- DL manuals

- Taylor

- Freezer

- C712

- Operator's Manual

Taylor C712 Operator's Manual

Summary of C712

Page 1

Operator's manual model c712 soft serve freezer original operating instructions 062179-m 2/03/05 (original publication) updated 3/12/14.

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: fax: e-mail: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: ...

Page 3: Table Of Contents

Table of contents model c712 table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Site ...

Page 4

Model c712 table of contents table of contents - page 2 disassembly 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Brush cleaning 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5: Section 1

1 model c712 to the installer 131121 section 1 to the installer the following information has been included in the manual as safety and regulatory guidelines. For complete installation instructions, please see the installation checklist. Installer safety in all areas of the world, equipment should b...

Page 6

2 model c712 to the installer 130304 water connections (water cooled units only) an adequate cold water supply must be provided with a hand shut-off valve. On the underside of the base pan or on the right side, two 3/8” i.P.S. Water connections for inlet and outlet are provided for easy hook-up. 1/2...

Page 7

3 model c712 to the installer 130923 beater rotation beater rotation must be clockwise as viewed looking into the freezing cylinder. Note: the following procedures should be performed by a trained service technician. To correct the rotation on a three-phase unit, interchange any two incoming power s...

Page 8: Section 2

4 model c712 to the operator 131121 section 2 to the operator your freezer has been carefully engineered and manufactured to give you dependable operation. This unit, when properly operated and cared for, will produce a consistent quality product. Like all mechanical products, it will require cleani...

Page 9: Section 3

5 model c712 safety 130304 section 3 safety we at taylor are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built-in safety features to protect both you and the service technician...

Page 10

6 model c712 safety 130304 do not use a water jet to clean or rinse the freezer. Failure to follow these instructions may result in serious electrical shock. S do not allow untrained personnel to operate this machine. S do not operate the freezer unless all service panels and access doors are restra...

Page 11: Section 4

7 model c712 operator parts identification 130703 section 4 operator parts identification model c712 figure 1.

Page 12

8 model c712 operator parts identification 130703 c712 exploded view parts identification item description part no. 1 cover-hopper *black* 053809-1 2 pump a.-mix simplified see pg. 10 3 panel-rear 064258-ser 4 pan-drip 7.875 059737 5 panel-side*right 059907 6 pan-drip 12.5 059736 7 panel a.-front-mi...

Page 13

9 model c712 operator parts identification 130703 model c712 door and beater assembly figure 2 item description part no. 1 handle a.-draw-welded x56421-1 2 plug-prime twin 059936 3 nut-stud-black 3.250 long 058765 4 nut-stud-black 2.563 long 058764 5 door a.-3spt*lg baffle x59921-ser 6 pin-handle-tw...

Page 14

10 model c712 operator parts identification 140312 x57029-xx pump a. - mix simplified figure 3 item description part no. 1 - 7 pump assembly - mix simplified soft serve x57029-14* 1 cylinder-pump-hopper- soft serve 057943 2 pin-retaining x55450 3 piston 053526 4 o-ring 2-1/8” od - red 020051 5 cap-v...

Page 15

11 model c712 operator parts identification 081120 accessories figure 4 item description part no. 1 pail-mix 10 qt. 013163 2 tool-o-ring removal 048260-wht 3 tool-mix pump shaft removal 057167 item description part no. 4 lubricant-taylor 4 oz. 047518 *5 sanitizer-stera sheen see note ** kit a.-tune-...

Page 16

12 model c712 operator parts identification 121022 brushes figure 5 item description part no. 1 black bristle brush 013071 2 double end brush 013072 3 white bristle brush (1” x 2”) 013073 4 brush set (3) 050103 item description part no. 5 white bristle brush (3” x 7”) 023316 6 brush-end-door-spout 0...

Page 17: Section 5

13 model c712 important: to the operator 130220 section 5 important: to the operator figure 6 item description 1 power switch 2 fluorescent display 3 keypads 4 mix out indicator 5 standby key 6 mix low indicator item description 7 select key 8 service menu key 9 brush clean counter 10 arrow keys 11 ...

Page 18

14 model c712 important: to the operator 110204 symbol definitions to better communicate in the international arena, symbols have replaced words on many of our operator switches, function, and fault indicators. Your taylor equipment is designed with these international symbols. The following chart i...

Page 19

15 model c712 important: to the operator 081205 reset mechanism the reset buttons are located in the back panel of the machine. It protects the beater motor from an overload condition. Should an overload occur, the reset mechanism will trip. To properly reset the freezer place the power switch in th...

Page 20

16 model c712 important: to the operator 050722 once the system has initialized, the safety timeout screen will display and the alarm will be on. (see figure 9.) safety timeout any key aborts figure 9 the safety timeout screen will be displayed with the alarm on, for 60 seconds or until any control ...

Page 21

17 model c712 important: to the operator 050722 entering access code with the access code screen on the display use the sel symbol to set the first code number in the cursor position. When the correct number is selected, touch the sel symbol to move the cursor to the next number position. (see figur...

Page 22

18 model c712 important: to the operator reset the serving counter by selecting the sel symbol to advance to the next screen. Select the up arrow symbol to move the arrow (>) to yes and select the sel symbol. The servings counter will reset to zero and exit back to the manager's menu. (see figure 16...

Page 23

19 model c712 important: to the operator enable the auto start time by selecting the up arrow symbol to move the arrow up to enable. Touch the sel symbol to advance to the next screen. (see figure 22.) auto start time 00:00 change > exit figure 22 program the auto start time by selecting the up arro...

Page 24

20 model c712 important: to the operator 070322 listed below are the variable messages which will appear, along with an explanation for the corrective action. No fault found - there was no fault found in the freezer. Nothing will appear on the screen after this variable message appears. Beater overl...

Page 25: Section 6

21 model c712 operating procedures section 6 operating procedures the c712 machine stores mix in a hopper. It has two 3.4 quart (3.2 liter) capacity freezing cylinders with a three spout door. We begin our instructions at the point where we enter the store in the morning and find the parts disassemb...

Page 26

22 model c712 operating procedures step 6 before installing the beater assembly, check the scraper blades for any nicks or signs of wear. If any nicks are present, or if the blades are worn, replace both blades. If the blades are in good condition, install the scraper blade clips over the scraper bl...

Page 27

23 model c712 operating procedures step 10 to assemble the freezer door, place the door gaskets into the grooves on the back of the freezer door. Figure 37 slide the front bearings over the baffle rods. The flanged edges should be against the door. Do not lubricate the gaskets or front bearings. Sli...

Page 28

24 model c712 operating procedures step 13 slide the three o-rings into the grooves of each standard draw valve. Slide the h-ring and o-ring into the grooves of the center draw valve. Lubricate the h-ring and o-rings. Figure 41 step 14 lubricate the inside of the freezer door spouts, top and bottom....

Page 29

25 model c712 operating procedures 081205 step 17 slide the pivot pin through the draw handles as the handles are inserted into the draw valves. Figure 45 note: this freezer features three adjustable draw handles to provide portion control, giving a better consistent quality to your product and cont...

Page 30

26 model c712 operating procedures step 20 install the front drip tray and splash shield under the door spouts. (see figure 49.) figure 49 mix pump assembly step 1 inspect the rubber pump parts. O-rings and gasket must be in 100% good condition for the pump and entire machine to operate properly. Th...

Page 31

27 model c712 operating procedures 121022 step 6 slide the pump valve gasket into the holes on the cap. Do not lubricate the gasket. (see figure 54.) figure 54 step 7 insert the valve body cap into the hole in the mix inlet adapter. (see figure 55.) figure 55 step 8 insert the mix inlet assembly int...

Page 32

28 model c712 operating procedures 080908 step 11 install one red o-ring on each end of the mix feed tube, and thoroughly lubricate. (see figure 59.) figure 59 step 12 lay the pump assembly, pump clip, cotter pin, and mix feed tube in the bottom of the mix hopper for sanitizing. Step 13 slide the la...

Page 33

29 model c712 operating procedures 121022 note: you have just sanitized the mix hopper and parts; therefore, be sure your hands are clean and sanitized before going on in these instructions. Step 3 while the solution is flowing into the freezing cylinder, take particular care to brush-clean the mix ...

Page 34

30 model c712 operating procedures step 11 with an empty pail beneath the door spouts, raise the prime plug and touch the pump symbol . Step 12 when a steady stream of sanitizing solution is flowing from the prime plug opening in the bottom of the freezer door, open the draw valve. Momentarily open ...

Page 35

31 model c712 operating procedures 080908 rinsing step 1 pour two gallons (7.6 liters) of cool, clean water into the mix hopper. With the white hopper brush, scrub the mix hopper and the mix level sensing probe. Using the double ended brush, brush clean the mix inlet hole. (see figure 65.) figure 65...

Page 36

32 model c712 operating procedures step 4 touch the wash symbol . This will cause the cleaning solution in the freezing cylinder to come in contact with all areas of the freezing cylinder. Wait at least 5 minutes before proceeding with these instructions. (see figure 67.) figure 67 step 5 place an e...

Page 37

33 model c712 operating procedures 080908 step 7 remove the two small o-rings and one large o-ring from each pump drive shaft. Step 8 remove the front drip tray and splash shield. Step 9 remove all drip pans. Take them to the sink for cleaning. (see figure 69.) figure 69 note: if the drip pans are f...

Page 38: Section 7

34 model c712 important: operator checklist 080107 section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by federal, state, or local regulatory agencies, and must be followed accordingly. If the unit ha...

Page 39

35 model c712 important: operator checklist 080226 winter storage if the place of business is to be closed during the winter months, it is important to protect the freezer by following certain precautions, particularly if the building is subject to freezing conditions. Disconnect the freezer from th...

Page 40: Section 8

36 model c712 important: operator checklist section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product is being dispensed. A. Low on mix. The mix out light is on. A. Add mix to the mix hopper. Return to auto mode. 30 b. The power switch is in the off position. B. Place the...

Page 41

37 model c712 important: operator checklist problem probable cause remedy page ref. 3. The product is too thick. A. Freezing cylinder not primed correctly. A. Drain the freezing cylinder and reprime the machine. 30 b. Air/mix pump incorrectly assembled. B. Follow assembly procedures carefully. 26 c....

Page 42

38 model c712 important: operator checklist problem probable cause remedy page ref. 10. The drive shaft is stuck in the drive coupling. A. Mix and lubricant collected in drive coupling. A. Brush clean the rear shell bearing area regularly. 33 b. Rounded corners of drive shaft, drive coupling, or bot...

Page 43: Section 9

39 model c712 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually scraper blade x drive shaft seal x freezer door gasket x front bearing x front beater shoes x draw valve o-ring x mix feed tube o-ring x pump o-ring x prime plug o-ri...

Page 44

40 model c712 limited warranty on equipment 131121 section 10 limited warranty on equipment taylor company limited warranty on freezers taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor-branded freezer equipment ...

Page 45

41 model c712 limited warranty on equipment 3. Replacement of wear items designated as class “000” parts in the taylor operator’s manual. 4. External hoses, electrical power supplies, and machine grounding. 5. Parts not supplied or designated by taylor, or damages resulting from their use. 6. Return...

Page 46: Section 11

42 model c712 limited warranty on parts 131121 section 11 limited warranty on parts taylor company limited warranty on taylor genuine parts taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor genuine replacement co...

Page 47

43 model c712 limited warranty on parts limited warranty exceptions this limited warranty does not cover: 1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of defective parts, replacement parts, or new parts. 2. Normal maintenance, clea...

Page 48

44 model c712 limited warranty on parts limitation of warranty this limited warranty is exclusive and is in lieu of all other warranties, conditions and/or remedies under the law, including any implied warranties or conditions of merchantability or fitness for a particular purpose. The original owne...

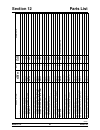

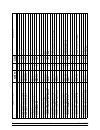

Page 49: Section 12

Section 12 parts list 45 model c712 parts list 100901 de s cri p t io n p art num be r qty . W arr. Cl as s co m m e nt s actuator a. -draw s w itch x62401 1 103 arm- sw it ch- draw -l 038649 1 103 arm- sw it ch- draw -r 038650 1 103 bracket a. -spri n g r eturn x38257 1 103 e- ri ng 1/ 4 032190 4 0...

Page 50

46 parts list model c712 de s cri p t io n co m m e nt s w arr. Cl as s qty . P art num be r brush- rear brg 1 "d x 2 "l g x 14 013071 1 000 brush- set lvb 050103 1 000 cable- ri bbo n- 20c- 17" l- di l/ di lr 040040- 013 1 103 cable- ri bbo n- 50c- 25" l. Di l/ di l 040040- 025 1 103 cable- ri bbo ...

Page 51

47 model c712 parts list de s cri p t io n co m m e nt s w arr. Cl as s qty . P art num be r control- uvc3 surface m ount 062529- ser 1 212 cord- 16- 2 spt- 3 023767- 40 1 nnn blow er a. Core- s chrader valve- teflon 037047 4 103 fo r 053565 vlvs coupli ng- dri ve 3/ 4 h ex x 1 -7 /8 012721 2 103 co...

Page 52

48 parts list model c712 de s cri p t io n co m m e nt s w arr. Cl as s qty . P art num be r eyelet- r eset button 013739 6 103 fastener- c li p 1 /4 -2 0 u -t ype 045865 12 000 panels, cntr b x fastener- d oor latch 030787 2 000 door l a tch f ast fastener- d oor stri ke 030788 2 000 door l a tch f...

Page 53

49 model c712 parts list de s cri p t io n co m m e nt s w arr. Cl as s qty . P art num be r cap- desi g n 1. 010" id -6 po in t 014218 3 nnn o -ri ng -7 /8 o d x .103w 014402 5 nnn o -ri ng -1 /2 o d x .070w 024278 4 nnn seal- draw valve 034698 1 nnn ki t a .- barrel *tw in ss* 8784* 1 x56200- 6 1 ...

Page 54

50 parts list model c712 121022 de s cri p t io n co m m e nt s w arr. Cl as s qty . P art num be r panel a. -f ro nt *c 712- c717* x59836 1 103 upper front w / n ose c one panel a. -f ront low e r x59854- ser 1 103 panel- c o rner- frnt- r *c 712/ c717 063087 1 103 replaces 059882 panel- c o rner- ...

Page 55

51 model c712 parts list de s cri p t io n co m m e nt s w arr. Cl as s qty . P art num be r relay- m t r s tart ti #4cr- 1- 625 039725- 27 2 103 relay- 3 p o l e- 20a- 208/ 240 50/ 60 012725- 33 2 103 relay- dpdt 100ua t o 7 a 1 /8 hp 052111- 03 2 103 sani t iz er kay- 5 2 5 packets 041081 1 nnn sc...

Page 56

52 parts list model c712 100930 de s cri p t io n co m m e nt s w arr. Cl as s qty . P art num be r sw it ch- pressure 405 psi -s older 052663 2 103 li ne di scharge sw it ch- reed *d oor in terlock* 056249 1 103 tool- s haft- dri ve- pump- h opper 057167 1 000 trans. -c o n t. -32va 120/ 200/ 240v ...

Page 57

53 model c712 parts list de s cri p t io n co m m e nt s w arr. Cl as s qty . P art num be r deflector- blow er exhaust 047912 1 103 guard- blow er 022505 1 103 hose- rubber 1/ 2 id x 7/ 8 o d r50200 15 000 outlet a. -t ee x25900 1 103 panel- s id e- l. W /c *c712/ c717 062160 1 103 panel- s id e- r...

Page 58

Model c712 059898-27 5/13.

Page 59

Model c712 059898-33 5/13.

Page 60

Model c712 059898-40 5/13.

Page 61

Model c712 059898-58 5/13.