- DL manuals

- TB Controls

- Recording Equipment

- TC02

- Operation & maintenance manual

TB Controls TC02 Operation & maintenance manual

Summary of TC02

Page 1

B u i l d i n g c o n f i d e n c e tc02 curtain heater controller (previously known as the mini-fcu) operations & maintenance manual ©tbcontrols 2011.

Page 2

Operations & maintenance manual doc: tc02 o&m page 2 of 20 status: final issue: 11 ©tb controls 2011 contents 1. ........ Document management ........................................................................... 3 1.1. Change control 3 1.2. Document review 3 1.3. Document status 3 1.4. Documen...

Page 3: Document Management

Operations & maintenance manual doc: tc02 o&m page 3 of 20 status: final issue: 11 ©tb controls 2011 1. Document management 1.1. Change control ver.No. Date of issue status changes description/comment 1 8 sept 04 final all sections first issue 2 13 oct 04 final changes relating to additional air sen...

Page 4: Tc02 Controller

Operations & maintenance manual january 2002 doc: tc02 o&m page 4 of 20 status: final issue: 11 ©tb controls 2011 2. Tc02 controller 2.1. Design the tb controls tc02 controller is designed to be a cost effective multi-purpose digital control unit fulfilling the requirements for over-door curtain hea...

Page 5

Operations & maintenance manual january 2002 doc: tc02 o&m page 5 of 20 status: final issue: 11 ©tb controls 2011 summer/winter setting. Return air temperature measurement in place of room stat for greater flexibility outside air temperature for fully automatic control. Rs485 network communications,...

Page 6: Wall Control Plate Unit

Operations & maintenance manual january 2002 doc: tc02 o&m page 6 of 20 status: final issue: 11 ©tb controls 2011 2.5. Engineering 2.5.1. Supply cables the tc02 controller requires a 12 to 24 vac supply. The valve actuators may be rated between 24 vac and 230 vac. The controller does not supply actu...

Page 7

Operations & maintenance manual january 2002 doc: tc02 o&m page 7 of 20 status: final issue: 11 ©tb controls 2011 3.1. Tc02 connections connecting the field devices caution there is no protection against accidental connection of 230 vac to 24 vac and data connections. Care must be taken to ensure co...

Page 8: Master / Slave

Operations & maintenance manual january 2002 doc: tc02 o&m page 8 of 20 status: final issue: 11 ©tb controls 2011 4. Master / slave where several controllers are operating in the same space, they must be synchronized via the master / slave interface. Up to 8 slaves may be used (further options avail...

Page 9

Operations & maintenance manual january 2002 doc: tc02 o&m page 9 of 20 status: final issue: 11 ©tb controls 2011 4.3. Error messages 4.3.3. Master there are a number of possible error or operation messages; these will be displayed on the lcd screen. Bms or time switch control when connected to the ...

Page 10

Operations & maintenance manual january 2002 doc: tc02 o&m page 10 of 20 status: final issue: 11 ©tb controls 2011 to change address use outer buttons to increase or decrease the address number, a maximum of 8 can be set in one group. The lcd backlight is the illumination property of the display; th...

Page 11

Operations & maintenance manual january 2002 doc: tc02 o&m page 11 of 20 status: final issue: 11 ©tb controls 2011 occupancy is detected by the occupancy sensor, this signal will be used by the controller to enable the fan and controls, the period for which it will work after detecting an occupant i...

Page 12

Operations & maintenance manual january 2002 doc: tc02 o&m page 12 of 20 status: final issue: 11 ©tb controls 2011 factory reset returns controller to factory defaults pressing the + button will restore the factory default settings. Pressing the – button restores the last power up settings. Displays...

Page 13

Operations & maintenance manual january 2002 doc: tc02 o&m page 13 of 20 status: final issue: 11 ©tb controls 2011 trip for overheat sensor room stat where present occupancy sensor where present / if not insert loop! Lcd plate if used communications cable lon communications cable loop mains transfor...

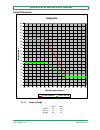

Page 14: Setpoints

Operations & maintenance manual january 2002 doc: tc02 o&m page 14 of 20 status: final issue: 11 ©tb controls 2011 default set-points setpoints 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 outside temperature c te m p e ra tu re c off...

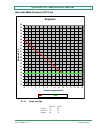

Page 15: Setpoints

Operations & maintenance manual january 2002 doc: tc02 o&m page 15 of 20 status: final issue: 11 ©tb controls 2011 new look mode set-points (dip 5 on) 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 tempe ra tu re c outside temperature c setpoints...

Page 16: Tc02 Dip-Switch Settings

Operations & maintenance manual january 2002 doc: tc02 o&m page 16 of 20 status: final issue: 11 ©tb controls 2011 6. Tc02 dip-switch settings 1 2 3 4 5 6 7 8 9 10 on mini-fcu dipswitch setting switch on position switch number table of switche s 1 to 8 sw1 = 1, sw2 = 2, sw3 = 4, sw4 = 8, sw5 = 16 sw...

Page 17

Operations & maintenance manual january 2002 doc: tc02 o&m page 17 of 20 status: final issue: 11 ©tb controls 2011 dipswitch settings from 0 to 17 d 8 h 8 1 2 3 4 5 6 7 8 9 10 on 1 2 3 4 5 6 7 8 9 10 on d 0 h 0 d 2 h 1 d 2 h 2 d 3 h 3 d 4 h 4 d 5 h 5 d 6 h 6 d 9 h 9 d 12 h c d 15 h f d 7 h 7 d 10 h ...

Page 18

Operations & maintenance manual january 2002 doc: tc02 o&m page 18 of 20 status: final issue: 11 ©tb controls 2011 7. Outside air temperature sensor 7.1. Fitting the sensor for best results locate the sensor on the north side of the structure high under an eave. This prevents incorrect readings due ...

Page 19

Operations & maintenance manual january 2002 doc: tc02 o&m page 19 of 20 status: final issue: 11 ©tb controls 2011 8. Modbus protocol and unit data the hardware interface is half duplex rs485 (single twisted pair) and we normally use a ¼ unit load driver chip with +/-60 volt line protection (lt1785c...

Page 20: Fault Finding

Operations & maintenance manual january 2002 doc: tc02 o&m page 20 of 20 status: final issue: 11 ©tb controls 2011 9. Fault finding fault indication: check: module add 0 the lcd has power but no data comms. Check wiring between lcd wall plate and unit mounted control board. Refer to wiring diagrams....