- DL manuals

- Taylor

- Freezer

- C302

- Operating Instructions Manual

Taylor C302 Operating Instructions Manual

Summary of C302

Page 1

Model c302 slush freezer original operating instructions 059661-m 6/22/04 (original publication) (updated 4/5/11).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: fax: e-mail: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: ...

Page 3: Table Of Contents

Model c302 table of contents table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 2 to the operator 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 3 safety 6 . ....

Page 4

Table of contents models c302 table of contents - page 2 disassembly 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Brush cleaning 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5: Section 1

1 model c302 to the installer section 1 to the installer the following are general installation instructions. For complete installation details, please see the checkout card. Installer safety in all areas of the world, equipment should be installed in accordance with existing local codes. Please con...

Page 6

2 model c302 to the installer 110329 air cooled units air cooled units require a minimum of 3” (76 mm) of air space on both sides, 3” (76 mm) at the rear, and 12” (305 mm) on the top of the unit. Minimum air clearances must be met to assure adequate air flow for optimum performance. Water cooled ref...

Page 7

3 model c302 to the installer 101130 electrical connections each freezer requires one power supply. Check the data label on the freezer for branch circuit overcurrent protection or fuse, circuit ampacity and electrical specifications. Refer to the wiring diagram provided inside of the control box, f...

Page 8

4 model c302 to the installer 110329 initial freezing cylinder cleaning due to the types of products used in fcb equipment, it is imperative that the freezing cylinder and the inlet tube be thoroughly brush cleaned, rinsed, and sanitized before running any product. Prepare a cleaning solution, using...

Page 9: Section 2

5 model c302 to the operator 110329 section 2 to the operator the freezer you have purchased has been carefully engineered and manufactured to give you dependable operation. The model c302, when properly operated and cared for, will produce a consistent quality product. Like all mechanical products,...

Page 10: Section 3

6 model c302 safety 110329 section 3 safety we, at taylor company, are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built-in safety features to protect both you and the service ...

Page 11

7 model c302 safety 080826 s do not allow untrained personnel to operate this machine. S do not operate the freezer unless all service panels and access doors are restrained with screws. S do not remove any internal operating parts (example: freezer door, beater, scraper blades, etc.) unless all con...

Page 12: Section 4

8 model c302 operator parts identification section 4 operator parts identification c302 figure 2 item description part no. 1 panel-side*left 059721 2 panel-rear 059657 3 panel-side*right 059722 4 display-lighted 059584-27 5 panel-front-upper 059577 6 panel-front-shell 059576 item description part no...

Page 13

9 model c302 operator parts identification 100323 beater door assembly figure 3 item description part no. 1 door a.-slush press. X39572-bla 1a cap-spout-door-fcb-blk 046191-bla 1b spring-comp.480x.072x3.0 039320 1c valve-draw-door-press. 039324 1d o-ring-9/16 od x .103w 016369 1e spout-door-fcb-blac...

Page 14

10 model c302 operator parts identification accessories figure 4 item description part no. 1 pail-mix 10 qt 013163 2 brush-mix pump body-3”x7” 023316 3 brush-double ended 013072 4 brush-rear brg 1”dx2“l 013071 item description part no. 5 brush-draw valve 1-1/2”od 014753 6 kit a.-tune up x59121 7 lub...

Page 15: Section 5

11 model c302 important: to the operator section 5 important: to the operator figure 5 item description 1 control switch-left side 2 control switch-right side 3 keypad 4 liquid crystal display 5 product light control switches there are two control switches located at the top left corner of the upper...

Page 16

12 model c302 important: to the operator liquid crystal displays there are two liquid crystal displays (lcd's) located on the upper front panel behind the illuminated display. The two lcd's display information for the two freezing cylinders located directly beneath them. These pairs of freezing cyli...

Page 17

13 model c302 important: to the operator 060823 operator menu timeout if the display is left in the operator menu or any of the operator menu selections, except for current conditions, the display will return to the system mode screen 60 seconds after the last keypress. The current conditions screen...

Page 18

14 model c302 important: to the operator 6. Syrup press low - when the syrup out indicator displays a lack of syrup, the barrel will enter a hold mode. At this time, no refrigeration or product flow from the flow control will be allowed. Only the beater will operate. When the syrup is satisfied the ...

Page 19

15 model c302 important: to the operator screen c is set clock. Use the auto (- ->) and off ( element to be set (hours, minutes, month, day, or year). Use the prime (+++) and beater (- - -) keys to increment or decrement the value. Press the menu (sel) key to advance to the daylight saving time scre...

Page 20

16 model c302 important: to the operator the fourth feature will display the power saver mode, off, rest, or standby status. If the power saver mode is off, the following screen will be displayed. Power saver mode off sel if a power saver mode is programmed, one of the following screens will appear....

Page 21

17 model c302 important: to the operator press the auto (- ->) key to move to the next screen. The next screen will indicate when the fault was satisfied. Fault history 2 02/25/04 14:06:19 restored from fault page 2 + + + - - - sel press the menu (sel) key to return to the operator menu. Screen h is...

Page 22

18 model c302 important: to the operator co 2 out indicator auto mode auto ok syrup ok co2-out water-ok on the lcd, if the word “out” appears next to the word “co2” it indicates a lack of co2 being supplied to the freezer. The product light will also illuminate and a warning tone will sound. This wi...

Page 23: Section 6

19 model c302 operating procedures section 6 operating procedures the model c302 contains four 7 quart (6.6 liter) freezing cylinders. Caution: this unit is pressurized when in operation. The control switches must be in the off position until the unit is completely assembled. No part should ever be ...

Page 24

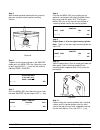

20 model c302 operating procedures step 2 lubricate the inside diameter of the drive shaft seal. Install the drive shaft seal bushing in the drive shaft seal. Figure 7 note: the drive shaft bushing must be positioned in the center of the drive shaft seal. Step 3 slide the seal and bushing over the s...

Page 25

21 model c302 operating procedures step 6 align the flats on the end of the beater assembly with the drive shaft. Make sure the beater assembly locating pin is in position in the locating hole of the drive shaft. Turn the beater slightly to be certain that the beater is properly seated. When in posi...

Page 26

22 model c302 operating procedures step 9 snap the draw valve handle onto the door spout. Align the hole in the draw valve with the slot in the draw handle. Figure 15 step 10 slide the pivot pin through the draw handle and into the draw valve. Figure 16 step 11 place the draw handle slide over the o...

Page 27

23 model c302 operating procedures step 14 install the prime plug. Place the two o-rings on the prime plug and lightly lubricate. Figure 20 figure 21 step 15 place the large o-ring into the door groove and lightly lubricate. Figure 22 note: every four months or less, discard the o-rings and install ...

Page 28

24 model c302 operating procedures 080307 sanitizing important: if a unit is sanitized, and will not be used for an extended period of time, clean water should be used to flush all sanitizer from the lines. Remove the water from all the lines and components prior to storage of the unit. Upon return ...

Page 29

25 model c302 operating procedures step 5 with the bag connector attached to the syrup line, place the syrup line into the pail of sanitizing solution. Figure 28 step 6 to place the left freezing cylinder in the sanitize mode, press the menu (sel) key. Move the cursor by pressing the auto (- ->) key...

Page 30

26 model c302 operating procedures step 12 press the beater (- - -) key. Agitate the solution in the freezing cylinders for five minutes. Figure 30 step 13 with a pail beneath the door spouts, open the draw valves and drain all the solution from the freezing cylinders. Press the off ( draw valves. F...

Page 31

27 model c302 operating procedures step 5 press the prime (+ + +) key. Figure 34 step 6 slowly move the syrup sampling valve to the fully open position by turning the handle “down” toward the sampling line. Allow the liquid to run into a pail until all the sanitizer is removed and full strength prod...

Page 32

28 model c302 operating procedures step 9 to adjust the brix, turn the adjustment screw located behind the drip tray shelf. Clockwise adjustments increase the amount of syrup to water, and counterclockwise adjustments decrease the amount of syrup to water. Adjust the screw in small increments and ch...

Page 33

29 model c302 operating procedures step 15 close the illuminated display when complete. Replace the panels and the hood, and attach with screws. Install the front drip tray and the splash shield on the front of the freezer. Figure 41 120 day closing procedure we recommend that the machine be complet...

Page 34

30 model c302 operating procedures 080307 rinsing note: the following instructions are for one pair of freezing cylinders under an lcd. After the instructions are complete, repeat for the two freezing cylinders on the other side of the machine under the other lcd. Step 1 to place the left cylinder i...

Page 35

31 model c302 operating procedures pressing the menu (sel) key will give you the option to sanitize the left cylinder. Move the cursor under the word “yes”. Pressing the menu (sel) key at this time will start the flow of cleaner/sanitizer through the syrup system into the freezing cylinder. Sanitize...

Page 36

32 model c302 operating procedures 080926 brush cleaning step 1 prepare a sink or a pail with an approved cleaning solution. Use warm water and follow the manufacturer's specifications (examples: kay-5® or stera-sheen®). Important: follow the label directions. Too strong of a solution can cause part...

Page 37: Section 7

33 model c302 important: operator checklist 080926 section 7 important: operator checklist during cleaning and sanitizing always follow local health codes cleaning and sanitizing schedules are governed by your state or local regulatory agencies and must be followed accordingly. The following check p...

Page 38

34 model c302 important: operator checklist winter storage if the place of business is to be closed during the winter months, it is important to protect the freezer by following certain precautions, particularly if the building is subject to freezing conditions. Disconnect the freezer from the main ...

Page 39: Section 8

35 model c302 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. Product is too stiff. A. Too much water to syrup ratio. Improper brix adjustment. A. Adjust the brix accordingly. 27 b. Consistency control needs adjustment. B. Contact a service technician...

Page 40

36 model c302 troubleshooting guide problem probable cause remedy page ref. 6. Unable to remove the drive shaft from the rear shell bearing. A. Rounded corners of hex end of drive shaft, drive coupling, or both. A. Replace the drive shaft, or call a service technician to replace the direct drive uni...

Page 41: Section 9

37 model c302 parts replacement schedule section 9 parts replacement schedule part description every 4 months every 8 months annually scraper blade x drive shaft seal x drive shaft o-ring x freezer door o-ring x draw valve o-ring x door spout o-ring x front bearing x prime plug o-ring x black bristl...

Page 42: Section 10

Section 10 parts list 38 parts list model c302 090521 + available separately de s cri p t io n p art num be r qty . W arr. Cl as s re m arks p art s up dat e arm a .- id ler *356* x64892 2 103 accumulator- c opper 2" di a 13" 053377 2 000 beari n g- front- slush- pressure 039349 4 000 beari n g- rea...

Page 43

39 model c302 parts list + available separately de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r +capaci t or- run 35uf/ 440v 048132 2 103 +relay- start- compressor 051957- 27 2 103 +capaci t or- s tart 189- 227uf/ 250v 053106 2 103 compressor c s17k6e- pfv- 238 05239...

Page 44

40 parts list model c302 + available separately de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r +cap- spout- d oor- f cb- black 046191- bla 4 103 +handle- draw -fcb- black 046192- bla 4 103 +nut- spout- d oor- slush- pressure 039323 4 103 +o -r in g -1. 129 o d x. 98...

Page 45

41 model c302 parts list + available separately de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r harness- w ire- h i volt- r *c302 059622- 27 1 103 208- 230v 60hz 1 ph/ 3 ph holder- f use- in li ne- t ype hlr 045606 2 103 ho o d *c 302* 059658 1 103 ki t a. -tune up *...

Page 46

42 parts list model c302 + available separately de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r li ne a. -c o2 man/ sol vlv x59672 1 103 sol vlv & c arb adaptor- s w v 1/ 4fflx1/ 4 barb- ss 016715 4 103 hose- bev. -. 250i dx. 438od- 100' r30317 1' 000 li ne a. -c o2 ...

Page 47

43 model c302 parts list + available separately de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r li ne a. -l iq ui d *c302* left x59632- 27 1 nnn elbow -3/ 8s- street- short radi us 013017 2 000 fi tti ng- 3 /8 fs x 3 /8 fs x 3 /8 fs 062265 1 103 valve- so l- 7/ 64 o ...

Page 48

44 parts list model c302 + available separately de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r fi tti ng- 3 /8 mor x 1/ 4 barb- ss 049427 1 103 hose- beverage- .265 id x. 465 r30313 7' 000 mani fold- s oda f cb 059438 1 103 valve- check 3/ 8 o ri ng x1/ 4 barb 05936...

Page 49

45 model c302 parts list 110405 + available separately de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r chi p- softw are u vc2 u 11 x40876- ser 2 103 control- slush- in tf w /ntb r ohs 064254 2 212 4/ 1/ 11: r e p la c e s n o n -r o h s b o a r d x 45622 pro b e a .-...

Page 50

46 parts list model c302 + available separately de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r shro ud a. -c o ndenser *c 302* x59569 1 103 sw it ch- membrane- 5 posi ti on- 23" 053138 4 103 sw it ch- pressure- c 02- au contact 059225 1 103 cut in 74 psi cut out 6 0...

Page 51

47 model c302 parts list + available separately de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r valve- reli ef 30 psi 1/ 8 m pt ss 039365 4 103 tube- feed- m ix 056807- 5 4 103 cli p -r etai ner *c300* tube- m ix 056822 4 000 bottom screw -6x3/ 8 h i- lo phl pnhd- ss...

Page 52

48 parts list model c302 + available separately de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r hose- rubber 1/ 2 id x 7/ 8 o d r50200 5' 000 label- inlet 037288 1 nnn li ne a. -w ater- o utlet x62459 1 103 li ne a. -w ater* inlet* c 302* x64398 1 103 panel- s id e- ...

Page 53

49 model c302 parts list + available separately de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r harness- w ire- h i volt- r *c302 059622- 40 1 103 200v 50hz 3 ph / 220- 240v 50hz 1 ph / 380- 415v 50hz 3 n harness- w ire- c 300 pw r/ comp 056334- 40 1 103 220- 240v 50...

Page 54

Model c302 059680-27s rev. 3/11.

Page 55

Model c302 059680-33s rev. 3/11.

Page 56

Model c302 059680-37s rev. 3/11.

Page 57

Model c302 059680-40s rev. 3/11.

Page 58

Model c302 059680-58s rev. 3/11.