- DL manuals

- Taylor

- Freezer

- H60

- Operator's Manual

Taylor H60 Operator's Manual

Summary of H60

Page 1

Operator’s manual model h60 shake freezer original operating instructions 055165- m 6/01/01 (original publication) (updated 7/17/14).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e 2001 carr...

Page 3: Table Of Contents

Table of contents model h60 table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Site p...

Page 4

Model h60 table of contents table of contents - page 2 manual brush cleaning 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Draining product from the freezing cylinder 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rinsing 31 . . . . . ...

Page 5: Section 1

1 model h60 to the installer 131108 section 1 to the installer the following information has been included in the manual as safety and regulatory guidelines. For complete installation instructions, please see the installation checklist. Installer safety in all areas of the world, equipment should be...

Page 6

2 model h60 to the installer 120416 air cooled units do not obstruct air intake and discharge openings: air cooled units require a minimum of 6” (152 mm) minimum air clearance on all sides and 7- 1/2” (191 mm) minimum on bottom. Minimum air clearances must be met to assure adequate air flow for opti...

Page 7

3 model h60 to the installer 131105 s stationary appliances which are not equipped with a power cord and a plug or another device to disconnect the appliance from the power source must have an all-pole disconnecting device with a contact gap of at least 3 mm installed in the external installation. S...

Page 8: Section 2

4 model h60 to the operator 131108 section 2 to the operator the model h60 shake freezer has been carefully engineered and manufactured to give you dependable operation. This unit, when properly operated and cared for, will produce a consistent, quality product. Like all mechanical products, it will...

Page 9: Section 3

5 model h60 safety section 3 safety we, at taylor company, are concerned about the safety of the operator at all times when they are coming in contact with the unit and its parts. Taylor makes every effort to design and manufacture built- in safety features to protect both operators and service tech...

Page 10

6 model h60 safety 131105 s do not allow untrained personnel to operate this machine. S do not operate the freezer unless all service panels and access doors are restrained with screws. S do not remove any internal operating parts (examples: freezer door, beater, scraper blades, etc.) unless all con...

Page 11: Section 4

7 model h60 operator parts identification 140611 section 4 operator parts identification h60

Page 12

8 model h60 operator parts identification 140611 h60 exploded view parts identification item description part no. 1 kit a.- cover- hopper x65369 2 agitator a.- mix hopper x44797 3 panel- side *left 067721 4 stud- nose cone 5/16- 18 011390 5 pan- drip 19- 1/2 long 035034 6 shield- splash- wire 046177...

Page 13

9 model h60 operator parts identification 140611 h60 door and beater assembly item description part no. 1 seal- drive shaft 032560 2 shaft- beater 035527 3 beater a.- 7qt- 1 pin x46233 4 bearing- front 013116 5 gasket- door 5.177id 016672 6 bearing- guide 014496 7 torque a. X17381 8 arm- torque 0145...

Page 14

10 model h60 operator parts identification h60 syrup tank - 045533 item description part no. 1 tank- syrup- 4 qt. 045533 1a cover- tank w/ ftg 035759- 1 1b tip- nylon- white transl. 042747* 1c o- ring- 3.437 id x .275 w 016037 1d tube- dip- 4 qt. 015441- 7 1d- 1 o- ring- .291 id x .080w 018550 2 plu...

Page 15

11 model h60 operator parts identification 140717 accessories item description part no. 1 brush-mix pump body - 3” x 7” white 023316 2 brush-end-door-spout 039719 3 kit a.-tune up x34615 4 brush-double ended 013072 5 brush-rear brg 1in.D x 2in 013071 item description part no. 6 brush-draw valve 0147...

Page 16: Section 5

12 model h60 important: to the operator section 5 important: to the operator item description 1 power switch (toggle) 2 liquid crystal display 3 lcd indicator - mix low (pcb a.- led) 4 lcd indicator - mix out (pcb a.- led) 5 consistency control (switch- torque) 6 flavor selector keypad (switch- memb...

Page 17

13 model h60 important: to the operator power switch when placed in the on position, the power switch allows control panel operation. The power switch is located on the left side of the control channel. Liquid crystal display the liquid crystal display (lcd) is located on the front control panel. Th...

Page 18

14 model h60 important: to the operator operating screen descriptions when the machine is powered the system will initialize. The screen will display “initializing”. There will be four types of data the system will check: language, system data, config data, and lockout data. During the initializing....

Page 19

15 model h60 important: to the operator 070316 the following displays pertain to the heat cycle: effective 12/8/06, a system alert screen was added to display an alert and alarm 15 minutes prior to the start of the heat cycle. The system alert functions similar to the fault description except there ...

Page 20

16 model h60 important: to the operator follow these guidelines will cause the control to lock the freezer out of the auto mode. Press the wash key. No auto operation allowed until brush cleaning press wash key the next display is the screen which will appear after the brush cleaning message and ill...

Page 21

17 model h60 important: to the operator 060807 operator menu the operator menu is used to enter the operator function displays. To access the operator menu, simply press the menu/sel key. The cursor will flash over the letter “a” indicating that this is screen “a”. To select a different screen, use ...

Page 22

18 model h60 important: to the operator 081111 screen “c” is set clock. This screen will display the current date and time. The date and time may only be changed after the freezer has been manually brush cleaned but before it has been placed in the auto mode. Move the cursor under the number you wis...

Page 23

19 model h60 important: to the operator the servings counter screen indicates the number of times the draw switch has closed (number of draws) since the last brush cleaning or since the last serving counter reset. A maximum of 32,767 draws can be recorded; an additional draw will cause the counter t...

Page 24: Section 6

20 model h60 operating procedures section 6 operating procedures the model h60 has one 7 quart (6.6 liter) freezing cylinder. This automatic freezer offers four separate flavors which are blended and ejected from one spout. (use only single strength syrup that is free of pulp and seeds.) we begin ou...

Page 25

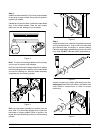

21 model h60 operating procedures step 2 install the beater assembly. First check scraper blades for any nicks or signs of wear. If any nicks are present, replace both blades. If blades are in good condition, install the scraper blade clips on the scraper blades. Place the rear scraper blade over th...

Page 26

22 model h60 operating procedures step 4 install the draw valve. Lubricate the plastic spinner bearing. Insert the plastic spinner bearing into the top of the draw valve. Figure 8 slide the two o- rings onto the draw valve and lubricate. Figure 9 lubricate the inside of the door spout, top and botto...

Page 27

23 model h60 operating procedures install the freezer door. Locate the torque rotor in the center hole of the freezer door. Position the door on the four studs on the front of the freezing cylinder and firmly push it into place. Install the four handscrews on the studs and finger- tighten equally in...

Page 28

24 model h60 operating procedures locate the spinner coupling and slip it over the slotted end of the spinner blade shaft. Raise the slip collar on the coupling and turn the shaft until the spinner coupling slips down into its locking position. Figure 16 step 8 rotate the draw valve to the left, and...

Page 29

25 model h60 operating procedures 080627 slide the two o- rings into the grooves of the outer air tube. Figure 21 step 13 lay the inner air tube, outer air tube, and agitator in the bottom of the mix hopper for sanitizing. Figure 22 sanitizing step 1 prepare an approved 100 ppm sanitizing solution (...

Page 30

26 model h60 operating procedures 140717 step 6 with a pail beneath the dispensing spout, open and close the draw valve six times. Draw off the remaining sanitizing solution. Figure 24 step 7 once the sanitizer stops flowing from the dispensing spout, close the draw valve and press the wash key, can...

Page 31

27 model h60 operating procedures step 2 when mix stops bubbling down into the freezing cylinder, install the assembled air tubes in the mix inlet hole. The pin on the inner air tube should be turned and positioned at the bottom of the notch in the outer air tube. This will align the holes in the ai...

Page 32

28 model h60 operating procedures 010917 step 2 remove the spinner blade from spinner housing. Remove the spinner bearing from the draw valve and the spinner housing from the freezer door spout. Disconnect syrup lines from fittings on front panel. Take these parts to the sink for further cleaning an...

Page 33

29 model h60 operating procedures 080627 daily opening procedures evaluate the condition of led’s (lights) and screen messages (hard lock or soft lock, etc.) before performing opening procedures. As indicated in the illustration below, 4 flashing led’s, indicate a “locked” condition. Figure 32 make ...

Page 34

30 model h60 operating procedures syrup system two main objectives in your opening procedures must be to: (1) fill the syrup tanks, and (2) calibrate the syrup flow. This must be checked daily to insure the high quality shake you desire. Discard syrup weekly and flush syrup lines at least once a wee...

Page 35

31 model h60 operating procedures if more than 1 fl. Ounce (29.6 ml.) of syrup is received, the pressure must be decreased. Loosen the lock nut and turn the adjusting screw counterclockwise to zero. Remove the air line to the syrup tank to allow the pressure in the tank to dissipate. Reconnect the a...

Page 36

32 model h60 operating procedures 140717 step 2 with a pail beneath the door spout, press the wash key. Step 3 open the draw valve on the freezer door. Drain all the rinse water from the door spout, close the draw valve, and press the wash key cancelling the wash cycle. Repeat this procedure until t...

Page 37

33 model h60 operating procedures step 2 remove the: s seal from the drive shaft s o- rings and guide bearing from the torque rotor s draw valve from the freezer door s o- rings from the draw valve s spinner bearing from the draw valve s gasket and front bearing from the freezer door. Note: to remov...

Page 38

34 model h60 operating procedures pour off all sanitizing solution and place the tank in an upside- down position on a clean dry surface to air dry. Repeat this procedure for all the syrup tanks. Step 2 sanitizing the syrup lines. Prepare one gallon (3.8 liters) of the recommended sanitizing solutio...

Page 39: Section 7

35 model h60 important: operator checklist 051208 section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by federal, state, or local regulatory agencies, and must be followed accordingly. The following c...

Page 40

36 model h60 important: operator checklist 080627 winter storage if the place of business is to be closed during the winter months, it is important to protect the freezer by following certain precautions, particularly if the building is subject to freezing conditions. On water cooled freezers, disco...

Page 41: Section 8

37 model h60 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. Soft lock message appears on lcd. A. More than 24 hours since the last heat cycle. A. The freezer must go through a heat cycle every 24 hours. The freezer must now be disassembled and brush ...

Page 42

38 model h60 troubleshooting guide problem probable cause remedy page ref. 2. Hard lock message appears on lcd. A. There has been a thermistor failure (freezing cylinder, hopper, or glycol) during the heat treatment process. A. The freezer must be disassembled and brush cleaned. 15 b. More than 14 d...

Page 43

39 model h60 troubleshooting guide problem probable cause remedy page ref. 5. The product is too soft. A. Improper consistency control adjustment. A. Product, with no syrup blended (vanilla), should be dispensed at 26_ to 28_f. (- 3.3_ to - 2.2_c.). 13 b. The torque rotor is binding. B. Before insta...

Page 44

40 model h60 troubleshooting guide problem probable cause remedy page ref. 9. The drive shaft is stuck in the gear box coupling. A. Rounded corners of drive shaft, coupling, or both. A. Call service technician to correct cause and replace the necessary components. Do not lubricate end of drive shaft...

Page 45

41 model h60 troubleshooting guide problem probable cause remedy page ref. 13. No freezer operation after placing unit in the auto mode. A. Unit unplugged. A. Plug into wall receptacle. - - - b. Circuit breaker off or blown fuse. B. Turn circuit breaker on or replace fuse. - - - c. Beater motor out ...

Page 46: Section 9

42 model h60 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually qty. Drive shaft seal x 1 scraper blades x 2 freezer door gasket x 1 front bearing x 1 draw valve o- rings x 2 torque rotor guide bearing x 1 torque rotor o- rings x 2...

Page 47

43 model h60 limited warranty on equipment section 10 limited warranty on equipment taylor company limited warranty on freezers taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor-branded freezer equipment availabl...

Page 48

44 model h60 limited warranty on equipment 3. Replacement of wear items designated as class “000” parts in the taylor operator’s manual. 4. External hoses, electrical power supplies, and machine grounding. 5. Parts not supplied or designated by taylor, or damages resulting from their use. 6. Return ...

Page 49: Section 11

45 model h60 limited warranty on parts section 11 limited warranty on parts taylor company limited warranty on taylor genuine parts taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor genuine replacement components...

Page 50

46 model h60 limited warranty on parts limited warranty exceptions this limited warranty does not cover: 1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of defective parts, replacement parts, or new parts. 2. Normal maintenance, clean...

Page 51

47 model h60 limited warranty on parts limitation of warranty this limited warranty is exclusive and is in lieu of all other warranties, conditions and/or remedies under the law, including any implied warranties or conditions of merchantability or fitness for a particular purpose. The original owner...

Page 52: Section 12

Section 12 parts list + available separately 48 parts list model h60 de s cri p t io n part num be r h60 qty . W arr. Cl as s re m arks part s up da t e accumulator a. -a ir *5472* prtl x46916 1 103 fi tti ng a. -a ir accumulator x48548 1 103 j5010000/ up 90 + t ube- vi nyl 1 /8 id x 1 /1 6 w all 02...

Page 53

49 + available separately model h60 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s h60 qty . Part num be r brush- double ended- pump& f eed tube 013072 1 000 brush- draw valve 1- 1/ 2” od x 3 ” 014753 1 000 brush- end- door- spout- ss- ht 039719 1 000 brush- mi x p ump b ody-...

Page 54

+ available separately 50 parts list model h60 de s cri p t io n part s up da t e re m arks w arr. Cl as s h60 qty . Part num be r + valve- access 1/ 4flx5/ 16sdr- 90 053027 1 103 use w it h f rench bui l t c ompressor com p ressor m 51b143bbca (bri s tol) 036880- 1 512 j4063682/ pri o r 83 + c apac...

Page 55

51 + available separately model h60 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s h60 qty . Part num be r door a. -parti al- 1 spt x17373 1 103 + beari n g- front 013116 1 000 + beari n g- spi nner *452* 017032 1 000 + valve a. -draw *h60* x54821 1 k1013585 replaces x46671 +...

Page 56

+ available separately 52 parts list model h60 de s cri p t io n part s up da t e re m arks w arr. Cl as s h60 qty . Part num be r + t ube- vi nyl 3 /16i d x 1/ 16 w a ll 020940- 6 2 000 bulk- 100ft r 30314 (syrup ho usi n g ) + t ube- vi nyl 3 /16i d x 1/ 16 w a ll 020940- 8 2 000 bulk- 100ft r 303...

Page 57

53 + available separately model h60 parts list 140717 de s cri p t io n part s up da t e re m arks w arr. Cl as s h60 qty . Part num be r mani fold a. -r egulator *h 60* x47285 1 103 decal- flavor c olor set '4 ' 022105 1 000 fi tti ng 1/ 4 x .170 90 deg r ee 075946 1 000 gauge- pressure 0- 60 psi 1...

Page 58

+ available separately 54 parts list model h60 de s cri p t io n part s up da t e re m arks w arr. Cl as s h60 qty . Part num be r panel a. -f ront *h 60* x46634 1 103 panel a. -s id e l ow er (l eft) x24397 1 103 j4063682/ pri o r 83 panel a. -s id e l ow er (r ig ht) x34681 1 103 j4063682/ pri o r...

Page 59

55 + available separately model h60 parts list 051103 de s cri p t io n part s up da t e re m arks w arr. Cl as s h60 qty . Part num be r p r o b ea .- m ixo u t -s q u a r eh o l e x41348 1 103 + o -r in g -1/ 2o d x .070w 024278 2 000 + spacer- p robe- round hole- 5 /8 di a 041347 1 103 + spacer- ...

Page 60

+ available separately 56 parts list model h60 de s cri p t io n part s up da t e re m arks w arr. Cl as s h60 qty . Part num be r shi e ld- splash- w ir e 13- 11/ 16l 046177 1 103 shroud- condenser *s h- ht- g en 3 041728 1 103 shro ud- left *5472 ht* 042083 1 103 shro ud- ri g h t *5472 ht* 042084...

Page 61

57 + available separately model h60 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s h60 qty . Part num be r sw it ch- pressure 25ps o pen 405 030886 1 103 j40663682/ pri o r 83 swi t ch- toggl e- dpdt* o n- none- o n 024295 1 103 pow e r tank- syr- 4 qt 045533 3 103 complete w...

Page 62

+ available separately 58 parts list model h60 de s cri p t io n part s up da t e re m arks w arr. Cl as s h60 qty . Part num be r elbow -1/ 4mp x 1 /4 barb- plasti c 016614 3 103 elbow -1/ 4mp x 3 /16barb- plasti c 016615 3 103 ferrule- .475 id np brass 021082 3 000 label- 1 /4 x 1 -1 /2 long- b ro...

Page 63

59 + available separately model h60 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s h60 qty . Part num be r 50 hz belt 007098 1 000 block- termi n al- 3 pole 039424 1 103 220- 240/ 380- 415v- 50- 3 capaci t or- run 012906 1 103 j4063682/ pri o r (bri s to l) capaci t or- run 0...

Page 64

Model h60 046638- 27 rev. 8/11.

Page 65

Model h60 046638- 33 rev. 8/11.

Page 66

Model h60 046638- 34 rev. 8/11.

Page 67

Model h60 046638- 35 rev. 8/11.