- DL manuals

- TDK-Lambda

- Power Supply

- GENESYS 1500W

- User Manual

TDK-Lambda GENESYS 1500W User Manual

Summary of GENESYS 1500W

Page 1

User manual for genesys tm 750w/1500w programmable dc power supplies document: 83-507-013 rev g tdk-lambda americas inc. 405 essex road, neptune, nj 07753 tel: (732) 922-9300 fax: (732) 922-9334 web: www.Us.Tdk-lambda.Com/hp.

Page 4

Genesys tm manual supplement for units equipped with the “iemd” option, for ieee-488 with multi-drop, also refer to iemd manual 83030200 for units equipped with the “lan” option for local area network with multi-drop, also refer to lan manual 83034100 for units equipped with “md” option, for multi-d...

Page 5

1 83507013 rev g table of contents warranty_________________________________________________________________ 7 english safety instructions______________________________________________ 8 francais (french) safety instructions___________________________________ 11 deutsch (german) safety instructions_...

Page 6

2 83507013 rev g 2.12 supplemental characteristics ________________________________________________ 32 2.13 genesys ™ outline drawings _______________________________________________ 33 3 installation ____________________________________________________________ 34 3.1 general _______________________...

Page 7

3 83507013 rev g 3.10.3 remote sensing __________________________________________________ 47 3.10.4 j2 sense connector technical information _______________________________ 48 3.11 repackaging for shipment __________________________________________________ 48 4 front and rear panel controls and conn...

Page 8

4 83507013 rev g 5.15.1 basic parallel operation ____________________________________________ 64 1. Setting up the master unit __________________________________________ 64 2. Setting up the slave units __________________________________________ 64 3. Daisy chain connection: (see fig. 5-6) _________...

Page 9

5 83507013 rev g 7.5.3 end of message ___________________________________________________ 79 7.5.4 command repeat __________________________________________________ 79 7.5.5 checksum ________________________________________________________ 79 7.5.6 acknowledge _______________________________________...

Page 10

6 83507013 rev g 9.5 parts replacement and repairs ______________________________________________ 95 9.6 troubleshooting ___________________________________________________________ 95 9.7 fuse rating ______________________________________________________________ 97.

Page 11

83-000-016 rev. F warranty this tdk-lambda americas inc. Product is warranted against defects in materials and workmanship for a period of five years from date of shipment. During the warranty period, tdk-lambda americas inc. Will, at it’s option, either repair or replace products which prove to be ...

Page 12

8 83507013 rev g english safety instructions caution the following safety precaution must be observed during all phases of operation, service and repair of this equipment. Failure to comply with the safety precautions or warnings in this document violates safety standards of design, manufacture and ...

Page 13

9 83507013 rev g parts substitutions & modifications parts substitutions and modifications are allowed by authorized tdk-lambda americas inc. Service personnel only. For repairs or modifications, the instrument must be returned to an authorized tdk- lambda americas inc. Service facility. Safety inst...

Page 14

10 83507013 rev g fcc compliance notice: note: this equipment has been tested and found to comply with the limits for a class a digital device, pursuant to part 15 of the fcc rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated...

Page 15

11 83507013 rev g francais consignes de securite attention les consignes de sécurité suivantes doivent être observées pendant toutes les phases de l'utilisation, entretien et réparations de cet équipement. Le non-respect des consignes de sécurité et des avertissements dans ce document viole les norm...

Page 16

12 83507013 rev g circuits sous tension le personnel d'exploitation ne doit pas enlever le couvercle de l'instrument. Le réglage ou le remplacement des composants internes ne peut être effectué que par un personnel qualifié tdk- lambda americas inc. Ne remplacez jamais les composants lorsque le câbl...

Page 17

13 83507013 rev g note concernant la conformite fcc : nota : cet équipement a été testé et s'est avéré conforme aux limites pour un appareil numérique classe a selon la part 15 des règles fcc. Ces limites sont conçues pour assurer une protection raisonnable contre les interférences dangereuses lorsq...

Page 18

14 83507013 rev g deutsch sicherheitsvorschriften vorsicht die folgenden sicherheitsvorschriften müssen in allen phasen des betriebs, der wartung und der reparatur der anlage eingehalten werden. Eine missachtung der sicherheitsvorschriften und warnhinweise aus diesem handbuch führt zur verletzung de...

Page 19

15 83507013 rev g spannungsschwankungen der hauptstromversorgung den oberen spannungsbereich nicht übersteigen. SpannungsfÜhrende teile die geräteabdeckung darf nicht durch betriebspersonal entfernt werden. Interne modifikationen sowie bauteileaustausch sind nur durch von tdk-lambda americas inc. Qu...

Page 20

16 83507013 rev g ein (versorgung) das warnsymbol deutet auf eine gefahr hin. Die aufmerksamkeit wird auf ein verfahren gelenkt. Eine missachtung der einhaltung des verfahrens kann zu personenschaden führen. Eine warnung darf nicht übergangen werden und alle angezeigten umstände müssen vollkommen ve...

Page 21

17 83507013 rev g italiano norme di sicurezza attenzione la seguente precauzione di sicurezza deve essere osservata a tutti gli stadi del funzionamento, della manutenzione e della riparazione di questa apparecchiatura. L'inosservanza delle precauzioni o delle avvertenze di sicurezza contenute in que...

Page 22

18 83507013 rev g sicurezza, eventuali fluttuazioni nella tensione di rete non devono superare il campo di potenze nominali suddetto. Circuiti sotto tensione nessun addetto deve mai rimuovere il coperchio dello strumento. Le regolazioni interne e la sostituzione dei componenti sono consentite unicam...

Page 23

19 83507013 rev g il simbolo di avvertimento denota un periodo. È necessario prestare attenzione alla procedura. Il mancato rispetto della procedura può sfociare in un infortunio. Non ignorare alcun simbolo di avvertimento. Tutte le condizioni indicate devono essere pienamente comprese e rispettate....

Page 24

20 83507013 rev g portugues instruÇÕes de seguranÇa cuidado as seguintes precauções de segurança devem ser respeitadas em todas as fases de funcionamento, assistência e reparação deste equipamento. A não observância dos avisos e precauções de segurança constantes neste documento viola os padrões de ...

Page 25

21 83507013 rev g circuitos sob tensÃo os operadores não devem retirar a cobertura do instrumento. A realização de ajustes internos ou substituições de componentes só é permitida se realizada por pessoal especializado da tdk-lambda americas inc. Nunca substitua componentes com o cabo de alimentação ...

Page 26

22 83507013 rev g activado (alimentação) o sinal de aviso assinala um perigo. Solicita-se atenção para um procedimento. Não seguir correctamente o procedimento pode resultar em ferimentos. Não se deve ignorar um sinal de aviso, e todas as condições indicadas devem ser compreendidas e respeitadas. O ...

Page 27

23 83507013 rev g espaÑol instrucciones de seguridad precauciÓn la siguiente precaución de seguridad debe ser respetada durante todas las fases de funcionamiento, mantenimiento y reparación de este equipo. El incumplimiento de las precauciones o advertencias de seguridad recogidas en este documento ...

Page 28

24 83507013 rev g de seguridad, las fluctuaciones en la tensión de alimentación de la red no deberían superar los rangos de tensión antedichos. Circuitos activos el personal operativo no debe retirar la cubierta del aparato. Los ajustes internos o el reemplazo de componentes sólo pueden ser realizad...

Page 29

25 83507013 rev g apagado (fuente de alimentación) encendido (fuente de alimentación) el símbolo de advertencia indica un peligro. Llama la atención ante un procedimiento. Si el procedimiento no se realiza correctamente, podrían producirse lesiones personales. Los símbolos de advertencia no se puede...

Page 30

26 83507013 rev g 1 general information 1.1 user manual content this user’s manual contains the operating instructions, installation instructions and specifications of the genesys ™ 750w and 1500w power supply series. The instructions refer to the standard power supplies, including the built-in rs23...

Page 31

27 83507013 rev g 1.2.3 features and options constant voltage / constant current with automatic crossover. Active power factor correction. Universal input voltage (85 265vac), continuous operation. Embedded microprocessor controller. Built-in rs232/rs485 interface. Voltage & current high resolution...

Page 32

28 83507013 rev g 1.2.6 analog voltage programming and monitoring analog inputs and outputs are provided at the rear panel for analog control of the power supply. The output voltage and the current can be programmed by analog voltage or by resistor, and can be monitored by analog voltage. The power ...

Page 33

29 83507013 rev g 1.3 accessories 1.3.1 included accessories the following accessories are delivered with the power supply: 1.3.1.1 serial link cable serial link cable for linking power supplies by rs485 communication.Gen/rj45. Cable description: 0.5m length, shielded, rj-45 type plugs, eight (8) co...

Page 34

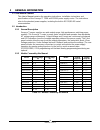

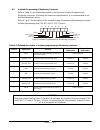

30 83507013 rev g 2 specifications 2.1 output rating model gen 6-100 8-90 12.5-60 20-38 30-25 40-19 – 60-12.5 80-9.5 100-7.5 150-5 300-2.5 600-1.3 1.Rated output voltage (*1) v 6 8 12.5 20 30 40 – 60 80 100 150 300 600 2.Rated output current 750w (*2) a 100 90 60 38 25 19 – 12.5 9.5 7.5 5 2.5 1.3 3....

Page 35

31 83507013 rev g 2.6 programming and readback (rs232/485, optional ieee int 1. Vout programming accuracy – 0.05% of actual output voltage + 0.05% of rated output voltage. 2. Iout programming accuracy – 0.1% of actual output current + 0.1% of rated output current 3. Vout programming resolution. – 0....

Page 36

32 83507013 rev g notes: *1. Minimum voltage is guaranteed to maximum 0.2% of the rated output voltage. *2. Minimum current is guaranteed to maximum 0.4% of the rated output current. *3. For cases where conformance to various safety standards (ul, iec etc.) is required, to be described as 100-240vac...

Page 37

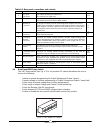

33 83507013 rev g 2.13 outline drawings.

Page 38

34 83507013 rev g 3 installation 3.1 general this chapter contains instructions for initial inspection, preparation for use and repackaging for shipment. Connection to pc, setting the communication port and linking genesys ™ power supplies are described in chapter 7. Note genesys tm power supplies g...

Page 39

35 83507013 rev g 3.4 rack mounting the genesys ™ power supply series is designed to fit in a standard 19” equipment rack. 3.4.1 to install the power supply in a rack: use the front panel rack-mount brackets to install the power supply in the rack. Use a support bar to provide adequate support for t...

Page 40

36 83507013 rev g 3.7 ac input power connection caution connection of this power supply to an ac power source should be made by an electrician or other qualified personnel. Warning there is a potential shock hazard if the power supply chassis (with cover in place) is not connected to an electrical s...

Page 41

37 83507013 rev g 3.7.4 ac input wire connection, 1500w models a) strip the outside insulation of the ac cable approx. 10cm (3.94 inches). Trim the wires so that the ground wire is 10mm (0.4 inches) longer than the other wires. Strip 14mm (0.55 inches) at the end of each of the wires. B) unscrew the...

Page 42

38 83507013 rev g 3.8.2 prior to operation a) ensure that the power supply is configured to the default setting: on/off switch at off position. Dip switch: all positions at down (“off”) position. J2 sense connector: configured to local sense as shown in fig. 3-4: 1 remote (+) sense 2 local (+) sense...

Page 43

39 83507013 rev g d) rotate the volt encoder ccw to adjust the ovp setting to 50% of the unit voltage rating. E) wait a few seconds until the volt display returns to show the output voltage. F) adjust the output voltage toward its maximum and check that the output voltage cannot be increased more th...

Page 44

40 83507013 rev g 3.9 connecting the load warning turn off the ac input power before making or changing any rear panel connection. Ensure that all connections are securely tightened before applying power. There is a potential shock hazard when using a power supply with a rated output greater than 40...

Page 45

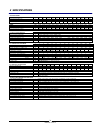

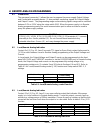

41 83507013 rev g cross sect. Area (mm²) resistivity ohm/km maximum length in meters to limit voltage drop to 1v or less 5a 10a 20a 50a 150a 2.5 8.21 24.0 12.0 6.0 2.4 0.8 4 5.09 39.2 18.6 9.8 4.0 1.4 6 3.39 59.0 29.4 14.8 5.8 2.0 10 1.95 102.6 51.2 25.6 10.2 3.4 16 1.24 160.0 80.0 40.0 16.0 5.4 25 ...

Page 46

42 83507013 rev g 3.9.6 making the load connections warning hazardous voltages may exist at the outputs and the load connections when using a power supply with a rated output greater than 40v. To protect personnel against accidental contact with hazardous voltages, ensure that the load and its conne...

Page 47

43 83507013 rev g 80v to 600v models warning hazardous voltages exist at the outputs and the load connections. To protect personnel against accidental contact with hazardous voltages, ensure that the load and its connections have no accessible live parts. Ensure that the load wiring insulation ratin...

Page 48

44 83507013 rev g 4. Insert the stripped wires into enclosure opening through the shutter and then to the terminals. Tighten the terminals screws securely. (see fig.3-8). 5. Loosen the two chassis screws marked “a” halfway. 6. Assemble the enclosure top cove r to the chassis and tighten screws “a” (...

Page 49

45 83507013 rev g 3.9.8 connecting single loads, remote sensing fig.3-11 shows recommended remote sensing connection for single loads. Remote sensing is used when, in constant voltage mode, the load regulation is important at the load terminals. Use twisted or shielded wires to minimize noise pick-u...

Page 50

46 83507013 rev g 3.9.10 multiple load connection with distribution terminals if remotely located output distribution terminals are used, the power supply output terminals should be connected to the distribution terminals by pair of twisted and/or shielded wires. Each load should be separately conne...

Page 51

47 83507013 rev g 3.10.2 local sensing the power supply is shipped with the rear panel j2 sense connector wired for local sensing of the output voltage. See table 3-4 for j2 terminals assignment. With local sensing, the output voltage regulation is made at the output terminals. This method does not ...

Page 52

48 83507013 rev g notes: 1. If the power supply is operating in remote sense and either the positive or negative load wire is not connected, an internal protection circuit will activate and shut down the power supply. To resume operation, turn the ac on/off to the off position, connect the open load...

Page 53

49 83507013 rev g 4 front and rear panel controls and connectors 4.1 introduction the genesys tm power supply series has a full set of controls, indicators and connectors that allow the user to easily setup and operate the unit. Before starting to operate the unit, please read the following sections...

Page 54

50 83507013 rev g table 4-1: front panel controls and indicators number control/indicator description section 4 current display 4 digit, 7 segment led display. Normally displays the output current. When the prev button is pressed, the display indicates the programmed setting of output current. 5 cur...

Page 55

51 83507013 rev g number control/indicator description section 14 prev/button main function: press prev to display the output voltage and current setting. For 5 sec. The display will show the setting and then it will return to show the actual output voltage and current. Auxiliary function: front pa...

Page 56

52 83507013 rev g table 4-2: rear panel connections and controls number item description section 1 ac input connector wire clamp connector for 1500w units. Iec connector for 750w units. 3.7.1 3.7.2 2 dc output bus-bars for 6v to 60v models. Wire clamp connector for 80v to 600v models. 3.9.6 3 remote...

Page 57

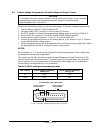

53 83507013 rev g 4.4.1 sw1 position function refer to table 4-3 for description of sw1 position functions. The factory default setting is down for all positions. Table 4-3: sw1 positions functions position function down (factory default) up sw1-1 output voltage remote analog programming output volt...

Page 58

54 83507013 rev g 4.5.1 making j1 connections j1 connector type: amp, p/n: 5747461-3 j1 plug description: amp, 749809-9 or equivalent. Wire dimension range: awg26-22 extraction tool: amp, 91232-1 or equivalent. Manual pistol grip tool: handle: amp, p/n: 58074-1 head: amp, p/n: 58063-2 before making ...

Page 59

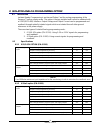

55 83507013 rev g table 4-4: j1 connector terminals and functions j1 contact signal name function section j1-1 ena_in enable/disable the power supply output by dry-contact (short/open) with ena_out. 5.8 j1-2 j1-3 if_com isolated interface common. Return for the so control, ps_ok signal and for the o...

Page 60

56 83507013 rev g 5 local operation 5.1 introduction this chapter describes the operating modes that are not involved in programming and monitoring the power supply via its serial communication port (rs232/rs485) or by remote analog signals. Ensure that the rem/loc led on the front panel is off, ind...

Page 61

57 83507013 rev g 5.2.2 constant current mode in constant current mode, the power supply regulates the output current at the selected value, while the voltage varies with the load requirement. While the power supply is operating in constant current mode, the current led on the front panel illuminate...

Page 62

58 83507013 rev g to preview the ovp setting, press the ovp/uvl pushbutton so that the current display will show “oup”. At this time, the voltage display will show the ovp setting. After 5 seconds, the display will return to its previous state. 5.3.2 activated ovp protection indications when the ovp...

Page 63

59 83507013 rev g armed, therefore, if the load current is higher than the current limit setting, the foldback protection will be activated again. Press the fold button to cancel the foldback protection. The power supply output will be disabled and the voltage display will show “off”. Press the out ...

Page 64

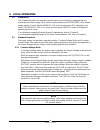

60 83507013 rev g 5.8 enable/disable control via rear panel j1 connector contacts 1 and 14 of j1 (fig.4-2, item 5) serve as output enable/disable terminals by switch or relay. This function is enabled or disabled by the sw1 setup switch position 9. Refer to table 5-3 for enable/disable function and ...

Page 65

61 83507013 rev g 5.11 safe-start and auto-restart modes when turning on the power supply ac on/off, it can start to its last setting of output voltage and current with the output enabled (auto-restart mode) or start with the output disabled (safe-start mode). Press and hold the out button to select...

Page 66

62 83507013 rev g 5.14 series operation power supplies of the same model can be connected in series to obtain increased output voltage. Split connection of the power supplies gives positive and negative output voltage. Caution do not connected power supplies from different manufacturers in series or...

Page 67

63 83507013 rev g remote programming in series operation for increased output voltage: 1. Programming by external voltage: the analog programming circuits of this power supply are referenced to the negative output potential. Therefore, the circuits used to control each series connected unit must be ...

Page 68

64 83507013 rev g remote programming in series operation for positive and negative output voltage 1. Programming by external voltage: the analog programming circuits of this power supply are referenced to the negative output potential. Therefore, the circuits used to control each series connected un...

Page 69

65 83507013 rev g master unit’s control. The output current setting of each unit should be programmed to the desired load current divided by the number of parallel units. 2. Set the rear panel setup switch sw1 position 2 to the up position. 3. Set sw1 position 3 of slave same as sw1 position 4 of ma...

Page 70

66 83507013 rev g 5.15.2.1 advanced parallel configuration 1. Sw1 position 2 - down in the master supply and up in all slave supplies. 2. Connect a short between j1-8 and j1-12 in all slave supplies. 3. Connect j1-25 of the master supply to j1-10 of all slave supplies. The following set-up connectio...

Page 71

67 83507013 rev g 5.15.2.4 current display accuracy in the advanced parallel mode, the master unit calculates the total current by multiplying the master output current by the number of slave units. In this method, the current display accuracy is 2% +/- 1 count. In cases that higher accuracy is requ...

Page 72

68 83507013 rev g fig.5-5: parallel operation with remote sensing master power supply slave#1 power supply j1-25 j1-10 p ipgm + v - v + v - v +s -s load as short as possible twisted pair +s -s +s -s twisted pair j1-8 j1-12 to j1-10 slave#2 power supply +s +ls -ls -s 5.16 daisy-chain connection it is...

Page 73

69 83507013 rev g 5.17.2 locked front panel in this mode the following front panel controls are disabled: voltage and current encoders. Fold button. Out button the power supply will not respond to attempts to use these controls. The volt display will show “lfp” to indicate that the front panel is lo...

Page 74

70 83507013 rev g 6 remote analog programming 6.1 introduction the rear panel connector j1 allows the user to program the power supply output voltage and current with an analog device. J1 also provides monitoring signals for output voltage and output current. The programming range and monitoring sig...

Page 75

71 83507013 rev g 6.4 remote voltage programming of output voltage and output current caution to maintain the power supply isolation and to prevent ground loops, use an isolated programming source when operating the power supply via remote analog programming at the j1 connector. Perform the followin...

Page 76

72 83507013 rev g 6.5 resistive programming of output voltage and current limit for resistive programming, internal current sources, for output voltage and/or output current control, supply 1ma current through external programming resistors connected between j1-9 & 22 and j1-10 & 23. The voltage acr...

Page 77

73 83507013 rev g 6.6 remote monitoring of output voltage and current the j1 connector, located on the rear panel provides analog signals for monitoring the output voltage and output current. Selection of the voltage range between 0-5v or 0-10v is made by setup switch sw1-4. The monitoring signals r...

Page 78

74 83507013 rev g 7 rs232 & rs485 remote control 7.1 introduction this chapter describes the operation of the genesys ™ 750w power supplies via the serial communication port. Details of the initial set-up, operation via rs232 or rs485, the command set and the communication protocol are described in ...

Page 79

75 83507013 rev g 7.2.5 setting the unit into remote or local mode 1. The unit will be put into remote mode only via serial communication command. Commands that will put the unit into remote mode are: rst pv n out n pc n rmt n (for n values see tables 7-3 and 7-4 and 7-5) 2. There are two remote mod...

Page 80

76 83507013 rev g 7.3 rear panel rs232/rs485 connector the rs232/rs485 interface is accessible through the rear panel rs232/rs485 in and rs485 out connectors. The connectors are 8 contact rj-45. The in and out connectors are used to connect power supplies in a rs232 or rs485 chain to a controller. R...

Page 81

77 83507013 rev g 2 3 7 1 8 7 1 pin no. Pin no. Name name shield tx rx sg shield rx tx sg db-25 connector 8 pin connector remarks twisted pair 8 1 13 1 2 3 5 7 8 1 pin no. Housing housing pin no. Name name shield rx tx sg shield tx rx sg db-9 connector 8 pin connector remarks twisted pair 8 1 5 1 9 ...

Page 82

78 83507013 rev g 7.4.2 multi power supply connection to rs232 or rs485 bus up to 31 units can be connected (daisy chained) to the rs232 or rs485 bus. The first unit connects to the controller via rs232 or rs485 and the other units are connected via the rs485 bus. A) first unit connection: refer to ...

Page 83

79 83507013 rev g 7.5 communication interface protocol note the address ( “adr n”) command must return an “ok” response before any other commands are accepted by a power supply. 7.5.1 data format serial data format is 8 bit, one start bit and one stop bit. No parity bit. 7.5.2 addressing the address...

Page 84

80 83507013 rev g 7.6 error messages the power supply will return error messages for illegal commands and illegal programming parameters. Refer to table 7-1 for programming error messages and table 7-2 for command error messages. Table 7-1: programming error messages error code description e01 retur...

Page 85

81 83507013 rev g 7.7 command set description 7.7.1 general guide 1. Any command or argument may be in capital letters or small letters. 2. In commands with an argument, a space must be between the command and the argument. 3. For any command that sets a numeric value, the value may be up to 12 char...

Page 86

82 83507013 rev g 7.7.5 output control commands # command description 1 pv n sets the output voltage value in volts. The range of voltage value is described in table 7-3. The maximum number of characters is 12. See the following examples for pv n format: pv 12, pv 012, pv 12.0, pv 012.00, etc… 2 pv?...

Page 87

83 83507013 rev g # comment description 23 uvl? Returns the setting “n” where “n” is the exact string in the user’s “uvl n”. When in local mode, returns the last setting from the front panel in a 4 digit string. 24 ast n sets the auto-restart mode to on or off. Ast 1 (or ast on): auto restart on. As...

Page 88

84 83507013 rev g table 7-3: voltage programming range table 7-4: current programming range model rated output voltage (v) minimum (v) maximum (v) model minimum (a) maximum (a) 8 0.000 8.000 gen6-100 000.00 100.00 10 00.000 10.000 gen8-90 000.00 90.00 15 00.000 15.000 gen12.5-60 000.00 60.000 20 00....

Page 89

85 83507013 rev g 7.9.1 fast test for connection this is an addressed query that is good for scanning to see what supplies are “on line”. If no response is returned within 10 msec, your control program has determined that no power supply is connected at that address. Query format: send two bytes of ...

Page 90

86 83507013 rev g 7.9.3 read power-on time this query allows you to read how many minutes the power supply has been running since it was built. The accuracy, in minutes, is not guaranteed for time critical applications. Query format: send two bytes of unreadable characters. First: byte 1 = 1010 0110...

Page 91

87 83507013 rev g srq messages response messages command error (”cnn”) execution error (”enn”) query response (”message”) command response (”ok”) cv cc nflt flt ast fde 0 lcl cv cc nflt flt 0 0 0 lcl 0 0 0 status registers condition enable event constant voltage constant current no fault fault auto ...

Page 92

88 83507013 rev g 7.11.3 conditional registers (continued) table 7-8: fault condition register (flt?) bit fault name fault symbol bit set condition bit reset condition 0 (lsb) spare bit spare fixed to zero fixed to zero 1 ac fail ac ac fail has occurred. The ac input returns to normal. 2 over temper...

Page 93

89 83507013 rev g 7.11.4 service request: enable and event registers the conditional registers are continuously monitored. When a change is detected in a register bit which is enabled, the power supply will generate an srq message. The srq message is: “!Nn” terminated by cr, where the nn is the powe...

Page 94

90 83507013 rev g 3. Status enable register (sena nn, sena?) the status enable register is set by the user to enable srqs for changes in power supply status. Table 7-12: status enable register bit status name status symbol bit set condition bit reset condition 0 (lsb) constant voltage cv user comman...

Page 95

91 83507013 rev g 7.12 serial communication test set-up use the following instructions as basic set-up to test the serial communication operation. 1. Equipment: pc with windows hyper terminal, software installed, genesys tm power supply, rs232 cable. 2. Pc set-up: 2.1 open hyper terminal……………………. Ne...

Page 96

92 83507013 rev g 8 isolated analog programming option 8.1 introduction isolated analog programming is an internal option card for analog programming of the genesys ™ power supply series. The option is factory installed and cannot be obtained with a gpib (ieee-488) interface. Output voltage and outp...

Page 97

93 83507013 rev g 8.3 isolated programming & monitoring connector refer to table 8-1 for detailed description of the rear panel isolated programming & monitoring connector. To provide the lowest noise performance, it is recommended to use shielded-twisted pair wiring. Refer to fig.8-1 for descriptio...

Page 98

94 83507013 rev g 8.4 setup and operating instructions caution to prevent damage to the unit, do not program the output voltage and current to higher than the power supply rating. 8.4.1 setting up the power supply for 0-5v/0-10v isolated programming and monitoring perform the following procedure to ...

Page 99

95 83507013 rev g 9 maintenance 9.1 introduction this chapter provides information about maintenance, calibration and troubleshooting. 9.2 units under warranty units requiring repair during the warranty period should be returned to a tdk-lambda americas inc. Authorized service facility. Refer to the...

Page 100

96 83507013 rev g table 9-1: troubleshooting guide symptom check action ref no output. All displays and indicators are blank. Is the ac power cord defective? Check continuity, replace if necessary. 3.7 is the ac input voltage within range? Check ac input voltage. Connect to appropriate voltage sourc...

Page 101

97 83507013 rev g 9.7 fuse rating there are no user replaceable fuses in the power supply. Internal fuses are sized for fault protection and if a fuse was opened, it would indicate that service is required. Fuse replacement should be made by qualified technical personnel. Refer to table 9-2 for a li...