- DL manuals

- TDK-Lambda

- Power Supply

- Genesys GEN10-240

- User manual

TDK-Lambda Genesys GEN10-240 User manual

Summary of Genesys GEN10-240

Page 1

Programmable dc power supplies 2.4kw in 1u built in rs-232 & rs-485 interface advanced parallel operation optional interface: compliant lan ieee488.2 scpi (gpib) multi-drop isolated analog programming user manual.

Page 2: Genesys

Genesys tm gen 2.4kw series power supplies user manual this manual covers models: gen8-300 gen10-240 gen16-150 gen20-120 gen30-80 gen40-60 gen60-40 gen80-30 gen100-24 gen150-16 gen300-8 gen600-4 ia669-04-01 rev.D genesys tm gen 2.4kw series power supplies user manual this manual covers models: gen8-...

Page 3: Ces

This information sheet was prepared based on people's republic of china "management methods for controlling pollution caused by electronic information products regulation"and "sj/t 11364—2006 marking for control of pollution caused by electronic information products ". As people's republic of china ...

Page 4

Tdk-lambda ltd., industrial zone p.O.B 500 karmiel, israel declaration of conformity gen2400w series we, tdk-lambda ltd., located at haharoshet st. 56 industrial zone p.O.B. 500 karmiel, israel declare under our sole responsibility that the gen2400w series as detailed on the products covered sheet c...

Page 5

Warranty .......................................................................................................................................... Regulatory notices .................................................................................................................... Safety instructi...

Page 6

Warranty .......................................................................................................................................... Regulatory notices .................................................................................................................... Safety instructi...

Page 7

3.9 connecting the load .......................................................................................................... 3.9.1 load wiring .......................................................................................................................... 3.9.2 current carrying capac...

Page 8

Chapter 6 remote analog programming chapter 7 rs232 & rs485 remote control chapter 8 isolated analog programming option chapter 9 maintenance ................................................................. 6.1 introduction ..............................................................................

Page 9

This page intentionaly left blank.

Page 10

Warranty this tdk-lambda ltd. Product is warranted against defects in materials and workmanship for a period of five years from date of shipment. During the warranty period, tdk-lambda ltd. Will, at it's option, either repair or replace products which prove to be defective. Limitation of warranty th...

Page 11: Regulatory Notices

Regulatory notices 2 fcc notice this device complies with part 15 of the fcc rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired ope...

Page 12: Safety Instructions

Safety instructions caution installation category grounding fuses input ratings live circuits parts substitutions & modifications the following safety precaution must be observed during all phases of operation, service and repair of this equipment. Failure to comply with the safety precautions or wa...

Page 13: Safety Instructions.

Safety instructions. Environmental conditions the genesys power supply series safety approval applies to the following operating conditions: *indoor use *ambient temperature: 0 c to 50 c *maximum relative humidity: 90% (no condensation) *altitude: up to 3000m *pollution degree 2 tm o o 4 ! Instructi...

Page 14

5.

Page 15

6.

Page 16: Chapter 1

Chapter 1 general information 1.1 user manual content 1.2 introduction this user’s manual contains the operating instructions, installation instructions and specifications of the genesys 2400w power supply series. The instructions refer to the standard power supplies, including the built-in rs232/48...

Page 17

* parallel operation (master/slave) with active current sharing. * remote sensing to compensate for voltage drop of power leads. * cooling fan speed control for low noise and extended fan life. * zero stacking- no ventillation holes at the top and bottom surface of the power supply. * optional gpib ...

Page 18

* parallel operation (master/slave) with active current sharing. * remote sensing to compensate for voltage drop of power leads. * cooling fan speed control for low noise and extended fan life. * zero stacking- no ventillation holes at the top and bottom surface of the power supply. * optional gpib ...

Page 19: Chapter 2

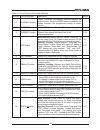

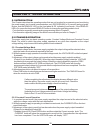

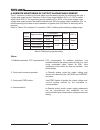

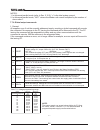

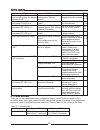

Chapter 2 specifications 1.Vout voltage programming 2.Iout voltage programming (*13) 3.Vout resistor programming 4.Iout resistor programming (*13 5.On/off control 6.Output current monitor (*13) 7.Output voltage monitor 8.Power supply ok signal 9.Parallel operation 10.Series operation 11.Cv/cc indica...

Page 20

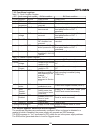

2.6.1 programming and readback (rs232/485, optional lan/ieee interface) 2.7 protective functions 1.Foldback protection 2.Over-voltage protection (ovp) 3.Over-voltage trip point 4.Output under voltage limit (uvl) 5.Over temperature protection v 8 16 20 10 30 40 60 80 100 150 300 600 --- --- --- --- v...

Page 21

12 *1: minimum voltage is guaranteed to maximum 0.2% of the rated output voltage. *2: minimum current is guaranteed to maximum 0.4% of the rated output current. *3: for cases where conformance to various safety standards (ul, iec etc.) is required, to be described as 190~240vac (50/60hz). *4: a ith ...

Page 22

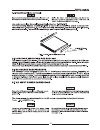

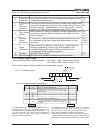

13 2.13 genesys 2400w power supplies outline drawings tm 482.8+/-1.0mm 43.6+/-0.3mm a a a 603.0+/-1.0mm 57.8+/-0.5 92.0+/-0.5 92.0+/-0.5 21.0 440.8+/-1.0mm 422.8+/-1.0mm note 1 note 1 note 4 note 2 (150v~600v) note 2 note 5 notes: 1.Mating plug supplied with power supply. 2.Bus-bars for 8v to 100v m...

Page 23: Chapter 3

Chapter 3 installation 3.1 general 3.2 preparation for use 3.3 initial inspection 3.4 rack mounting this chapter contains instructions for initial inspection, preparation for use and repackaging for shipment. Connection to pc, setting the communication port and linking genesys power supplies are des...

Page 24

15.

Page 25

16 3.7.1 ac input connector 3.7.2 ac input cord 3.7.3 ac input wire connection 1.Strip the outside insulation of the ac cable approx. 10cm. Trim the wires so that the ground wire is 10mm longer than the other wires. Strip 10mm at the end of each of the wires. 2.Unscrew the base of the strain relief ...

Page 26

Fig.3-3: ac input cover and strain relief, 2400w models 4.Route the ac wires to the input connector terminals as required. To connect the wires, loosen the terminal screw, insert the stripped wire into the terminal and tighten the screw securely (4.4-5.3 lb-inch.). 5.Route the wires inside the cover...

Page 27

2. Connect the unit to an ac source as described in section 3.7. 3. Connect a dvm with appropriate cables for the rated voltage to the output terminals. 4. Turn the front panel ac power switch to on. 1. Turn on the output by pressing out pushbutton so the out led illuminates. 2. Observe the power su...

Page 28

2. Connect the unit to an ac source as described in section 3.7. 3. Connect a dvm with appropriate cables for the rated voltage to the output terminals. 4. Turn the front panel ac power switch to on. 1. Turn on the output by pressing out pushbutton so the out led illuminates. 2. Observe the power su...

Page 29

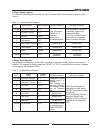

When local sensing, a short from +ls or +s to -v or -s or - ls, will cause damage to the power supply. Reversing the sense wires might cause damage to the power supply in local and remote sensing. (do not connect -s to +v or +s to -v.) 20 table 3-2: maximum wire length for 1v drop on lead (in feet) ...

Page 30

3.9.4 noise and impedance effects 3.9.5 inductive loads 3.9.6 making the load connections to minimize the noise pickup or radiation, the load wires and remote sense wires should be twisted- pairs to the shortest possible length. Shielding of sense leads may be necessary in high noise environments. W...

Page 31

22.

Page 32

23 the 150v to 600v models have a four terminal wire clamp output connector: phoenix contact p/n: front4-h-7.62/4. The two left terminals are the positive outputs and the other two right terminals are the negative outputs. Max. 30a per terminal. The connector requirements are as follows: 1. Wires: a...

Page 33

24 3.9.7 connecting single loads, local sensing (default). Fig.3-11 shows recommended load and sensing connections for a single load. The local sense lines shown are default connections at the rear panel j2 sense connector. Local sensing is suitable for applications where load regulation is less cri...

Page 34

25 - - rem.Sense local sense local sense rem.Sense + + load lines, twisted pair, shortest length possible. +v -v load#1 + - load#3 + - load#2 + - power supply fig.3-13: multiple loads connection, radial distribution, local sense - - rem.Sense local sense local sense rem.Sense + + distribution termin...

Page 35

26 output terminal grounding there is a potential shock hazard at the rs232/485 and the ieee ports when using power supplies with rated or combined voltage greater than 400v with the positive output of the power supplies is grounded. Do not connect the positive output to ground when using the rs232/...

Page 36

27 there is a potential shock hazard at the sense point when using power supply with a rated output voltage greater than 40v. Ensure that the connections at the load end are shielded to prevent accidental contact with hazardous voltages. When using shielded sense wires, ground the shield in one plac...

Page 37: Chapter 4

Chapter 4 front and rear panel controls and connectors 4.1 introduction 4.2 front panel controls and indicators the genesys power supply series has a full set of controls, indicators and connectors that allow the user to easily setup and operate the unit. Before starting to operate the unit, please ...

Page 38

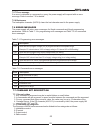

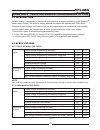

4 number control/indicator description section 4 digit, 7-segment led display. Normally displays the output current. When the prev button is pressed, the display indicates the programmed setting of output current. Current display 6 current control high resolution rotary encoder for adjusting the out...

Page 39

30 16 number control/indicator description section fine button 18 alarm indicator table 4-1: front panel controls and indicators 17 fine indicator ac power switch 19 voltage and current fine/coarse adjustment control. Operates as a toggle switch. In fine mode, the voltage and current encoders operat...

Page 40

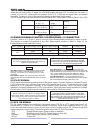

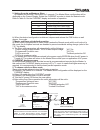

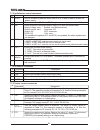

1 2 3 4 5 6 7 sec. 5.7, 5.10 sec. 6.2, 5.9, 6.6 if_com +5v +5v+/-5% max current 0.2a +15v+/-5% max current 0.2a isolated interface common return for the so, ena control, ps_ok signal and for the rs232/485 optional ieee interface. Nc nc +15 nc com control common. Return for vmon, imon, cv/cc, loc/rem...

Page 41

32 4.4.2 resetting the sw1 switch before making any changes to the sw1 switch setting, disable the power supply output by pressing the front panel out button. Ensure that the output voltage falls to zero and out led is off, then use any small flat-bladed screwdriver to change the sw1 switch setting....

Page 42

33 4.5 rear panel j1 programming and monitoring connector the j1 programming and monitoring connector is a db25 subminiature connector located on the power supply rear panel. Refer to table 4-4 for description of the connector functions. The power supply default configuration is local operation whic...

Page 43

34 fig.4-4: j1 connector terminals and functions 14 15 16 17 18 19 20 21 22 23 24 25 1 2 3 4 5 6 7 8 10 11 12 13 9 same ground as p/s negative output isolated from ps outputs, same ground as rs232/485 imon ipgm_rtn vpgm_rtn loc/rem signal if_com if_com ena_in vmon com cv/cc ipgm vpgm loc/ rem p ena_...

Page 44: Chapter 5

35 chapter 5 local operation 5.1 introduction 5.2 standard operation this chapter describes the operating modes that are not involved in programming and monitoring the power supply via its serial communication port (rs232/rs485) or by remote analog signals. Ensure that the rem/loc led on the front p...

Page 45

36 - enabled output, power supply in constant voltage mode: press the prev button and then rotate the current encoder knob. The current meter will show the programmed current limit for 5 seconds after the adjustment has been completed, and then will return to show the actual load current. - enabled ...

Page 46

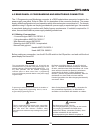

5.4 under voltage limit (uvl) 5.5 foldback protection 5.6 output on/off control 5.7 output shut-off (so) control via rear panel j1 connector the uvl prevents adjustment of the output voltage below a certain limit.The combination of uvl and ovp functions, allow the user to create a protection window ...

Page 47

When the unit is shut-off by j1 signal, the voltage display will show “so” to indicate the unit state. J1 contact 15 is the so signal input and contacts 2 and 3, if_com, are the signal return (connected internally). Contacts 2,3 and 15 are optically isolated from the power supply output. The so cont...

Page 48

39 5.11 safe start and auto-restart modes 5.12 over temperature protection (otp) 5.13 last setting memor 5.14 series operation when turning on the power supply ac on/off, it can start to its last setting of output voltage and current limit with the output enabled (auto-restart) or start with the out...

Page 49

40 do not connect power supplies from different manufacturers in series or in parallel. When power supplies are connected in series, and the load or one of the output terminals is grounded, no point may be at a greater potential of 60vdc from ground for models up to 60vdc rated output and 600vdc fro...

Page 50

41 fig.5-3: series connection for positive/negative output voltages 3. Programming by external resistor: 1. Programming by external voltage: programming by external resistor is possible . Refer to section 6-5 for details. The analog programming circuits of this power supply are referenced to the neg...

Page 51

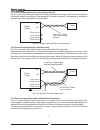

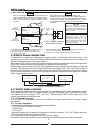

42 5.15 parallel operation up to four units of the same voltage and current rating can be connected in parallel to provide up to four times the output current capability. One of the units operates as a master and the remaining units are slaves. The slave units are analog programmed by the master uni...

Page 52

43 make sure that the connection between -vo terminals is reliable to avoid disconnection during operation. Disconnection may cause damage to the power supply. + v - v + v - v +s +ls -s -ls +s +ls -s -ls master power supply slave#1 power supply j1-25 j1-12 com j1-10 j1-23 p ipgm ipgm_rtn to j1-23 sl...

Page 53

44 fig.5-5: parallel operation wiith remote sensing with local sensing it is important to minimize the wire length and resistance. Also the positive and negative wire resistance should be close as possible to each other to achieve current balance between power supplies. 5.16 daisy-chain connection i...

Page 54: Chapter 6

45 chapter 6 remote analog programming 6.1 introduction the rear panel connector j1 allows the user to program the power supply output voltage and current limit with an analog device. J1 also provides monitoring signals for output voltage and output current. The programming range and monitoring sign...

Page 55

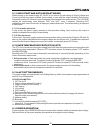

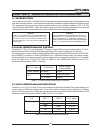

46 6.4 remote voltage programming of output voltage and current limit sw1-3 setting up down output voltage programming vpgm (j1-9) 0-10v 0-5v current limit programming ipgm (j1-10) 0-10v 0-5v table 6-3: sw1-3 setting and programming range 1 14 13 25 10 12 8 9 23 22 + - + - current limit programming ...

Page 56

6.5 resistive programming of output voltage and current limit for resistive programming, internal current sources, for output voltage and/or output current control, supply 1ma current through external programming resistors connected between j1-9 & 22 and j1-10 & 23. The voltage across the programmin...

Page 57

48 6.6 remote monitoring of output voltage and current the j1 connector, located on the rear panel provides analog signals for monitoring the output voltage and output current. Selection of the voltage range between 0-5v or 0-10v is made by setup switch sw1-4. The monitoring signals represent 0 to 1...

Page 58

Chapter 7 rs232 & rs485 remote control 7.1 introduction 7.2 configuration this chapter describes the operation of the genesys 2400w power supplies via the serial communication port. Details of the initial set-up, operation via rs232 or rs485, the command set and the communication protocol are descri...

Page 59

2. There are two remote modes: 1. Remote: 2. Local lockout: in this mode, return to local can be made by the front panel rem/loc or via serial port command rmt 0. Set the unit into remote mode via serial port rmt 1 command. In this mode the unit can be returned to remote mode via the serial port rmt...

Page 60

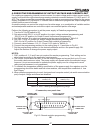

51 7.4 connecting power supplies to rs232 or rs485 bus 7.4.1 single power supply 1. Select the desired interface rs232 or rs485 using rear panel setup switch sw1-6 (section 4-4). - rs232: down position - rs485: up position 2. Connect rear panel in connector to the controller rs232 or rs485 port usin...

Page 61

52 7.4.2 multi power supply connection to rs232 or rs485 bus daisy-chain up to 31 units can be connected to rs232 or rs485 bus. The first unit connects to the controller via rs232 or rs485 and the other units are connected with rs485 bus, the user must set all slave supplies to a unique address. No t...

Page 62

53 7.5.7 error message 7.5.8 backspace if an error is detected in a command or query, the power supply will respond with an error message. Refer to section 7.6 for details. The backspace character (ascii 8) clears the last character sent to the power supply. The power supply will return error messag...

Page 63

7.7.3 initialization control commands adr is followed by address which can be 0 to 30 and is used to access the power supply . Clear status. Sets feve and seve registers to zero (refer to section 7-8). Reset command. Brings the power supply to a safe and known state: output voltage: zero, remote: no...

Page 64

7.7.5 output control commands-cont 55 # command description sets the foldback protection to on or off. Fld 1 (or fold on) - arms the foldback protection. Fld 0 (or fold off)- cancels the foldback protection. When the foldback protection has been activated, out 1 command will release the protection a...

Page 65

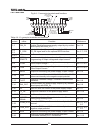

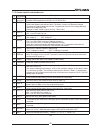

56 table 7-3: voltage programming range model rated output voltage (v) minimum (v) maximum (v) 8 10 16 20 30 40 60 80 100 150 300 600 0.000 00.000 00.000 00.000 00.000 00.000 00.000 00.00 000.00 000.00 000.00 000.00 8.000 10.000 16.000 20.000 30.000 40.000 60.000 80.00 100.00 150.00 300.00 600.00 no...

Page 66

57 note: the power supply can accept values higher by 5% than the table values, however it is not recommended to program the power supply over the rated values. 7.7.7 status control commands refer to section 7-8 for definition of the registers. Command # description 1 stt? Reads the complete power s...

Page 67

58 or or or srq messages address changed response messages command error (”cnn”) execution error (”enn”) query response (”message”) command response (”ok”) cv cc nflt flt ast fde 0 lcl cv cc nflt flt 0 0 0 lcl 0 0 0 or status registers condition enable event constant voltage constant current no faul...

Page 68

59 7.8.2 conditional registers 7.8.3 service request: enable and event registers the conditional registers are continuously monitored. When a change is detected in a register bit which is enabled, the power supply will generate an srq message. The srq message is: "!Nn" terminated by cr, where the nn...

Page 69

60 refer to tables 7-9 to 7-12 for details of the enable and event registers. The fault enable register is set to the enable faults srqs. 1.Fault enable register 2.Fault event register the fault event will set a bit if a condition occurs and it is enabled. The register is cleared when feve?, cls or ...

Page 70

61 table 7-11: status enable register bit status symbol 0 (lsb) 1 2 3 4 5 6 7(msb) constant voltage constant current no fault fault active auto-restart enabled fold enabled spare local mode cv cc nflt flt ast fde spare lcl bit set condition bit reset condition user command: "sena nn" is received, wh...

Page 71

7.9 serial communication test set-up use the following instructions as basic set-up to test the serial communication operation. 1.Equipment: 2.Pc set-up: 3.Power supply set-up: 4.Communication test: pc with windows hyper terminal, private edition, software installed, genesys power supply, rs232 cabl...

Page 72: Chapter 8

63 chapter 8 isolated analog programming option 8.1 introduction isolated analog programming is an internal option card for analog programming of the genesys power supply series. The option is factory installed and cannot be obtained with gpib (ieee) interface. Output voltage and current limit can b...

Page 73

64 8.3 isolated programming & monitoring connector refer to table 8-1 for detailed description of the rear panel isolated programming & monitoring connector. To provide the lowest noise performance, it is recommended to use shielded-twisted pair wiring. Refer to fig.8-1 for description of the connec...

Page 74

65 sw1 position 3 and 4 must be in their up position for operation with 4-20ma isolated programming and monitoring. To prevent damage to the unit, do not program the output voltage and current to higher then the power supply rating. Perform the following procedure to configure the power supply: 1. T...

Page 75

8.5 parallel operation with isolated analog option power supplies, should be connected in a daisy-chain configuration 8.5.1 setting up the master unit setting up the power supply for 0-5/0-10v isolated programming and monitoring. Perform the following procedure to configure the power supply: 1. Turn...

Page 76: Chapter 9

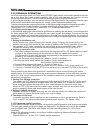

66 9.1 introduction 9.2 units under warranty 9.3 periodic maintenance 9.4 adjustments and calibration 9.5 parts replacement and repairs this chapter provides information about maintenance, calibration and troubleshooting. Units requiring repair during the warranty period should be returned to a lamb...

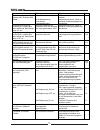

Page 77

67 check if the positive or negative load wire is loose. Output is present momentarily but shuts off quickly. The display indicates "oup". Symptom check action ref. 3.9.6 3.9.8 is the power supply configured to remote sense? Output voltage will not adjust. Front panel cc led is on. Is the unit in co...

Page 78

Kapitel 9 wartung & service 9.1 einleitung dieses kapitel liefert informationen über wartung und fehlersuche. 9.2 reparaturen während der garantie sollte ein gerät innerhalb der garantiezeit ausfallen, so dürfen reparaturen nur durch lambda oder autorisierte servicestellen durchgeführt werden. Die a...

Page 79

Tabelle 9-1: fehlersuche symptom prüfung tätigkeit ref. Keine ausgangsspannung. Displays und anzeigen sind dunkel. Ist das netzkabel defekt? Ist die netzspannung innerhalb des eingangsbereiches? Falls erforderlich, netzkabel ersetzen. Netzspannung prüfen, gerät an passende versorgungsspannung anschl...

Page 80

9.7 sicherungswerte im gerät befinden sich keine sicherungen die durch den anwender ersetzt werden können. Sicherungen sind als schutz eingebaut, falls im gerät fehler auftreten sollten. Sollte eine sicherung auslösen, so muss das gerät zur reparatur gegeben werden. Sicherungen dürfen ausschließlich...

Page 81

User manual index a b c d e f g h ac cables ac fail accessories acknowledge address adjustment auto-restart back space baud rate bipolar voltage calibration configuration checksum communication constant current constant voltage cooling cv indicator cc indicator daisy-chain display enable error messag...

Page 82: Innovating Reliable Power

Japan tdk-lambda corporation international sales divison nittetsu bldg. 6f, 1-13-1 nihonbashi, chuo-ku, tokyo 103-0027, japan tel: +81-3-5201-7175 fax: +81-3-5201-7287 www.Tdk-lambda.Com china shanghai branch of wuxi tdk-lambda electronic co. Ltd. 28f, xingyuan technology building no.418, guiping ro...