- DL manuals

- Taylor

- Freezer

- C706

- Operator's Manual

Taylor C706 Operator's Manual

Summary of C706

Page 1

Operator's manual model c706 soft serve freezer original operating instructions 056436-m february, 2003 (original publication) (updated 9/2/14).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e 2003 carr...

Page 3: Table Of Contents

Table of contents model c706 table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 2 to the operator 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 3 safety 5 . ....

Page 4

Table of contents model c706 table of contents - page 2 cleaning 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Disassembly 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5: Section 1

1 model c706 to the installer 131122 section 1 to the installer the following information has been included in the manual as safety and regulatory guidelines. For complete installation instructions, please see the installation checklist. Installer safety in all areas of the world, equipment should b...

Page 6

2 model c706 to the installer 101027 water connections (water cooled units only) an adequate cold water supply must be provided with a hand shut- off valve. On the underside rear of the base pan, two 3/8” i.P.S. Water connections for inlet and outlet have been provided for easy hook- up. 1/2” inside...

Page 7

3 model c706 to the installer 130809 supply cords used with this unit shall be oil-resistant, sheathed flexible cable not lighter than ordinary polychloroprene or other equivalent synthetic elastomer-sheathed cord (code designation 60245 iec 57) installed with the proper cord anchorage to relieve co...

Page 8: Section 2

4 model c706 to the operator 131122 section 2 to the operator the model c706 has been carefully engineered and manufactured to give you dependable operation. This unit, when properly operated and cared for, will produce a consistent quality product. Like all mechanical products, it will require clea...

Page 9: Section 3

5 model c706 safety 130304 section 3 safety we, at taylor company, are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built- in safety features to protect both the operator and th...

Page 10

6 model c706 safety 130304 s do not allow untrained personnel to operate this machine. S do not operate the freezer unless all service panels and access doors are restrained with screws. S do not remove any internal operating parts (examples: freezer door, beater, scraper blades, etc.) unless all co...

Page 11: Section 4

7 model c706 operator parts identification 140625 section 4 operator parts identification figure 1 item description part no. 1 kit a.- cover- hopper x65368- sp 2 pan- drip 11- 5/8 long 027503 3 pin- retaining- hopper cover 043934 4 panel- side- left 066722- sp2 5 stud- nose cone 055987 6 shield- spl...

Page 12

8 model c706 operator parts identification 110509 model c706 single spout door and beater assembly figure 2 item description part no. 1 door a.- w/baffle x56071- ser 2 handle a.-draw-welded x56246 3 screw-adjustment-5/16-24 056332 4 o-ring-1/4 od x .070w 50 015872 5 pin - handle - s.S. 055819 6 plug...

Page 13

9 model c706 operator parts identification 140625 x57029- xx pump a. - mix simplified figure 3 item description part no. 1- 7 pump a.- mix simplified s.S.- complete x57029- 14 1 cylinder- pump hopper softserve 057943 2 pin a.- retaining x55450 3 piston- pump- simplified 053526 4 o- ring- 2- 1/8 od x...

Page 14

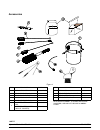

10 model c706 operator parts identification 140717 accessories figure 4 item description part no. 1 tool-o-ring removal 048260-wht 2 brush-rear·brg·1in.Dx2in. 013071 3 brush-double·ended 013072 4 brush-draw·valve·1”odx2 013073 5 brush-mix·pump·body-3”x7 023316 6 sanitizer stera sheen (jar) 010425-cs...

Page 15: Section 5

11 model c706 important: to the operator 041118 section 5 important: to the operator c706 figure 5 item description 1 mix low indicator light 2 mix out indicator light 3 mix refrigeration key 4 standby key 5 wash key 6 auto key item description 7 pump key 8 reset button - beater motor 9 reset button...

Page 16

12 model c706 important: to the operator symbol definitions to better communicate in the international arena, symbols have replaced words on many of our operator switches, function, and fault indicators. Your taylor equipment is designed with these international symbols. The following chart identifi...

Page 17

13 model c706 important: to the operator 060518 wash key when the wash key is pressed, the light comes on. This indicates beater motor operation. The standby or auto modes must be cancelled first to activate the wash mode. Auto key when the auto key is pressed, the light comes on. This indicates tha...

Page 18

14 model c706 important: to the operator 050126 feed tube (back- up option) if the air/mix pump has become inoperable because of a missing or damaged part, the operator can temporarily operate the unit using the feed tube. The product ejection rate will be slower when the feed tube is used instead o...

Page 19: Section 6

15 model c706 operating procedures 080714 section 6 operating procedures the c706 unit stores mix in a hopper. The mix is pumped into the freezing cylinder. It has a 3.4 quart (3.2 liter) capacity freezing cylinder and a 20 quart (18.9 liter) mix hopper. We begin our instructions at the point where ...

Page 20

16 model c706 operating procedures 041118 insert the drive shaft into the freezing cylinder, hex end first, and into the rear shell bearing until the seal fits securely over the rear shell bearing. Engage the hex end firmly into the drive coupling. Be sure the drive shaft fits into the drive couplin...

Page 21

17 model c706 operating procedures 050112 slide the two o- rings into the grooves on the prime plug. Apply an even coat of taylor lube to the o- rings and shaft. Figure 13 insert the prime plug into the hole in the top of the freezer door, and push down. Figure 14 step 4 install the draw valve. Slid...

Page 22

18 model c706 operating procedures 041118 step 8 install the front drip tray and the splash shield under the door spout. Figure 18 step 9 slide the rear drip pan into the hole in the side panel. Slide the pump drip pan into the hole in the back panel. Figure 19 mix hopper assembly step 1 inspect the...

Page 23

19 model c706 operating procedures step 5 assemble the piston. Slide the red o- ring into the groove of the piston. Do not lubricate the o- ring. Figure 23 step 6 lightly lubricate the inside of the pump cylinder at the bottom with a paper thin layer of lubricant. Figure 24 step 7 insert the piston ...

Page 24

20 model c706 operating procedures 030206 step 9 secure the pump parts in position by sliding the retaining pin through the cross holes located at the bottom of the pump cylinder. Figure 27 note: the head of the retaining pin should be facing up with the pump correctly installed. Step 10 assemble th...

Page 25

21 model c706 operating procedures 080714 step 13 slide the large black o- ring and the two smaller black o- rings into the grooves on the drive shaft. Thoroughly lubricate the o- rings and shaft. Do not lubricate the hex end of the shaft. (see figure 31.) figure 31 step 14 install the hex end of th...

Page 26

22 model c706 operating procedures 041118 step 4 install the pump assembly. To position the pump on the drive hub at the rear of the mix hopper, align the drive hole in the piston with the drive crank of the drive shaft. Secure the pump in place by slipping the pump clip over the collar of the pump,...

Page 27

23 model c706 operating procedures 050126 step 8 when a steady stream of sanitizing solution is flowing from the prime plug opening in the bottom of the freezer door, pull the draw handle down. Draw off all of the sanitizing solution. Figure 38 step 9 once the sanitizer stops flowing from the door s...

Page 28

24 model c706 operating procedures 041118 step 2 once a steady stream of mix starts to flow from the prime plug opening in the bottom of the freezer door, push down the prime plug. Figure 41 step 3 when the mix stops bubbling down into the freezing cylinder, insert the mix feed tube. Remove the lock...

Page 29

25 model c706 operating procedures 140717 draining product from the freezing cylinder step 1 press the auto key, cancelling compressor and beater motor operation. Press the mix ref key, cancelling the mix hopper refrigeration system. Step 2 remove the hopper cover and take it to the sink for cleanin...

Page 30

26 model c706 operating procedures 080714 disassembly step 1 be sure the power switch is in the off position. No lights should be illuminated on the control panel. Note: failure to follow this instruction may result in severe personal injury to fingers or hands from hazardous moving parts. Step 2 re...

Page 31

27 model c706 operating procedures 030102 note: for proper brush cleaning of the adapter, cap, feed tube, and orifice, refer to the following illustration which indicates proper brush usage. Rinse all parts with clean, warm water. Place the pump parts on a clean, dry surface. Step 8 wipe clean all e...

Page 32: Section 7

28 model c706 important: operator checklist 071205 section 7 important: operator checklist during cleaning and sanitizing cleaning and sanitizing schedules are governed by federal, state, or local regulatory agencies, and must be followed accordingly. If the unit has a “standby mode”, it must not be...

Page 33

29 model c706 important: operator checklist 080714 j 6. If your machine is air cooled, check the condensers for accumulation of dirt and lint. Dirty condensers will reduce the efficiency and capacity of the machine. Condensers should be cleaned monthly with a soft brush. Never use screwdrivers or ot...

Page 34: Section 8

30 model c706 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product is being dispensed with draw valve open and the machine in the auto mode. A. Freeze- up in mix inlet hole. A. Call service technician to adjust the mix hopper temperature. - - - ...

Page 35

31 model c706 troubleshooting guide problem probable cause remedy page ref. 5. The mix in the mix hopper is too warm. A. The temperature is out of adjustment. A. Call service technician to adjust the mix hopper temperature. - - - b. The mix hopper cover is not in position. B. Place the cover in posi...

Page 36

32 model c706 troubleshooting guide problem probable cause remedy page ref. 11. Product is not feeding into the freezing cylinder. A. Inadequate level of mix in the mix hopper. A. Fill the mix hopper with mix. 24 b. The mix inlet hole is frozen up. B. The mix hopper temperature needs adjustment. Cal...

Page 37

33 model c706 troubleshooting guide 030206 problem probable cause remedy page ref. 15. Excessive pump cylinder wear. A. Inadequate or incorrect lubrication of pump cylinder. A. Follow lubrication procedures carefully. 19 b. Incorrect ball crank rotation. B. Contact service technician. - - - 16. Pitt...

Page 38: Section 9

34 model c706 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually drive shaft seal x scraper blade x freezer door gasket x front bearing x beater shoes x draw valve o- ring x prime plug o- ring x feed tube o- ring x air orifice o- r...

Page 39

35 model c706 limited warranty on equipment 131122 section 10 limited warranty on equipment taylor company limited warranty on freezers taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor-branded freezer equipment ...

Page 40

36 model c706 limited warranty on equipment 3. Replacement of wear items designated as class “000” parts in the taylor operator’s manual. 4. External hoses, electrical power supplies, and machine grounding. 5. Parts not supplied or designated by taylor, or damages resulting from their use. 6. Return...

Page 41: Section 11

37 model c706 limited warranty on parts 131122 section 11 limited warranty on parts taylor company limited warranty on taylor genuine parts taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor genuine replacement co...

Page 42

38 model c706 limited warranty on parts limited warranty exceptions this limited warranty does not cover: 1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of defective parts, replacement parts, or new parts. 2. Normal maintenance, clea...

Page 43

39 model c706 limited warranty on parts limitation of warranty this limited warranty is exclusive and is in lieu of all other warranties, conditions and/or remedies under the law, including any implied warranties or conditions of merchantability or fitness for a particular purpose. The original owne...

Page 44

Model c706 064288-27 06/14 taylor company 2014 carrier commercial refrigeration, inc. C blk fig. 1 gra/wht grn/yel mix pump motor reset switch 1 3 1 2 5 4 c s r line relay run cap. Start cap. Compressor terminal cover above electrical diagram shows wirin g necessary to hook up a compressor using a s...