- DL manuals

- Taylor

- Ice Maker

- C029

- Service Manual

Taylor C029 Service Manual - Refrigerant

10

Introduction

Model C029

101027

Refrigerant

______________________________

In consideration of our environment, Taylor

uses only HFC refrigerants. The HFC refrigerant

used in this unit is R404A. This refrigerant is

generally considered nontoxic and nonflammable,

with an Ozone Depleting Potential (ODP) of zero (0).

However, any gas under pressure is potentially

hazardous and must be handled with caution.

NEVER fill any refrigerant cylinder completely with

liquid. Filling the cylinder to approximately 80% will

allow for normal expansion.

This equipment uses CO2 and must be

installed in an area with adequate ventilation. CO2 in

high concentrations is toxic to humans and may

cause asphyxiation in confined areas.

Refrigerant liquid sprayed onto the skin may

cause serious damage to tissue. Keep eyes and skin

protected. If refrigerant burns should occur, flush

immediately with cold water. If burns are severe,

apply ice packs and contact a physician

immediately.

Taylor reminds technicians to be cautious of

government laws regarding refrigerant recovery,

recycling, and reclaiming systems. If you have any

questions regarding these laws, please contact the

factory Service Department.

WARNING: R404A refrigerant used in

conjunction with polyolester oils is extremely

moisture absorbent. When opening a refrigeration

system, the maximum time the system is open must

not exceed 15 minutes. Cap all open tubing to

prevent humid air or water from being absorbed by

the oil.

Compressor Warranty Disclaimer

The refrigeration compressor(s) on this machine are

warranted for the term indicated on the warranty

card accompanying this machine. However, due to

the Montreal Protocol and the U.S. Clean Air Act

Amendments of 1990, many new refrigerants are

being tested and developed; thus seeking their way

into the service industry. Some of these new

refrigerants are being advertised as drop-in

replacements for numerous applications. It should

be noted that, in the event of ordinary service to this

machine's refrigeration system, only the refrigerant

specified on the affixed data label should be used.

The unauthorized use of alternate refrigerants will

void your compressor warranty. It will be the owners'

responsibility to make this fact known to any

technicians they employ.

It should be noted, that Taylor does not warrant the

refrigerant used in its equipment. For example, if the

refrigerant is lost during the course of ordinary

service to this machine, Taylor has no obligation to

either supply or provide its replacement either at

billable or unbillable terms. Taylor does have the

obligation to recommend a suitable replacement if

the original refrigerant is banned, obsoleted, or no

longer available during the five year warranty of the

compressor.

Taylor will continue to monitor the industry and test

new alternates as they are being developed. Should

a new alternate prove, through our testing, that it

would be accepted as a drop-in replacement, then

the above disclaimer would become null and void.

To find out the current status of an alternate

refrigerant as it relates to your compressor, call the

local Taylor Distributor or the Taylor Factory. Be

prepared to provide the model/serial number of the

unit in question.

Summary of C029

Page 1

Service manual model c029 blended ice machine original service instructions 067214-s 2/15/10 (original publication) updated 02/10/16.

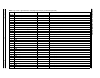

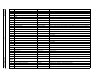

Page 3: Table Of Contents

Table of contents model c029 table of contents section 1: introduction 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Safety 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C0...

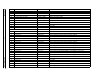

Page 4

Model c029 table of contents table of contents - page 2 section 3: troubleshooting 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . General troubleshooting 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Blender tro...

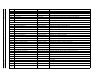

Page 5

Table of contents model c029 table of contents - page 3 parts list 95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Wiring diagram 114 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6

Model c029 table of contents notes:.

Page 7: Section 1: Introduction

1 model c029 introduction section 1: introduction s safety s c029 specifications s running specifications s general installation instructions s refrigerant s environmental notices s important to the operator.

Page 8: Safety

2 introduction model c029 130802 safety ______________________________ we at taylor are committed to manufacturing safe operating and serviceable equipment. The many built-in safety features that are part of all taylor® equipment are aimed at protecting operators and trained service technicians alik...

Page 9

3 model c029 introduction 130114 this unit must be installed on a level surface to avoid the hazard of tipping. Extreme care should be taken in moving this equipment for any reason. Two or more people are required to safely move this unit. Failure to comply may result in personal injury or equipment...

Page 10: C029 Specifications

4 introduction model c029 150604 c029 specifications the model c029 produces blended ice beverages such as smoothies and frozen coffee. The product and shaved ice are delivered automatically to a blending pitcher. Finished frozen beverages are produced in seconds. Refrigerated storage eight 2-gallon...

Page 11

5 model c029 introduction 150604 c029 specifications (continued) figure 1.

Page 12: Running Specifications

6 introduction model c029 130111 running specifications the following pressure settings are recommended by taylor for the model c029. Refrigerant pressure epr valve 67 to 69 psi (462 to 476 kpa) co2 pressure 90 psi (621 kpa) incoming water pressure 55 psi (380 kpa) incoming 175 psi (1.2 mpa) maximum...

Page 13

7 model c029 introduction 130111 general installation instructions caution: only trained, authorized service technicians should install the c029 blended ice machine. Failure to comply will void the factory warranty. The following are general installation instructions. For complete installation detai...

Page 14

8 introduction model c029 130111 installer safety in all areas of the world, equipment should be installed in accordance with existing local codes. Please contact your local authorities if you have any questions. Care should be taken to ensure that all basic safety practices are followed during the ...

Page 15

9 model c029 introduction 130802 caution: this equipment must be properly grounded! Failure to do so can result in severe personal injury from electrical shock! This unit is provided with an equipotential grounding lug that is to be properly attached to either the rear of the frame or the under side...

Page 16: Refrigerant

10 introduction model c029 101027 refrigerant ______________________________ in consideration of our environment, taylor uses only hfc refrigerants. The hfc refrigerant used in this unit is r404a. This refrigerant is generally considered nontoxic and nonflammable, with an ozone depleting potential...

Page 17: Environmental Notices

11 model c029 introduction 140808 environmental notices ______________________________ in consideration of our environment, taylor uses only earth friendly hfc refrigerants. The hfc refrigerant used in this unit is r404a. This refrigerant is generally considered nontoxic and nonflammable, with an ...

Page 18: Important To The Operator

12 introduction model c029 120111 important to the operator figure 2 item description function 1 rocker switch on/off switch which powers the machine on or off. 2 touch screen control interface screen which allows the operator to control the operation of the machine..

Page 19

13 model c029 controls and systems section 2: controls and systems s control overview s control assembly s blender control board s universal control board connections - uvc4 s refrigerant system s refrigerant system components s product delivery system s product delivery components s rinse station s...

Page 20: Control Overview (Uvc3)

14 controls and systems model c029 130909 control overview (uvc3) 8 1 x66815-ser interface board j8 j10 j6 j12 j11 l1 l2 j15 j16 j3 j18 j5 j4 w1 j2 a b thermistor probes +24vdc +12vdc 16vac syrup out 1 syrup out 2 syrup out 3 syrup out 4 syrup out 5 syrup out 6 syrup out 7 syrup out 8 reset j1 +5vdc...

Page 21

15 model c029 controls and systems 121026 control overview (uvc4 - production units) 1 1 1 8 6 8 1 9 2 10 1 1 1 10 6 +24v 12 vdc gnd +5v gnd 4 interface board x66815-ser j8 j10 j6 j12 j11 l1 l2 j15 j16 1 10 j3 j17 j18 j5 j4 w1 j1 j2 a b thermistors: 1 & 2 cabinet 3 & 4 dispense head +24vdc 1 8 +5vdc...

Page 22

16 controls and systems model c029 111205 control overview (uvc4 - field updated) figure 5.

Page 23: Control Assembly

17 model c029 controls and systems control assembly interface board jumpers pins 1 & 2 with the jumper installed: allows the clock to be changed without brush cleaning the unit. Pins 3 & 4 with the jumper installed: sets the unit to a brush cleaned state. Pins 5 & 6: unused pins 7 & 8: unused pins 9...

Page 24: Blender Control Board

18 controls and systems model c029 150223 blender control board figure 6 note: see page 57 for blender control board led indicator troubleshooting. Item description 1 motor-shaver *2 floor-hopper **3 115 vac power supply 4 fuse-board-driver i.O. 5 led-heartbeat item description ***6 panel-front w/cu...

Page 25

19 model c029 controls and systems 110630 universal control board connections - uvc4 beginning in january 2011, taylor started transitioning from the uvc3 to the uvc4. Note: uvc4 can only be used to replaced uvc3 boards. Uvc4 is not compatible with uvc1 or uvc2. Figure 7 the following chart identifi...

Page 26

20 controls and systems model c029 110630 universal control the universal control is the command center for the machine. The software program for the uvc3 control, including multiple language selections, resides in the eprom chip. The eprom chip is not used on the uvc4 universal control. The setting...

Page 27

21 model c029 controls and systems 110630 uvc4 jumper pin function and configuration chart uvc4 board function jumper installed initially jp1 pins 1 & 2 jumper installed-normal applications using refrigerated mix . No no jumper installed-general market configuation using non-refrigerated mix. Ignore...

Page 28

22 controls and systems model c029 110630 uvc3 eprom chip note: not applicable to uvc4. The eprom is inserted into a socket on the uvc3 board. The angled corner on the chip identifies the correct position for installation. A plcc type extraction tool (part no. 059479) is needed to remove the chip fr...

Page 29

23 model c029 controls and systems 110308 uvc3 software update the software update menu allows the user to install software updates by using an sd card. Note: if the uvc3 code version is v1.41 or earlier, bootloading is not available from the sd card. The first screen displays a warning to verify if...

Page 30

24 controls and systems model c029 figure 13 warning: power must not be removed from the system while the software update is being performed. If power is removed from the system while the software update is being performed, the software will be corrupted and a service call will be required to instal...

Page 31

25 model c029 controls and systems 121119 uvc4 cables - factory installed figure 15 boards installed at the factory have two cables connected to the uvc4 board. Connected at j13 is the usb cable part number 069491 (1), and connected at j12 is the lon cable part number 068582 (2)..

Page 32

26 controls and systems model c029 110726 uvc4 cables - field replacements figure 16 the uvc4 board is interchangeable with the uvc3 board. When replacing a uvc3 board in the field, use x69302 kit a.-uvc3 to uvc4, which contains the necessary adapter cable, usb cable, and communication adapter board...

Page 33: Refrigerant System

27 model c029 controls and systems refrigerant system (domestic units prior to s/n m1070287) epr valve 67-69 psi epr valve 67-69 psi thermistor for cabinet space thermistor for flavor lines flavor line evaporator liquid line solenoid valve dryer-2 cap tubes condenser compressor cabinet evaporator de...

Page 34: Refrigerant System

28 controls and systems model c029 150729 refrigerant system (domestic units starting with s/n m1070287 & all international units) figure 18.

Page 35

29 model c029 controls and systems 160205 refrigerant system components refrigeration set-up the refrigeration set-up menu item is available in the test menu. The refrigeration set-up menu turns on the liquid line solenoid and the hot gas solenoid and disables refrigeration. This menu item is used d...

Page 36: Product Delivery System

30 controls and systems model c029 product delivery system drain drain evaporator fan drain motor and magnetic drive magnetic coupling in pitcher base duckbill pump flow jet pitcher reed switch actuator pinch valve 75 psi low pressure switch cut in 90 psi cut out 80 psi pitcher pinch valve 24 vdc qu...

Page 37: Product Delivery Components

31 model c029 controls and systems 130111 product delivery components product storage the refrigerated cabinet can hold eight product bins. A bag is placed in each bin and connected with the inlet fitting. The cabinet door can be mounted on either side of the cabinet to allow it to open to the left ...

Page 38

32 controls and systems model c029 blender pitcher rinse station the blender pitcher rinse station activates when a pitcher is properly placed in position, which lowers the actuator. When the actuator is lowered, the magnet inside the actuator closes a reed switch beneath the bowl. After a one secon...

Page 39: Control Display

33 model c029 controls and systems 150420 control display beverage selection the beverage selection screen is displayed below. The product selection keys are used to select the product to dispense. The menu key is used to access the main menu. Figure 22 the product selection keys have color-coded bo...

Page 40: Manager Menu

34 controls and systems model c029 150420 manager menu there are three levels of menu access: main, manager, and service. Each level of access allows access to a greater number of menu options. To access the manager menu, press the menu key on the beverage selection screen. On the main menu screen, ...

Page 41

35 model c029 controls and systems 150420 the daylight savings time screen will display. Press the on key to enable daylight savings time or press the off key to disable daylight savings time. (see figure 28.) figure 28 press the ok key to confirm the selection. The screen will return to the main me...

Page 42

36 controls and systems model c029 scale the select temperature scale menu allows the user to select which temperature scale to use when displaying temperature; fahrenheit or celsius. The current temperature scale is displayed in the text bar at the top of the screen. If fahrenheit is displayed in t...

Page 43

37 model c029 controls and systems 110308 note: pressing the back key instead of the ok key returns to the manager menu without starting a manual defrost cycle. The schedule defrost menu allows the user to either select the intelligent mode or the number of defrost cycles to run daily. If the intell...

Page 44

38 controls and systems model c029 110308 drain pause the set drain pause menu allows the user to set the time between sequential pumping actions. The time is adjustable from 0 to 120 seconds. This is done to allow time for the rinser sink to empty before the next pump is activated to help prevent t...

Page 45: Service Menu

39 model c029 controls and systems 111101 service menu the service menu option allows an authorized service technician to access and modify critical operating parameters for the machine. All the menu screens found in the manager's menu are also included in the service menu. Entering access code to a...

Page 46

40 controls and systems model c029 enter the value by pressing the digits. The new value will appear in the text bar at the top of the screen. To save the new value, press the ok key and the display will return to the service menu. To return to the service menu without changing the daily lockout per...

Page 47

41 model c029 controls and systems 110308 change tube change single pinch tube the change single pinch tube menu allows the user to change and break in a single pinch tube. The first screen to display is the pinch valve selection screen. Press the number for the pinch tube to be changed. (see figure...

Page 48

42 controls and systems model c029 110308 if the file cannot be read from the usb flash drive, a file error screen displays. Get a replacement flash drive or update the flash drive with a valid software file. (see figure 45.) figure 45 pressing the next key will return to the service menu. If the so...

Page 49

43 model c029 controls and systems 110308 figure 49 if the previous screen is displayed longer than the time displayed, the update has been unsuccessful. The uvc4 board will have to be reprogrammed by an alternate means or the uvc4 board will have to be replaced. When the update is complete and succ...

Page 50

44 controls and systems model c029 110308 fault history fault history menu the fault history menu allows the technician to view the last forty faults. Faults are generated when a condition exists that may impact product quality, system functionality, and safety. Fault reporting is broken into a faul...

Page 51: Test Menu

45 model c029 controls and systems test menu refrigeration set-up and change tube are the menu items available in the test menu. (see figure 55.) figure 55 pressing one of the menu items will proceed to that menu item. Pressing the back key will return to the menu select screen. Refrigeration set-up...

Page 52

46 controls and systems model c029 note: pressing the back or next key before the bar graph times out stops the change tube process before completion. The back key returns the user to the test menu and the next key proceeds to the break in all tubes screen. Press the next key to display the break in...

Page 53: System Alerts

47 model c029 controls and systems 150416 system alerts when in the beverage select screen, the following message screens may be presented to alert the user to system events. Cleaning warnings clean in 23 hours the clean in 23 hours alert occurs 24 hours prior to the cleaning lockout. Pressing the n...

Page 54: System Faults

48 controls and systems model c029 system faults system faults are categorized by fault type and zone. The zone refers to the area of the unit or the product flavor experiencing the fault. The fault message screen will appear when the system has experienced a fault. The text at the top of the screen...

Page 55

49 model c029 controls and systems comm fail fault a comm fail fault in the shaver/blender zone indicates the control is unable to communicate with the shaver/blender unit. The fault clears once communication is reestablished. A comm fail fault in the uvc control zone indicates the control is unabl...

Page 56

50 controls and systems model c029 no pitcher fault a no pitcher fault occurs if the blending pitcher is not present prior to or removed during a dispense. Pressing the next key clears the fault and returns the screen to the beverage select screen. Any product dispensed prior to the fault should be ...

Page 57

51 model c029 troubleshooting section 3: troubleshooting s general troubleshooting s blender troubleshooting s touch screen troubleshooting s interface inputs/outputs.

Page 58: General Troubleshooting

52 troubleshooting model c029 general troubleshooting problem probable cause remedy blender pitcher is under-filling. Incorrect recipe was selected. Select the correct recipe. Ice hopper is out of ice. Refill ice hopper. Ice is bridging in the hopper. Use a sanitized cup to push the ice down into th...

Page 59

53 model c029 troubleshooting problem probable cause remedy product is too thin. Product, ice or yogurt is out of calib ration. Recalibrate. (note: if 6 oz of ice doesn't shave within 3 seconds, check blade for sharpness.) the ice chute is clogged. Remove and clean the ice chute. Co2 leak. Repair l...

Page 60

54 troubleshooting model c029 problem probable cause remedy machine will not dispense. No blender pitcher in dispensing area. Place blender pitcher into dispens ing area. Machine is not in the “ready to dis pense” mode. Press the menu/cancel key until the “ready to dispense” screen is dis played....

Page 61

55 model c029 troubleshooting 150810 problem probable cause remedy when attempting to dispense a drink, the keys won't work. No blender pitcher in dispensing area. Place blender pitcher into dispens ing area. Machine is not in the “ready to dis pense” mode. Press the menu/cancel key until the “rea...

Page 62: Blender Troubleshooting

56 troubleshooting model c029 blender troubleshooting ice shaver motor troubleshooting 1. Pin continuity a. Pins 8, 9, and 10 should have continuity. B. Pins 8, 9, and 10 should not have continuity to pins 1 7. C. No pins should have continuity to ground. If any of the continuity tests above fail, ...

Page 63

57 model c029 troubleshooting 141219 control board troubleshooting 1. Check the supply circuit providing power to the machine for proper voltage (~120 vac). 2. Turn the machine off, unplug, and wait 10 seconds for the charged capacitors to lose charge. Expose the control board and check these items ...

Page 64

58 troubleshooting model c029 141219 11. If the led is flashing 9 times, the shaver circuit detects an over currrent fault. Field test the motor. If the motor is okay and the fault persists, replace the drive. 12. If the led is flashing 10 times, the blender motor winding has a short to the motor ca...

Page 65

59 model c029 troubleshooting 160216 touch screen troubleshooting note: see the touch screen troubleshooting chart at the end of this section. Prior to beginning any touch screen troubleshooting, follow the steps below to verify that the uvc flash chip and sd card are compatible versions. Figure 61 ...

Page 66

60 troubleshooting model c029 how to perform the “s” test: start at one of the corners of the touch screen and make an “s” across the entire screen with your index finger. If the cursor jumps or disappears during this test, clean the touch screen and repeat the test. If after cleaning the screen the...

Page 67

61 model c029 troubleshooting 130116 t o uchs cre e n : bl a c k (o ff) turn pow er: on s tart t im ing t o uchs cre e n : s ti ll bl a ck (o ff) ? A b out 10 s e c onds a ft e r pow er up… n y che ck: 110v a c to m a chi ne , em i fi l t e r , p o we r s wit c h , uni t re l a y, 16 v a c t r a n s...

Page 68: Interface Inputs/outputs

Interface inputs/outputs 62 troubleshooting model c029 note: logic level = approximately 5 volts (high logic level) or ground (low logic level). Pin direction signal type signal function j1 pin 1 out to uvc3 (x67409 control pcb a.) 5vdc supply supplies 5vdc to uvc3 j1 pin 1 2 out to uvc3 (x67409 con...

Page 69

63 model c029 troubleshooting pin signal function signal type direction 5 gnd 6 in from syrup 3 out switch ~11vdc or gnd detects syrup when gnd 7 gnd 8 in from syrup 4 out switch ~11vdc or gnd detects syrup when gnd j8 pin 1 (not used) 2 (not used) 3 (not used) 4 (not used) j9 pin (j9 is not install...

Page 70

64 troubleshooting model c029 pin signal function signal type direction 40 in from uvc logic level control signal for hv output at j11-1 (island oasis power supply) 42 in from uvc logic level control signal for hv output at j11-8 (compressor relay) 44 in from uvc logic level control signal for hv ou...

Page 71

65 model c029 troubleshooting pin signal function signal type direction j17 pin 1 gnd 2 in from cabinet thermister analog dc analog dc inversely proportional to temperature 3 gnd 4 in from dispense head thermister analog dc analog dc inversely proportional to temperature 5 (not used) 6 (not used) j1...

Page 72

66 troubleshooting model c029.

Page 73: Section 4: Parts

67 model c029 parts section 4: parts s warranty explanation s exploded views s parts list s wiring diagram.

Page 74: Warranty Explanation

68 parts model c029 warranty explanation the c029 has a parts and labor warranty of three years, excluding wear items. Warranty is valid only if the parts are authorized taylor parts, purchased from an authorized taylor distributor, and the required service work is provided by an authorized taylor s...

Page 75

69 model c029 parts notes:.

Page 76

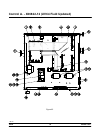

70 parts model c029 160210 model c029 main exploded view figure 63.

Page 77

71 model c029 parts 160210 model c029 main exploded view parts identification item description part no. 1 stand a.-basket x66259 2 screw-10-32x1/2 sltd 037734 3 cup-sensor 065194-33 4 manifold-c02 (see pg 83) 066271-12 5 switch-rocker dpst 067961 6 box a.-manifold *dpst x68265 7 cord a.-power-125v 0...

Page 78

72 parts model c029 150924 model c029 main exploded view parts identification (continued) item description part no. 77 hose-corrugated-1 x 96 066756-96 78 tube-vinyl 3/8 id x 9/16 od r30315 79 cord-power-125v-nema 066893 item description part no. 80 pan-drip *valve-exp-rear 067495 81 door a.-cart x6...

Page 79

73 model c029 parts notes:.

Page 80: Model C029 Operator Parts

74 parts model c029 150903 model c029 operator parts figure 64.

Page 81

75 model c029 parts 150903 model c029 operator parts identification item description part no. 1 cover a.-hopper-large 065194-2b 2 hopper a.-ice-large 065194-2a * label-bin *ice-fill 067920 3 dispenser a.-cup x66687 4 pitcher-blender-2 blade 083354 5 panel a.-cart-rear x68329 6 screw-10-32x1/2 sltd t...

Page 82

76 parts model c029 121119 control a. - x66822-12 (uvc4 field updated) figure 65.

Page 83

77 model c029 parts 150220 control a. - x66822-12 (uvc4 field updated) parts identification item description part no. 1 standoff-nylon-snap-7/16 068259 2 pcb a.-control *uvc4 x69277-ser 3 clamp-cable-flat ribbon 046367 4 cable-ribbon-50c-20"l-dil 040040-011 5 control-blended ice*roh 067702-ser 6 bus...

Page 84

78 parts model c029 150220 control a. - x66822-12 (uvc3) s/n m1044360 & prior figure 66.

Page 85

79 model c029 parts 150220 control a. - x66822-12 (uvc3) parts identification - s/n m1044360 & prior item description part no. 1 standoff-nylon-snap-7/16 068259 2 pcb a.-control see note 3 nut-6-32 keps nut 18-8 ss 054431 4 screw-6-32x7/8 sltd 007017 5 standoff-ss-6-32 x 1/2 l 067421 6 control-ser d...

Page 86

80 parts model c029 150729 condenser a.-compressor - x66121-12s figure 67.

Page 87

81 model c029 parts 150729 condenser a.-compressor - x66121-12s parts identification item description part no. 1 screw-8-32x1/4 socket hd 012321 2 shroud-condenser 068333-3 3 valve-solenoid 7/64orf 043449-12 4 screw-10x7/16 unsl td hwh 066234 5 dryer-two cap.Tubes 049346 6 valve-epr 1/4s 022665 7 co...

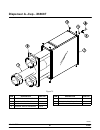

Page 88: Evaporator A. - X68061-12

82 parts model c029 120111 evaporator a. - x68061-12 figure 68 item description part no. 1 guard-fan 028534-1 2 screw-10-32x1/2 unsl hwh 049877 3 bracket-evaporator 066321 4 motor-fan 95.3 cfm 2700 062253-12 5 bracket a.-evaporator x68062 6 clamp-hose-snap it-17/32 052021 7 tube-vinyl 3/8 id x 9/16 ...

Page 89

83 model c029 parts 150903 manifold-co2 complete - 066271-12 figure 69 item description part no. 1 fitting-3/8 x 1/4mpt 066271-6 2 filter-inline 1/4 npt 066271-17 3 valve-dump 9-4300-55775-1-00 (-12) 066271-13 valve-dump-230v 60ha 1 phase (-27) 066271-28 valve-dump-240v 50hz 1 phase (-40) 066271-18 ...

Page 90: Valve-Inlet-H20 - 067805-12

84 parts model c029 150507 valve-inlet-h20 - 067805-12 (serial number m0017282 & up) figure 70 item description part no. 1 coil-valve*solenoid-h20 066872-03 2 valve-stem-drink 5/64 orifice 067805-06 3 valve-stem-rinse *5/32 orifice 067805-05 4 regulator*water-inlet 067805-03 5 switch-pressure *water...

Page 91: Valve-Inlet-H20 - 066872-12

85 model c029 parts 150507 valve-inlet-h20 - 066872-12 (old valve - serial number m0017281 & prior) figure 71 item description part no. 1 coil-valve*solenoid-h20 066872-03 2 valve-stem-drink 067805-06 3 valve-stem-rinse 067805-05 4 regulator-water 065173 5 pressure switch 066872-08 item description ...

Page 92

86 parts model c029 150729 plate a.-dec. Touch - x67485 figure 72 item description part no. 1 nut-10-32 flange lock 079150 2 plate-speaker 072071 3 speaker-micro-mylar cone 065333 item description part no. 4 shield-grease-speaker 071118 5 plate a.-mounting x67486.

Page 93: Dispenser A.-Cup - X66687

87 model c029 parts 150729 dispenser a.-cup - x66687 figure 73 item description part no. 1 dispenser-cup*adjustable 066691 2 cover-dispenser*cup 066690 3 rivet-1/8d .065-.125 gr. Ss 022517 4 washer-.281idx1.00odx.063 079754 item description part no. 5 nut-wing-1/4-20 nylock 039126 6 cap-vinyl-round-...

Page 94: Bracket A.-Tray - X66840

88 parts model c029 150903 bracket a.-tray - x66840 figure 74.

Page 95

89 model c029 parts 150903 bracket a.-tray - x66840 parts identification item description part no. 1 bracket a.-tray x66839 2 screw-10-32x1/2 sltd truss 037734 3 valve-shutoff-1/4 barb 066071 4 manifold a.-soda x66625 5 nut-10-32 flange locknut 020983 6 hose-bev.-.250idx.438od r30317 7 hose-bev.-.25...

Page 96: Sensor A.-Rinse - X66383

90 parts model c029 150729 sensor a.-rinse - x66383 figure 75 item description part no. 1 block-sensor *rinser 066382 2 switch-reed*door interlock 056249 item description part no. 3 plate-support-sensor 065121 4 screw-10x7/16 unsl td hwh 066234.

Page 97

91 model c029 parts 150220 plate a.-pinch valve - x68100 figure 76 item description part no. 1 tube-poly-4mm od x 2.5 mm 065306-40 2 tube-poly-4mm od x 2.5 mm 065306-12 3 plate-mount-pinch valve 068099 item description part no. 4 screw-10-32x3/8 serrated 075985 5 valve-pinch w/tee-celcon 069176 6 pl...

Page 98: Bracket A.-Fitment - X66890

92 parts model c029 150903 bracket a.-fitment - x66890 figure 77 item description part no. 1 elbow-inlet-liquid-pump -bib 065884 2 o-ring-9/16 od x .103w 016369 3 clamp-hose 13/16-stepless 062944 4 tube-pvc-clr-1/2 id r30320 5 clip-retaining-sw-syr pressure 048710 6 switch-vacuum-mix-17" hg co 06803...

Page 99: Accessories

93 model c029 parts 150220 accessories figure 78.

Page 100

94 parts model c029 150220 accessories parts identification item description part no. 1 kit a.-brush x68468 1a brush-tube *mix 068460 1b brush-end-door-spout-ss 039719 1c brush-mix pump body-3" x 7" 023316 2 tube a.-cleaning x66468 3 pail-wash 067960-w 4 pail-sanitize 067960-s 5 pail-rinse 067960-r ...

Page 101: Parts List

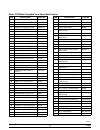

Parts list 95 + available separatel y, nnn = not a service item, * see remarks model c029 parts list 160210 description part number qty. Warr. Class remarks c02912h000 - 115v 60hz 1ph - a/c-tecumseh-(r404a) - standard unit actuator a.-rinser *c029* x66755 1 103 s/n k9064898 - new magnet 5/21/09 arma...

Page 102

+ available separately, nnn = not a service item, * see remarks 96 parts list model c029 description remarks warr. Class qty. Part number brush * 000 see kit a.-brush x68468 kit a.-brush x68468 1 000 brush-mix pump body-3" x 7" 023316 1 000 brush-end-door-spout-ss-ht 039719 1 000 brush-tube *c029* m...

Page 103

97 + available separately, nnn = not a service item, * see remarks model c029 parts list description remarks warr. Class qty. Part number +screw-5/16-18x7/8 serr. Hwh 017973 8 000 chip-software c029tc ts uvc4 x40621-ser 1 103 touchscreen chute-shaver *c029* ice 065194-7 2 000 net item to store clamp...

Page 104

+ available separately, nnn = not a service item, * see remarks 98 parts list model c029 description remarks warr. Class qty. Part number cover-box *c029* manifold 066253 1 103 cover-cone*c029*island oasis 065194-49 1 103 s/n m1015079 & up cover-control *c029* 065086 1 103 cover-pump *c029* center 0...

Page 105

99 + available separately, nnn = not a service item, * see remarks model c029 parts list description remarks warr. Class qty. Part number +element-filter*c029*90 micro 066271-17r 1 000 fitting-3/8 mor x 1/4 barb-ss 049427 1 103 replaces 059981 3/8 mor x 3/8 barb-ss 4/1/2009 fitting-3/8 mor x 3/8barb...

Page 106

+ available separately, nnn = not a service item, * see remarks 100 parts list model c029 description remarks warr. Class qty. Part number +screw-1/4-20x1 hex head cap 017254 2 000 hinge-door-rh-top *c029* 066294-70 1 103 +screw-1/4-20x1 hex head cap 017254 2 000 m0018102 holder-bottle *c029* front ...

Page 107

101 + available separately, nnn = not a service item, * see remarks model c029 parts list description remarks warr. Class qty. Part number kit a.-control touch screen x67213-ser 1 212 +chip-software c029tc ts uvc4 x40621-ser 1 103 kit a.-pan-drain *c029* x6519417sv 1 103 replaces 083582 pan-drain ki...

Page 108

+ available separately, nnn = not a service item, * see remarks 102 parts list model c029 description remarks warr. Class qty. Part number label-mix *c029* 067466-008 3 000 c029-12 label-mix *c029* 067466-001 * 000 n/a use 067466-008 label-on/off-co2-pump-mix 067444-003 1 000 label-skirt *c029* 0679...

Page 109

103 + available separately, nnn = not a service item, * see remarks model c029 parts list description remarks warr. Class qty. Part number gauge-pressure 0-100 psi1/8npt 066271-5 1 103 gauge-pressure 0-60 psi 1/8npt 066271-14 3 103 plug-1/4 npt-parker: 066271-4 1 103 regulator-co2 0-100 psi 066271-1...

Page 110

+ available separately, nnn = not a service item, * see remarks 104 parts list model c029 description remarks warr. Class qty. Part number pail-sanitize *c029* 067960-s 1 000 s/n k9093386 & up - replaces x66168-s - u/d 208 pail-wash *c029* 067960-w 1 000 s/n k9093386 & up - replaces x66189-w - u/d 2...

Page 111

105 + available separately, nnn = not a service item, * see remarks model c029 parts list description remarks warr. Class qty. Part number regulator-co2 0-60 psi 066271-11 3 103 manifold-co2 regulator-co2 0-100 psi 066271-15 1 103 manifold-co2 regulator*c029*water-inlet 067805-03 1 103 relay-start-c...

Page 112

+ available separately, nnn = not a service item, * see remarks 106 parts list model c029 description remarks warr. Class qty. Part number switch-pressure 066271-10 1 103 manifold-co2 switch-reed*door interlock*60" 056249 1 103 rinse sensor +screw-10x1/2 unsltd hwh 055389 3 000 switch-rocker dpst of...

Page 113

107 + available separately, nnn = not a service item, * see remarks model c029 parts list description remarks warr. Class qty. Part number tube-pvc-clr-1/2 id-polyspring 067199-18 1 000 tube-pvc-clr-1/2 id-polyspring 067199-24 1 000 tube-poly-4mmod x 2.5mmid x12" 065306-12 7 000 co2 lines tube-poly-...

Page 114

+ available separately, nnn = not a service item, * see remarks 108 parts list model c029 description remarks warr. Class qty. Part number +valve-stem-rinse 5/32 orifice 067805-05 * 103 5/32 orifice - valve stem available separately valve-pinch-w/tee-celcon/ss sp 069176 8 103 s/n m0017282 & up s/b #...

Page 115

109 + available separately, nnn = not a service item, * see remarks model c029 parts list description remarks warr. Class qty. Part number c02927lw00 208-230v 60hz 1ph danfoss (r134a) rohs compliant block-terminal 2p l1,l2 039422 1 103 208-230v 60hz 1ph brush-draw valve 1-1/2"od 014753 1 000 chip-so...

Page 116

+ available separately, nnn = not a service item, * see remarks 110 parts list model c029 description remarks warr. Class qty. Part number gauge-pressure 0-60 psi 1 066271-14 3 103 plug-1/4 npt-parker: 066271-4 1 103 regulator-co2 0-100 psi 066271-15 1 103 regulator-co2 0-60 psi 066271-11 3 103 swit...

Page 117

111 + available separately, nnn = not a service item, * see remarks model c029 parts list description remarks warr. Class qty. Part number label-caution-grd-perm-pt 032164-ps 1 000 label-door-move part-pt/s 032749-ps 3 000 label-mix *c029* 067466-009 1 000 label-warn-cover-portugue 051433-pt 7 000 l...

Page 118

+ available separately, nnn = not a service item, * see remarks 112 parts list model c029 description remarks warr. Class qty. Part number kit a.-board-circuit*c029*driv x6519441sv 1 212 kit a.-motor blender *c029* x6519430sv 1 103 kit a.-motor-shaver x6519446sv 1 103 label-mix *c029* 067466-014 3 0...

Page 119

113 + available separately, nnn = not a service item, * see remarks model c029 parts list description remarks warr. Class qty. Part number plug-hole 7/8 dia. Black 010077 1 000 relay-spst-30 a-240 v 032607-27 2 103 supply-power 60w 24vdc 068876 1 103 s/n m1051524 & up - prior 059313-12 valve-inlet*c...

Page 120

Model c029 067978-12c 10/15 taylor company 2015 carrier commercial refrigeration, inc. C.