- DL manuals

- Taylor

- Freezer

- C606

- Operating Instructions Manual

Taylor C606 Operating Instructions Manual

Summary of C606

Page 1

Model c606 combination freezer operating instructions 059714--m 8/1/05.

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e may, 2004...

Page 3: Table Of Contents

Table of contents model c606 table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Site ...

Page 4

Model c606 table of contents table of contents - page 2 air/mix pump reset mechanism 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Adjustable draw handle 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Shake fill l...

Page 5: Section 1

1 model c606 to the installer 081208 section 1 to the installer the following are general installation instructions. For complete installation details, please see the check out card. Installer safety in all areas of the world, equipment should be installed in accordance with existing local codes. Pl...

Page 6

2 model c606 to the installer 080902 electrical connections in the united states, this equipment is intended to be installed in accordance with the national electrical code (nec), ansi/nfpa 70-1987. The purpose of the nec code is the practical safeguarding of persons and property from hazards arisin...

Page 7

3 model c606 to the installer 080902 refrigerant in consideration of our environment, taylor proudly uses only earth friendly hfc refrigerants. The hfc refrigerant used in this unit is r404a. This refrigerant is generally considered non-toxic and non-flammable, with an ozone depleting potential (odp...

Page 8: Section 2

4 model c606 to the operator 080902 section 2 to the operator the freezer you have purchased has been carefully engineered and manufactured to give you dependable operation. The taylor freezer, when properly operated and cared for, will produce a consistent quality product. Like all mechanical produ...

Page 9: Section 3

5 model c606 safety 080902 section 3 safety we at taylor company are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built-in safety features to protect both you and the service te...

Page 10

6 model c606 safety 080902 this unit has many sharp edges that can cause severe injuries. S do not put objects or fingers in the door spout. This may contaminate the product and cause severe personal injury from blade contact. S use extreme caution when removing the beater asssembly. The scraper bla...

Page 11: Notes:

7 model c606 safety notes:.

Page 12: Section 4

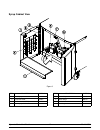

8 model c606 operator parts identification 080723 section 4 operator parts identification exploded view figure 1.

Page 13

9 model c606 operator parts identification exploded view (see figure 1) item description part no. 1 cover-hopper*black* 053809-1 2 agitator assembly x44797 3 pin-retaining hopper cover 043934 4 pan-drip-rear 8-3/4” l (22.2 cm) x56003 5 panel-rear-upper 055958 6 guide a.-drip pan mix pump x48228 7 pa...

Page 14

10 model c606 operator parts identification 050112 front view figure 2.

Page 15

11 model c606 operator parts identification 041008 front view (see figure 2) item description part no. 1 motor a.-spinner x35584ser2 2 solenoid-draw valve 059462 3 coupling-flexible w/screws 020108 4 bumper-recessed 057910 4a screw-1/4-20 x 3/4 057911 5 bracket-coupling actuator 056620 6 coupling a....

Page 16

12 model c606 operator parts identification syrup cabinet view figure 3 item description part no. 1 shelf-syrup 056016 2 pump-peristaltic 052916 3 motor-gear 161 rpm 058725 4 rack-syrup cabinet door 059144 item description part no. 5 block-hinge 058613 6 block-hinge 058614 7 latch-cabinet 062178 * p...

Page 17

13 model c606 operator parts identification syrup pump & tubes figure 4 item description part no. 1 pump-peristaltic 052916 2 kit a.-peristaltic pump tube x54978 3 ferrule-.625 id 053036 item description part no. 4 fitting-peristaltic pump 054526 5 o-ring 1/2 od x .070 024278.

Page 18

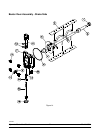

14 model c606 operator parts identification x57028-xx pump a. - mix simplified - shake figure 5 item description part no. 1 - 7 pump a.-mix simplified shake x57028-xx 1 cylinder-pump-hopper- shake 057944 2 pin a.-retaining x55450 3 piston 053526 4 o-ring 2-1/8” od- red 020051 5 cap-valve 056873-xx 6...

Page 19

15 model c606 operator parts identification x57029-xx pump a. - mix simplified - soft serve figure 6 item description part no. 1 - 7 pump a.-mix simplified soft srv x57029-xx 1 cylinder-pump-hopper-soft serve 057943 2 pin a.-retaining x55450 3 piston 053526 4 o-ring 2-1/8” od - red 020051 5 cap-valv...

Page 20

16 model c606 operator parts identification x59304 syrup line assembly - thin viscosity syrup figure 7 item description part no. 1 ferrule-.650 id 029834 2 fitting-barb 056675 3 o-ring 500205 4 tube-vinyl 500038-9 5 fitting-syrup elbow 056651 item description part no. 6 valve-check duckbill 500598 7...

Page 21

17 model c606 operator parts identification x56652 syrup line assembly - thick viscosity shake syrup (optional) figure 8 item description part no. 1 ferrule-.625 id 053036 2 fitting-barb 056675 3 o-ring 500205 4 hose-beverage 053052-9 5 fitting-syrup elbow 056651 item description part no. 6 valve-ch...

Page 22

18 model c606 operator parts identification x58450 syrup line assembly - syrup-in-bag option figure 9 item description part no. 1 o-ring-1/2 od x .070 024278 2 fitting-male 054526 3 ferrule-.625 id np brass 053036 4 coupling-qd female 3/8 barb 058451 item description part no. 5 coupling-qd male 1/4 ...

Page 23

19 model c606 operator parts identification 050128 mix hopper - top view figure 10 item description part no. 1 sleeve a.-mix pump x44761 2 probe a.-mix out x41348 3 housing a. Agitator (shake) x51664 3a 4a magnet a.-agitator- inner x41733 item description part no. 4 housing a.-agitator (soft serve) ...

Page 24

20 model c606 operator parts identification 050128 accessories figure 11.

Page 25

21 model c606 operator parts identification 050128 accessories (see figure 11) item description part no. *1 dispenser a.-cone x56121 1a baffle-rubber cone 052193 2a plug-syrup port 053867 2b o-ring-11mm green (syrup hole plug) 053890 2c tool-seal install-remove 035460 3 bottle-plastic wash 044818 4 ...

Page 26

22 model c606 operator parts identification x44127 brush kit assembly figure 12 item description part no. 1 black bristle brush 013071 2 double end brush 013072 3 white bristle brush (1” x 2”) 013073 4 white bristle brush (1-1/2” x 3”) 014753 5 white bristle brush (1/2” x 3”) 033059 item description...

Page 27

23 model c606 operator parts identification x53800-brn/tan syrup pump figure 13 item description part no. 1 plunger assembly x36576-tan x36576-brn 1a knob-plunger 032762-tan 032762-brn 1b o-ring-knob 016369 1c nut-plunger 036577 1d tube-plunger 032757 1e insert-plunger 032758 1f spring-plunger-syrup...

Page 28

24 model c606 operator parts identification 041008 beater door assembly - shake side figure 14.

Page 29

25 model c606 operator parts identification 041008 beater door assembly - shake side (see figure 14) item description part no. 1 seal-drive shaft 032560 2 shaft-beater 7 qt. Fluted blade 050985 3 blade-scraper-16” 041103 4 bearing-door front 1.390 od 055605 5 beater a.-7 qt. Fluted blade x50958 6 o-...

Page 30

26 model c606 operator parts identification 091002 beater door assembly - soft serve side figure 15 item description part no. 1 handle a.-draw x56421-1 2 stud nut 055989 3 door a.-w/baffle x57332-ser 4 gasket (freezer door) 048926 5 shoe-front helix-rear 050346 6 bearing-front 050348 7 shoe-front he...

Page 31

27 model c606 operator parts identification 059088 tray-parts-shake side figure 16 item part no. Description 1 x50958 beater a.-7 qt. 2 041103 blade-scraper-16” 3 050985 shaft-beater 7 qt. 4 032560 seal-drive shaft 5 055989 nut-stud 6 053890 o-ring -syrup port 11mm id green 7 053867 plug-syrup port ...

Page 32

28 model c606 operator parts identification 059087 tray-parts-soft serve side figure 17 item part no. Description 1 x56421-1 handle a.-draw 2 055819 pin-pivot 3 050348 bearing-front 4 055989 nut-stud 5 014402 o-ring (draw valve) 6 048926 gasket (freezer door) 7 x55820 valve a.-draw 8 x57332-ser door...

Page 33

29 model c606 operator parts identification 050621 056525 tray-parts-pump-simplified figure 18 shake side item description part no. 1 clip-mix pump retainer 044641 2 cylinder-pump-hopper- shake 057944 3 pin a.-retaining x55450 4 piston 053526 5 pin-cotter 044731 6 o-ring 2-1/8” od- red 020051 7 cap-...

Page 34: Section 5

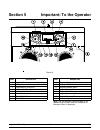

30 model c606 important: to the operator section 5 important: to the operator figure 19 item description 1 keypads-shake 2 display-vacuum fluorescent menu (vfd) 3 keypad-menu (entry/exit) 4 keypads-soft serve 5 indicator light-mix out 6 switch-power 7 standby-soft serve 8 standby-shake item descript...

Page 35

31 model c606 important: to the operator symbol definitions to better communicate in the international arena, symbols have replaced words on many of our operator switches, function, and fault indicators. Your taylor equipment is designed with these international symbols. The following chart identifi...

Page 36

32 model c606 important: to the operator 091002 heat mode symbol when the heat mode symbol is illuminated, the freezer is in the process of a heat cycle. The heat mode symbol may be selected to start a heat cycle following a freezer soft lock condition. For some models, the heat symbol can be select...

Page 37

33 model c606 important: to the operator shake fill level adjustment the portion control sensor located under the cup holder can be adjusted to fill the cup to the desired level. If the fill level is too low, or the cup is overfilling, it may be necessary to adjust the sensor position. (see figure 2...

Page 38

34 model c606 important: to the operator power switch on when the power switch is placed in the on position, the control panel touch keys become operative. The vfd will be either blank or indicate that the unit has been cleaned. (see figure 26.) unit cleaned figure 26 some models will continuously d...

Page 39

35 model c606 important: to the operator there are two types of freezer lock conditions that can occur: hard lock or soft lock. A hard lock requires the machine be disassembled and brush cleaned. A soft lock can be corrected by either disassembling and brush cleaning the machine, or by starting anot...

Page 40

36 model c606 important: to the operator if the reason for the soft lock has been corrected, selecting the heat symbol initiates a heat cycle immediately. Selecting the wash symbol when the above message is displayed will hard lock the machine and brush cleaning will be necessary. Following are the ...

Page 41

37 model c606 important: to the operator manager's menu the manager's menu is used to enter the operator function displays. To access the menu, touch the center of the cone symbol on the control panel. (see figure 41.) figure 41 the shake auto symbol , the optional flavor symbol and the cone symbol ...

Page 42

38 model c606 important: to the operator menu options touch the auto symbol or optional flavor symbol to move up or down through the menu. Select a menu option by aligning the option with the arrow on the left side of the screen, then touch the calibration symbol . Exit the menu program by selecting...

Page 43

39 model c606 important: to the operator reset the serving counter by selecting the calibration symbol to advance to the next screen. Select the auto symbol to move the arrow (>) to yes and select the calibration symbol . The servings counter will reset to zero and exit back to the manager's menu. (...

Page 44

40 model c606 important: to the operator auto heat time 00:00 figure 52 select the auto symbol or the optional flavor symbol to increase or decrease the hour to the desired setting. Then move the cursor to the minutes position by selecting the calibration symbol . Adjust the setting for minutes, the...

Page 45

41 model c606 important: to the operator discontinue standby operation for either side by exiting the manager's menu and select the auto mode. The brush clean cycle option allows the manager to select the maximum number of days between brush cleaning the machine. The brush clean cycle may only be ch...

Page 46

42 model c606 important: to the operator listed below are the variable messages which will appear, along with an explanation for the corrective action. No fault found - there was no fault found in the freezer. Nothing will appear on the screen after this variable message appears. Beater overload - p...

Page 47

43 model c606 important: to the operator 050622 faults occurring while in auto mode (l/r) hpr>41f (5c) after 4 hr - the mix temperature in the left or right hopper was above 41°f (5°c) more than four hours. (l/r) brl>41f (5c) after 4 hr - the mix temperature in the left or right barrel was above 41°...

Page 48

44 model c606 important: to the operator 070216 the heat time indicates the amount of time taken in each zone to reach 150.9°f (66.1°c). Each zone must remain above 150°f (65.6°c) for a minimum of 35 minutes. In addition, each zone must be heated for a minimum of 115 minutes. Select the auto symbol ...

Page 49

45 model c606 important: to the operator 050622 the current conditions screen provides the viscosity readings for the product when the side is running and hopper and barrel temperatures for both sides of the machine. The left column displays the readings for the shake side and the right column displ...

Page 50: Section 6

46 model c606 operating procedures section 6 operating procedures if you are disassembling the machine for the first time or need information to get to this starting point in our instructions, turn to page 84, “disassembly” and start there. Equipment set-up freezing cylinder assembly - shake side ma...

Page 51

47 model c606 operating procedures step 3 check scraper blades for any nicks or signs of wear. If any nicks are present, replace the blades. Note: shake side scraper blades should be replaced every 6 months. Step 4 if the blades are in good condition, place each scraper blade over the holding pins o...

Page 52

48 model c606 operating procedures 070228 step 8 insert the spinner shaft seal into the bottom of the draw valve as far as it will go. The spinner shaft seal should fit into the seal groove located inside the draw valve cavity. Important: inspect to see that the spinner shaft seal is correctly insta...

Page 53

49 model c606 operating procedures step 12 place the freezer door o-ring into the groove on the back of the freezer door. Lubricate the outside diameter of the front bearing. Slide the front bearing into the door hub. Note: if necessary, put two small spots of lubricant at the 10 o'clock and 2 o'clo...

Page 54

50 model c606 operating procedures 040803 step 16 raise the locking collar of the spinner coupling and insert the spinner shaft into the cavity of the coupling until the locking collar can drop into the locked position. (see figure 87.) figure 87 step 17 snap the restrictor cap over the end of the d...

Page 55

51 model c606 operating procedures note: to ensure the mix does not leak out of the back of the freezing cylinder, the middle section of the boot seal should be convex or extend out from the seal. If the middle section of the boot seal is concave or extending into the middle of the seal, turn the se...

Page 56

52 model c606 operating procedures step 6 install the beater shoes. (see figure 94.) figure 94 step 7 slide the beater assembly the rest of the way into the freezing cylinder. Make sure the beater assembly is in position over the drive shaft by turning the beater slightly until the beater is properl...

Page 57

53 model c606 operating procedures step 11 assemble the freezer door. Place the door gasket into the groove on the back of the freezer door. Slide the front bearing over the baffle rod so the flanged edge is against the door. Do not lubricate the gasket or bearing. (see figure 99.) figure 99 step 12...

Page 58

54 model c606 operating procedures step 15 slide the two shorter drip pans into the holes in the rear panel. Slide the two notched drip pans into the left and right side panels. (see figure 103.) figure 103 step 16 install the front drip tray and splash shield under the door spouts. (see figure 104....

Page 59

55 model c606 operating procedures step 4 insert the piston into the retaining pin hole end of the pump cylinder. (see figure 107.) figure 107 step 5 assemble the valve cap. Slide the red o-ring into the groove of the valve cap. Do not lubricate the o-ring. (see figure 108.) figure 108 step 6 slide ...

Page 60

56 model c606 operating procedures step 8 insert the mix inlet assembly into the pump cylinder. (see figure 111.) figure 111 note: the adapter must be positioned into the notch located at the end of the pump cylinder. Step 9 secure the pump parts in position by sliding the retaining pin through the ...

Page 61

57 model c606 operating procedures 080716 step 12 lay the pump assembly, pump clip, cotter pin and agitator in the bottom of the mix hopper for sanitizing. (see figure 115.) figure 115 step 13 slide the large black o-ring and the two smaller black o-rings into the grooves on the drive shaft. Thoroug...

Page 62

58 model c606 operating procedures 080716 step 3 pour the sanitizing solution over all parts in the bottom of the mix hopper and allow it to flow into the freezing cylinder. Note: you have just sanitized the mix hopper and parts; therefore, be sure your hands are clean and sanitized before going on ...

Page 63

59 model c606 operating procedures 080723 step 15 touch the wash and pump symbols to stop the wash and pump modes and to close the draw valve. (see figure 121.) figure 121 note: be sure your hands are clean and sanitized before going on in these instructions. Step 16 place the agitator on the agitat...

Page 64

60 model c606 operating procedures 080716 sanitizing - soft serve side step 1 prepare a pail of an approved 100 ppm sanitizing solution (examples: 2-1/2 gal. [9.5 liters] of kay-5r or 2 gal. [7.6 liters] of stera-sheenr). Use warm water and follow the manufacturer's specifications. Step 2 pour the s...

Page 65

61 model c606 operating procedures 080723 step 11 place the agitator on the agitator drive shaft housing. (see figure 126.) figure 126 note: if agitator should stop turning during normal operation, with sanitized hands, remove agitator from agitator drive shaft housing and brush clean with sanitizin...

Page 66

62 model c606 operating procedures 080723 step 4 select the auto symbol . Step 5 fill the hopper with fresh mix and place the mix hopper cover in position. Priming - soft serve side note: use only fresh mix when priming the freezer. Step 1 with a mix pail beneath the door spout, open the draw valve....

Page 67

63 model c606 operating procedures 041008 step 3 take the agitator, hopper cover, shake cup holder, drip pans, front drip tray, splash shield and restrictor cap to the sink for further cleaning and sanitizing. Take the syrup hole plugs, spout cap, and spout cap o-ring to the sink for further cleanin...

Page 68

64 model c606 operating procedures 041008 step 13 with the syrup port brush, brush each syrup port hole 10 to 15 times. Dip the brush in the cleaning solution before brushing each port. (see figure 134.) figure 134 step 14 with sanitized hands, remove the syrup valve retainers. Brush clean the retai...

Page 69

65 model c606 operating procedures 080723 step 18 fill the squeeze bottle with sanitizing solution. Hold the bottle over a pail. Squeeze the bottle and thoroughly rinse the slot of each syrup nose fitting. Figure 138 step 19 wipe the outside of each syrup nose fitting with a sanitized towel. Step 20...

Page 70

66 model c606 operating procedures step 6 prepare a small amount of an approved 100 ppm sanitizing solution (examples: kay-5® or stera-sheen®). Use warm water and follow the manufacturer's specifications. Brush clean the parts. Step 7 prepare a small amount of an approved 100 ppm sanitizing solution...

Page 71

67 model c606 operating procedures automatically abort and return to the standby mode. A failure message will appear on the vacuum fluorescent display (vfd) to inform the operator that the machine did not successfully complete the heat treatment cycle. The product may not be safe to serve. The freez...

Page 72

68 model c606 operating procedures 040803 step 3 return to the freezer with a small amount of sanitizing solution. With a pail below the door spout, dip the door spout brush into the sanitizing solution. Brush clean the door spout, the bottom of the driven spinner and spinner blade, and the syrup li...

Page 73

69 model c606 operating procedures 050112 step 8 with the pail still beneath the door, remove the syrup nose fitting from the syrup line fitting by turning it counter-clockwise. Hold the syrup fittings in an “up“ position to minimize syrup loss. (see figure 148.) figure 148 step 9 remove the duckbil...

Page 74

70 model c606 operating procedures 050112 if the tip is not flat, remove the syrup nose fitting and remove/reinstall the duckbill valve. Using a shake cup filled with sanitizing solution, rinse the syrup nose fitting to wet the bottom of the duckbill valve. Reinstall the syrup nose fitting onto the ...

Page 75

71 model c606 operating procedures 041008 step 24 when a steady stream of syrup is flowing from the syrup valve and all air has been purged from the syrup line, touch any syrup flavor symbol to stop the pump. Step 25 repeat steps 23 - 24 to prime the rest of the syrup lines. After priming is complet...

Page 76

72 model c606 operating procedures 041013 note: to assure sanitary conditions are maintained, brush clean each item for a total of 60 seconds, repeatedly dipping the brush in sanitizing solution. Step 3 using a clean, sanitized towel, wipe down the freezer door, front panel, the area around the bott...

Page 77

73 model c606 operating procedures 041008 the screen will display the calibration menu options. (see figure 162.) unflavored draw syrup calibration syrup prime > exit figure 162 note: when the calibration screen is displayed, the flavor selection symbols will not raise the draw valve to dispense sha...

Page 78

74 model c606 operating procedures step 7 exit the calibration mode by touching the calibration symbol . A blank screen will appear and the auto symbol and the optional flavor symbol will return to their normal function. Note: whenever a particular syrup line is not used, the syrup hole plug found i...

Page 79

75 model c606 operating procedures step 10 touch the corresponding syrup flavor symbol . The flavor symbol should be illuminated and the syrup pump for the selected flavor will start running at the maximum speed. (see figure 170.) figure 170 step 11 when a steady stream of syrup is flowing from the ...

Page 80

76 model c606 operating procedures step 4 to remove the knob, compress the spring toward the knob, using the washer. Compress it enough to grab onto the plunger with your hand for support. Begin removing the knob with your other hand. Remove the knob o-ring. Remove the plunger nut from the plunger t...

Page 81

77 model c606 operating procedures step 9 remove the discharge tube lock nut by turning it counterclockwise. Remove the discharge lock nut from the discharge tube. (see figure 177.) figure 177 step 10 remove the lid by sliding it off the discharge tube. Step 11 remove the cylinder from the valve bod...

Page 82

78 model c606 operating procedures step 3 advance the brush completely through the discharge tube and pull the brush from the bottom of the tube. Step 4 insert the black shielded brush into the top side of the inlet valve. Scrub this area, specifically around the steel ball. (see figure 181.) figure...

Page 83

79 model c606 operating procedures step 8 insert the black shielded brush into the bottom side of the inlet valve. Move the brush back and forth to scrub this area, specifically around the steel ball. (see figure 185.) figure 185 step 9 advance the brush completely through the inlet valve, and pull ...

Page 84

80 model c606 operating procedures step 4 install the plunger insert into the plunger tube by positioning the end of the insert with the beveled edge and smaller hole to enter into the plunger tube first. Step 5 install the plunger nut onto the plunger tube. Step 6 install the knob o-ring into the g...

Page 85

81 model c606 operating procedures step 12 install the cylinder onto the larger opening in the valve body by tilting the cylinder away from the discharge tube and sliding the widest section of flange under the center locking groove on the valve body. Align the tabs on the cylinder with the locking g...

Page 86

82 model c606 operating procedures 041008 draining product from the freezing cylinder to drain the product from the freezing cylinders on both sides of the machine, the steps will be the same. Therefore, first drain the product from the shake side, then go back and duplicate these procedures for the...

Page 87

83 model c606 operating procedures 080716 rinsing step 1 pour two gallons (7.6 liters) of cool, clean water into the shake mix hopper. With the white hopper brush, scrub the mix hopper, mix level sensing probes and the outside of the agitator drive shaft housing. Using the double ended brush, brush ...

Page 88

84 model c606 operating procedures step 10 repeat steps 1 through 8 for the soft serve side of the freezer. Disassembly - shake side note: failure to remove the parts specified below for brush cleaning and lubrication will result in damage to the machine. These parts must be removed every 14 days or...

Page 89

85 model c606 operating procedures 050801 remove the two small o-rings and one large o-ring from the pump drive shaft. Disassembly - soft serve side note: failure to remove the parts specified below for brush cleaning and lubrication will result in damage to the machine. These parts must be removed ...

Page 90

86 model c606 operating procedures step 10 remove the two short drip pans from the rear panel. Remove the two notched drip pans from the left and right side panels. Take them to the sink for cleaning. (see figure 203.) figure 203 note: if the drip pans are filled with an excessive amount of mix, it ...

Page 91

87 model c606 operating procedures step 8 repeat step 3 with the sanitizing solution. Step 9 place disassembled parts on clean and sanitized parts trays. Step 10 wipe all exterior surfaces of the freezer with a clean, sanitized towel. Step 11 repeat steps 1 through 10 for the soft serve side of the ...

Page 92

88 model c606 operating procedures 080716 step 12 grasp the pump tube by both ends and remove it from the pump body. (see figure 207.) figure 207 step 13 remove the clips from their respective collars. Step 14 remove the fittings from the pump tube. Pump tube installation step 1 lubricate the o-ring...

Page 93

89 model c606 operating procedures 050112 step 3 raise the retainer and remove the syrup valve from the freezer door. Place the valve in a pail located under the draw valve. Step 4 select the calibration symbol on the control panel to display the menu options. Step 5 touch the auto symbol to move th...

Page 94

90 model c606 operating procedures step 17 inspect the duckbill valve for proper installation inside the syrup nose fitting. The tip of the duckbill valve must be flat to seal the syrup line. (see figure 151.) figure 210 if the tip is not flat, remove the syrup nose fitting and remove/reinstall the ...

Page 95: Section 7

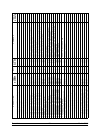

91 model c606 important: operator checklist 051207 section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by your state or local regulatory agencies and must be followed accordingly. The following check ...

Page 96

92 model c606 important: operator checklist 080327 winter storage if the place of business is to be closed during the winter months, it is important to protect the freezer by following certain precautions, particularly if the building is subject to freezing conditions. Disconnect the freezer from th...

Page 97: Section 8

Section 8 troubleshooting guide 93 model c606 troubleshooting guide pr o b l e m s hake s ide p r o babl e caus e so f t ser ve si d e p r o babl e caus e ei t h er si d e p r o babl e caus e re m e dy pa g e re f . 1. S o ft loc k m e s s age appear s o n d isp la y. A. A n equipm ent fault has oc ...

Page 98

94 troubleshooting guide model c606 pr o b l e m pa g e re f . Re m e dy ei t h er si d e p r o babl e caus e so f t ser ve si d e p r o babl e caus e s hake s ide p r o babl e caus e 1. S o ft loc k m e s s age appear s o n d isp la y. (c ont inued) e. M ix out c ondit ion. E. T h e lev el of m ix ...

Page 99

95 model c606 troubleshooting guide pr o b l e m pa g e re f . Re m e dy ei t h er si d e p r o babl e caus e so f t ser ve si d e p r o babl e caus e s hake s ide p r o babl e caus e 3. No pr oduc t is being dis pens ed. A. Low on m ix . T h e m ix o u t light is on. A . A d d m ix to th e m ix hop...

Page 100

96 troubleshooting guide model c606 pr o b l e m pa g e re f . Re m e dy ei t h er si d e p r o babl e caus e so f t ser ve si d e p r o babl e caus e s hake s ide p r o babl e caus e 3. No pr oduc t is being dis pens ed. (c ont inued) j. Dr aw v a lv e not opening. J. Dr aw v a lv e not aligned wit...

Page 101

97 model c606 troubleshooting guide pr o b l e m pa g e re f . Re m e dy ei t h er si d e p r o babl e caus e so f t ser ve si d e p r o babl e caus e s hake s ide p r o babl e caus e 6. T h e m ix in th e hopper is to o w a rm. A. Hopper c o v e r is not in pos it ion. A. Clean and s anit iz e hopp...

Page 102

98 troubleshooting guide model c606 pr o b l e m pa g e re f . Re m e dy ei t h er si d e p r o babl e caus e so f t ser ve si d e p r o babl e caus e s hake s ide p r o babl e caus e 1 2 . Exce ssi ve m ix leak age in to th e lo n g dr ip pan. A. T h e s eal on dr iv e s haf t is im p roper ly lubr...

Page 103

99 model c606 troubleshooting guide pr o b l e m pa g e re f . Re m e dy ei t h er si d e p r o babl e caus e so f t ser ve si d e p r o babl e caus e s hake s ide p r o babl e caus e 14. T h e fr eez ing c y linder walls ar e s c o red. A. M is s ing or wor n fr ont bear ing. A. In s tall o r repla...

Page 104

100 troubleshooting guide model c606 pr o b l e m pa g e re f . Re m e dy ei t h er si d e p r o babl e caus e so f t ser ve si d e p r o babl e caus e s hake s ide p r o babl e caus e 17. T h e d ra w v a lv e is not opening. A. T h e power s wit c h is o ff. A. P lac e the power s wit c h in th e ...

Page 105

101 model c606 troubleshooting guide pr o b l e m pa g e re f . Re m e dy ei t h er si d e p r o babl e caus e so f t ser ve si d e p r o babl e caus e s hake s ide p r o babl e caus e 18. T h e d ra w v a lv e is not c los ing. A. T h e d ra w v alv e was not aligned wit h the ac tuat or br ac k e ...

Page 106

102 troubleshooting guide model c606 pr o b l e m pa g e re f . Re m e dy ei t h er si d e p r o babl e caus e so f t ser ve si d e p r o babl e caus e s hake s ide p r o babl e caus e 20. T h e m ix pum p runs c ons tant ly in th e a u t o m ode. A. Dr aw v a lv e is not fu lly c los ed. A. Rais e ...

Page 107

103 model c606 troubleshooting guide pr o b l e m pa g e re f . Re m e dy ei t h er si d e p r o babl e caus e so f t ser ve si d e p r o babl e caus e s hake s ide p r o babl e caus e 21. S y ru p c annot be c a libr a te d or has inc ons is tent c a libr a ti on readings . (c ont inued) h. T h e s...

Page 108

104 troubleshooting guide model c606 pr o b l e m pa g e re f . Re m e dy ei t h er si d e p r o babl e caus e so f t ser ve si d e p r o babl e caus e s hake s ide p r o babl e caus e 24. S y ru p toppings ar e not hot . A. T opping heat er s a re not o n . A. S e lec t topping heat er s y m bols ....

Page 109: Section 9

105 model c606 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually scraper blade-shake x scraper blade-soft serve x drive shaft seal x freezer door o-ring-shake x freezer door gasket-soft serve x front bearing x front beater shoes-s...

Page 110: Section 10

106 model c606 warranty explanation 080723 section 10 warranty explanation class 103 parts the warranty for new equipment class 103 parts is one year from the original date of unit installation, with a replacement parts warranty of three months. Class 212 parts the warranty for new equipment class 2...

Page 111: Section 11

Section 11 parts list 107 modelc606 parts list 080716 see d a t a l abel f o r m o d el spec if ic at io n s. R o h s c o mpl ian t par t s ar e r eq u ir e d o n l y f o r u n it s w it h r o h s mar k o n t h e d at a l abel. See separat e r o h s part s li st f o llo w ing t h is part s li st . F...

Page 112

108 parts list model c606 de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r housi n g- blow er- 6 pole 053728 1 103 m o to r- fan 208- 230v 50/ 60 hz 053481- 27 1 103 screen- b low e r 053729 1 103 wh e e l -b l o we r 053726 1 103 cabi net a .- ult syrup *c 602* x5598...

Page 113

109 modelc606 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r coupli ng- dri ve 3/ 4 h ex x 1 -7 /8 012721 1 103 coupli ng- f lexi ble w /s crew s 020108 1 103 decal- in str- clean- d ai ly c606 059712 1 000 decal- in str- clean- w eekly c 606 059713 1 000...

Page 114

110 parts list model c606 de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r dryer- f il ter- hp62- 3/ 8 x 1/ 4s 048901 2 000 fastener- c li p 1 /4 -2 0 u -t ype 045865 16 000 panels fi lter- a ir -18. 00lx13. 50hx. 70w 052779- 3 2 000 fi lter- c orcom 6 eh1 040140- 001...

Page 115

111 modelc606 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r fuse- 12 amp- in li ne- n on delay 062431 1 000 fuse- 15 amp- in li ne- n on delay 045293 2 000 gear a. *r educer 4 .21: 1 021286- ser 2 212 gear a. *r educer- agi t ator 047988 1 103 g r o m m ...

Page 116

112 parts list model c606 de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r cover- h opper *b lack* 053809- 1 2 103 label- c auti on- a gi tator 045191 2 000 ki t a .- peri s talti c pump tube x54979 1 000 ki t a .- syrup do o r *c 602* x65932 1 000 k7110000 & u p brac...

Page 117

113 modelc606 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r tube- nylobrade 3 /8 id x5/ 8 od 500038- 9 4 000 valve- check- duckbi ll 500598 4 000 li ne a. -syrup blue *c 602* x56687 1 103 stai nless li ne a. -syrup bro w n *c602* x56684 1 103 stai nless ...

Page 118

114 parts list model c606 de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r ki t a .- control- li mi t m anual x77951- ser 2 103 heater- s tri p -175w -240v 042782 2 103 label- a dj temp- symbol 030994 2 000 label- inst- syrup label reset 055810 2 000 plug- drai n -w y...

Page 119

115 modelc606 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r pulley- ak64- 5/ 8 007538 1 103 shake gear pump a. -m ix si mpli fi ed shake x57028- 10 1 103 s u f f ix in d ic a t e s v a l v e c a p a ir o r if ic e s iz e adaptor- m ix in let *shake* blue...

Page 120

116 parts list model c606 de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r relay- dpdt 20a- 12vdc 077164- 02 2 103 relay- dpdt- 24vac- 30a@277v 054703- 03 3 103 relay- spst- 3 0 a -240 v 032607- 27 1 103 sani t iz er kay- 5 c ase 125 pckts 041082 1 000 senso r a .- ev...

Page 121

117 modelc606 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r n u t -4 -4 0 h e x -p l a t e d 038623 2 000 pi n- pi vot 015478 1 103 screw -4- 40x1 r d h d s teel- z p 028890 2 000 spri n g- return r. 023488 1 103 sw it ch- lever- spdt- 10a- 125- 250v 028...

Page 122

118 parts list model c606 de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r n u t -1 /4 -2 0 m f l o c k 017523 2 000 screw -1/ 4- 20x1- 1/ 4m f h ex cap 024351 1 000 screw -1/ 4- 20x3/ 4 s hc* lo w h d 057911 1 000 solenoi d -draw valve- sh *c 602 059462- cp 1 103 val...

Page 123

119 modelc606 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r ki t a .- door/ barrel* shake c602 x56200- 13 1 000 seal- dri ve shaft 032560 1 000 o- ri ng- 6 in odx5 3/ 4 idx 1/ 8 033493 1 000 o -ri ng -1 -11/ 16 o d x. 139w 041923 1 000 o -ri ng -11m m id...

Page 124

120 parts list model c606 de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r tool- seal in stall- remove 035460 1 000 plug- syrup port tts 053867 4 000 o -ri ng -11m m id x 2m m w g r een 053890 4 000 cup- d iv id ed syrup 017203 1 000 ladle- 1 o z- 120d bend in h and 0...

Page 125

121 modelc606 parts list see d a t a l abel f o r m o d el spec if ic at io n s. R o h s c o mpl ian t par t s ar e r eq u ir e d o n l y f o r u n it s w it h r o h s mar k o n t h e d at a l abel. F o r recycle inst ruct io n s p lease see o u r w eb si t e : www.Ta y l or -c om p a n y .C o m de ...

Page 126

122 parts list model c606 de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r connector- p rogrami n g s hunt 040084- 001 1 000 opti onal tanks decal- set of 4 syrup flav 021523 1 000 380- 415v 50hz 3 di ag ram -w iri ng *c 602* 059480- 35 1 000 220- 240v 50hz 3 di ag ra...

Page 127

123 modelc606 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r valve- check- duckbi ll 500598 1 000 mot o r- 1 .0 h p 013102- 35 1 212 shake +cap- rubber mount 011844 2 103 +grommet- 7/ 16 x 5 /1 6 s hock absb 016212 2 000 +hi n ge a. -m otor x25731 1 103 +...

Page 128

124 parts list model c606 de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r pulley- ag t m tr- 2 .110pdx3 045718 1 103 agi t ator motor pulley- ak30 x 58 033559 1 103 shake motor pump a. -m ix si mpli fi ed sh x57028- 10 1 103 220/ 240v 50hz 3 pump a. -m ix si mpli fi ...

Page 129

125 modelc606 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s qty . P art num be r shro ud- to p *c602* 064659 1 103 ro hs 50 hz uni ts in stalled 7 /1 /2006 & u p (6 /11/ 06 to 12/ 20/ 06) starter- 3 p hase 3 t o 5 a 041950- 33j 2 103 220/ 240v 50hz 3 starter- 3 p h 1 .4 to 2...

Page 130

Model c606 059480-33 5/09.

Page 131

Model c606 059480-58 3/10