- DL manuals

- Taylor

- Freezer

- RC25

- Operator's Manual

Taylor RC25 Operator's Manual

Summary of RC25

Page 1

Operator’s manual model rd30 & rc25 remote slush freezer original operating instructions 051060- m 11/99 (original publication) (updated 7/22/14).

Page 2: Table Of Contents

Models rd30/rc25 table of contents table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installer safety 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 3

Models rd30/rc25 table of contents table of contents - page 2 section 7 important: operator checklist 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . During cleaning and sanitizing 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Troubleshooting bac...

Page 4: Section 1

1 models rd30/rc25 to the installer 131209 section 1 to the installer the following information has been included in the manual as safety and regulatory guidelines. For complete installation instructions, please see the installation checklist. Installer safety in all areas of the world, equipment sh...

Page 5

2 models rd30/rc25 to the installer 130319 electrical connections in the united states, this equipment is intended to be installed in accordance with the national electrical code (nec), ansi/nfpa 70-1987. The purpose of the nec code is the practical safeguarding of persons and property from hazards ...

Page 6

3 models rd30/rc25 to the installer 120611 refrigerant in consideration of our environment, taylor proudly uses only earth friendly hfc refrigerants. The hfc refrigerant used in this unit is r404a. This refrigerant is generally considered non-toxic and non-flammable, with an ozone depleting potentia...

Page 7

4 models rd30/rc25 to the installer units equipped with post mix valve step 1 connect syrup and water lines. Note: adjust the syrup supply pressure to maintain 60 psig. Water pressure minimum 40 psig, maximum 100 psig, may require regulated water supply. Step 2 turn the “fill” switch in the front of...

Page 8: Section 2

5 models rd30/rc25 to the operator 131209 section 2 to the operator the freezer you have purchased has been carefully engineered and manufactured to give you dependable operation. The taylor model rd30/rc25, when properly operated and cared for, will produce a consistent quality product. Like all me...

Page 9: Section 3

6 models rd30/rc25 safety 130319 section 3 safety we at taylor company are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built- in safety features to protect both you and the ser...

Page 10

7 models rd30/rc25 safety 130319 s do not allow untrained personnel to operate this machine. S do not operate the freezer unless all service panels and access doors are restrained with screws. S do not remove any internal operating parts (examples: freezer door, beater, scraper blades, etc.) unless ...

Page 11: Section 4

8 models rd30/rc25 operator parts identification section 4 operator parts identification model rd30 item description part no. 1 cover- rear 049201 2 cover- hopper 049081 3 retainer- clip 049419 4 panel a.- rear x48983 5 panel- side- right 048977 6 leg a.- 4”- 3/8- 16 stud w/cap x43408 7 panel- side-...

Page 12

9 models rd30/rc25 operator parts identification beater door assembly item description part no. 1 door assembly- complete x48768 1a screw- 1/4- 20 x 9/16 thumb 047632 1b knob- draw valve- black plastic 047358 1c plate- draw spout mounting 049275 1d spout- door zero waste 049276 1e o- ring- 2.375 od ...

Page 13: Section 5

10 models rd30/rc25 important: to the operator section 5 important: to the operator figure 1 control switch the control switch is located on the front of the machine. The center position is “off”. The down position is the “wash” mode and activates the beater motor only. The up position is the “auto”...

Page 14: Section 6

11 models rd30/rc25 operating procedures section 6 operating procedures we begin our instructions at the point where the parts are disassembled and laid out to dry from the previous night’s cleaning. The following procedures will explain how to assemble the parts into the freezer, sanitize them, and...

Page 15

12 models rd30/rc25 operating procedures step 2 install the beater assembly. First check scraper blades for any nicks or signs of wear. If any nicks are present or if the blade is worn, replace both blades. Figure 5 if blades are in good condition, install the scraper blade clip over the scraper bla...

Page 16

13 models rd30/rc25 operating procedures insert the torque rotor (guide bearing end first) into the pilot hole in the center of the drive shaft. The hole in the torque rotor shaft should be rotated to the 12 o’clock position. Figure 10 step 4 install the freezer door. Slide the draw valve o- ring in...

Page 17

14 models rd30/rc25 operating procedures place the door spout seal o- ring into the groove in the door and lubricate the components. Figure 14 align the draw spout assembly with the door. Place the draw spout mounting plate over the draw spout assembly and align the holes. Figure 15 using the thumb ...

Page 18

15 models rd30/rc25 operating procedures 081029 step 6 install the handscrews on the studs. Tighten the screws equally, using a criss- cross pattern. Do not overtighten the handscrews. Figure 19 step 7 install the torque arm. Position the torque arm by inserting it through the slot in the torque swi...

Page 19

16 models rd30/rc25 operating procedures 081029 place the control switch in the “wash” position. Press the fill switch to activate the mix solenoid. The mix solenoid will remain open until the mix level float switch is satisfied. Drain sanitizer from the freezing cylinder and repeat this procedure u...

Page 20

17 models rd30/rc25 operating procedures 140721 step 2 dispenser. Prepare a pail of approved 100 ppm sanitizing solution (examples: 2- 1/2 gal. [9.5 liters] of kay- 5r or 2 gal. [7.6 liters] of stera- sheenr). Use warm water and follow the manufactur- er’s specifications. Remove the upper rear cover...

Page 21

18 models rd30/rc25 operating procedures 140721 priming step 1 with a pail beneath the door spout, open the draw valve. Press the fill switch to allow fresh product to flow into the freezing cylinder. This will force out any remaining sanitizing solution. When full strength product is flowing from t...

Page 22

19 models rd30/rc25 operating procedures 140721 rinsing step 1 remove the upper rear cover, and open the hopper cover. Step 2 pour cool, clean water into the mix hopper and allow it to flow into the freezing cylinder. With the brushes provided, scrub the mix hopper, mix inlet hole, and mix level flo...

Page 23

20 models rd30/rc25 operating procedures brush cleaning step 1 prepare a sink with an approved cleaning solution in warm water according to the manufacturer’s specifications. Make sure all brushes provided with the freezer are available for brush cleaning. Step 2 remove the: s seal and o- ring from ...

Page 24: Section 7

21 models rd30/rc25 important: operator checklist 051214 section 7 important: operator checklist during cleaning and sanitizing always follow local health codes. Cleaning and sanitizing schedules are governed by your state or local regulatory agencies and must be followed accordingly. The following ...

Page 25: Section 8

22 models rd30/rc25 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. No product is being dispensed with the draw valve open. A. Product freeze- up due to improper product mixing. A. Follow directions for mixing product carefully. - - b. The torque arm ...

Page 26

23 models rd30/rc25 troubleshooting guide problem probable cause remedy page ref. 4. The freezing cylinder walls are scored. A. Broken beater pins. A. Repair or replace the beater assembly. - - b. The gear unit is out of alignment. B. Contact a service technician. - - c. The beater assembly is bent....

Page 27

24 models rd30/rc25 troubleshooting guide problem probable cause remedy page ref. 8. The unit is not freezing product when placed in the “auto” mode. A. The torque rotor is bound, leaving the torque arm in the cold position. Therefore the compressor will not run. A. Free the torque rotor. - - b. The...

Page 28: Section 9

25 models rd30/rc25 parts replacement schedule section 9 parts replacement schedule part description every 3 months every 6 months annually scraper blade inspect & replace if necessary minimum drive shaft seal x freezer door o- ring x door port o- ring x front bearing x door spout o- ring x drive sh...

Page 29

26 models rd30/rc25 limited warranty on equipment 131209 section 10 limited warranty on equipment taylor company limited warranty on freezers taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor-branded freezer equi...

Page 30

27 models rd30/rc25 limited warranty on equipment 3. Replacement of wear items designated as class “000” parts in the taylor operator’s manual. 4. External hoses, electrical power supplies, and machine grounding. 5. Parts not supplied or designated by taylor, or damages resulting from their use. 6. ...

Page 31: Section 11

28 models rd30/rc25 limited warranty on parts 131209 section 11 limited warranty on parts taylor company limited warranty on taylor genuine parts taylor company, a division of carrier commercial refrigeration, inc. (“taylor”) is pleased to provide this limited warranty on new taylor genuine replacem...

Page 32

29 models rd30/rc25 limited warranty on parts limited warranty exceptions this limited warranty does not cover: 1. Labor or other costs incurred for diagnosing, repairing, removing, installing, shipping, servicing or handling of defective parts, replacement parts, or new parts. 2. Normal maintenance...

Page 33

30 models rd30/rc25 limited warranty on parts limitation of warranty this limited warranty is exclusive and is in lieu of all other warranties, conditions and/or remedies under the law, including any implied warranties or conditions of merchantability or fitness for a particular purpose. The origina...

Page 34: Section 12

Section 12 parts list 31 + available separately models rd30/rc25 parts list rd3 0 de s cri p t io n part num be r rd30 qty . W arr. Cl as s re m arks part s up da t e arm -to rq ue *340- 1- 2* 014500 1 103 beari n g- front 013116 1 000 beari n g- gui d e 014496 1 000 beari n g- rear shell *plasti c ...

Page 35

+ available separately 32 parts list models rd30/rc25 de s cri p t io n part s up da t e re m arks w arr. Cl as s rd30 qty . Part num be r decal- refri g erati o n- li qui d 049205 1 000 decal- refri g erati o n- sucti o n 049204 1 000 di agram- w iri ng *rd30* 049179- 12 1 000 115v- 60- 1 di agram-...

Page 36

33 + available separately models rd30/rc25 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s rd30 qty . Part num be r label- w arni ng- c over 51433 3 000 l e g a .-4 ”-3 /8 -1 6 s t u d -w /c a p x43408 4 103 l e g -4 ”-3 /8 -1 6 s t u d 036397 4 103 cap- rubber 037268 4 000 l ...

Page 37

+ available separately 34 parts list models rd30/rc25 de s cri p t io n part s up da t e re m arks w arr. Cl as s rd30 qty . Part num be r pulley- ak30 x 5/ 8 033559 1 103 beater motor pulley- ak64- 5/ 8 007538 1 103 gear relay- dpdt- 2 0 a -120v 026581- 12 1 103 refri g erati o n s o l eno id (115v...

Page 38

35 + available separately models rd30/rc25 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s rd30 qty . Part num be r bracket- c ontrol *rd30* 049047 1 103 bushi n g- 1/ 2od x 3/ 8i d- plasti c 014474 2 000 pi vot hub bushi n g- control *rd30* 049046 1 103 torq adj u stment scre...

Page 39

+ available separately 36 parts list models rd30/rc25 de s cri p t io n part s up da t e re m arks w arr. Cl as s rd30 qty . Part num be r valve- solenoi d -7 /64orf x 1 /4 s 043449- 1 103 j8012411/ up (f o r li q u id li ne) 125 +bracket- s olenoi d 047303 1 103 j8012411/ up 125 valve- solenoi d -r...

Page 40

37 + available separately models rd30/rc25 parts list rc2 5 de s cri p t io n part num be r rc25 qty . W arr. Cl as s re m arks part s up da t e boot- r otolock valve 037116 1 000 j7032493/ pri o r (tecum seh) blo c k- term in al 2p- l1, l2 039422 1 103 j7032493/ up (b ri sto l ) cap- dust- bulkhead...

Page 41

+ available separately 38 parts list models rd30/rc25 de s cri p t io n part s up da t e re m arks w arr. Cl as s rc25 qty . Part num be r +fan- b lade condenser *rc25* 049515 1 103 m o tor- fan 050265- 27 1 103 j7032493/ up (b ri sto l & c o peland) +fan- 5 blade 12" pull 26 deg c w 031532 1 103 pa...

Page 42

39 + available separately models rd30/rc25 parts list de s cri p t io n part s up da t e re m arks w arr. Cl as s rc25 qty . Part num be r +capaci t or- run- 45uf/ 370v 52400 1 103 +capaci t or- s tart- 145- 175uf/ 250v 052399 1 103 +relay- start- compressor 052401- 27 1 103 condenser 048629 1 103 a...

Page 43

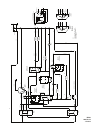

Rd30 049179-12 11/12/13 blk l1 n wht auto wash off auto wash off power switch mix out relay 2 (no) 1 (no) 6 5 b a 120v 24v mix out light beater motor (see fig. 1) blk org/wht blk/yel blk/wht wht wht blk/wht blk/wht refrigeration solenoid brn brn/wht wht wht blk/wht org blk blk/wht org wht yel splice...

Page 44

Rd30 049179-12c 11/12/13 m corcom filter (spinner) spinner nc no com gra/wht wht blk blk blk wht for optional spinner assembly refrigeration liquid line solenoid wht gra/wht blk from transformer from fill switch 208v 240v (no) (no) (nc) (nc) (c) (c) (no) (no) (nc) (nc) (c) (c) gray/blk 1 3 input loa...

Page 45

Rd30 049179-40 11/12/13 blk l1 n wht auto wash off auto wash off power switch mix out relay 2 4 1 3 6 5 b a 24v mix out light beater motor blk org/wht blk/yel blk/wht wht wht blk/wht blk/wht refrigeration solenoid brn brn/wht wht wht blk/wht org blk blk/wht org wht yel splice box gra/wht 2 4 1 3 6 5...