TDK-Lambda PFE300SA Series Instruction Manual - Tdk-Lambda

10

TDK-Lambda

PFE300SA

・

500SA Series

INSTRUCTION MANUAL

6-4. Over Voltage Protection (OVP)

This module is equipped with OVP function. OVP function operates within 125%-145% of nominal output

voltage. When OVP triggers, the output will be shut down.

When the OVP function activates, first cut off input line and verify that boost voltage has dropped down to 7V

or less. Then, recover output by recycling input line.

OVP value is fixed and cannot be set externally.

Pay attention not to apply higher voltage externally to the

output terminal to avoid power supply damage.

6-5. Over Current Protection (OCP)

This module is equipped with OCP function. OCP function operates when the output current exceeds 105% of

maximum DC output current of specification.

Output will automatically recover when short circuit or overload condition is removed. OCP value is fixed and

cannot be adjusted externally.

Note that continuous short circuit or overload condition might result in power supply damage.

6-6. Over Temperature Protection (OTP)

This module is equipped with OTP function. This function will activate and shutdown the output when ambient

temperature or internal temperature abnormally rises. OTP activates at following base-plate temperature.

PFE300SA-12,28,48 : 105℃ - 130℃

PFE500SA-12 : 90℃ - 115℃

PFE500SA-28,48 : 105℃ - 130℃

When OTP function operates, output can be recovered by cooling down the baseplate sufficiently and letting

the boost voltage drop down to 7V or less before recycling the input line.

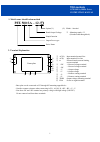

6-7. Remote Sensing (+S, -S Terminals)

This module has remote sensing terminals to compensate for voltage line drop from the output terminals to the

output load. When remote sensing is not required, (local sensing) short +S to +V and -S to -V terminals

respectively.

Note that line drop (voltage drop due to wiring ) compensation voltage range must be such that the output

voltage is within the output voltage adjustment range and that the voltage between -V and -S must be within 2V.

Consider power loss due to line drop and use power supply within the maximum allowable output power.

Before using, do adequate prior evaluation such that module does not receive any effect of noise by using a

parallel pattern, etc. for remote sensing line

Fig.6-2 Remote Sensing is used Fig.6-3 Remote Sensing is not used

(Local Sensing)