- DL manuals

- Taylor-Dunn

- Utility Vehicle

- B 50

- Operation, T Roubleshooting And Replacement Parts Manual

Taylor-Dunn B 50 Operation, T Roubleshooting And Replacement Parts Manual

Summary of B 50

Page 1

T h e b e s t w a y to go a b o u t your b u s i n e s s ® serial number starting: 157300 manual mb-050-00 operation, troubleshooting and replacement parts manual models included: b0-050-00 (b 50) shuttle master published: 12/16/2003 revision: c.

Page 3

Taylor-dunn contact information service, parts, sales: taylor-dunn has a network of dealers distributed around the globe to support our vehicles. Information regarding vehicle sales, replacement parts, or service should be obtained through your local dealer. A dealer locator can be found on the tayl...

Page 4

B2-48 with stake side dump bed option sc1-59 stock chaser e4-55 sit down tow tractor c4-25 sit down tow tractor.

Page 5: Taylor-Dunn

Section index introduction 1 safety rules and operating instructions 2 general maintenance 3 front axle service 4 steering component service 5 brakes service 6 motor service 7 transaxle service 8 tires and wheels 9 battery service 10 control system troubleshooting 11 chargers 12 wire diagram 13 illu...

Page 6: Taylor -Dunn

Taylor -dunn.

Page 7: Introduction

Table of contents introduction about this manual ......................................... 2 who should read this manual .................... 3 responsibilities ............................................. 3 how to use this manual .............................. 4 conventions ..........................

Page 8: About This Manual

Introduction introduction page-2 about this manual the purchase of this vehicle shows a belief in high quality products manufactured in the usa. Taylor-dunn ® , a leading manufacturer of electric burden and personnel carriers since 1949, wants to be sure this vehicle provides years of reliable servi...

Page 9: Who Should Read This Manual

Introduction introduction page-3 who should read this manual this manual is intended for use by anyone who is going to operate, own, perform maintenance on, service, or order parts for this taylor-dunn ® vehicle. Each person should be familiar with the parts of this manual that apply to their use of...

Page 10: How to Use This Manual

Introduction introduction page-4 how to use this manual this manual is organized into five main sections: introduction this section describes how to use this service manual and how to identify your vehicle. Safety rules and operating instructions this section outlines the safety and operational issu...

Page 11

Introduction introduction page-5 a shaded box with the word “warning” on its left denotes a warning. A warning alerts the reader of a hazard that may result in injury to themselves or others. Be sure to follow any instructions contained within a warning and exercise extreme care while performing the...

Page 12

Introduction introduction page-6 how to identify your vehicle this manual applies to vehicles with the same model and serial numbers listed on the front cover. These vehicles are designed for driving on smooth surfaces in and around facilities such as industrial plants, nurseries, institutions, mote...

Page 13

Introduction introduction page-7 taking delivery of your vehicle inspect the vehicle immediately after delivery. Use the following guidelines to help identify any obvious problems: • examine the contents of all packages and accessories that may have come in separate packages with the vehicle. • make...

Page 14

B2-48 with dump bed option b2-10 ambulance b2-48 with steel cab, foldaway 4-passenger seat and stake sides et 3000 et1-50 full size truck p2-50 30,000 pound tow tractor.

Page 15: Safety Rules and Operating

Table of contents standard specifications personnel carrier .. 2 safety rules and guidelines ......................... 3 driver training program ................................ 4 driver qualifications. ............................................... 4 vehicle controls .................................

Page 16

Safety rules and operating instructions safety rules page 2 standard specifications personnel carrier item voltage specification occupancy 2-passenger dimensions 199l x 112w x 120.6h centimeters 78.5l x 44.25 x 47.5h inches turning radius 366 centimeters (144 inches) dry weight 322 kg (710 lbs) with...

Page 17

Safety rules page 3 safety rules and operating instructions 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. 5. Disco...

Page 18: Driver Training Program

Safety rules and operating instructions safety rules page 4 driver training program according to ansi b56.8, the owner of this vehicle shall conduct an operator training program for all those who will be operating this vehicle. The training program shall not be condensed for those claiming to have p...

Page 19: Vehicle Controls

Safety rules page 5 safety rules and operating instructions vehicle controls key-switch a key-switch, located to the front of the consol between the seats, turns on the vehicle. Rotate the key clockwise to turn the vehicle power on, counterclockwise to turn the vehicle power off. The key-switch shou...

Page 20

Safety rules and operating instructions safety rules page 6 battery status indicator, analog (optional) the battery status indicator is located to the left of the hour meter. The normal operating range is in the green zone. Park the vehicle for a few minutes for an accurate reading. The vehicle need...

Page 21

Safety rules page 7 safety rules and operating instructions steering the steering wheel and steering system are similar to an automobile. To turn right, turn the steering wheel clockwise. To turn left, turn the steering wheel counter-clockwise. If equipped with tilt steering, the release lever is lo...

Page 22

Safety rules and operating instructions safety rules page 8 foot brake pedal the foot brake pedal, is located to the right of the steering column, it is for operation with the right foot only. It works similar to the brake in an automobile. Applying pressure to the brake pedal slows the vehicle acco...

Page 23

Safety rules page 9 safety rules and operating instructions electrolyte alarm (optional) the electrolyte alarm is located in the battery area, in the 4th battery cell from the main battery positive cable. The electrolyte alarm is activated when the battery cell fluid level falls below the level of t...

Page 24

Safety rules and operating instructions safety rules page 10 the seat interlock switch is only one part of the vehicle safety system. The interlock switch should not be relied upon as the only safety feature used to disable or disengage this vehicle. Doing so could result in unexpected movement of t...

Page 25

Safety rules page 11 safety rules and operating instructions vehicle operational guidelines safety guidelines • only qualified and trained operators may drive this vehicle. • drive only on level surfaces or on surfaces having an incline of no more than 10% (5.6 degrees). • drive slowly when making a...

Page 26

Safety rules and operating instructions safety rules page 12 while driving: • slow down and sound the horn to warn pedestrians or when approaching a corner or other intersection. • no reckless driving. • do not drive this vehicle on steep inclines or where prohibited. • immediately report any accide...

Page 27: Charging Your Vehicle

Safety rules page 13 safety rules and operating instructions explosive mixtures of hydrogen gas are present within battery cells at all times. Do not work with or charge battery in an area where open flames (including gas furnace or water heater pilots), sparks, cigarettes, or any other sources of c...

Page 28

Safety rules and operating instructions safety rules page 14 signet charger operation, model hbs series the signet ® hbs series chargers are fully automatic. The charger will turn itself on when the ac power cord is connected to the ac power source and turn itself off when the batteries are fully ch...

Page 29: Storing / Returning To

Safety rules page 15 safety rules and operating instructions storing / returning to service both storing your vehicle and returning it to service should only be performed by authorized personnel. Storing your vehicle • clean the batteries, then fill and charge before putting the vehicle in storage. ...

Page 30

Safety rules and operating instructions safety rules page 16 maintenance item weekly (20hrs) monthly (80hrs) quaterly (250hrs) semi - annual (500hrs) annualy (1000hrs) check condition of tires and tire pressure l check all lights, horns, beepers and warning devises l check and fill batteries l check...

Page 31: General Maintenance

Table of contents general maintenance general maintenance 1 maintenance guidelines ............................... 2 maintenance guidelines for vehicles used in severe conditions .................................. 3 troubleshooting guide ................................. 4 lubrication chart ...........

Page 32: Maintenance Guidelines

Maintenance, service and repair maintenance page 2 maintenance guidelines • avoid fire hazards and have fire protection equipment present in the work area. Conduct vehicle performance checks in an authorized area where safe clearance exists. • before starting the vehicle, follow the recommended safe...

Page 33: Severe Conditions

Maintenance, service and repair maintenance page 3 maintenance guidelines for vehicles used in severe conditions if this vehicle is operated in severe conditions all maintenance items listed in the periodic maintenance table should be carried out twice as often as stated. In addition, the entire veh...

Page 34: Troubleshooting Guide

Maintenance, service and repair maintenance page 4 troubleshooting guide symptom probable cause steering pulls in one direction front end out of alignment low tire pressure hard steering dry lube points in steering linkage damaged king pin/ball joint low tire pressure excessive steering play worn ba...

Page 35: Lubrication Chart

Maintenance, service and repair maintenance page 5 lubrication chart # description locations lubricant type 1 2 king pin 2 general purpose grease 3 ball joints 2 general purpose grease 4 pedal linkages 2 general purpose grease 5 front wheel bearings 2 high temperature wheel bearing grease 6 7 drive ...

Page 36: Taylor -Dunn

Taylor -dunn.

Page 37: Front Axle Service

Table of contents inspect the front wheel bearings and king pin ............................ 2 adjust front wheel bearings ....................... 3 front a-arm removal and installation ......... 4 removal ................................................................... 4 installation ..............

Page 38

Maintenance, service, and repair front axle page 2 inspect the front wheel bearings and king pin 6. Raise the front of the vehicle and support with jack stands. 7. Grab the top and bottom of the tire/wheel assembly. Feel for any movement or play while pulling and pushing on the top and bottom of the...

Page 39

Maintenance, service, and repair front axle page 3 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the rear wheels to prevent vehicle movement. 5. Disconnect the ...

Page 40

Maintenance, service, and repair front axle page 4 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the rear wheels to prevent vehicle movement. 5. Disconnect the ...

Page 41

Maintenance, service, and repair front axle page 5 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the rear wheels to prevent vehicle movement. 5. Disconnect the ...

Page 42: Replace Front Wheel Bearings

Maintenance, service, and repair front axle page 6 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the rear wheels to prevent vehicle movement. 5. Disconnect the ...

Page 43

Maintenance, service, and repair front axle page 7 13. Install the hub dust cap. 14. Reinstall the brake body and the tire/wheel assembly. Note: refer to the brakes section for information regarding the installation of the brake body. 15. Lower the vehicle. 16. Reconnect the main positive and negati...

Page 44

Maintenance, service, and repair front axle page 8 replace the king pins and bushings there are different types of king pin bushings depending on the configuration of your vehicle. • bronze bushings in the axle beam. • bronze bushings in the steering knuckle. • metal backed teflon bushings in the ax...

Page 45

Maintenance, service, and repair front axle page 9 failure to correctly broach or ream bronze bushings may result in steering difficulty and loss of control of the vehicle causing severe bodily injury and /or property damage. 7. Remove the steering knuckle. Refer to replace the steering knuckle for ...

Page 46: Replace The Steering Knuckle

Maintenance, service, and repair front axle page 10 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the rear wheels to prevent vehicle movement. 5. Disconnect the...

Page 47

Maintenance, service, and repair front axle page 11 12. Thoroughly clean and/or replace all bearings, nuts, washers, and bushings. Note: both the left and right side bushings and thrust bearings should be replaced as a set. 13. Assemble in reverse order. 14. Pack the thrust bearing with grease. 15. ...

Page 48

Maintenance, service, and repair front axle page 12 t a y l or - du n n t h e b e st w ay to go about yo ur bu si n e s s r.

Page 49: Steering Component Service

Table of contents front end alignment ..................................... 2 inspect ball joints ......................................... 6 inspect rod ends .......................................... 7 adjust the steering gear ............................... 8 replace the steering wheel .............

Page 50: Front End Alignment

Maintenance, service, and repair steering page 2 front end alignment this section will refer to two different types of ball joints. One type has a grease fitting and a tapered shaft where it is fitted to the steering arm or pitman arm. The second type cannot be greased and has a straight shaft. See ...

Page 51

Maintenance, service, and repair steering page 3 9. At this point both the steering wheel and the front wheels should be tied up and held in position. If one or the other is not tied up then you must start from the beginning. 10. Loosen the ball joint clamps or the rod end jam nuts on the drag link....

Page 52

Maintenance, service, and repair steering page 4 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the rear wheels to prevent vehicle movement. 5. Disconnect the ma...

Page 53

Maintenance, service, and repair steering page 5 rotate the steering wheel from a full left turn to a full right turn and make sure that the ball joint clamps do not contact any other component. Clamps positioned so that they contact other components may result in steering failure and loss of contro...

Page 54: Inspect Ball Joints

Maintenance, service, and repair steering page 6 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the rear wheels to prevent vehicle movement. 5. Disconnect the ma...

Page 55: Inspect Rod Ends

Maintenance, service, and repair steering page 7 inspect rod ends note: a set of ball joints and/or rod ends will wear at the same rate. If a ball joint and or rod end is worn out, then all should be replaced as a set. 6. Visually inspect each rod end for any signs of play between the ball and the n...

Page 56: Adjust The Steering Gear

Maintenance, service, and repair steering page 8 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the rear wheels to prevent vehicle movement. 5. Disconnect the ma...

Page 57: Replace The Steering Wheel

Maintenance, service, and repair steering page 9 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. 5. Disconnect the m...

Page 58: Replace The Steering Gear

Maintenance, service, and repair steering page 10 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the rear wheels to prevent vehicle movement. 5. Disconnect the m...

Page 59

Maintenance, service, and repair steering page 11 replace the ball joints, tie rods, and drag link this section will refer to two different types of ball joints. One type is has a grease fitting and a tapered shaft where it is installed on the steering arm or pitman arm. The second cannot be greased...

Page 60

Maintenance, service, and repair steering page 12 10. Install the new rod end into the steering sleeve. Screw it into the sleeve the same number of turns counted in the previous step. Do not tighten the rod end clamp or jam nut at this time. 11. Install the rod end into the steering arm. Tighten the...

Page 61

Maintenance, service, and repair steering page 13 12. Install the ball joint into the steering arm. Tighten the ball joint nut to 40-45 ft-lbs. And install a new cotter pin. 13. Realign the front wheels. Note: refer to the steering section for information regarding realignment of the front wheels. 1...

Page 62

Maintenance, service, and repair steering page 14 11. Lower the vehicle. 12. Reconnect the main positive and negative cables at the batteries. 13. Remove the blocks from behind the wheels. 14. Release the park brake and test drive the vehicle. Replacing the tie rod the tie rod is the linkage that co...

Page 63: Center The Steering Gear

Maintenance, service, and repair steering page 15 center the steering gear note: the drag link must be disconnected from the pitman arm or the pitman arm removed from the steering gear to perform this procedure. Refer to the appropriate section for details. 1. Rotate the input shaft clockwise until ...

Page 64: Repair The Steering Gear

Maintenance, service, and repair steering page 16 repair the steering gear disassembly for this procedure, the steering gear assembly must be removed from the vehicle. Refer to replace the steering gear section for information regarding removing the steering gear from the vehicle. 1. Center the stee...

Page 65

Maintenance, service, and repair steering page 17 steering gear exploded.

Page 66: Taylor -Dunn

Taylor -dunn.

Page 67: Brake Service

Table of contents inspect the service brake ............................. 2 auto-adjust brake mechanism operation .............. 2 inspecting the auto-adjust brake mechanism ....... 3 brake shoes ............................................................ 4 brake drum (dana) ..........................

Page 68: Inspect The Service Brake

Maintenance, service, and repair brakes page 2 inspect the service brake auto-adjust brake mechanism operation the auto-adjust mechanism is located on the bottom of the brake assembly and accessible through the oval slot in the brake drum. As the brake pad material wears down, the distance the brake...

Page 69

Maintenance, service, and repair brakes page 3 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. 5. Disconnect the mai...

Page 70

Maintenance, service, and repair brakes page 4 do not use a brake drum that is worn beyond its service limits. A drum worn beyond its service limits could fail and cause loss of brakes resulting in severe bodily injury and/or property damage. Current taylor-dunn ® brakes are asbestos free. However, ...

Page 71: Inspect The Park Brake

Maintenance, service, and repair brakes page 5 inspection and replacement of park brake pedal lock 6. Raise the rear of the vehicle and support with jack stands. 7. With the brake pedal in its fully extended position, remove the 1/2” bolt and locknut from under the pedal. 8. Remove the pedal and par...

Page 72

Maintenance, service, and repair brakes page 6 rear brake linkage adjustment 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle m...

Page 73

Maintenance, service, and repair brakes page 7 6. Raise the rear of the vehicle and support with jack stands. 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the ...

Page 74: Taylor -Dunn

Taylor -dunn.

Page 75: Motor Service

Table of contents inspecting the motor brushes ............ 2 motors with internal cooling fans ......................... 2 enclosed motors (ge, no cooling fan) ................. 2 motor removal and installation ......... 3 motor inspection ................................ 3 replacing the brushes......

Page 76: Inspecting The Motor Brushes

Motor service motor page 2 enclosed motors (ge, no cooling fan) general electric motors note: some motors may not have the brush inspection holes. In this case, the motor must be disassembled to inspect the brushes. For future inspections, holes msy be drilled into the motor housing after it has bee...

Page 77: Motor Removal And

Motor service motor page 3 advanced dc motors the enclosed advanced dc motors must be disassembled to inspect the motor brushes. Refer to motor inspection for information regarding disassembling the motor. Motor removal and installation see the transmission section for information on removing or ins...

Page 78

Motor service motor page 4 5. Inspect the commutator for burn marks. • burn marks and/or raised commutator segments 90 or 180 degrees apart is evidence of a shorted armature. A tool called a growler is required to reliably test for a shorted armature. 6. Inspect the commutator for raised segments. R...

Page 79: Replacing The Brushes

Motor service motor page 5 replacing the brushes note: it is recommended that all four brushes be replaced as a set. Note: motors without removable brush covers must be disassembled to replace the brushes. Refer to motor inspection-disassembly section for information on taking the motor apart. Note:...

Page 80: Replacing The Bearings

Motor service motor page 6 replacing the bearings 1. The motor must be removed from the vehicle for this procedure. Refer to transmission service section for information on removing the motor. 2. Remove the armature. Refer to motor inspection- disassembly section for information on taking the motor ...

Page 81: Service Limits

Motor service motor page 7 service limits motor specification number undercut depth commutator diameter (min) brush length (min) wire depth (max) mm inches mm inches mm inches mm inches 5bc58jbs6129a 0.635 0.025 66.75 2.625 19.05 0.75 38.1 1.5 5bc58jbs6129b 0.635 0.025 66.75 2.625 19.05 0.75 38.1 1....

Page 82: Taylor -Dunn

Taylor -dunn.

Page 83: Transmission Service

Table of contents check oil level ............................................. 2 change oil ..................................................... 3 motor ............................................................. 4 removal ................................................................... 4 ins...

Page 84: Check Oil Level

Maintenance, service, and repair transmission page 2 check oil level park the vehicle on a level surface. 6. Place a drain pan that can hold a minimum of 2-quarts of oil under the transmission level plug. 7. Remove the level plug. When the plug is removed, a small amount of oil should come out. This...

Page 85: Change Oil

Maintenance, service, and repair transmission page 3 level plug viewed from in front of the right rear wheel 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the f...

Page 86: Motor

Maintenance, service, and repair transmission page 4 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. 5. Disconnect t...

Page 87: Rear Hub With Brake Drum

Maintenance, service, and repair transmission page 5 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. 5. Disconnect t...

Page 88: Rear Axle

Maintenance, service, and repair transmission page 6 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. 5. Disconnect t...

Page 89

Maintenance, service, and repair transmission page 7 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. 5. Disconnect t...

Page 90

Maintenance, service, and repair transmission page 8 do not drill all of the way through the retainer into the axle shaft. Drilling into the axle shaft will weaken the axle shaft and could cause the axle to fail resulting in severe bodily injury and/or property damage. Replace the axle bearing note:...

Page 91: Transmission

Maintenance, service, and repair transmission page 9 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. 5. Disconnect t...

Page 92: Differential Case

Maintenance, service, and repair transmission page 10 differential case disassemble 1. Remove the transmission from the vehicle. Refer to transmission-remove section for information on removing the transmission. 2. Thoroughly clean the transmission assembly before disassembly. 3. Remove the left and...

Page 93

Maintenance, service, and repair transmission page 11 8. Remove the final drive gear from the differential housing. 9. Punch or drill a small hole into the center of both of the intermediate shaft bore plugs. 10. Thread a sheet metal screw into each plug until the bore plug is forced out. 11. Remove...

Page 94

Maintenance, service, and repair transmission page 12 the shaft and gear assembly must be supported by hand during the next step. Failure to properly support the shaft and gear assembly could result in damage to the gear teeth. 13. Remove the intermediate bearing with an id bearing puller. 14. While...

Page 95

Maintenance, service, and repair transmission page 13 19. Remove the o-rings from both sides of the intermediate shaft bore and the input shaft bore and discard the o-rings. Assemble note: when pressing bearings, do not press against or support the outer race as this will damage the bearing. Note: a...

Page 96

Maintenance, service, and repair transmission page 14 use a hard wood dowel the same diameter as the bearing bore to drive the bearing into place. Do not drive against the inner race as this will damage the bearing. 4. Install the input shaft into the housing and install the snap ring. 5. Insert the...

Page 97: Suspension

Table of contents suspension replace the rear springs ............................. 2 replace the front spring .............................. 3 replace the shocks ...................................... 4.

Page 98: Replace The Rear Springs

Maintenance, service, and repair suspension page 2 replace the rear springs 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle mo...

Page 99: Replace The Front Spring

Maintenance, service, and repair suspension page 3 replace the front spring 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the rear wheels to prevent vehicle mov...

Page 100: Replace The Shocks

Maintenance, service, and repair suspension page 4 replace the shocks it is recommended to replace both front shocks as a set. Note: on some vehicles it may be required to remove the front wheel to gain access to the shock mounting bolts. Refer to tires and wheels section for information regarding r...

Page 101: Tires and Wheels

Table of contents tire inflation .................................................. 2 tire inspection .............................................. 2 replace the front tire/wheel ....................... 3 replace the rear tire/wheel ........................ 3 repair the tire (pneumatic) ..............

Page 102: Tire Inflation

Maintenance, service, and repair tires and wheels page 2 tire inflation 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle moveme...

Page 103: Replace The Tire/wheel

Maintenance, service, and repair tires and wheels page 3 8. Inspect for uneven tire wear on the front tires. Uneven tire wear could be a result of an improperly inflated tire or a misaligned or damaged front end. Note: refer to tire inflation section or steering component service section for informa...

Page 104

Maintenance, service, and repair tires and wheels page 4 1 2 3 4 5 3 4 2 1 4-bolt pattern 5-bolt pattern pattern for tightening the wheel nuts do not attempt to repair a tire with a damaged side wall or a slice in the tread. This type of repair could fail prematurely resulting in severe bodily injur...

Page 105

Maintenance, service, and repair tires and wheels page 5 explosion hazard. Fully deflate the tire before attempting to remove the tire from the wheel. Do not over inflate the tire when seating the bead. Failure to deflate the tire or over inflating the tire to seat the bead may cause explosive failu...

Page 106: Taylor -Dunn

Taylor -dunn.

Page 107: Battery Service

Table of contents cleaning ........................................................ 2 testing ........................................................... 3 watering ........................................................ 5 charging ........................................................ 6 replacin...

Page 108: Cleaning

Maintenance, service, and repair batteries page 2 cleaning battery electrolyte will stain and corrode most surfaces. Immediately and thoroughly clean any surface outside of the battery that the battery electrolyte comes in contact with. Failure to clean may result in property damage. 1. Make sure th...

Page 109: Testing

Maintenance, service, and repair batteries page 3 testing note: a combination of the load test and specific gravity test should be used to accurately determine the condition of the batteries. Load test (6-volt batteries only) note: the batteries must be fully charged before performing this test. 1. ...

Page 110

Maintenance, service, and repair batteries page 4 typical hydrometer float specific gravity test note: the batteries must be fully charged before performing this test. The specific gravity of a cell is an indication of the actual state of charge of the cell. A fully charged cell should have a readin...

Page 111: Watering

Maintenance, service, and repair batteries page 5 watering note: the electrolyte level in a battery rises while charging and will be close to its highest level after the end of a charging cycle. It is recommended to fill the batteries at the end of a charging cycle. If the electrolyte is below the t...

Page 112: Charging

Maintenance, service, and repair batteries page 6 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. 5. Disconnect the ...

Page 113

Maintenance, service, and repair batteries page 7 battery electrolyte will stain and corrode most surfaces. Immediately and thoroughly clean any surface outside of the battery that the battery electrolyte comes in contact with. Failure to clean may result in property damage. 1. Make sure the key-swi...

Page 114

Maintenance, service, and repair batteries page 8 do not leave cables on batteries that have been removed from the vehicle. Cables left on batteries could cause a short circuit resulting in battery explosion, severe bodily injury and/or property damage. When torquing battery hardware, use a backup w...

Page 115

Maintenance, service, and repair batteries page 9 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. 5. Disconnect the ...

Page 116

Maintenance, service, and repair batteries page 10 if the batteries are removed from the vehicle, do not place them directly on the ground, concrete or solid metal surface. It is recommended to store them on a wooden pallet or equivalent. Storing on the ground, concrete or solid metal surface will c...

Page 117

Maintenance, service, and repair batteries page 11 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. 5. Disconnect the...

Page 118: Taylor -Dunn

Taylor -dunn.

Page 119: Electrical

Table of contents electrical troubleshooting symptoms: .....................................2 read this first ............................3 test equipment required: ....................................................... 3 important notes and instructions ...................... 3 definitions: .........

Page 120: Symptoms:

Curtis pmc troubleshooting page 2 rev fwd solenoids pmc speed control circuit breaker iso typical control panel symptoms: if your vehicle exhibits any of the following symptoms then skip the main troubleshooting sequence and proceed to symptom troubleshooting later in this section. • runs slow in bo...

Page 121: Read This First

Curtis pmc troubleshooting page 3 read this first test equipment required: • digital multimeter (dmm) with diode test function, fluke 79 model used in illustrations. • shunt or clamp-on dc ammeter to measure up to 400 amps. • test light with a rated voltage equal to or exceeds maximum battery voltag...

Page 122

Curtis pmc troubleshooting page 4 definitions: • “ms-1” = the first switch in the accelerator module. • “battery volts” = the voltage at the batteries at the time the test is completed. • “pick up” = energizing a solenoid or contactor. • “f&r” = forward and reverse. • “iso” = isolator. • “battery ne...

Page 123

Curtis pmc troubleshooting page 5 power output test set the test light voltage to the same voltage as the battery volts. Connect the test light from the pmc ‘m-’ terminal to battery positive. Close all interlock switches, turn the key switch on, and place the f&r switch in forward. Depress the accel...

Page 124

Curtis pmc troubleshooting page 6 control wire inputs the voltage shown is for illustration only. The actual voltage may vary. _ + positive main battery solenoids are shown for reference only. The type of solenoid in your truck may look different rev fwd iso iso fwd rev _ + solenoids are shown for r...

Page 125

Curtis pmc troubleshooting page 7 negative main battery b- m- a2 b+ #2 ksi fluke 79 off v hz series ii multimeter + − a Ω mv v the voltage shown is for illustration only. The actual voltage may vary. Negative main battery b- m- a2 b+ #2 ksi _ + the voltage shown is for illustration only. The actual ...

Page 126

Curtis pmc troubleshooting page 8 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. The rear drive wheels may rotate d...

Page 127

Curtis pmc troubleshooting page 9 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. The rear drive wheels may rotate d...

Page 128

Curtis pmc troubleshooting page 10 accelerator 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. The rear drive wheels...

Page 129

Curtis pmc troubleshooting page 11 key switch 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. The rear drive wheels ...

Page 130

Curtis pmc troubleshooting page 12 the cold terminal is the violet/black wire on either end of the switch battery negative or, the hot terminal is the violet/black wire on the center terminal battery negative violet/black forward and reverse side typical configuration of the terminals on a forward a...

Page 131

Curtis pmc troubleshooting page 13 f/r switch 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. The rear drive wheels ...

Page 132

Curtis pmc troubleshooting page 14 the reverse terminal is diagonally opposite the reverse side of the rocker on the switch battery negative a off mv v v hz fluke 79 series ii multimeter f&r switch seen from the rear f&r switch seen from the side depressed in the reverse gear the forward terminal is...

Page 133

Curtis pmc troubleshooting page 15 solenoids 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. The rear drive wheels m...

Page 134

Curtis pmc troubleshooting page 16 solenoids are shown for reference only. The type and position of the reverse solenoid in your truck may be different fwd/rev forward (does not run in reverse) connect a voltmeter across the pmc ksi terminal and battery negative. Close all interlock switches, turn t...

Page 135

Curtis pmc troubleshooting page 17 stop stop, do not continue. If you reached this point without a solution, then you may have an unanticipated problem or have made an error during testing. It is important to review the trouble shooting steps that have led to this point. The tests may need to be rep...

Page 136

Curtis pmc troubleshooting page 18 stop stop, do not continue. If you reached this point without a solution, then you may have an unanticipated problem or have made an error during testing. It is important to review the trouble shooting steps that have led to this point. The tests may need to be rep...

Page 137: Special Troubleshooting

Curtis pmc troubleshooting page 19 symptoms go to Ø runs slow in both directions plus high armature and field current in both directions. Note: armature and field current should be equal. Motor Ø runs slow in both directions plus high armature current in both directions. Note: field current will be ...

Page 138

Curtis pmc troubleshooting page 20 pmc control disconnect the wire from the ‘m-’ terminal on the pmc control and tape it off to prevent electrical contact. Connect a volt meter across the pmc #2 terminal and battery negative. Turn the key-switch on, close all interlock switches (if equipped), depres...

Page 139

Curtis pmc troubleshooting page 21 connect a volt meter across the pmc b+ and pmc m- terminals. Turn the key-switch on, close all interlock switches (if equipped), depress the accelerator pedal to engage the first micro switch only (creep speed), then perform the following tests: • the meter reading...

Page 140

Curtis pmc troubleshooting page 22 plugging diode remove the wires from the ‘b+’ and ‘a2’ terminals on the pmc control and perform the following test: using the diode test function on the dmm check for the presence of a diode across ‘b+’ and ‘a2’ on the pmc control.. If you do not know how to test f...

Page 141

Curtis pmc troubleshooting page 23 freewheel diode remove the wires from the ‘b+’ and ‘m-’ terminals on the pmc control and perform the following test: using the diode test function on the dmm check for the presence of a diode across ‘b+’ and ‘m- ’ on the pmc control. Refer to diode figure 2. If you...

Page 142

Curtis pmc troubleshooting page 24 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. 5. Disconnect the main positive a...

Page 143

Curtis pmc troubleshooting page 25 stop stop, do not continue. If you reached this point without a solution, then you may have an unanticipated problem or have made an error during testing. It is important to review the trouble shooting steps that have led to this point. The tests may need to be rep...

Page 144

Curtis pmc troubleshooting page 26 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. 5. Disconnect the main positive a...

Page 145

Curtis pmc troubleshooting page 27 motor shown for reference only. Terminal positions on your motor may not be in the same location. S2 a1 a2 s1 _ + b- m- a2 b+ #2 ksi motor shown for reference only. Terminal positions on your motor may not be in the same location. S2 a1 a2 s1 _ + stop trouble shoot...

Page 146

Curtis pmc troubleshooting page 28 with the key-switch on and the f&r switch in reverse, depress the accelerator pedal and perform the following tests: • check continuity from the wire that was connected to the pmc ‘m-’ terminal to the wire that was connected to the motor ‘s1’ terminal. If you do no...

Page 147

Curtis pmc troubleshooting page 29 motor high motor current in both the field and the armature, accompanied with a lack of power, would indicate a shorted armature and\or field. Another symptom that may exist is jumping or stuttering at low speeds and/or the motor will not run unless the armature is...

Page 148

Curtis pmc troubleshooting page 30 check continuity from ‘s1’ to the frame of the motor. If you do not know how to test for continuity, refer test to a qualified technician. This should be an open circuit. If there is continuity from ‘s1’ to the frame of the motor, then the motor field is shorted. S...

Page 149: Lestronic II

Table of contents lestronic ii ® charger troubleshooting operating instructions and theory of operation .........................2 testing the charging cycle ....................3 test equipment required for troubleshooting ..............................4 important notes and instructions -----------...

Page 150

Electrical troubleshooting charger troubleshooting page 2 operating instructions and theory of operation the lestronic ii ® chargers are designed as semiautomatic chargers. The lestronic ii ® charger turns itself on when the “built- in” charger is plugged into the wall outlet, or when the “portable”...

Page 151: Testing The Charging Cycle

Electrical troubleshooting charger troubleshooting page 3 testing the charging cycle in typical installations, the charger will remain on for up to 12 hours depending on the state of charge of the battery when the charge cycle was started. A charger could remain on for longer than 12 hours if: • the...

Page 152

Electrical troubleshooting charger troubleshooting page 4 test equipment required for troubleshooting digital multi meter (dmm) with diode and capacitor test function, fluke 79 ® model shown at right and in the troubleshooting illustrations. Important notes and instructions • this troubleshooting gu...

Page 153

Electrical troubleshooting charger troubleshooting page 5 troubleshooting for built-in charger 5. Disconnect the charger from the ac source. Locate the charger harness connectors where the charger harness is connected to the vehicle’s control harness. There will be two 10 gauge and two 14 gauge wire...

Page 154

Electrical troubleshooting charger troubleshooting page 6 • disconnect the charger from the ac source. • disconnect the batteries. • disconnect the charger from the vehicle’s harness. • remove the charger from the vehicle. Remove the charger cover and perform the following tests: 1. Inspect the inte...

Page 155

Electrical troubleshooting charger troubleshooting page 7 • test the voltage from the fuse assembly (-) to the diode block (+). This voltage should be equal to the battery voltage. If the voltage is less than the battery voltage, then the wires from the harness connectors to the charger are bad. Sto...

Page 156

Electrical troubleshooting charger troubleshooting page 8 troubleshooting for portable charger disconnect the charger from the ac outlet and the batteries. 1. Test the voltage from the positive terminal on the vehicles dc receptacle to main battery negative. This voltage should be equal to the batte...

Page 157: Testing The Timer Relay

Electrical troubleshooting charger troubleshooting page 9 5. Reconnect the lead to the diode. 6. Connect the charger to the ac source. Insert the dc charger plug into the dc receptacle and perform the following tests: • test the voltage from the fuse assembly (-) to the diode block (+). This voltage...

Page 158: Testing The Interlock Relay

Electrical troubleshooting charger troubleshooting page 10 testing the interlock relay operation the interlock relay disables the vehicle from running whenever the charger is connected to a working ac power source. When the charger is plugged in, the relay contacts open and break the key switch conn...

Page 159

Table of contents ® operating instructions and theory of operation ........................................2 hb/pt and gel indicator lamps ...........3 testing the charging cycle ....................3 test equipment required for troubleshooting ...............................4 important notes and in...

Page 160

Electrical troubleshooting signet charger troubleshooting page 2 operating instructions and theory of operation the model hb600w ® and hb1000w ® chargers are designed as semiautomatic chargers. The charger turns itself on when it is plugged into the wall outlet and turns off when the batteries are f...

Page 161: Testing The Charging Cycle

Electrical troubleshooting signet charger troubleshooting page 3 testing the charging cycle in typical installations, the charger will remain on for up to 12 hours depending on the state of charge of the batteries when the charge cycle was started. Note: charging time is limited to 18-hours (max). A...

Page 162

Electrical troubleshooting signet charger troubleshooting page 4 test equipment required for troubleshooting digital multi meter (dmm), fluke 79 ® model shown at right and in the troubleshooting illustrations. Clamp on dc ammeter to measure up to 20-amps. Important notes and instructions • this trou...

Page 163: Status Led Error Code Table

Electrical troubleshooting signet charger troubleshooting page 5 status led error code table there are three status lights (led’s) on the charger name plate. These led’s normally indicate the current operating state of the charger. If all three led’s are flashing, it indicate an error has occurred i...

Page 164: Troubleshooting

Electrical troubleshooting signet charger troubleshooting page 6 1. Make sure the key-switch is in the “off” position, then remove the key. 2. Place the forward-reverse switch in the center “off” position. 3. Set the park brake. 4. Place blocks under the front wheels to prevent vehicle movement. Tro...

Page 165: Charger Models:

Table of contents charger models: hbs 600 hbs 1000 signet ® charger troubleshooting definitions: ............................................2 test equipment required for troubleshooting ...............................2 important notes and instructions 2 operating instructions and theory of operatio...

Page 166: Definitions:

Electrical troubleshooting signet charger troubleshooting page 2 test equipment required for troubleshooting digital multi meter (dmm), calibrated and accurate down to 0.00001 volts. Clamp on dc ammeter to measure up to 20-amps. Important notes and instructions • this troubleshooting guide assumes a...

Page 167

Electrical troubleshooting signet charger troubleshooting page 3 operating instructions and theory of operation the model hbs 600w ® and hbs 1000w ® chargers are designed as automatic chargers. The charger turns itself on when it is plugged into the wall outlet and turns off when the batteries are f...

Page 168: Testing The Charging Cycle

Electrical troubleshooting signet charger troubleshooting page 4 testing the charging cycle in typical installations, the charge cycle will be completed in 8 to 12 hours depending on the state of charge of the batteries when the charge cycle was started. Note: the charge cycle time is limited to 20-...

Page 169

Electrical troubleshooting signet charger troubleshooting page 5 status light error code table if the fault light is on or flashing, it indicates a problem has occured during the charging cycle. If the light is flashing, it will flash from 2 to 6 times before a pause. This is the fault code. Refer t...

Page 170: Troubleshooting

Electrical troubleshooting signet charger troubleshooting page 6 troubleshooting note: there are no internally serviceable components in the charger. To test charger operation: connect a dc volt meter to the main battery positive and negative terminals. Attach a clamp on dc ammeter to one of the cha...

Page 171: Wire Diagrams

Table of contents wire diagrams complete vehicle .......................................... 2 dash ............................................................... 3 control panel ................................................. 4 accelerator module detail ............................. 5 lights .......

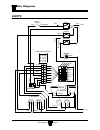

Page 172: Complete Vehicle

Wire diagrams wire diagrams page 2 complete vehicle 4 4 off right 4 way left white 3 3 black flasher 9 9 yellow black 6 6 8 7 7 black 8 blue gray/black 5 1 1 5 gray green blue b+ (flasher) turn switch logic black gry/blk gray red green left rr stop in right rr left ft right ft 2 1 3 red 6 5 9 8 4 7 ...

Page 173: Dash

Wire diagrams wire diagrams page 3 dash _ brown/white strobe + _ white hm + black white/black blue/black green/black violet/black r brown brown violet/black gray switch stop d1 strobe red _ black bsi + red light red key red red red violet/black violet/black violet/black black r black yellow violet/b...

Page 174: Control Panel

Wire diagrams wire diagrams page 4 control panel connect to r+ (coil) for reverse alarm or i+ (coil) for motion alarm 135a m- a2 black white green motion/reverse alarm green r blue/black white/black f yellow blue s2 black horn blue/white white black black green/black i red black d1 red r1 s1 red cb ...

Page 175: Accelerator Module Detail

Wire diagrams wire diagrams page 5 accelerator module detail black yellow violet/black green/black ms2 = micro switch 2 ms1 = micro switch 1 internal components are illustrated for reference only. There are no user serviceable parts inside of the accelerator module..

Page 176: Lights

Wire diagrams wire diagrams page 6 lights brown black white black white blue white gray tail lights red left right red green gray blue yellow white gray red stop switch gray violet/black white white yellow green head lights brown turn lights white left right brown white to -12v brown brown/white whi...

Page 177: Illustrated Parts

Table of contents front axle and suspension .......................... 2 steering linkage ......................................... 4 steering gear .............................................. 6 transmission differential case .................... 8 rear axle and brakes ...............................

Page 178: Front Axle and Suspension

Illustrated parts parts page 2 front axle and suspension.

Page 179

Ilustrated parts parts page 3 front axle and suspension item # part # description qty 1 92-104-00 beatring cap 2 2 88-239-85 castle nut 2 3 88-228-61 3/4 sae flat washer 2 4 80-017-00 bearing 4 5 80-103-00 race 6 12.124-00 hub 2 7 45-308-00 grease seal 8 14-110-25 steer knuckle, right 1 14-110-20 st...

Page 180: Steering Linkage

Illustrated parts parts page 4 steering linkage.

Page 181

Ilustrated parts parts page 5 steering linkage item # part # description qty 1 88-159-85 1/2nf castle nut 2 2 88-527-11 1/8 x 1 cotter pin 2 3 86-501-98 ball joint (left thread) 1 4 86-510-00 ball joint clamp 2 5 18-041-01 tie rod 1 6 86-501-99 ball joint (right thread) 1 7 86-519-10 rod end (right ...

Page 182: Steering Gear

Illustrated parts parts page 6 steering gear.

Page 183

Ilustrated parts parts page 7 steering gear (18-308-30) item # part # description qty 1 * steering wheel nut 1 2 * upper column bearing 1 3 * worm shaft 1 4 * upper worm bearing and race 1 5 * output shaft nut 1 6 * split lock washer 1 7 * oil seal 1 8 * lower worm bearing and race 1 9 * shim, 0.10 ...

Page 184

Illustrated parts parts page 8 transmission differential case 1 2 3b 4 5 6 7 6 5 8 3c 9 3d 9 8 5 6 7 15 10 16 10 3a 14 11 11 17 12 13.

Page 185

Ilustrated parts parts page 9 transmission (dana spec# 012aj308-1) item # part # description qty 4c-100-00 complete transmission assembly including brakes 1a special order housing 1 1b - carrier bearing cap (included with #1) 2 2 80-480-10 input shaft bearing 1 3a ** see kit below final gear 1 3b **...

Page 186: Rear Axle and Brakes

Illustrated parts parts page 10 rear axle and brakes.

Page 187

Ilustrated parts parts page 11 rear axle and brakes item # part # description qty 24 66-611-00 axle bolt 8 25 66-610-97 axle nut 8 26 66-611-10 retaining ring 2 27 45-303-40 oil seal 2 28 66-611-11 retaining ring 2 29 66-611-12 axle bearing 2 30 66-611-13 snap ring 4 31 * brake assembly (l) 1 32 * b...

Page 188: Rear Suspension

Illustrated parts parts page 12 rear suspension.

Page 189

Ilustrated parts parts page 13 rear suspension item # part # description qty 1 - - - 2 88-149-81 1/2 nc lock nut 8 3 96-248-01 bolt with grease fitting 3 4 88-169-82 9/16nf lock nut, grade c 3 5 32-249-00 bushing assembly 3 6 85-140-00 spring 2 7 86-602-00 shock 2 8 17-106-00 spacer 2 9 01-110-83 sp...

Page 190: Motor

Illustrated parts parts page 14 motor 2 3 5 6 4 7 8 1 9 10 armature 12.

Page 191

Ilustrated parts parts page 15 motor ge spec# 5bc58jbs6129a item # part # description qty 70-049-05 complete motor assembly (does not include #11) 1 70-201-15 field coils (mounted in motor housing) 1 2 70-210-51 inulator 2 3 85-412-00 brush spring 4 4 70-172-15 brush holder (includes #3) 1 5 70-104-...

Page 192: Brake Linkage

Illustrated parts parts page 16 brake linkage.

Page 193

Ilustrated parts parts page 17 brake linkage item # part # description qty 1 88-140-13 1/2 nc x 1-1/4 hex bolt 1 2 02-536-09 brake pedal 1 3 88-149-81 nut 1 4 * brake pedal shaft weldment 1 5 32-033-00 collar 2 6 96-773-00 5/16 x 1 clevis pin 4 7 88-517-11 1/8 x 1 cotter pin 4 8 50-002-17 brake rod ...

Page 194: Wheels and Tires

Illustrated parts parts page 18 wheels and tires ref., wheel hub 1 2 5 (assembly) 4 3 6 7 8 9 10

Page 195

Ilustrated parts parts page 19 wheels and tires item # part # description 1 wheels 12-012-00 5 x 8" tubeless 12-020-00 8.5 x 8 tubeless 12-050-00 12-1/8 diameter cast iron 2 tires 10-075-00 4.80 x 8 lr b pneumatic 10-076-00 4.80 x 8 lr c pneumatic 10-081-00 5.70 x 8 lr b pneumatic 10-082-00 5.70 x 8...

Page 196: Instrument Panel Console

Illustrated parts parts page 20 instrument panel console.

Page 197

Ilustrated parts parts page 21 instrument panel item # part # description qty 1 71-120-10 key switch 1 2 71-100-00 light switches 2 3 74-009-00 battery status meter 1 4 71-039-02 forward and reverse switch 1 5 94-386-03 console decal 1 6 00-110-01 console 1 7 74-000-00 hour meter 1.

Page 198: Speed Control Panel

Illustrated parts parts page 22 speed control panel 4 6 7 5 21 20 19 13 10 rev fwd iso 8 8 1 2 11 12 14 15 16 solenoid end view from side closest to pmc 9 17 17 18 end view of pmc (#5).

Page 199

Ilustrated parts parts page 23 speed control panel item # part # description qty 1 79-844-00 circuit breaker 1 2 88-818-06 #8 x 1/2 pan head screw, type b thread 2 3 - - - 4 79-840-20 circuit breaker 1 5 62-204-00 pmc speed control 1 6 72-501-36 iso solenoid (spst), includes #15, 16 and 18 1 7 72-50...

Page 200: Miscellaneous Electrical

Illustrated parts parts page 24 miscellaneous electrical horn switch mounted 5 7 6 floorboard mechanical brake light switch mounted under floorboard 8 9 seat interlock switch accelerator module 10 14 13 11 12 seat frame 1 motion alarms miscellaneous wire harness clamps 2 3 17 16 15 18 4.

Page 201

Ilustrated parts parts page 25 miscellaneous electrical item # part # description qty not shown 75-152-70 chassie control harness 1 not shown 75-149-85 power harness 1 not shown not shown 98-599-15 plastic grommet for 1.75 hole not shown 98-599-20 plastic grommet for 2.5 hole not shown not shown not...

Page 202: Miscellaneous Frame and Body

Illustrated parts parts page 26 miscellaneous frame and body.

Page 203

Ilustrated parts parts page 27 miscellaneous frame and body item # part # description qty 1 90-147-30 driver seat cushion 1 2 90-147-30 passenger seat cushion 1 3 90-179-10 seat back 1 4 01-110-16 deck lid 1 5 94-035-01 seat trim 7 feet 6 98-455-50 heat shrink tube 6 inches 7 01-110-20 accelerator p...

Page 204: Charger Page 1

Illustrated parts parts page 28 charger page 1 chargers.Dwg 6 8 5 4 3 7 11 1 2 8 3 4 5 10 7 6 2 1 8 9 typical built in charger typical portable charger.

Page 205

Ilustrated parts parts page 29 16920 79 -309 -20 48lc25 -8et 230/50/na 48/25 built -in - s/o 79 -808 -20 79 -902 -00 79 -749 -13 s/o n/a 79 -831 -00 79 -530 -00 - - - n/a 22620 79 -303 -25 48lc25 -8et 115/60/15 48/25 built -in - 79 -805 -68 79 -808 -20 79 -902 -00 79 -749 -13 79 -603 -10 - 79 -831 -...

Page 206: Charger Page 2

Illustrated parts parts page 30 chargers.Dwg 6 8 5 4 3 7 11 1 2 8 3 4 5 10 7 6 2 1 8 9 typical built in charger typical portable charger charger page 2.

Page 207

Ilustrated parts parts page 31 12315 79 -306 -90 36lc40 -8et 230/50/8 36/40 portable 79 -852 -00 k4 -071 -87 79 -808 -00 79 -902 -00 79 -749 -10 s/o s/o 79 -831 -00 79 -532 -00 79 -530 -00 79 -567 -10 - - 7030 79 -304 -60 36lc25 -8et 230/50/7 3625 portable 79 -851 -10 k4 -071 -87 79 -808 -00 79 -902...

Page 208: Charger Page 3

Illustrated parts parts page 32 charger page 3 note: the harness connectors and ac plug are not included with the charger. Qty part # description 2 75-318-20 butt splice 2 75-320-51 knife connector 1 76-200-00 ac plug, 115v domestic model hbs for flooded batteries part # description * 24 volt charge...

Page 209: Lights

Ilustrated parts parts page 33 lights lights item # part # description qty 94-050-10 headlight, left 1 94-050-11 headlight, right 1 94-050-04 headlight retainer 4 00-110-02 headlight panel 1 72-022-00 tailight 1 or 2 72-022-51 tailight gasket 1 or 2 72-023-20 strobe light 1 illustration not availabl...

Page 210: Batteries

Illustrated parts parts page 34 batteries pos pos pos pos pos pos neg neg neg neg neg 1 2 7 8 neg main positive 12-v negative tap main negative 6 5 4 3.

Page 211

Ilustrated parts parts page 35 batteries item # part # description qty 1 75-231-00 battery jumper 5 2 77-042-00 217ah, t-105 0 or 6 77-042-50 217ah, td-217 0 or 6 77-042-80 217ah, t-105 moist charge (dry) 0 or 6 77-044-00 230ah, t-125 0 or 6 77-044-10 195ah, mainenance free (note: requires special c...

Page 212: Decals

Illustrated parts parts page 36 decals.

Page 213

Ilustrated parts parts page 37 decals item # part # description qty 1 94-384-00 park brake 1 2 94-301-42 arms and legs 1 3 94-384-14 when leaving vehicle 1 4 94-384-01 not a motor vehicle 0 or 1 94-384-04 not a motor vehicle (export vehicles) 0 or 1 5 94-313-00 battery warning 1 6 94-319-00 dissconn...

Page 214: Sun Top and Windshield

Illustrated parts parts page 38 sun top and windshield.

Page 215

Ilustrated parts parts page 39 sun top and windshield item # part # description qty 1 91-046-00 sun top 1 2 91-028-88 rear suport 1 3 90-825-06 right post 1 4 90-825-05 left post 1 5 91-028-90 upper support 1 6 90-825-20 windshield 1 7 98-314-01 gasket 1 8 98-603-00 grommet 8 9 88-065-11 1/4nc x 1 t...

Page 216: Mirrors

Illustrated parts parts page 40 mirrors multi-panel mirror side mirror 9 11 2 1 2 5 4 6 7 3.

Page 217

Ilustrated parts parts page 41 multi-panel mirror item # part # description qty 1 92-207-00 mirror 1 2 01-110-95 mounting bracket 2 side mirror item # part # description qty 1 92-201-00 mirror 1 or 2 2 92-202-12 mounting bracket (left) 1 3 88-088-61 5/16 sae flat washer 2 4 88-080-09 5/16nc x 3/4 he...

Page 218: Tool Box / Luggage Rack

Illustrated parts parts page 42 tool box / luggage rack 2 1 3 tool box luggage rack.

Page 219

Ilustrated parts parts page 43 tool box / luggage rack item # part # description qty 1 71-040-95 lock 1 2 90-547-14 tool box 1 3 90-547-11 luggage rack 1.

Page 220

Illustrated parts parts page 44.

Page 221: Taylor -Dunn

Taylor -dunn.

Page 222: Appendix A-Special Tools

Appendix a-special tools.

Page 223: Special Tools

Appendix a page 2 special tools special tools d e s c r i p t i o n p u r p o s e p a r t n u m b e r pinion seal installation tool used to install the pinion seal on all chain drive trucks with the band style brake or the speed sensor on the chain case cover. 43-201-50 chain case centering tool use...

Page 224: Appendix B:

Table of contents appendix b: standard hardware suggested torque limits hardware identification ................................. 2 standard head markings ......................................... 2 hex bolts .................................................................. 2 other bolts .............

Page 225: Hardware Identification

Appendix b appendix b page-2 hardware identification standard head markings s.A.E. Grade 2 s.A.E. Grade 5 truss head, grade 2 carriage bolt, grade 2 (unless marked as above) other bolts note: torque value used should be for lowest grade of hardware used. If a grade 2 nut is used on a grade 8 bolt, u...

Page 226

Appendix b appendix b page-3 hex nuts s.A.E. Grade 5 s.A.E. Grade 8 hex lock nuts (stover) c or, or, b or, or, nuts with no markings are to be treated as s.A.E. Grade 2 lock nuts use a letter to indicate the grade of the nut. Grade a’ locknuts would be the equivelent of grade ‘2’ hex nuts, grade ‘b’...

Page 227: Suggested Torque Values

Appendix b appendix b page-4 diameter and tpi grade 2 tightening torque (ft-lb) grade 5 tightening torque (ft-lb) grade 8 tightening torque (ft-lb) l'9 tightening torque (ft-lb) 1/4-20 4-7 7-10 10-14 11 1/4-28 5-8 8-12 11-16 12 5/16-18 9-14 14-21 20-29 22 5/16-24 10-15 15-23 22-33 25 3/8-16 16-24 25...

Page 228: Suggested Torque Values

Appendix b appendix b page-5 suggested torque values (critical hardware) torque table torque range group description ft-lbs in-lbs nm brakes - - - - - - - - - - - - - - - - - - - - - - - - brake bolt (disc brake body) 11 - 11 132 - 132 15 - 15 brake line tube nut fittings 12 - 13 144 - 156 16.3 - 17...

Page 229: Taylor -Dunn

Taylor -dunn.

Page 230: Appendix C

Appendix c.

Page 231

Brake lining precautions appendix c page 2 brake lining handling precautions taylor-dunn does not currently supply asbestos fiber-brake pads/shoes with any vehicle. However, there is the possibility that the original brake pads/shoes were replaced with aftermarket pads/shoes containing asbestos. Sin...

Page 233

Taylor-dunn ® mfg. 2114 w. Ball rd. Anaheim, ca 92804 (800)-688-8680 (714) 956-4040 (fax) (714) 956-0504 mailing address: p.O. Box 4240 anaheim, california 92803 visit our website: www.Taylor-dunn.Com.