- DL manuals

- TDK-Lambda

- Power Supply

- FPS-S1U

- Instruction Manual

TDK-Lambda FPS-S1U Instruction Manual

Summary of FPS-S1U

Page 1

This manual cover models: fps1000-12 fps1000-24 fps1000-32 fps1000-48 fps-s1u 19” rack single output fps-t1u 19” rack triple output fps series 1000w in 1u front end power supplies instruction manual dwg no: ia599-04-02-a.

Page 2: Fps1000 Series

Fps1000 series instruction manual dwg no: ia599-04-02 a.

Page 3

Table of contents warranty .................................................................................................................................Pg. 1 fps1000, fps-s1u and fps-t1u rack safety instructions ................................................. Pg. 2 fps1000 power supply chapter...

Page 4

1 warranty this densei-lambda product is warranted against defects in materials and workmanship for a period of two years from date of shipment. During the warranty period , densei-lambda will, at it's option, either repair or replace products which prove to be defective. Limitation of warranty the ...

Page 5

2 fps1000 power supply and fps-s1u rack safety instructions important safety instructions operating personnel must not remove the fps1000, fps-s1u and the fps-t1u cover. No internal adjustment or component replacement is allowed by non densei-lambda qualified service personnel. Never replace compone...

Page 6

3 fps1000 instruction manual attention: risque de choc et de danger e'lectriques. Le de'branchement d'une seule alimenttation stabilise'e ne de'branche uniquement qu'un module "alimentation stabilise'e". Pour isoler completement le module en cause, il faut de'brancher toutes les alimentations stabil...

Page 7

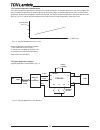

4 chapter 1 fps1000 series specifications model fps1000 fps1000 fps1000 v/i -24 -32 -48 24 32 48 29 38.4 58 33 26 17.25 40 31 21 v1 (v) v2 (v) i1 (a) i2 (a) v1 v2 fig. 1: rated output current vs output voltage vout (v) i1 iout (a) i2 notes: *1: for cases where conformance to various safety standards...

Page 8

5 chapter 2 outline drawings 1.2 fps 1000 series outline drawings fps1000 instruction manual.

Page 9

6 2.2 fps 1000/p series outline drawings.

Page 10

7 chapter 3 fps1000 power supply installation 3.1 general this chapter contains instructions for initial inspection, preparation for use and repackaging forshipment. Note fps1000 power supplies series generate magnetic field which might affect the operation of other instruments. If your equipment is...

Page 11

8 3.7 connecting the load wire size resistivity maximum length in feet to limit voltage awg ohm/kft drop to 1v or less. 5a 10a 20a 50a 150a 14 2.526 80 40 20 8 2 12 1.589 120 60 30 12 3.4 10 0.9994 200 100 50 20 6 8 0.6285 320 160 80 32 10 6 0.3953 500 250 125 50 16 4 0.2486 800 400 200 80 26 2 0.15...

Page 12

Fig. 3-2: fps1000/p front panel 1 2 3 4 5 6 fig. 3-1: fps1000 front panel 1 4 5 3 2 9 3.7.6 front panel controls and indicator 3.7.3 noise and impedance effects to minimize the noise pickup or radiation, the load wires and remote sense wires should be twisted-pairs of the shortest possible length. S...

Page 13

10 3.7.7 input/output connector information the fps1000 series uses male connector pcib24w9m400a1, positronic connector. To mate fps1000 series to the load circuitry, use female connector pcib24w9f400a1-s1031, positronic connector. Refer to table 3-4 and to the outline drawing in chapter 2 for the c...

Page 14

11 chapter 4 functions and features 4.1 input voltage range input voltage is single phase 85~265vac (47~63hz). The power supply can be operated also with a dc input voltage, 120~330vdc but the safety approvals apply to the ac voltage only. Input voltage which is out of the specifications might cause...

Page 15

12 4.8 dc_ok signal an open collector output provides a low output voltage detection signal. The open collector output is on when the output voltage is higher than 80%+/-5% of the rated output voltage of the power supply. The open collector output is referenced to the signals_return potential and is...

Page 16

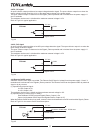

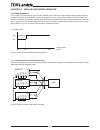

13 fig 4-6 4.11 remote sensing the remote sensing compensates voltage drop on the load wiring. The maximum voltage drop on each wire is 1v, however, it is recommended to minimize the voltage drop on the load wires to improve the response to load current changes. In case that the sensing wires are lo...

Page 17

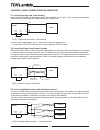

14 fig 5-1: single load connection, local sensing fig 5-2: remote sensing, single load. Chapter 5 basic connections for operation 5.1 connecting single load, local sensing local sensing is suitable for applications where load regulation is not critical. Fig 5-1 shows recommended load and sensing con...

Page 18

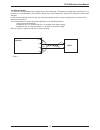

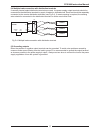

15 fig 5-4: multiple loads connection with distribution terminal 5.4 multiple loads connection with distribution terminals if remotely located output distribution terminals are used, the power supply output terminals should be connected to the distribution terminals by a pair of twisted or shielded ...

Page 19

16 chapter 6 parallel and series operation 6.1 parallel operation up to 8 fps1000 units of the same output voltage rating can be connected in parallel. By connecting the cs signal between the paralleled units, automatic current balance is achieved, with +/-10% accuracy. Derate the total output curre...

Page 20

17 fig 6-3: signal return connection at parallel operation fig 6-4: remote on/off control at parallel operation 6.1.3 signal return bus at parallel operation the signal return of each paralleled unit can be connected together to form a common signal return bus. By this way, the control and monitorin...

Page 21

18 fig 6-6: series connection for bipolar output voltage 6.2 series operation two units can be seriesly connected to increase the output voltage or to create a bipolar voltage source. It is recommended to connect diodes in parallel with each output to prevent reverse voltage in case of failure in on...

Page 22

19 fps1000 instruction manual 7.2 i 2 c interface specifications 7.2.1 general specifications 1. Clock frequency: 100khz 2. Address lines: three (a0, a1, a2). Support 8 power supply modules 7.2.2 output voltage measurement 7.2.3 output current measurement 7.2.4 internal temperature measurement 7.2.5...

Page 23

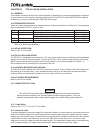

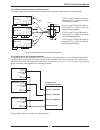

20 pcf8574 slave address: table 7-2 7.3 block diagram of the i 2 c option refer to fig 7-1 for description of the i 2 c block diagram and for typical application. A0 a1 a2 register a0 output voltage a1 a2 adc temperature a0 a0 a1 a1 a2 a2 eeprom fig 7-1: i 2 c option bloack diagram output fail otp t...

Page 24

21 the pcf8591 slave address is: the pcf8591 device initially requires a control byte to be written to the configuration register. The control byte is as follows: when a single channel is to be read, a,b,c and d should be determined as follows: refer to the following table for the scaling of the a/d...

Page 25

22 internal temperature calculation example: 1. Hex readback: 68 (0110 1000). 2. Convert hex readback to decimal: 104 3. Calculate the measured temperature: temp=104*0.391=40.664 o c fig 7-3: typical application of i 2 c interface 7.5.3 internal temperature measurement the internal ambient temperatu...

Page 26

23 fig 8-1: expected fan life vs. Ambient temperature chapter 8 fps1000 maintenance 8.1 introduction this chapter contains information about maintenance, calibration and troubleshooting of the fps1000 power supply. 8.2 units under warranty units requiring repairs during the warranty period should be...

Page 27

24 fps-s1u 19” rack single output.

Page 28

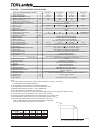

25 chapter 9 fps-s1u rack specifications fps-s1u instruction manual notes: *1: the output of all the fps1000 modules are connected in parallel in the rack. *2: for input voltage lower than 100vac, maximum output power derated by 10% of the power rating. *3: for cases where conformance to to various ...

Page 29

26 step no item description reference 1 inspection initial physical inspection of the power supply section 3.3 2 installation installing the power supply. Section 10.4 ensuring adequate ventilation. Section 10.5 3 ac source ac source requirements section 3.6 4 load connection wire size selection. Se...

Page 30

1 4 3 2 5 1 27 10.7.3 making the load connections 10.7.4 rear panel description fig. 10-1: fps-s1u rear panel the load wires should be properly terminated with terminals securely attached. Do not use unterminated wires for load connection at the fps-s1u. Hazardous voltages may exist at the outputs a...

Page 31

28 10.7.5 control and monitoring signals connector current sharing signal. When fps-s1u racks are connected in parallel, the cs pins of the units should be connected to allow current balance between units. Cs 9 connection for output voltage trimming of fps1000 unit "c". The voltage can be trimmed wi...

Page 32

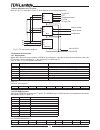

29 fig 10-2: fps1000 modules location 10.7.6 modules location up to three fps1000 modules of the same output voltage rating can be plugged into an fps-s1u rack. Refer to fig 10-2 for the modules location. 10.7.7 blank panels each fps-s1u rack is supplied with two blank panels in the package. Use the...

Page 33

30 chapter 11 fps-s1u and fps-s1u/p outline drawings 11.1 fps-s1u outline drawing.

Page 34

31 11.2 fps-s1u/p outline drawing fps-s1u instruction manual.

Page 35

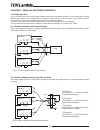

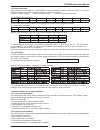

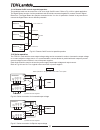

32 fig 12-1: single load connection, local sensing fig 12-2: remote sensing, single load. Fig 12-3: multiple loads connection with distribution terminal chapter 12 basic connections for operation fps-s1u rack 12.1 connecting single load, local sensing local sensing is suitable for applications where...

Page 36

33 fig 12-4: individual on/off control fig 12-5: single on/off control fig 12-6: output voltage trimming fig 12-7: supervisory signals 12.4 on/off control fig 12-4 shows typical connection for individual on/off control of each installed fps1000 unit. The on/off control signal is applied to the db25 ...

Page 37

34 chapter 13 parallel and series operation 13.1 parallel operation up to 3 fps-s1u racks with up to 8 fps1000 installed units of the same output voltage rating can be connected in parallel. The built-in oring diodes on the main output and on the +12v auxiliary voltage in each fps1000 unit allow n+1...

Page 38

35 fig 13-3: output voltage trimming at parallel operation fig 13-4: signal return connection at parallel operation 13.1.2 output voltage trimming at parallel operation the output voltage of the units connected in parallel can be made by a single trimmer or resistive divider. 13.1.3 signal return bu...

Page 39

36 fig 13-5: remote on/off control at parallel operation fig 13-6: series connection for increased output voltage 13.1.4 remote on/off control at parallel operation the paralleled racks can be turned on or off via a single on/off control. Refer to fig 13-5 for typical application. The signal return ...

Page 40

37 chapter 14 fps-s1u i 2 c bus interface option 14.1 introduction the fps-s1u rack provides access to the i 2 c bus interface in each installed fps1000/s unit via the rear panel db25 female connector located at the rear panel. The clock is connected to pin 20 and the data is connected to pin 21. Th...

Page 41

38 chapter 15 fps-s1u maintenance 15.1 introduction this chapter contains information about maintenance, calibration and troubleshooting of the fps-s1u rack. 15.2 units under warranty units requiring repairs during the warranty period should be returned to densei-lambda authorized service office. Un...

Page 42

39 fps-t1u 19” rack triple output.

Page 43

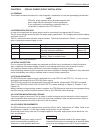

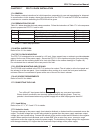

40 notes: *1: the output of all the fps1000 modules are floating in the rack. *2: for input voltage lower than 100vac, maximum output power derated by 10% of the power rating. *3: for cases where conformance to to various safety standards (ul, en etc.) is required, to be described as 100-240vac (50/...

Page 44

41 step no item description reference 1 inspection initial physical inspection of the power supply section 3.3 2 installation installing the power supply. Section 10.4 ensuring adequate ventilation. Section 10.5 3 ac source ac source requirements section 3.6 4 load connection wire size selection. Se...

Page 45

42 17.7.3 making the load connections 17.7.4 rear panel description fig. 17-1: fps-t1u rear panel the load wires should be properly terminated with terminals securely attached. Do not use unterminated wires for load connection at the fps-t1u. Hazardous voltages may exist at the outputs and the load ...

Page 46

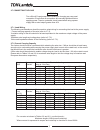

43 17.7.5 rear panel in/out connector pins function description j1(a), j2(b), j3(c) pin no function description 14 temp_alarm open collector signal, referenced to pin 3 (signal return). On when the internal temperature of fps1000 unit is within safe limit, off approx. 10 °c below thermal shut down. ...

Page 47

44 fig 17-2: fps1000 modules location 17.7.6 modules location up to three fps1000 modules can be plugged into an fps-t1u rack. Refer to fig 17-2 for the modules location. 17.7.7 blank panels each fps-t1u rack is supplied with two blank panels in the package. Use the blank panels to close the front p...

Page 48

Fps-t1u instruction manual 45 chapter 18 fps-t1u and fps-t1u/p outline drawings 18.1 fps-t1u outline drawing.

Page 49

46 11.1 fps-t1u outline drawing 18.2 fps-t1u/p outline drawing.

Page 50

47 fig 19-1: remote sensing, three load. Chapter 19 basic connections for operation fps-t1u rack 19.1 connecting single load, remote sensing remote sensing is used in cases where the load regulation is important at the load terminals. Use twisted or shielded wires to minimize noise pick-up. If shiel...

Page 51

48 fig 19-4 shows typical output voltage trimming connection for fps1000 unit ‘a’ inside the rack units ‘b’ and ‘c’ connections - refer to 17.7.5 signals are accessible at the j1(a), j2(b), j3(c) connectors on the rear panel of the rack fig 19-5 shows typical connection for fps1000 unit ‘a’. Inside ...

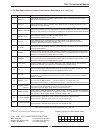

Page 52

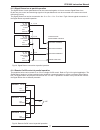

49 fps-t1u fps-1000 module a fps-1000 module b fps-1000 module c j1(a)-12 j3(c)-3 on/ off_1 a j2(b)-12 j2(b)-3 on/ off_1 b j3(c)-12 j1(a)-3 on/ off_1 c load +v +s -s -v +s -s +v +s -s -v +s -s +s -s +v +s -s -v +s -s +v -v cs cs cs j1(c)-10 j1(b)-10 j1(a)-10 chapter 20 parallel and series operation ...

Page 53

50 (*) diodes are user supplied fps-t1u fps-1000 module a fps-1000 module b fps-1000 module c j1(a)-12 j3(c)-3 on/ off_1 a j2(b)-12 j2(b)-3 on/ off_1 b j3(c)-12 j1(a)-3 on/ off_1 c load +v +s -s -v +s -s +v -v +v +s -s -v (*) (*) +v +s -s -v (*) 20.2 series operation up to three fps1000 with the sam...

Page 54

51 chapter 21 fps-t1u i 2 c bus interface option 21.1 introduction the fps-t1u rack provides access to the i 2 c bus interface in each installed fps1000/s unit via the rear panel molex female connector located at the rear panel. The clock is connected to pin 2 and the data is connected to pin 1. The...

Page 55

52 chapter 22 fps-t1u maintenance 22.1 introduction this chapter contains information about maintenance, calibration and troubleshooting of the fps-t1u rack. 22.2 units under warranty units requiring repairs during the warranty period should be returned to densei-lambda authorized service office. Un...

Page 56: Notes

53 notes.

Page 57: Notes

56 notes.