Summary of BC12

Page 1

Model bc12 blender operating instructions 067802-m 7/24/09 (original publication) updated 4/13/11.

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: fax: e-mail: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: ...

Page 3: Table Of Contents

Model bc12 table of contents table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electrical connections 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 2 to ...

Page 4

Table of contents model bc12 table of contents - page 2 daily cleaning 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Sanitizing 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5: Section 1

1 model bc12 to the installer section 1 to the installer this machine is designed for indoor use only. Do not install the machine in an area where a water jet could be used to clean or rinse the machine. Failure to follow this instruction may result in serious electrical shock. Electrical connection...

Page 6: Section 2

2 model bc12 to the operator 101021 section 2 to the operator the blender you have purchased has been carefully engineered and manufactured to give you dependable operation. Mixing various candies, cookies, fruits, nuts, liquid flavors, and other food items into dairy slush or neutral slush has made...

Page 7: Section 3

3 model bc12 safety section 3 safety taylor is concerned about the safety of the operator when he or she comes in contact with the blender and its parts. Taylor has gone to extreme efforts to provide built-in safety features to protect both you and the service technician. As an example, warning labe...

Page 8

4 model bc12 safety s do not allow children or untrained personnel to operate this machine. S do not operate the unit unless all service panels and access doors are restrained with screws. S avoid contact with the agitator shaft and other moving parts. S make sure the splash guard is installed prior...

Page 9: Notes

5 model bc12 safety notes :.

Page 10: Section 4

6 model bc12 operator parts identification 110413 section 4 operator parts identification bc12 figure 1.

Page 11

7 model bc12 operator parts identification 110413 bc12 parts identification item description part no. 1 switch-rod-snap action 067650 2 spring-switch rod*bc12* 067648 3 rod a.-switch*bc12* 067647 4 bridge-rectifier w/wires 067646 5 rod-switch*bc12* 067649 6 cap-mixer 051484 7 screw-mixer-retainer ca...

Page 12: Section 5

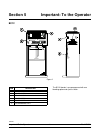

8 model bc12 important: to the operator 091020 section 5 important: to the operator bc12 figure 2 item description 1 pulse/rinse switch 2 power switch 3 program dial 4 reset switch 5 power cord 6 programming port the bc12 blender is pre-programmed with one blending option and a pulse switch..

Page 13

9 model bc12 important: to the operator on/off power switch the power switch is located on the front of the machine. The power switch controls the power to the machine. The switch illuminates when placed in the on position. Shut the power switch off at night and whenever the machine will be left una...

Page 14

10 model bc12 important: to the operator program dial the program dial allows the operator to select a number of pre-programmed settings. The machine will shut off automatically at the end of the program. Figure 7 reset switch the reset switch is located above the power switch on the front panel. Th...

Page 15: Section 6

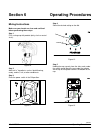

11 model bc12 operating procedures 091020 section 6 operating procedures mixing instructions make sure your hands are clean and sanitized before performing these steps. Step 1 fill a serving cup with product (dairy slush or neutral slush). Figure 10 step 2 add “mix-in” ingredients such as liquid fla...

Page 16

12 model bc12 operating procedures 100921 step 6 while holding the cup securely in your hand, use your fingers to push the switch rod (actuator), located behind the agitator, to activate a programmed blending cycle. Figure 14 step 7 using a swirling motion, gradually move the cup up and down around ...

Page 17

13 model bc12 operating procedures 091020 pulse switch operation make sure your hands are clean and sanitized before performing these steps. Step 1 place the power switch in the on position. Figure 17 step 2 hold the cup under the agitator and lift up, so the agitator touches the bottom of the cup. ...

Page 18

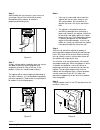

14 model bc12 operating procedures step 6 release the switch to stop the agitator. Figure 21 daily cleaning taylor recommends daily cleaning and sanitizing. Always follow local health codes step 1 prepare a sink with an approved cleaning solution (examples: kay-5r or stera-sheenr). Use hot water (11...

Page 19

15 model bc12 operating procedures 100921 sanitizing taylor recommends daily cleaning and sanitizing. Step 1 prepare a sink with an approved sanitizing solution (examples: kay-5r or stera-sheenr). Use hot water (110_f/43_c) and follow the manufacturer's specifications. Step 2 repeat steps 4 - 5 of t...

Page 20: Section 7

Section 7 parts list 16 parts list model bc12 100921 de s cri p t io n p art num be r qty . W arr. Cl as s re m arks alarm- audi ble w /m ount *bc12* 067660 1 103 agi t ator- c one* bc10* bc12* 067549 1 000 di sc agi t ator- m ixer- perm soft serve (g lobe) 051497 * 000 opti onal board- control- uni...

Page 21

17 model bc12 parts list 100921 de s cri p t io n re m arks w arr. Cl as s qty . P art num be r +rod a. -sw itch* bc12* 067647 1 103 +rod- sw itch* bc12* 067649 1 000 +seal- s w itch r od* b c12* 067651 1 000 +spri n g- sw it ch rod* bc12* 067648 1 000 sw it ch- selector- control* b 067634 1 103 kno...

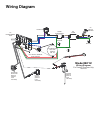

Page 22: Wiring Diagram

Wiring diagram model bc12 wiring diagram for training purposes only 2009hz0528 to programming port ground ground ground lit switch hall effect sensor - non-contact dc pm motor 220v-240v 50/60 hz pm - dc initiate switch (safety low voltage) pulse switch (safety low voltage) program selector switch (s...