41 step 11 once the sanitizer stops flowing from the door spout, close the draw valve. Press the pump and wa...

Page 36

32 models 8752, 8756, 8757 operating procedures 140306 step 5 place an empty pail beneath the door spout and open the draw valve. With the prime plug still in the up position, press the pump key. This will allow the mix to be pumped through the freezing cylinder and force out any remaining sanitizer...

Page 37

33 models 8752, 8756, 8757 operating procedures 140814 step 3 place the suction line in an empty pail in the mix cabinet. Step 4 if local health codes permit the use of rerun, place a sanitized, nsf approved stainless steel rerun container beneath the door spout. Open the draw valve and press the wa...

Page 38

34 models 8752, 8756, 8757 operating procedures 121218 repeat steps 1 through 7 for the other side of the freezer on the models 8756 and 8757. Step 8 place the power switch in the off position before disassembling the machine. Disassembly be sure the power switch is in the “off” position to eliminat...

Page 39

35 models 8752, 8756, 8757 operating procedures step 7 using the long, flexible brush and the cleaning solution, clean the mix inlet tube(s) located in the mix cabinet. Thoroughly clean the tube(s) all the way up to the freezing cylinder. This area needs special attention because bacteria and milkst...

Page 40: Section 7

36 models 8752, 8756, 8757 important: operator checklist 080820 section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by federal, state, or local regulatory agencies, and must be followed accordingly. I...

Page 41

37 models 8752, 8756, 8757 important: operator checklist 080820 j 7. If your machine is air cooled, check the condensers for accumulation of dirt and lint. Dirty condensers will reduce the efficiency and capacity of the machine. Condensers should be cleaned monthly with a soft brush. Note: for machi...

Page 42: Section 8

38 models 8752, 8756, 8757 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product is being dispensed. A. Low on mix. The mix out light is on. A. Add mix to the mix tank and press the auto key. 17 b. The power switch is in the off position. B. Plac...

Page 43

39 models 8752, 8756, 8757 troubleshooting guide problem probable cause remedy page ref. 2. Insufficient mix in the freezing cylinder. (cont’d.) d. Missing, defective, or no lubrication on the mix inlet fitting o- ring. D. Replace or evenly lubricate the o- ring on the mix inlet fitting. 25/ 43 e. T...

Page 44

40 models 8752, 8756, 8757 troubleshooting guide problem probable cause remedy page ref. 4. Product is too soft. A. Viscosity control is set too warm. A. Contact a service technician. - - - b. Worn scraper blades. B. Replace scraper blades regularly. 43 c. Dirty condensers or air filters on air cool...

Page 45

41 models 8752, 8756, 8757 troubleshooting guide problem probable cause remedy page ref. 8. Excessive mix leakage into the rear drip pan. A. Worn or missing drive shaft seal. A. Install or replace the seal. 20/ 43 b. Improper lubrication of the drive shaft. B. Lubricate properly. 20 c. Worn rear she...

Page 46

42 models 8752, 8756, 8757 troubleshooting guide problem probable cause remedy page ref. 11. The air/mix pump does not operate. A. The pump motor is not activated. A. Place the power switch in the off position. Push the reset button on the pump drive motor. Return the power switch to the on position...

Page 47: Section 9

43 models 8752, 8756, 8757 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 4 months every 6 months annually qty. Scraper blades x 2* drive shaft seal x 1* freezer door gasket x 1* front bearing x 1* beater shoes x 2* draw valve o- ring x 2** prim...

Page 48

44 models 8752, 8756, 8757 limited warranty on equipment 131210 section 10 limited warranty on equipment taylor company limited warranty on freezers taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor-branded freez...

Page 49

45 models 8752, 8756, 8757 limited warranty on equipment 3. Replacement of wear items designated as class “000” parts in the taylor operator’s manual. 4. External hoses, electrical power supplies, and machine grounding. 5. Parts not supplied or designated by taylor, or damages resulting from their u...

Page 50: Section 11

46 models 8752, 8756, 8757 limited warranty on parts 131210 section 11 limited warranty on parts taylor company limited warranty on taylor genuine parts taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor genuine r...

Page 51

47 models 8752, 8756, 8757 limited warranty on parts limited warranty exceptions this limited warranty does not cover: 1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of defective parts, replacement parts, or new parts. 2. Normal main...

Page 52

48 models 8752, 8756, 8757 limited warranty on parts limitation of warranty this limited warranty is exclusive and is in lieu of all other warranties, conditions and/or remedies under the law, including any implied warranties or conditions of merchantability or fitness for a particular purpose. The ...

Page 53: Section 12

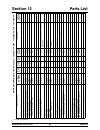

Section 12 parts list 49 + available separately models 8752, 8756, & 8757 parts list mai n ref ig e ra t io n syst em hp -62, 8752 - j6090915/ up ,8756 - j5032993/ up ,8757 - j51 11000/ up de s cri p t io n part num be r 8752 qty . 8756 qty . 8757 qty . W arr. Cl as s re m arks part s up da t e adap...

Page 54

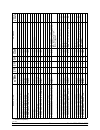

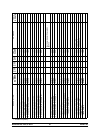

+ available separately 50 parts list models 8752, 8756, & 8757 111129 de s cri p t io n part s up da t e re m arks w arr. Cl as s 8757 qty . 8756 qty . 8752 qty . Part num be r brush- pressure sw it ch- 1/ 8” di a 027647 1 2 1 000 brush- rear brg 1 in .D x2i n .L gx14 013071 1 1 1 000 brush- 1/ 2 in...

Page 55

51 + available separately models 8752, 8756, & 8757 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 8757 qty . 8756 qty . 8752 qty . Part num be r cover- c ompressor- sound barri er 052816 1 103 j9025975/ up 139 cover a. -m ix tank x38726 1 103 cover- m ix storage- center 0388...

Page 56

+ available separately 52 parts list models 8752, 8756, & 8757 de s cri p t io n part s up da t e re m arks w arr. Cl as s 8757 qty . 8756 qty . 8752 qty . Part num be r door a. -3 spout x51532- 12 1 1 103 +gasket- d oor- 4 ” s hell 048926 2 2 000 +handle a .- draw -adj . X33687 3 3 103 +handle- adj...

Page 57

53 + available separately models 8752, 8756, & 8757 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 8757 qty . 8756 qty . 8752 qty . Part num be r plate- low e r h in ge 020323 1 1 1 103 holder- f use 300 volt panel mt. 027581 2 4 4 103 hood 050464 1 103 hood 048526 1 1 103 in...

Page 58

+ available separately 54 parts list models 8752, 8756, & 8757 140814 de s cri p t io n part s up da t e re m arks w arr. Cl as s 8757 qty . 8756 qty . 8752 qty . Part num be r o -ri ng -5 /1 6 o d x .070w 016272 1 1 000 o -ri ng -7 /8 o d x .103w 014402 6 6 000 ri ng- check 1- 1/ 4 o d x 3/ 8 03321...

Page 59

55 + available separately models 8752, 8756, & 8757 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 8757 qty . 8756 qty . 8752 qty . Part num be r pan a. -dri p *8756* x22811 1 103 expansi on valve pan a. -dri p *8757* x36761 1 103 expansi on valve pan- dri p 11- 5/ 8 l o n g ...

Page 60

+ available separately 56 parts list models 8752, 8756, & 8757 071018 de s cri p t io n part s up da t e re m arks w arr. Cl as s 8757 qty . 8756 qty . 8752 qty . Part num be r o -ri ng -1 -3 /8 o d x .103w 018664 1 2 2 000 o -ri ng -13/ 16 o d x .139w 021278 1 2 2 000 o -ri ng -2 -1 /8 o d x .139w ...

Page 61

57 + available separately models 8752, 8756, & 8757 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 8757 qty . 8756 qty . 8752 qty . Part num be r sw it ch- toggle- spst 012626 1 103 pri o r t o j 8120000 137 sw it ch- toggle- spst 015974 1 103 j8120000/ up 137 sw it ch a. -dr...

Page 62

+ available separately 58 parts list models 8752, 8756, & 8757 de s cri p t io n part s up da t e re m arks w arr. Cl as s 8757 qty . 8756 qty . 8752 qty . Part num be r tool- l iq .Valve body extracti n g 035793 1 1 1 000 tray- dri p 16- 7/ 8l x 5 -1 /8 020157 1 103 tray- dri p 22- 7/ 8l x 5 -1 /8 ...

Page 63

59 + available separately models 8752, 8756, & 8757 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s 8757 qty . 8756 qty . 8752 qty . Part num be r valve- access 1/ 4fl x 3/ 8solder 043232 2 2 103 valve- access- 1/ 4 m flx1/ 4 s- 90 047016 1 2 2 103 valve- epr 1/ 4s 022665 1 1 ...

Page 64

+ available separately 60 parts list models 8752, 8756, & 8757 de s cri p t io n part s up da t e re m arks w arr. Cl as s 8757 qty . 8756 qty . 8752 qty . Part num be r com p ressor l63a113bbka - b ri stol 048259- 40 1 2 2 512 mai n + c apaci t or- run- 25uf/ 370v 023739 1 2 2 103 m a in - s in g l...

Page 65

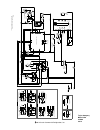

Model 8752 037808 04/14 taylor company 2014 carrier commercial refrigeration, inc. C grn/yel blk blk blk/wht gnd l2 l1 ol comp btr pump fan mix a1 a2 btr. Contactor m a1 a2 comp. Contactor comp l1 14 t3 t2 t1 l1 l2 l3 13 l1 l2 l3 13 14 t3 t2 t1 b b power switch 2pdt power/relay board grn/yel wht blk...

Page 66

Model 8752 037808-33 04/14 taylor company 2014 carrier commercial refrigeration, inc. C grn/yel blk blk blk/wht gnd l2 l1 ol comp btr pump fan mix a1 a2 btr. Relay m a1 a2 comp. Relay comp l1 l2 14 t3 t2 t1 l1 l2 l3 13 l1 l2 l3 13 14 t3 t2 t1 b b power switch 2pdt power/relay board grn/yel wht blk/w...

Page 67

Model 8752 037808-35 04/14 taylor company 2014 carrier commercial refrigeration, inc. C grn/yel blk blk blk/wht gnd l2 l1 ol comp btr pump fan mix a1 a2 btr. Relay m a1 a2 comp. Relay comp ext. Grd. L1 l2 14 t3 t2 t1 l1 l2 l3 13 l1 l2 l3 13 14 t3 t2 t1 b b power switch 2pdt power/relay board grn/yel...

Page 68

Model 8752 037808-40 04/14 taylor company 2014 carrier commercial refrigeration, inc. C grn/yel blk blk blk/wht gnd l2 l1 ol comp btr pump fan mix a1 a2 btr. Contactor m a1 a2 comp. Contactor comp l1 n 14 t3 t2 t1 l1 l2 l3 13 l1 l2 l3 13 14 t3 t2 t1 b b power switch 2pdt power/relay board grn/yel wh...

Page 69

Model 8752 037808-58 04/14 taylor company 2014 carrier commercial refrigeration, inc. C grn/yel blk blk blk/wht gnd l2 l1 ol comp btr pump fan mix a1 a2 btr. Relay m a1 a2 comp. Relay comp ext. Grd. L1 l2 14 t3 t2 t1 l1 l2 l3 13 l1 l2 l3 13 14 t3 t2 t1 b b power switch 2pdt power/relay board grn/yel...

Page 70

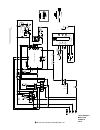

8756 037807 11/12/13 brn blk grn/yel mix low mix shk.Temp/ viscosity colder dip switch up = off 1-co mp 5 2-co mp 10 3-btr 5 4-btr 10 5-fan 2 6-stby dis 7-interval 8-interval sw itch interval 7 8 time off off on on off on off on 16 14 11 5 mix out draw shk pump mix 1 brl probe fan mix 2 set point mi...

Page 71

8756 037807-33 11/12/13 brn draw switch blk red blk brn red grn/yel mix hopper temp membrane switches brn blk grn/yel brn blk blk mix low mix shk.Temp/ viscosity colder dip switch up = off 1-comp 5 2-comp 10 3-btr 5 4-btr 10 5-fan 2 6-stby dis 7-interval 8-interval switch interval 7 8 time off off o...

Page 72

8756 037807-40 11/12/13 brn blk grn/yel mix lo w mix shk.Temp/ visco sity colder dip switch up = off 1-co mp 5 2-co mp 10 3-btr 5 4-btr 10 5-fan 2 6-stby dis 7-interval 8-interval switch interval 7 8 time off off on on off on off on 16 14 11 5 mix out draw shk pump mix 1 brl probe fan mix 2 set poin...

Page 73

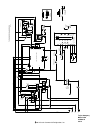

8757 042793-27 11/12/13 brn draw swi tch blk red blk brn red grn/yel mix hopper temp membrane swi tches brn blk grn/yel brn blk blk mix low mix shk.Temp/ vi scosi ty colder dip switch up = off 1-comp 5 2-comp 10 3-btr 5 4-btr 10 5-fan 2 6-stby dis 7-interval 8-interval swi tch interval 7 8 time off ...

Page 74

8757 042793-33 11/12/13 brn draw switch blk red blk brn red grn/yel mix hopper temp membrane switches brn blk grn/yel brn blk blk mix lo w mix shk.Temp/ viscosity co lder dip switch up = off 1-comp 5 2-comp 10 3-btr 5 4-btr 10 5-fan 2 6-stby dis 7-interval 8-interval switch interval 7 8 time off off...

Page 75

8757 042793-34 11/12/13 brn draw switch blk red blk brn red grn/yel mix hopper temp membrane switches brn blk grn/yel brn blk blk mix low mix shk.Temp/ viscosity colder dip switch up = off 1-comp 5 2-comp 10 3-btr 5 4-btr 10 5-fan 2 6-stby dis 7-interval 8-interval switch interval 7 8 time off off o...

Page 76

8757 042793-62 11/12/13 brn draw switch blk red blk brn red grn/yel mix hopper temp membrane switches brn blk grn/yel brn blk blk mix low mix shk.Temp/ viscosity colder dip switch up = off 1-comp 5 2-comp 10 3-btr 5 4-btr 10 5-fan 2 6-stby dis 7-interval 8-interval switch interval 7 8 time off off o...