TDK-Lambda ZERO-UP 200W User manual

NORTH AMERICA

TDK-Lambda Americas, Inc.

3055 Del Sol Boulevard

San Diego, CA 92154

Tel: +1-619-575-4400 Fax: +1-619-429-1011

www.us.tdk-lambda.com/lp

TDK-Lambda Americas Inc

405 Essex Rd. Neptune, NJ 07753

Tel: +1-732-922-9300 Fax: +1-732-922-1441

E-mail: sales@us.tdk-lambda.com

www.us.tdk-lambda.com/hp

UK

TDK-Lambda UK Ltd.

Kingsley Avenue Ilfracombe, Devon

EX 34 8ES United Kingdom

Tel: +44-1271-856666 Fax: +44-1271-864894

E-mail: powersolutions@emea.tdk-lambda.com

www.uk.tdk-lambda.com

FRANCE

TDK-Lambda France SAS

ZAC des Delaches

BP 1077 - Gometz le Chatel

91940 LES ULIS

Tel: +33 1 60 12 71 65

Fax: +33 1 60 12 71 66

E-mail: france@fr.tdk-lambda.com

www.fr.tdk-lambda.com

GERMANY

TDK-Lambda Germany GmbH

Karl-Bold-Str.40,

D-77855 Achern, Germany

Tel: +49-7841-666-0 Fax: +49-7841-500-0

E-mail: info.germany@de.tdk-lambda.com

www.de.tdk-lambda.com

AUSTRIA

TDK-Lambda Austria Sales Office

Aredstrasse 22,

A - 2544 Leobersdorf, Austria

Tel: +43-2256-65584 Fax: +43-2256-64512

E-mail: info.germany@de.tdk-lambda.com

www.de.tdk-lambda.com

ITALY

TDK-Lambda Italy

Via dei Lavoratori 128/130

IT20092 Cinisello Balsamo, Milano, Italy

Tel: +39-02-6129-3863 Fax: +39-02-6129-0900

E-mail: info.italia@lambda-europe.com

www.it.tdk-lambda.com

ISRAEL

Nemic Lambda Ltd.

Sales Office: Kibbutz Givat Hashlosha Tel-Aviv 48800, Israel

Tel: +972-3-9024-333 Fax: +972-3-9024-777

Plant: POB 500 Karmiel Industrial Zone 21651, Israel

Tel: +972-4-9887-491 Fax: +972- 4-9583-347

www.nemic.co.il E-mail: info@nemic.co.il

JAPAN

TDK-Lambda Corporation

International Sales Divison

Nittetsu Bldg. 6F, 1-13-1 Nihonbashi, Chuo-ku, Tokyo 103-0027, Japan

Tel: +81-3-5201-7175

Fax: +81-3-5201-7287

www.tdk-lambda.com

CHINA

Shanghai Branch of Wuxi TDK-Lambda Electronic Co. Ltd.

28F, Xingyuan Technology Building No.418, Guiping Road,

Shanghai, China 200233

Tel: +86-21-6485-0777 Fax: +86-21-6485-0666

www. cn.tdk-lambda.com

Beijing Branch of Wuxi TDK-Lambda Electronic Co. Ltd.

Room 12B11-12B12, Unit 7 DACHENG SQUARE, No.28

Xuanwumenxi Street, Xuanwu District Beijing, 100053, CHINA

Tel: +86-10-6310-4872 Fax: +86-10-6310-4874

www. cn.tdk-lambda.com

Shenzhen Branch of Wuxi TDK-Lambda Electronics Co.Ltd.

Room 4302, Excellence Times Square Building,

4068 Yi Tian Road, Futian District,

Shenzhen, China 518048

Tel: +86 -755-83588261 Fax: +86 -755-83588260

www. cn.tdk-lambda.com

KOREA

TDK-Lambda Corporation Seoul Office

6F Songok Bldg. 4-1 Soonae-Dong

Pundang-Gu, Songnam-Shi Kyonggi-Do, 463-020 Korea

Tel: +82-31-717-7051 +82-31-726-9137

www.tdk-lambda.com

SINGAPORE

TDK-Lambda Singapore Pte. Ltd.

Blk 1008 Toa Payoh North # 07-01/03

Singapore 318996

Tel: +65-6251-7211 Fax: +65-6250-9171

www.tdk-lambda.com.sg

INDIA

TDK-Lambda Bangalore Office

#526, Ground Floor, 10th Main, 7th Cross,

Jeevanbhimanagar, Bangalore 560 075

Karnataka, India

Tel: +91-80-43550 550

Fax: +91-80-43550 501

www.tdk-lambda.com.sg

MALAYSIA

TDK-Lambda (M) Sdn. Bhd.

Suite 4.3, Level 4, Menara Merais, No.1, Jalan 19/3, Section 19/3,

46300 Petaling Jaya, Selangor Darul Ehsan Malaysia

Tel: +60-3-7957-8800 Fax: +60-3-7958-2400

www.tdk-lambda.com

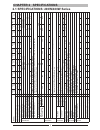

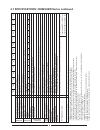

ZERO-UP

200W/400W/800W

Programmable DC Power Supplies

Constant Voltage/Constant Current

Built-in RS-232 & RS-485 Interface

with GPIB option.

ZERO-UP 200W/400W/800W

Programmable DC Power Supplies

IA549-04-01 Rev M AD0610

TDK-Lambda EMEA

www.emea.tdk-lambda.com

USER’S MANUAL