- DL manuals

- Taylor

- Beverage Dispenser

- C006

- Operating Instructions Manual

Taylor C006 Operating Instructions Manual

Summary of C006

Page 1

Model c006 flavor dispenser operating instructions 066869--m 8/21/08 (original publication) (updated 8/16/12).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: fax: e-mail: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: ...

Page 3: Table Of Contents

Table of contents model c006 table of contents section 1 safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 2 to the installer 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installing th...

Page 4

Model c006 table of contents table of contents - page 2 dispensing flavor shots - hot beverages 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dispensing flavor shots - box of coffee 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dispensing flavor shots - ic...

Page 5: Section 1

1 model c006 safety 120816 section 1 safety we at taylor are concerned about the safety of the operator when he or she comes in contact with the dispenser and its parts. Taylor has gone to extreme efforts to design and manufacture built-in safety features to protect both you and the service technici...

Page 6

2 safety model c006 do not operate the dispenser unless all service panels and access doors are restrained with screws. Failure to follow this instruction may result in electrocution. Contact your local authorized taylor distributor for service. Do not operate the dispenser with larger fuses than sp...

Page 7: Section 2

3 model c006 to the installer section 2 to the installer overview the flavor shot dispenser model c006 dispenses nine flavors, combinations of flavors, and liquid sugar products in different volumes. The dispenser is supplied with a cord and grounding type plug. The dispenser is designed for indoor ...

Page 8

4 to the installer model c006 supply cords used with this unit shall be oil-resistant, sheathed flexible cable not lighter than ordinary polychloroprene or other equivalent synthetic elastomer-sheathed cord (code designation 60245 iec 57) installed with the proper cord anchorage to relieve conductor...

Page 9

5 model c006 to the installer air clearance always allow a minimum of 1” (25.4 mm) at the rear and 4” (102 mm) under the unit for adequate air flow. Warranty one year parts and labor, excluding wear items. Caution: warranty is valid only if required service work is provided by an authorized taylor s...

Page 10

6 to the installer model c006 installing the flavor shot dispenser step action 1 place the flavor shot dispenser where it will best serve your operation. 2 make sure that counters, platforms, and shelves are strong enough to support the weight of the dispenser and full containers of product (109 lbs...

Page 11: Section 3

7 model c006 operator parts identification section 3 operator parts identification exploded view item description part no. 1 switch-rocker (power switch) 048093 2 tray-drip 058346 3 shield a.-splash x59366 4 tube a.-outlet x59334.

Page 12

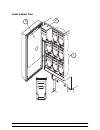

8 operator parts identification model c006 inside cabinet view 1 2 3 max. Fill line low level.

Page 13

9 model c006 operator parts identification inside cabinet view identification item description abbreviation part no. 1 syrup tank 062244- 2 cover-tank mix - - - 059133 3 decal-mag-instruction - - - 059532-tay important: there are nine individual flavor tanks. The tanks must be placed in their proper...

Page 14: Section 4

10 important: to the operator model c006 section 4 important: to the operator item description 1 power switch 2 flavor buttons 3 product buttons / calibration 4 size buttons / calibration 5 promo portion button 6 box of coffee button 7 sugar button 8 indicator lights (led) 9 lcd screen 10 clean/cali...

Page 15

11 model c006 important: to the operator power switch when the unit is plugged into a receptacle and the power switch is placed in the on position, the power indicator light will illuminate. The power switch is left in the on position during normal operations. Selection buttons flavor shot buttons t...

Page 16

12 important: to the operator model c006 flavor refill and level reset when a mix low condition is present, the flavor indicator will flash at 1/2 second intervals and at 1/4 second intervals when a mix out is present. When a mix out condition is present, that specific flavor will lock out until it ...

Page 17

13 model c006 important: to the operator service display menu the service display menu provides several screens to the operator and technician for set- up, monitoring and evaluation. To enter the service display menu, press the clean/cal button. The screen will prompt the operator to enter the acces...

Page 18

14 important: to the operator model c006 cleaning flavors and liquid sugar clean menu screen the clean menu screen allows the operator to clean a maximum of 4 flavors simultaneously, including the sugar. Step action 1 press the clean/cal button. The screen will prompt the operator to enter the acces...

Page 19

15 model c006 important: to the operator cleaning all flavors and liquid sugar clean all menu screen the clean all menu screen allows the operator to clean all the flavors and the liquid sugar simultaneously. Step action 1 remove the flavor tanks from the unit. 2 clean the inside of the unit with a ...

Page 20

16 important: to the operator model c006 prime all flavors and liquid sugar prime all menu screen the prime all menu screen allows the operator to prime all of the flavors, including liquid sugar, simultaneously. Be sure that every flavor, including liquid sugar, being primed has been refilled to th...

Page 21

17 model c006 important: to the operator calibrate flavors and liquid sugar calibrate menu screen the calibrate menu screen allows the operator to calibrate and dispense volume for each flavor and liquid sugar. Important: calibration is by weight, not volume. Step action 1 place a scale under the di...

Page 22

18 important: to the operator model c006 data menu data menu screen the data menu screen allows the operator to view the total number of cycles completed since the last reset for a product flavor combination. Step action 1 press the clean/cal button. The screen will prompt the operator to enter the ...

Page 23: Section 5

19 model c006 operating procedures section 5 operating procedures assembly and start up step action 1 plug the machine into an approved receptacle. The power indicator will illuminate on the front of the dispenser. 2 open the front door to the dispenser. 3 remove all tanks and lids. Always follow lo...

Page 24

20 operating procedures model c006 cleaning/sanitizing (continued) step action 10 press the “1” (x-sm) button to begin cleaning. The three flavors corresponding to the top row of flavor keys will clean first. Upon completion, the three flavors in the next row will clean, followed by the three flavor...

Page 25

21 model c006 operating procedures product tube removal/installation step action 1 discard any remaining product in the tank. 2 wash and rinse the tank and the lid. 3 fill the tank with clean water to the fill line on the tank. 4 place a cup under the dispensing spout. Note: refer to the “clean flav...

Page 26

22 operating procedures model c006 product tube removal/installation (continued) step action 16 follow the break in flavor instructions starting on page 23 for the flavor line that was replaced. 17 refer to cleaning flavors and liquid sugar on page14. Note: to minimize or eliminate any mistakes when...

Page 27

23 model c006 operating procedures break in flavor (product tube) step action 1 prepare a cleaning container with an approved 100 ppm cleaning/sanitizing solution (example: kay-5® or stera sheen®). Use warm water and follow the manufacturer's specifications. 2 remove all three syrup tanks from the s...

Page 28

24 operating procedures model c006 dispensing flavor shots - hot beverages to dispense flavor shots for hot beverages (coffee, hot chocolate), follow these steps: step action 1 select the appropriate cup for the customer's order. 2 place the cup under the dispensing spout. 3 press the flavor button....

Page 29

25 model c006 operating procedures dispensing flavor shots - box of coffee to dispense the flavor shots for the box of coffee, follow these steps: step action 1 place a small coffee cup under the dispensing spout and press the flavor button. 2 press the box of coffee button. This will dispense the p...

Page 30

26 operating procedures model c006 dispensing flavor shots - iced coffee to dispense the flavor shots for iced coffee, follow these steps: step action 1 select the appropriate cup for the customer's order. 2 fill the cup 2/3 full with ice. 3 place the cup under the dispensing spout. 4 press the flav...

Page 31

27 model c006 operating procedures dispensing flavor shots - latté (hot or iced) to dispense the flavor shots for latté drinks, follow these steps: step action 1 select the appropriate cup for the customer's order. 2 fill the cup 2/3 full with ice. Note: skip this step for hot latté. 3 place the cup...

Page 32: Section 6

28 cleaning and maintenance model c006 101005 section 6 cleaning and maintenance cleaning procedure always follow local health codes! To disassemble and clean the unit, the following items will be needed: s brushes (provided) s cleaner/sanitizer (example: kay-5® or stera sheen®) s single service han...

Page 33: Section 7

29 model c006 troubleshooting guide section 7 troubleshooting guide general troubleshooting problem probable cause remedy 1. Dispenser will not operate. A. Unit is not plugged in. A. Plug the unit into a receptacle. B. Power switch is in the off position. B. Place the power switch in the on position...

Page 34

30 troubleshooting guide model c006 problem probable cause remedy 3. An improper amount of product is being dispensed. A. Incorrect calibration. A. Re-calibrate. B. The product tube is obstructed or kinked. B. Clear the obstruction or kink. C. The product tube is not properly aligned over the pump r...

Page 35: Section 8

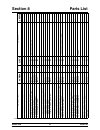

Section 8 parts list 31 + available separately model c006 parts list de s cri p t io n p art num be r qty . W arr. Cl as s re m arks p art s up dat e board- control- flavor s hot 058542- ser 1 103 brush- dbl e nd- pump & f eed 013072 1 000 brush- draw valve 1- 1/ 2” od 014753 1 000 brush- end- door-...

Page 36

+ available separately 32 parts list model c006 100712 de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r tank- m ix 2 *c006* 062244- 11 1 103 tank- m ix 3 *c006* 062244- 12 1 103 tray- dri p *c006* 058346 1 103 tube a. -o utlet *c006* x59334 1 103 tube a. -s ucti o n- ...

Page 37

Model c006 059359-12 rev. 10/10