- DL manuals

- TCS

- Measuring Instruments

- 700-20

- Installation, Operation & Maintenance Manual

TCS 700-20 Installation, Operation & Maintenance Manual

Summary of 700-20

Page 1

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com cat alog title catalog subtitle installation, operation & maintenance manual 700 - 40/45 rotary meter.

Page 2

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 2 table of contents warning symbols caution follow the warning instructions within the following information to avoid equipment failure, personal injury or death. Turn power off before performing any maintenance, be sure to turn syst...

Page 3

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 3 receipt & inspection upon receipt of meter shipment, be sure to inspect the packaging and the flow meter assembly for any damage before signing the receipt of the shipment. Notify the delivery company about possible damage and refu...

Page 4

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 4 meter overview the tcs model 700 series flow meter is a simple and efficient design. The meter consists of a single fluid chamber that contains a single blocking rotor and two displacement rotors whose rotation is synchronized with...

Page 5

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 5 meter specifications flange connection: 4” npt flange connection, 3” npt flange. Optional bspt, slip weld or ansi flanges available upon request. Flow rate: 700 - 40 up to 500 gpm (1893 lpm) 700 - 45 up to 600 gpm (2271 lpm); only ...

Page 6

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com simriz ® is a registered trademark of freudenberg - nok. Page 6 material of construction description sp spa spd ip ic af housing hardcoat anodized aluminum hardcoat anodized aluminum ductile iron hardcoat anodized aluminum hardcoat anodiz...

Page 7

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 7 system recommendations (continued) control valves safety and isolation valves should be used throughout the metering system. In any pumping system where there is one (1) pump and multiple flow meters, a digital or hydro - mechanica...

Page 8

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 8 thermal shock the metal parts within the flow meter will expand or contract with variations in the system operating temperature. For any systems where sudden or immediate temperature increases of 68 f (20 c) degrees or more are pos...

Page 9

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 9.

Page 10

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 10

Page 11

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 11 start up recommendations start - up instruction for new installations or after maintenance and repairs: 1) only properly trained personal should design, install, or operate metering system. 2) remove plastic threaded plugs placed ...

Page 12

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 12 start-up recommendations (continued) direction of flow the meter is set up at the factory for left to right flow. To change the meter for right to left flow, begin by removing the screws (#9 on the meter assembly breakdown) and th...

Page 13

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 13 meter calibration the method of proving should be selected, and necessary provisions made, during the design stage of the installation. Of the most commonly used systems, portable provers have the advantage of more closely reprodu...

Page 14

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 14 meter calibration (continued) making the tests reset the register to zero, and run the required test quantity through the meter. Do not exceed the maximum recommended rate of flow for the meter. Maximum and minimum recommended rat...

Page 15

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com meter calibration (continued) one complete turn of the adjuster barrel is equal to 1 gallon in 100 gallons or 1% of delivered volume. The adjuster body will show divisions of 1%, while the adjuster barrel has divisions of 0.02%. For volum...

Page 16

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 16 split compartment test purpose: a product depletion test verifies the proper operation of the air elimination system when the storage tank for the product being measured is pumped dry. This test is necessary for meters that may dr...

Page 17

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 17 split compartment test (continued) single compartment test procedure: the test of single - compartment tanks is easier to accomplish if there is a quick - connect hose coupling between the compartment valve and the pump that suppl...

Page 18

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 18 split compartment test (continued) with a quick - connect coupling: 1) during a normal full flow test run, close the compartment valve when the prover is approximately one - half full to its normal capacity. Then slowly and carefu...

Page 19

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 19 maintenance ¡warning! Test equipment should be grounded to prevent a possible spark. Test area should have no ignition source. Operators should wear personal protection and prevent any product exposure and environmental issues. 1)...

Page 20

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 20 maintenance (continued) 10) when removing gaskets or o - rings, carefully check for damage or corrosion. Any cracked, rough, worn, elongated or swollen o - rings must be replaced. When replacing the o - rings, place grease along t...

Page 21

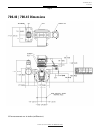

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 21 700-40 / 700-45 dimensions all measurements are in inches (millimeters)..

Page 22

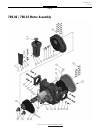

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 22 700-40 / 700-45 meter assembly.

Page 23

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 23 description qty 700 - 40 700 - 45 sp spa spd ip ic af spa spd 1 round head screw 10 1 - 128279 1 - 128279 1 - 128279 1 - 128279 1 - 128279 1 - 128279 1 - 128279 1 - 128279 2 adjuster assembly 1 700100 700100 700100 700100 700100 7...

Page 24

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 24 740 air eliminator / strainer assembly.

Page 25

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 25 740 air eliminator / strainer assembly item description qty 740 - 40 sp spd ip af 1a cap screw 8 740050 740050 740050 740050 2 ring washer 12 740051 740051 740051 740051 3a outlet cover, npt 2 740010 740016 740010 740016 4 valve p...

Page 26

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 26 750-40 hydraulic preset valve assembly.

Page 27

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 27 750-40 hydraulic preset valve assembly item description qty sp ip spd 1 linkage assembly kit 1 754062kt 754062kt 754062kt 2 seal kit 1 754314kt 754314kt 754314kt 3 flat washer 4 754013 754013 754013 4 cap screw 2 754012 754012 754...

Page 28

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 28 this torque chart is for 18 - 8 stainless steel bolts **values can be +/ - 10% of value listed** torque specifications 700 - 40/45 meter assembly part number & description tool foot lbs. Newton meter unlubricated unlubricated tcs ...

Page 29

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 29 drive components removing the dust cover 1) cut dust cover seal. Remove the dust cover screws with a standard flathead screwdriver. 2) note the setting on calibration adjuster. 3) note the position of the drive gear (either above ...

Page 30

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 30 disassembly of meter (continued) draining meter & removing counter support 1) drain the meter by turning it on either the inlet or outlet side. 2) remove the counter bracket screws with a hex wrench or socket driver. 3) remove the...

Page 31

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 31 disassembly of meter (continued) front & rear cover 1) remove the screws on the front cover using a socket or box wrench. 2) remove front cover. 3) remove the screws on the back and remove rear cover. 4) remove the o - ring from b...

Page 32

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 32 disassembly of meter (continued) removing bearing plate 1) remove the bearing plate retaining screws with a standard flathead screwdriver. 2) to remove bearing plate & rotors, insert a screwdriver into the notches near the dowel p...

Page 33

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 33 inspection of parts 1) inspect the surfaces of rotors, bearing plates, meter housing and gear teeth for any damage or wear. 2) replace parts as needed. Gear wear a) meter has been run on air. B) meter has been operated at a higher...

Page 34

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 34 reassembly of meter reinstalling rotors 1) install rear bearing plate on meter. 2) insert threaded end of blocking rotor and the right displacement rotor into front gear plate (reinsert rotor keys if necessary). 3) align the two r...

Page 35

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 35 reassembly of meter reinstalling bearing plate 1) align rotors on bearing plate (see picture) before inserting into meter. 2) slide front bearing plate with rotors into meter housing and rear bearing plate. 3) again, rotate gears ...

Page 36

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 36 reassembly of meter reinstalling packing capsule & front/rear covers 1) reinstall cover o - rings on the front and rear of meter housing. 2) reinsert packing capsule into front cover of meter with retaining plate and tighten screw...

Page 37

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 37 reassembly of meter (continued) reinstalling adjuster 1) reinsert the adjuster into the top of the counter support and assuring that it mates with the drive shaft. 2) tighten the screws that secure the adjuster plate to the counte...

Page 38

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 38 page 38 disassembly of 720 strainer assembly 1) using a hex or socket wrench, remove the four screws and washers from the cover plate. 2) remove the cover plate and o - ring from the housing. 3) remove the strainer screen. 4) chec...

Page 39

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 39 page 39 disassembly of 730 air eliminator assembly ¡warning! All internal pressure must be relieved to zero (0) pressure before beginning disassembly of meter or components 1) using a 1/2” wrench or socket, remove the cover screws...

Page 40

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 40 ¡warning! All internal pressure must be relieved to zero (0) pressure before beginning disassembly of meter or components disassembly of 750-40 hydraulic valve 1) drain all fluid from metering system prior to valve removal. 2) usi...

Page 41

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 41 disassembly of 750-40 hydraulic valve 1) remove the piston guide from the valve body. 2) remove and inspect the upper and lower seals and replace as needed. 3) using a flathead screwdriver, gently remove the valve body o - ring, i...

Page 42

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 42 750 hydraulic valve seal replacement 1) remove retaining ring (tcs 753021) and o - ring (tcs 754075) from shaft. 2) remove spacer bearing (tcs 754060), bearing sleeve (tcs 754055) and sleeve (tcs 754050). 3) remove seal (tcs 75406...

Page 43

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 43 meter trouble shooting problem: leaking packing gland and/or housing a) check to see whether any o - rings have been damaged or cover bolts have not been tightened enough. B) two common causes of packing gland leakage are thermal ...

Page 44

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 44 page 44 air eliminator trouble shooting problem: product is flowing from the air eliminators vents a) foreign matter located in between seal plate o - rings and metal reeds. B) the seal plate oring may be worn through service life...

Page 45

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 45 preset valve trouble shooting problem: the valve will not close completely. A) the shaft of the piston may be bent from excessive force. B) debris may be located between the piston and piston guide. C) the upper or lower seals may...

Page 46

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 46 material safety data sheet (msds) 24 hour emergency assistance general msds assistance (260) 833 - 3173 (260) 484 - 0301 code: rps ========================================================================================== hazard r...

Page 47

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 47 page 47 material safety data sheet (continued) product: rp 1060 page - 2 ========================================================================================== section iv - fire and explosion hazard data ======================...

Page 48

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 48 material safety data sheet (continued) product: rp 1060 page - 3 ========================================================================================== section vii - spill or leak procedures ===================================...

Page 49

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 49 material safety data sheet (continued) product: rp 1060 page - 4 ========================================================================================== section x - hmis/nfpa ratings ============================================...

Page 50

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 50 notes.

Page 51

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com page 51 warranty information new 700 rotary meters, equipment or components manufactured by total control systems, a division of murray equipment, inc. (tcs) with which this warranty is enclosed, are warranted by tcs to the original purch...

Page 52

Tcs900004, rev.4 07/12/2016 check us out at www.Tcsmeters.Com 2515 charleston place fort wayne, in 46808 toll free: (800) 348 - 4753 phone: (260) 484 - 0382 fax: (260) 484 - 9230 email: sales@tcsmeters.Com.