- DL manuals

- Taylor

- Welding System

- SYSTEM CD200 SERIES

- Operating Manual

Taylor SYSTEM CD200 SERIES Operating Manual

Summary of SYSTEM CD200 SERIES

Page 1

Taylor studwelding systems limited. Operating manual for system cd200 series compact capacitor discharge studwelding equipment.

Page 2: Index

Index page content 1 general information 3 introduction 4 equipment schedule 5 exterior features 7 safety 10 setting up and welding 16 weld settings 27 location methods 28 weld assessment / testing 29 contact pistol explosion and parts list 31 mark v lift gap pistol explosion and parts list 34 contr...

Page 3: General Information

General information manufacturers details taylor studwelding systems limited commercial road dewsbury west yorkshire wf13 2bd england telephone : +44 (0)1924 452123 facsimile : +44 (0)1924 430059 e-mail : info@taylor-studwelding.Com technical tel : +44 (0)1924 487703 sales tel : +44 (0)1924 487701 p...

Page 4: General Information

General information further information should you require additional technical information, please contact us directly (details on page 1) or our local agent / distributor (details of agents etc. Can be obtained from us). This manual contains important information which is a pre-requisite for safe ...

Page 5: Introduction

Introduction introduction the complete range of taylor studwelding systems capacitor discharge units are compact, portable stud welding equipment's. The units are specifi- cally designed to enable a small diameter range of ferrous and non-ferrous weld studs to be welded to light gauge, self-finish o...

Page 6: Equipment Schedule

Equipment schedule equipment no. Off description part no. 1 system cd200 - 66 contact 99-100-110 complete or system cd200 - 66 lift gap 99-100-114 complete or system cd200 - 99 contact 99-100-111 complete or system 200cd - 99 lift gap 99-100-115 complete or system cd200 - 132 contact 99-100-119 comp...

Page 7: External Features

External features front panel 1 welding voltage selector knob 2 welding voltage digital display 3 welding earth panel connections 4 welding pistol panel connection 5 welding pistol control socket 1 2 indicator led's 1 ready (green) indicates that the capacitor bank is charged to the pre-selected val...

Page 8: External Features

External features rear panel serial / rating plate casing ventilation holes ventral holes not shown) blanking plate or 7 pin output socket. (used in automatic units only). Switched, filtered and fused iec mains input socket. Important notes ! Due to the power requirements and electromagnetic emissio...

Page 9: Safety

Safety protect yourself and others ! Read and understand these safety notices. 1. Electrical no portion of the outer cover of the welding controller should be re- moved by anyone other than suitably qualified personnel and never whilst mains power is connected. Always disconnect the mains plug from ...

Page 10: Safety

Safety 3. Personnel safety arc rays can burn your eyes and skin and noise can damage your hear- ing. Operators and personnel working in close proximity must wear suitable eye, ear and body protection. Fumes and gases can seriously harm your health. Use the equipment only in a suitably ventilated are...

Page 11: Safety

Safety 6. Installation ensure that the site chosen for the equipment is able to support the weight of the equipment and that it will not fall or cause a danger in the course of its normal operation. Do not hang connecting cables over sharp edges and do not install connecting cables near heat sources...

Page 12: Setting Up & Welding

Setting up & welding setting up & welding set up the control unit at the place of work, ensuring that the mains switch is in the off position. Ensure that this is done in line with the notes and safety rec- ommendations on pages 7 through 9 of this manual. Plug the controller into the mains ac suppl...

Page 13: Setting Up & Welding

Setting up & welding setting up & welding connect the welding pistol cable to the controller. Note that the cable end plug has a peg which mates with a key slot in the panel mounted socket. Important ! Secure the connector with a clockwise turn until it locks. Failure to do this will result in damag...

Page 14: Setting Up & Welding

Setting up & welding setting up & welding after setting the chuck, insert it into the pistol chuck holder and push firmly home until it comes to a rest. Note! When welding m10 studs or studs between 35 and 50 mm in length, the pistol will require longer tripod legs fitting (see page 34). Tighten the...

Page 15: Setting Up & Welding

Setting up & welding setting up & welding setting the pistol mkv lift gap pistol (continued) it is at this point that further twisting of the end cap begins to lift the tripod legs/nosecone away from the plate. The pistol is now in the zero lift position and twisting the rear end cap anti-clockwise ...

Page 16: Setting Up & Welding

Setting up & welding setting up & welding place the pistol perpendicular to the work piece with the stud touching down at the desired location to be welded. Press down on the pistol until the legs come firmly into contact with the work piece. Press the trigger. The welding process is as follows :- a...

Page 17: Setting Up & Welding

Setting up & welding setting up & welding a cold stud weld is noticeable by undercutting of the flange and lack of / minimal formation of spatter. A cold weld is usually caused by too little energy and / or too high spring pressure. A hot stud weld is noticeable by excessive spatter formation and pa...

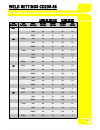

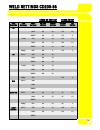

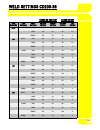

Page 18: Weld Settings

Weld settings the following pages (17 to 22) detail the suggested settings for the following cd200 models : 66, 99 & 132 both contact & lift gap the setting charts were established with the performance of repetitive weld tests using the standard equipment's specified above, studs manufac- tured to t...

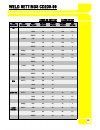

Page 19: Weld Settings Cd200-66

Weld settings cd200-66 cd200-66 contact cd200-66 gap 17 stud diameter stud material sheet material voltage setting spring setting voltage setting lift setting m2.5 st37-3 cr4 60 2½ 65 2½ s304 60 2½ 65 2½ zintec 80 2½ 90 2 m3 st37-3 cr4 75 2½ 80 2½ s304 75 2½ 80 2½ zintec 100 2½ 110 2 1.4303 cr4 75 2...

Page 20: Weld Settings Cd200-66

Weld settings cd200-66 cd200-66 contact cd200-66 gap 18 stud diameter stud material sheet material voltage setting spring setting voltage setting lift setting m6 st37-3 cr4 125 2½ 135 2½ s304 125 2½ 135 2½ zintec 160 2½ 175 2 1.4303 cr4 135 2½ 145 2½ s304 135 2½ 145 2½ zintec 175 2½ 180 2 almg3 he3 ...

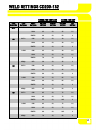

Page 21: Weld Settings Cd200-99

Weld settings cd200-99 cd200-99 contact cd200-99 gap 19 stud diameter stud material sheet material voltage setting spring setting voltage setting lift setting m2.5 st37-3 cr4 40 2½ 45 2½ s304 40 2½ 45 2½ zintec 60 2½ 70 2 m3 st37-3 cr4 45 2½ 50 2½ s304 45 2½ 50 2½ zintec 75 2½ 85 2 1.4303 cr4 45 2½ ...

Page 22: Weld Settings Cd200-99

Weld settings cd200-99 cd200-99 contact cd200-99 gap 20 stud diameter stud material sheet material voltage setting spring setting voltage setting lift setting m6 st37-3 cr4 90 2½ 120 2½ s304 90 2½ 120 2½ zintec 140 2½ 160 2 1.4303 cr4 110 2½ 120 2½ s304 110 2½ 120 2½ zintec 140 2½ 160 2 almg3 he3 12...

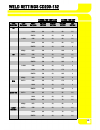

Page 23: Weld Settings Cd200-132

Weld settings cd200-132 cd200-132 contact cd200-132 gap 21 stud diameter stud material sheet material voltage setting spring setting voltage setting lift setting m2.5 st37-3 cr4 25 2½ 25 2½ s304 25 2½ 25 2½ zintec 40 2½ 50 2 m3 st37-3 cr4 25 2½ 30 2½ s304 25 2½ 30 2½ zintec 55 2½ 65 2 1.4303 cr4 25 ...

Page 24: Weld Settings Cd200-132

Weld settings cd200-132 cd200-132 contact cd200-132 gap 22 stud diameter stud material sheet material voltage setting spring setting voltage setting lift setting m6 st37-3 cr4 80 2½ 90 2½ s304 80 2½ 90 2½ zintec 110 2½ 130 2 1.4303 cr4 80 2½ 90 2½ s304 80 2½ 90 2½ zintec 110 2½ 130 2 almg3 he3 120 4...

Page 25: Methods of Stud Location

Methods of stud location economic stud location may be obtained using any one of the following methods, depending on the type of work involved :- tripod leg assembly. Nose cone assembly. Extended leg assembly. Tripod leg assembly. This is generally used for low volume production and one off compo- n...

Page 26: Weld Assessment / Testing

Weld assessment / testing visual examination of weld quality can, even with limited experience, provide a useful quality assessment. In such a check the presence of a small even witness of weld material around the base of the stud flange after weld- ing should be ensured. Poor welds are indicated by...

Page 27: Component Explosion

Component explosion standard contact pistol. 25 1 2 3 4 5 6 7 8 9 10 11 12 15 16 17 13 14 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32.

Page 28: Parts List

Parts list standard contact pistol. 26 item qty part no. Description 1 1 71-101-018 rear end cap 2 1 71-101-017 spring preload adjustor 3 1 71-101-016 adjustable spring seat 4 1 71-101-014 spring 5 1 71-101-012 fixed spring seat 6 1 71-101-011 shaft circlip 7 1 71-101-005 pistol body moulding (2 par...

Page 29: Component Explosion

Component explosion mark v lift gap pistol. 27 1 2 3 4 5 6 7 8 9 12 11 10 13 14 15 16 17 40 41 42 43 44 45 46 47 48 49 50 51 52 53 31 32 33 34 35 36 37 38 39 18 19 20 21 22 23 24 25 26 27 28 29 30

Page 30: Parts List

Parts list mark v lift gap pistol. 28 item qty part no. Description 1 2 z115-04-010 end cap screw 2 1 71-102-067 rear end cap 3 1 71-102-066 rear bush 4 1 71-102-073 detent spring 5 2 81-101-082 detent ball 6 1 71-102-075 indicator pin 7 1 71-102-056 solenoid coil complete 8 1 71-102-061 weldshaft 9...

Page 31: Parts List

Parts list mark v lift gap pistol. 29 item qty part no. Description 28 1 71-101-009 contact spring 29 1 71-102-071 shaft bearing 30 4 z210-02-010 screw (switch / cable grip) 31 4 z600-02-000 washer (switch / cable grip) 32 1 71-101-036 trigger bezel 33 1 71-101-035 trigger push button 34 1 71-101-02...

Page 32: Component Explosion

Component explosion cd200 series controller 30 1 2 3 4 5 6 7 8 9 15, 14, 13 12 11 10 29 28 27 26 25 24 23 16 17 18 19 20 21 22.

Page 33: Component Explosion

Component explosion cd200 series controller 31 item qty part no. Description 1 1 70-105-014 carrying handle 2 1 70-105-001 housing cover 3 1 70-105-009 positive busbar 4 1 70-105-008 negative busbar 5 2 70-102-131 flyback diode (66 contact only) or 3 70-102-131 flyback diode (all other models) 6 1 7...

Page 34: Component Explosion

Component explosion cd200 series controller 32 item qty part no. Description 19 1 70-105-015 control panel overlay 20 1 70-105-007 panel plug link bar 21 4 70-102-002 casing foot 22 1 70-105-016 cordset (uk 230v - iec) or 1 70-105-017 cordset (schuko 230v - iec) or 1 70-105-028 cordset (uk 110v - ie...

Page 35: Circuit Schematic

Circuit schematic cd200 series controller 33 display pcb 6 way header 16 way ribbon cable 10 way ribbon cable power supply unit danger! High voltage enclosure contains no user service- able parts orange purple black green white black red broken line indicates lift gap controller only flyback diode(s...

Page 36: Accessories

Accessories 34 standard tripod leg assembly. 3 2 1 complete assembly available under part number : 79-101-050 (standard) note # long legs are used when welding stud lengths between 35 and 50, or when welding m10 studs. Item qty description part no. 1 3 tripod leg (standard) 79-101-052 or 3 tripod le...

Page 37: Accessories

Accessories 35 standard nose cone assembly. 3 2 1 complete assembly available under part numbers : Ø30 mm assy : 79-101-070 Ø25.4 mm (1”) assy : 79-101-069 Ø22 mm assy : 79-101-068 4 5 item qty description part no. 1 1 Ø30 mm nose cone 79-101-072 or 1 Ø22 mm nose cone 79-101-078 or 1 Ø25.4 mm nose c...

Page 38: Accessories

Accessories 36 standard screw-in nose cone assembly. 4 3 2 complete assembly 1 available under part numbers : Ø30 mm assy : 79-101-082 Ø25.4 mm (1”) assy : 79-101-081 Ø22 mm assy : 79-101-080 5 6 note : fit chucks with 12 mm long backstop 79-101-071 & 2 locking nuts item qty description part no. 1 1...

Page 39: Accessories

Accessories 37 extended leg assembly. Complete assembly available under the following part numbers : c/w tripod legs 79-101-148 c/w ø30 nose cone 79-101-147 1 7 2 8 3 9 4 10 5 or 6 11 12 item qty description part no. 1 2 extended leg 81-101-004 2 2 grub screw z430-05-006 3 2 pivotal grip insert 79-1...

Page 40: Accessories

Accessories 38 offset chuck adaptor complete assembly available under part number : 79-101-110 nose cone centring device 1 2 complete assemblies available under part numbers : Ø22 cup & rod 79-101-112 Ø25.4 (1”) cup & rod 79-101-113 Ø30 cup & rod 79-101-114 item qty description part no. 1 1 Ø30 mm c...

Page 41: Accessories

Accessories 39 offset chuck adaptor complete assembly 2 3 4 available under part number : 79-101-120 1 5 6 7 item qty description part no. 1 1 bending bar 79-101-121 2 1 m10 nozzle 79-101-128 3 1 m8 nozzle 79-101-127 4 1 m6 nozzle 79-101-126 5 1 m5 nozzle 79-101-125 6 1 m4 nozzle 79-101-124 7 1 m3 n...

Page 42: Accessories

Accessories 40 chucks / collets earth tag chuck part no. 79-101-019 large bracket chuck (not illustrated) part no. 79-101-022 standard cd chuck with backstop part no. S : m2.5 : 79-101-002 m3 : 79-101-003 m4 : 79-101-004 m5 : 79-101-005 m6 : 79-101-006 m7.1 : 79-101-007 m8 : 79-101-008 standard m10 ...

Page 43: Ec Declaration of Conformity

Ec declaration of conformity 41 taylor studwelding systems limited commercial road dewsbury west yorkshire england wf13 2bd tel : +44 (0)1924 452123 fax : +44 (0)1924 430059 email : sales@taylor-studwelding.Com statement : this is to certify that the machinery listed below is designed and manufactur...

Page 44: Emc Certificate

Emc certificate 42.