- DL manuals

- Taylor

- Freezer

- H62

- Operating Instructions Manual

Taylor H62 Operating Instructions Manual

Summary of H62

Page 1

Models h62 & h63 shake/slush freezers original operating instructions 067343--m 4/1/09 (original publication) (updated 4/16/12).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: a e april, 20...

Page 3: Table Of Contents

Models h62 & h63 table of contents table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

Table of contents models h62 & h63 table of contents -- page 2 daily opening procedures 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Manual brush cleaning 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5: Section 1

1 models h62 & h63 to the installer section 1 to the installer the following are general installation instructions. For complete installation details, please see the check out card. Installer safety in all areas of the world, equipment should be installed in accordance with existing local codes. Ple...

Page 6

2 models h62 & h63 to the installer 111012 air cooled units do not obstruct air intake and discharge openings: air cooled units require a minimum of 6” (152 mm) of clearance around all sides of the freezer and 7--1/2” (191 mm) on the bottom to allow for adequate air flow across the condenser. Failur...

Page 7

3 models h62 & h63 to the installer s stationary appliances which are not equipped with a power cord and a plug or another device to disconnect the appliance from the power source must have an all-pole disconnecting device with a contact gap of at least 3 mm installed in the external installation. S...

Page 8: Section 2

4 models h62 & h63 to the operator section 2 to the operator the models h62 and h63 shake freezers have been carefully engineered and manufactured to give you dependable operation. These units, when properly operated and cared for, will produce a consistent, quality product. Like all mechanical prod...

Page 9: Section 3

5 models h62 & h63 safety 111020 section 3 safety we, at taylor company, are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built--in safety features to protect both you and the s...

Page 10

6 models h62 & h63 safety s do not allow untrained personnel to operate this machine. S do not operate the freezer unless all service panels and access doors are restrained with screws. S do not remove any internal operating parts (examples: freezer door, beater, scraper blades, etc.) unless all con...

Page 11: Section 4

7 models h62 & h63 operator parts identification 120215 section 4 operator parts identification h62 exploded view figure 1 item description part no. 1 kit a.-cover-hopper x65368 2 spacer-probe *sq hole* 030966 3 disc-probe *sq hole* 030965 4 probe a.-mix low-ht x42077 5 blade a.-agitator x56591-sp1 ...

Page 12

8 models h62 & h63 operator parts identification 120214 h63 exploded view figure 2 item description part no. 1 kit a.-cover-hopper x65369 2 blade a.-agitator x56591-sp1 3 trim-rear corner 046668 4 panel a.-duct-right x67958-sp1 5 panel-rear w/louvers 026980-sp 6 adaptor a.-caster x18915 7 caster-swv...

Page 13

9 models h62 & h63 operator parts identification 120214 door and beater assembly figure 3 item description part no. 1 valve a.--draw x56119 2 o--ring--1--1/16 od x .139w 020571 3 o--ring 5/8 od x .103 w 016030 4 nut--stud 021508 5 plug--prime 067192 6 door a.--1 spout x67194--ser 7 o--ring--.291 id ...

Page 14

10 models h62 & h63 operator parts identification 111012 accessories figure 4 item description part no. 1 brush-mix pump body - 3” x 7” white 023316 2 brush-end-door-spout 039719 3 brush-double ended 013072 4 brush-rear brg 1in.D x 2in 013071 5 brush-draw valve 014753 item description part no. 6 lub...

Page 15: Section 5

11 models h62 & h63 important: to the operator 120206 section 5 important: to the operator h62 figure 5 item description 1 power switch (toggle) 2 led indicator--mix low (pcb a--led) 3 led indicator--mix out (pcb a--led) 4 led indicator--heat mode 5 liquid crystal display item description 6 led indi...

Page 16

12 models h62 & h63 important: to the operator 120206 h63 figure 6 item description 1 power switch (toggle) 2 liquid crystal display 3 led indicator--mix low (pcb a--led) 4 led indicator--mix out (pcb a--led) 5 led indicator--heat mode 6 led indicator--clean manually 7 consistency control (switch--t...

Page 17

13 models h62 & h63 important: to the operator power switch when placed in the on position, the power switch allows control panel operation. The power switch is located on the left side of the control channel. Liquid crystal display the liquid crystal display (lcd) is located on the front control pa...

Page 18

14 models h62 & h63 important: to the operator operating screen descriptions when the machine is powered the system will initialize. The screen will display “initializing”. There will be four types of data the system will check: language, system data, config data, and lockout data. During the initia...

Page 19

15 models h62 & h63 important: to the operator the following displays pertain to the heat cycle: a system alert screen displays an alert and alarm 15 minutes prior to the start of the heat cycle. The alarm will sound and show on the display. The alarm will sound until the sel key is pressed to clear...

Page 20

16 models h62 & h63 important: to the operator freezer locks there are two types of freezer lock conditions that can occur: hard lock or soft lock. A hard lock requires that the machine be disassembled and brush cleaned. A soft lock can be corrected by either disassembling and brush cleaning the mac...

Page 21

17 models h62 & h63 important: to the operator following are the variable messages which will appear on line 3: 1. Power switch off: power switch was in the off position. 2. Mix out present: there was a mix out condition present. 3. Auto or standby off: the unit was not in the auto or standby mode. ...

Page 22

18 models h62 & h63 important: to the operator 091210 clearing fault tones to clear the tone for any faults which have been corrected, press the more than one fault, press the menu/sel key. When the last fault is displayed, the control will return to the operator menu. To return to the main screen, ...

Page 23

19 models h62 & h63 important: to the operator 120126 the menu/sel key while under “enable” will accept the selection and will automatically increase the clock one hour at 2:00 a.M. On the first sunday in every april. It will decrease one hour at 2:00 a.M. On the last sunday in every october. Pressi...

Page 24

20 models h62 & h63 important: to the operator screen “h” is heat cycle data. The information from the previous heat treatment cycles can be obtained through this screen. The most recent heat treatment cycle data will be shown first; press the plus key to scroll through the remaining heat cycle disp...

Page 25

21 models h62 & h63 important: to the operator 091209 screen “l” is auto start time. This option allows the manager to set the time of day that the machine automatically enters the auto mode from the standby mode. Selecting this option displays the auto start time enable/disable screen. Pressing the...

Page 26: Section 6

22 models h62 & h63 operating procedures 120416 section 6 operating procedures the models h62 and h63 have 7 quart (6.6 liter) freezing cylinders and offer one flavor. The model h63 has been selected to show you the pictured step--by--step operating procedures for both models contained in this manua...

Page 27

23 models h62 & h63 operating procedures 111012 step 3 slide the beater into the freezing cylinder. Figure 9 step 4 make sure the beater assembly is in position over the drive shaft. Turn the beater slightly to be certain that the beater is properly seated. When in position, the beater will not prot...

Page 28

24 models h62 & h63 operating procedures step 7 slide the two o--rings onto the draw valve and lubricate. Figure 13 step 8 lubricate the inside of the door spout, top and bottom. Insert the draw valve into the freezer door from the top. It will be necessary to rotate the draw valve bracket to the ri...

Page 29

25 models h62 & h63 operating procedures step 12 install the freezer door. Locate the torque rotor in the center hole of the freezer door. Position the door on the four studs on the front of the freezing cylinder and firmly push it into place. Install the four handscrews on the studs and finger--tig...

Page 30

26 models h62 & h63 operating procedures 110527 step 17 lay the agitator in the bottom of the mix hopper for sanitizing. Figure 21 sanitizing step 1 prepare a pail of an approved 100 ppm sanitizing solu- tion (examples: 2--1/2 gal. [9.5 liters] of kay--5 r or 2 gal. [7.6 liters] of stera--sheen r )....

Page 31

27 models h62 & h63 operating procedures 091210 step 7 once the sanitizer stops flowing from the dispensing spout, close the draw valve and press the wash key, cancelling the beater motor operation. Figure 24 make sure your hands are clean and sanitized before performing the next step. Step 8 place ...

Page 32

28 models h62 & h63 operating procedures step 4 fill the hopper with fresh mix and place the mix hopper cover in position. Note: use only fresh mix when priming the freezer. Daily closing procedures this procedure must be performed once daily! The function of the heat treatment cycle is to destroy b...

Page 33

29 models h62 & h63 operating procedures 110527 step 7 return to the freezer with a small amount of cleaning solution. Dip the end brush into the cleaning solution and brush clean the door spout and bottom of the draw valve. Note: to assure sanitary conditions are maintained, brush each item for a t...

Page 34

30 models h62 & h63 operating procedures do not use a water jet to clean or rinse the freezer. Failure to follow these instructions may result in serious electrical shock. Step 5 return to the freezer with a small amount of sanitizing solution. Dip the end brush into the sanitizing solution and brus...

Page 35

31 models h62 & h63 operating procedures draining product from the freezing cylinder step 1 press the auto key, cancelling compressor and beater motor operation. Figure 32 step 2 remove the hopper cover and the agitator from the mix hopper. Take these parts to the sink for cleaning. Step 3 with a pa...

Page 36

32 models h62 & h63 operating procedures 110531 rinsing step 1 pour two gallons (7.6 liters) of cool, clean water into the mix hopper. With the brushes provided, scrub the mix hopper, mix level sensing probes, the outside of the agitator housing, and the mix inlet hole. Figure 36 step 2 with a mix p...

Page 37

33 models h62 & h63 operating procedures step 4 press the wash key and allow the cleaning solution in the freezing cylinder to agitate for five minutes. Figure 39 step 5 place an empty pail beneath the door spout. Step 6 open the draw valve on the freezer door and draw off all the solution. Step 7 o...

Page 38

34 models h62 & h63 operating procedures brush cleaning do not use a water jet to clean or rinse the freezer. Failure to follow these instructions may result in serious electrical shock. Step 1 prepare a sink with an approved cleaning solution (examples: kay--5 r or stera--sheen r ). Use warm water ...

Page 39: Section 7

35 models h62 & h63 important: operator checklist section 7 important: operator checklist during cleaning and sanitizing cleaning and sanitizing schedules are governed by your state or local regulatory agencies and must be followed accordingly. The following check points should be stressed during th...

Page 40

36 models h62 & h63 important: operator checklist winter storage if the place of business is to be closed during the winter months, it is important to protect the freezer by following certain precautions, particularly if the building is subject to freezing conditions. On water cooled freezers, disco...

Page 41: Section 8

37 models h62 & h63 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. Soft lock message appears on lcd. A. More than 24 hours since the last heat cycle. A. The freezer must go through a heat cycle every 24 hours. The freezer must now be disassembled and...

Page 42

38 models h62 & h63 troubleshooting guide 090826 problem probable cause remedy page ref. 2. Hard lock message appears on lcd. A. There has been a thermistor failure (freezing cylinder, hopper, or glycol) during the heat treatment process. A. The freezer must be disassembled and brush cleaned. 16 b. ...

Page 43

39 models h62 & h63 troubleshooting guide problem probable cause remedy page ref. 5. The product is too soft. A. Improper consistency control adjustment. A. Product should be dispensed at 27 _ to 29 _ f. (-2.8 _ to -1.7 _ c.). 13 b. The torque rotor is binding. B. Before installing the torque arm, c...

Page 44

40 models h62 & h63 troubleshooting guide problem probable cause remedy page ref. 9. The freezing cylinder walls are scored. A. The front bearing is missing or worn. A. Install or replace front bearing. 24 b. The gear box is out of alignment. B. Call a service technician to realign gear box. ------ ...

Page 45

41 models h62 & h63 troubleshooting guide problem probable cause remedy page ref. 12. No freezer operation after placing unit in the auto mode. A. Unit unplugged. A. Plug into wall receptacle. ------ b. Circuit breaker off or blown fuse. B. Turn circuit breaker on or replace fuse. ------ c. Beater m...

Page 46: Section 9

42 models h62 & h63 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually qty. Drive shaft seal x 1 front bearing x 1 freezer door gasket x 1 draw valve o-rings x 2 torque rotor guide bearing x 1 torque rotor o-rings x 2 prime plug o-...

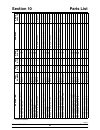

Page 47: Section 10

Section 10 parts list 43 + available separately models h62 & h63 parts list 120213 de s cri p t io n p art num be r h62 qty . H63 qty . W arr. Cl as s re m arks p art s up dat e accumulator- c opper 2" di a 13" 053377 1 1 103 adaptor a. -c aster x18915 4 103 adaptor- 5 /1 6 barb- 5/ 16fs 047958 7 4 ...

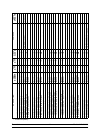

Page 48

+ available separately 44 parts list models h62 & h63 de s cri p t io n p art s up dat e re m arks w arr. Cl as s h63 qty . H62 qty . P art num be r cable- ri bbon- 20c- 33" l- di l 040040- 027 1 1 103 cable- ri bbon- 50c- 35" l- di l 040040- 044 1 103 cable- ri bbon- 50c- 20" l- di l 040040- 011 1 ...

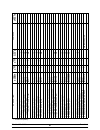

Page 49

45 + available separately models h62 & h63 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s h63 qty . H62 qty . P art num be r di splay- li qui d crystal x38062- ser 1 1 103 door a. -parti al- 1 spt x67194- ser 1 1 103 +plug -pri m e *h63* 067192 1 1 103 +o -r in g -5/ 8 o d x ...

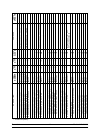

Page 50

+ available separately 46 parts list models h62 & h63 de s cri p t io n p art s up dat e re m arks w arr. Cl as s h63 qty . H62 qty . P art num be r harness- w ire- m ai n p ow er 067405- 33g 1 208- 230v 60hz 3 ph - 3 w ire harness- w ire 5472 m ai n pow er 056884- 33g 1 208- 230v 60hz 3 ph - 3 w ir...

Page 51

47 + available separately models h62 & h63 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s h63 qty . H62 qty . P art num be r ki t a. -tune up* 0 h63* x67224 1 1 000 beari ng- front 013116 1 1 000 beari ng- gui de 014496 1 1 000 gasket- d oor 5 .177i d x 5. 938o 016672 1 1 000...

Page 52

+ available separately 48 parts list models h62 & h63 de s cri p t io n p art s up dat e re m arks w arr. Cl as s h63 qty . H62 qty . P art num be r o -ri ng -. 291 id x .080w 018550 2 2 000 pai l- mi x 1 0 q t. 013163 1 1 000 pan- dri p 11- 5/ 8 l o n g 027503 1 103 pan- dri p 19- 1/ 2 l o n g 0350...

Page 53

49 + available separately models h62 & h63 parts list de s cri p t io n p art s up dat e re m arks w arr. Cl as s h63 qty . H62 qty . P art num be r pulley- ak74 x 5/ 8 051013 1 1 103 pum p -g lyco l- 1/ 8npt- 1650 rpm 041785 1 1 212 +adaptor- 1 /8 mp x 5 /1 6 barb- br 047325 2 2 103 +boot- p ump- g...

Page 54

+ available separately 50 parts list models h62 & h63 de s cri p t io n p art s up dat e re m arks w arr. Cl as s h63 qty . H62 qty . P art num be r sw it ch a. -draw *h60* x54791 1 1 103 arm a. -draw *h60* x54792 1 1 103 sw it ch- lever- spdt- 11a- 125- 27 039252 1 1 103 pi n- pi vot 015478 1 1 103...

Page 55

51 + available separately models h62 & h63 parts list 50 c ycle u nits de s cri p t io n p art num be r h62 qty . H63 qty . W arr. Cl as s re m arks belt- v- 4l410 007530 1 000 220- 240v 50hz 1 ph / 380- 415v 50hz 3 n~ belt- v- 4l420 004338 1 220- 240v 50hz 1 ph / 380- 415v 50hz 3 n~ belt- v- 4l410 ...

Page 56

+ available separately 52 parts list models h62 & h63 de s cri p t io n re m arks w arr. Cl as s h63 qty . H62 qty . P art num be r harness- w ire 5472 m ai n po 056884- 33g 1 1 103 200v 50/ 60hz 3 ph harness- w ire- m ai n p ow er * 067405- 33g 1 103 200v 50/ 60hz 3 ph harness- w ire- m ai n p ow e...

Page 57

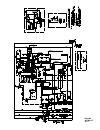

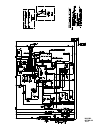

H62/h63 067368--27 10/11.

Page 58

H62/h63 067368--33 10/11.

Page 59

H62/h63 067368--40 10/11.

Page 60

H62/h63 067368--58 10/11.