- DL manuals

- TCT Solar

- Water Heater

- ProgressiceTube

- Installation And Operation Manual

TCT Solar ProgressiceTube Installation And Operation Manual

Summary of ProgressiceTube

Page 1

Tct s olar 101 copeland street jacksonville, florida 32204 www.Tctsolar.Com techsupport@tctsolar.Com p rogressiv t ube ® passive solar water heater installation and operations manual.

Page 2: Table of Contents

2 table of contents i. Introduction ii. Utilization iii. System characteristics iv. Pre-installation check list v. Installation precautions vi. Collector orientation vii. Collector mounting hardware options viii. Roof mounts a. Load bearing and bracing b. Roof piping and penetrations c. Roof mount p...

Page 3: Flow Pattern

3 flow pattern the p rogressiv t ube ® solar water heater works simply on sunlight and your local water pressure. There is no electrical energy needed to make it function. Once the system has been filled, it will operate on main water pressure or flow rates that are normal to your household. The sim...

Page 4: Rogressiv

4 p rogressiv t ube i nstallation manual i. Introduction this installation manual is intended to provide the requirements, recommendations, and guidelines necessary to achieve simplified installation and years of trouble free system operation. There are many ways to plumb a p rogressiv t ube system,...

Page 5

5 ii. Utilization p rogressiv t ube passive solar water heaters are designed as self-contained units that act as a solar collector and storage tank integrated into one piece of equipment. In most cases, they are utilized as a pre-heater to a conventional water heater; however, they can be installed ...

Page 6

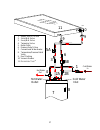

6 2–way system for electric water heater cold hot mi x 8 7 6 5b 5a 4 3 2 hot water out cold water in cold water inlet hot water outlet 1 9 11 9 inlet outlet 10 2-way system for gas water heater 8 7 6 5b 5a 4 3 2 hot water out cold water in cold water inlet hot water outlet 1 9 co l d ho t mix 11 9 i...

Page 7

7 iv. Pre-installation check list 1. Check local codes for plumbing and roof load requirements. Installations must meet all local code requirements for penetrating structural members and fire rated assemblies. 2. Obtain all applicable permits. 3. Inspect the roof. If it is in poor condition, advise ...

Page 8

8 5. Use 95/5 or 60/40 lead free solder for the collector piping because of the high temperature stagnation of the unit. 6. Keep the collector covered during installation. Even early morning sun can quickly heat up the absorber. It is most important that the unit be vented to the atmosphere before a...

Page 9

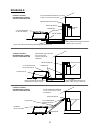

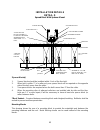

9 collector mounting options drawing a - fixed mount for installation parallel to the roof ptms ptms part list a) clamps: qty 4 b) mounting brackets: qty 4 c) 3/8”x 1” hex head cap screws: qty 4 d) 3/8” x 2 ¼” h ex h ead c ap s crews : q ty 4 e) 3/8” lock nuts: qty 8 f) c ross c hannels : q ty 2.

Page 10

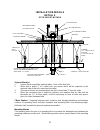

10 drawing b - adjustable tilt mount for installation with additional angle of the roof or ground mounting include standoff rear legs-sts sts p art l ist g) rear leg sq. Tube 1 ft, 2 ft, 3 ft or 4 ft sq tube note: standoff rear legs include h) 3/8”x 2 ¼” hex head cap screws: qty 2 i) 3/8” lock nuts:...

Page 11

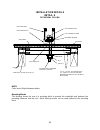

11 drawing c - flush mount mount dimensions and angles collector standoff dim “a” angle pt-20-cn 1 foot 29 1/8 ” 26º pt-20-cn 2 foot 4 7/8 ” 85º pt-30-cn 1 foot 35 5/16 ” 17º pt-30-cn 2 foot 29 1/8 ” 38º pt-30-cn 3 foot 12 5/8 ” 70º pt-40-cn/pt-45-cn / pt-50-cn 1 foot 47 ¾” 13º pt-40-cn/pt-45-cn / p...

Page 12

12 viii. Roof mounts the structure of the roof should first be examined to determine the dimensions of its members. Check applicable codes as to loading requirements. The roof penetrations should be located over an attic or similar space that is not blocked by a chimney, beams, or other obstacles. P...

Page 13

13 provide a waterproof seal. Another method is to make a flat copper flashing with an oversize tube, which is penetrated by the copper water pipe. A coolie cap is made from a reducing coupling that fits the oversized copper tube and is large enough for the copper water pipe to just pass through. It...

Page 14

14 roofing material. Weather proof with appropriate sealant. Consult the waterproofing and roof attachment drawings details q – z in the appendix for additional details. In retrofit situations, rafters or roof trusses may be located from inside the attic if the crawl space is large enough to permit ...

Page 15

15 d. South/north roof mounts most homes have a south facing roof. This roof area should be utilized for the collector location unless there are shade or aesthetic problems. Follow the guidelines in section vi collector orientation, while taking into consideration the appearance of the system on the...

Page 16

16 the flush mount system, 2” x 6” pressure treated lumber blocks or exterior grade material are used to create the air space under the collector. See drawing c. To avoid potential roof damage from mildew and rotting it is not recommended for the collector to sit directly on the roof surface. Someti...

Page 17

17 do not mount the unit vertically f. Tile roof installations p rogressiv t ube collectors are easily installed on tile roofs or flush to the roof with the tile abutted to the collector. Installation details q and z in the appendix illustrates these two methods. For anchoring the collector to the r...

Page 18

18 c) clean off each location of all membrane grit, dirt, and tile debris. D) drill the four penetration holes into the roof. If using lag bolts, be sure the starter holes are in the center of the rafter. Because of the added difficulty of installing on tile roofs it is sometimes much easier to use ...

Page 19

19 f) remove the clear plastic protective lining on the jiffy seal. Lay the exposed side of the sealing compound on the membrane and press into the roof with palms of hands. G) after all four strips have been laid into place, use a rubber mallet and firmly hammer the entire strip down. H) remove the...

Page 20

20 drawing j recommended foundation for ground mount installation front view 50” to 60” 48” to 50” for pt-40-cn, pt-45-cn, and pt–50-cn 36” to 37” for pt-30-cn 22” to 23” for pt-20-cn standard concrete pier side view threaded j- bolt embedded in pier 4" 12" 10".

Page 21

21 drawing k boiler drain freeze prevention valve storage tank pressure relief copper pipe make sure pipes are below frost line in cold climates place freeze prevention valve as close to house as possible consult systems drawings for control valves configuration insulate pipes with proper undergroun...

Page 22

22 x. System plumbing a p rogressiv t ube unit can be installed as a pre-heater system or as a direct solar system. Consult the recommended system plumbing diagrams for the type of system to be installed. All piping must meet local code requirements for potable hot water service and must be installe...

Page 23

23 direct solar systems should not use plastic pipe to feed cold water to the tempering valve. The water from the collector can melt the pipe from the valve. High temperature cpv plastic pipe may be used down line of the tempering valve if a six foot copper stub is installed in the tempering valve b...

Page 24

24 xii. Freeze prevention p rogressiv t ube collectors are virtually freeze proof throughout the sunbelt area of the country due to their thermal mass and heavy insulation. However, the pipes leading to and from the collector can freeze. Collector piping should be as short as possible and should pen...

Page 25: Model Fp-35

25 model fp-35 (valve opens at +/-38 f) valve must be installed with drain port down caution: do not solder near freeze valve do not over tighten use pipe dope or teflon tape do not insulate freeze valve from collector ¾” c x ½” f flush bushing 12” do not insulate or ¾” x ½” f adapter may be...

Page 26

26 pipe freeze times rubatex and armaflex k = 0.270 btu-in/hr-f-sq ft type m type l pipe id/od (in.) 0.811/0.875 0.785/0.875 insulation (r) 2.6 4.4 6.3 10.7 2.6 4.4 6.3 10.7 thickness (in.) 0.50 0.75 1.00 1.50 0.50 0.75 1.00 1.50 ambient (f) hours to freeze solid hours to freeze solid 30 89.0 116.7 ...

Page 27

27 xiii. Two or more collector systems households with more than six members or with a large hot water demand should consider having a two-unit system. Light commercial applications such as restaurants, car washes, housing with central hot water systems, bathhouses, and process hot water can be serv...

Page 28

28 multiple collector systems can be installed in series in non-freezing areas, but in order to drain the system each collector must have a boiler drain at the inlet connection and a boiler drain or vacuum breaker at the outlet connection. Never plumb more than two units in series. Plumbing three or...

Page 29

29 drawing n drawing o proper positioning of two units on south roofs. This position is not allowed. This position must be within 15” of roof crown. This position must be over a load bearing wall. Supply line return line west facing roof east facing roof maximum distance collector mount from roof cr...

Page 30

30 drawing p xiv. Direct systems direct solar systems are usually installed in low latitude areas of the world that have an abundance of sunlight. Since the solar collection day is longer and solar radiation is more intense, a p rogressiv t ube collector can easily produce 180 0 f to 200 0 f water. ...

Page 31

31 in some areas, such as the caribbean, there is a brief period during the year in which rain and heavy cloud cover can reduce the thermal performance of the collector. This can be a problem if a large hot water demand is made on the collector in the late afternoon or evening and then another hot w...

Page 32

32 12. Give owner’s manual and warranty to homeowner and go over all operations of the system. 13. For installation and operation of the instantaneous water heater, please follow the manufacturer operation manual. Xvi. Drain procedures 1. Position the flow control valve in the solar by-pass mode. Co...

Page 33

33 faucet in the household and allow the water to run. If it goes from cold to warm to hot, the system is working properly. This test is the same as for any conventional residential gas or electric water heater. For a more precise measurement follow the procedure above for comparing the temperature ...

Page 34: Appendix

34 appendix srcc certified og 300 three-way system srcc section: the solar energy system described by this manual, when properly installed and maintained, meets the minimum standards established by the srcc. This certification does not imply endorsement or warranty of this product by srcc. The follo...

Page 35

35 freeze protection information the freeze protection method of this system is thermal mass and manual draining. In some areas an automatic freeze prevention valve may have been installed. This valve will open during freezing weather and allow a small flow of water. Drain the system as instructed i...

Page 36

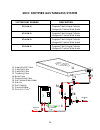

36 srcc certified og 300 three-way system system part number description pt-20-cn progressivtube® integral collector storage with electric water heater pt-30-cn progressivtube® integral collector storage with electric water heater pt-40-cn progressivtube® integral collector storage with electric wat...

Page 37

37 9 10 9 inlet outlet cold hot mi x 8 7 6 5b 5a 4 3 2a hot water out cold water in cold water inlet hot water outlet 1 2b 11 1. Supply shut off valve 2. 3-way ball valve 3. 2-way ball valve 4. Tempering valve 5. Boiler drain 6. Pressure relief valve 7. Conventional water heater 8. Temperature/press...

Page 38

38 srcc certified gas tankless system system part number description pt-20-cn-tl progressivtube® integral collector storage with tankless water heater pt-30-cn-tl progressivtube® integral collector storage with tankless water heater pt-40-cn-tl progressivtube® integral collector storage with tankles...

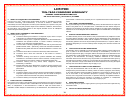

Page 39: Limited

39 limited ten-year consumer warranty thermal conversion technology 101 c opeland s treet , j acksonville , fl 32204 1. What is covered by this warranty the p rogressiv t ube ® passive solar water heater (product) is warranted by thermal conversion technology (the manufacturer), to be free of defect...

Page 40: Srcc Og 300 3-Way System

40 p rogressiv t ube srcc og 300 3-way system col d hot mi x 6 5b 5a 4 3 2a 1 2b col d hot mi x 6 5b 5a 4 3 2a 1 2b col d hot mi x 6 5b 5a 4 3 2a 1 2b 1. Supply shut off valve 2. 3-way ball valve 3. 2-way ball valve 4. Tempering valve 5. Boiler drain 6. Pressure relief valve legend a – solar direct ...

Page 41

41 fsec approved 2-way systems system part number description pt-20-cn progressivtube® integral collector storage with electric or gas water heater pt-30-cn progressivtube® integral collector storage with electric or gas water heater pt-40-cn progressivtube® integral collector storage with electric ...

Page 42

42 label a: freeze protection information the freeze protection method of this system is thermal mass and manual draining. In some areas an automatic freeze prevention valve may have been installed. This valve will open during freezing weather and allow a small flow of water. Drain the system as ins...

Page 43

43 8 7 6 5b 5a 4 3 2 hot water out cold water in cold water inlet hot water outlet 1 9 co l d hot mix 11 9 inlet outlet 10 cold hot mi x 8 7 6 5b 5a 4 3 2 hot water out cold water in cold water inlet hot water outlet 1 9 11 9 inlet outlet 10 7 6 5b 5a 4 3 2 hot water out cold water in cold water inl...

Page 44

44 electric 2-way system co ld hot mi x 8 7 6 5b 5a 4 3 2 hot water out cold water in cold water inlet hot water outlet 1 open to solar from solar solar pre-heat electric 2-way system cold hot mi x 8 7 6 5b 5a 4 3 2 hot water out cold water in cold water inlet hot water outlet 1 from solar to solar ...

Page 45

45 installation details detail q spaced block with spanner mount *spacer block(s) 1. Spacer blocks should be installed within 1 inch of the thru-bolt. 2. When bolt is within 2” of a rafter only one spacer block will be required on the opposite side of the bolt, away from the rafter. 3. Two spacer bl...

Page 46

46 installation details detail r lag bolt mounting * lead holes required – pre-drill lead holes for the shank at 100% of the shank diameter. Lead holes for the threads at 60-75% of the shank diameter. **roof sealant – required between mounting block to and shingles/sheathing. Bolt holes shall be sea...

Page 47

47 installation details detail s pitch pocket method *spaced block(s) 1. Spacer blocks should be installed within 1 inch of the thru-bolt. 2. When bolt is within 2” of a rafter only one spacer block will be required on the opposite side of the bolt, away from the rafter. 3. Two spacer blocks are req...

Page 48

48 installation details detail t j-bolt mount note: 1. The bent portion of the j-bolt shall not be threaded. 2. Roof sealant is required between mounting block and shingles/sheathing. Boltholes shall be sealed to prevent moisture penetration. Mounting blocks this drawing shows the use of a mounting ...

Page 49

49 installation details detail u cathedral ceiling note: cat(s) must fit tight between rafters. Mounting blocks this drawing shows the use of a mounting block to provide the watertight seal between the mounting hardware and the roof. Metal flashing sheets can be used instead of the mounting block. P...

Page 50

50 installation details detail w extra tank insulation option: if a junction box is installed on the outer shell of the tank, the super insulation shall be installed up to the box but not covering it. Note: 1. Tanks shall be completely wrapped using an insulation blanket with a vapor barrier and wit...

Page 51

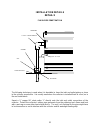

51 installation details detail x flush pipe penetration the following technique is used when it is desirable to have the inlet and outlet piping as close to the collector as possible. It is usually used when the collector is installed flush to a roof, as in tile roof installations. Sweat a ¾” copper...

Page 52

52 installation details detail y solar direct with back-up solar pre-heat solar direct co l d ho t mix co l d ho t mix installation details detail z instructions for repairing a tank leak in the unlikely event that a leak should develop in a p rogressiv t ube ® collector, the instructions below shou...

Page 53

53 carefully lift out the teflon frame and place in a secure location. Caution: even a slight breeze can turn the frame into a sail. 6. Remove the stainless steel rod that crosses over the top of the tank securing the two framewalls together. This rod is part of the unit’s high wind load reinforceme...

Page 54

54 typical roof bracing the following drawings are suggested techniques for roof structure bracing. These are not engineer certified drawings and all suggested bracing in these drawings are intended to be used with structurally sound roofs. Individual installations may require additional bracing. Th...

Page 55

55 side view – mount parallel to rafters front view 3/8” x 4” lag bolt 2” x 4” x 48” nominal stringer roof beam roof 3/8” x 4” lag bolt 3/8” x 3” lag bolt 3/8” x 3” lag bolt 3/8” x 4” lag bolt 2” x 4” x 48” nominal stringer roof beam roof 3/8” x 4” lag bolt 3/8” x 3” lag bolt 3/8” x 3” lag bolt.

Page 56

56 suggested roof bracing for cathedral ceilings and other wide rafter spans 3/8” x 4” lag bolt 48” 4” x 4” purlin roof 3/8” x 4” lag bolt roof beam simpson u44 hanger simpson u44 hanger 3/8” x 5” lag bolt 4” x 4” purlin roof 3/8” x 12” lag bolt roof beam 3/8” x 12” lag bolt 2” x 4” x 6” treated woo...

Page 57: Your Notes

57 your notes.

Page 58

58 101 copeland street jacksonville, florida 32204 tel: 904-358-3720 fax: 904-358-3728 www.Tctsolar.Com techsupport@tctsolar.Com rev. 6/2008.