TE TETRA-CRIMP 59824-1 Instruction Sheet

©2014 TE Connectivity family of companies

All Rights Reserved

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product and/or Company names may be trademarks of their respective owners.

1 of 6

Instruction Sheet

TOOLING ASSISTANCE CENTER 1-800-722-1111

PRODUCT INFORMATION 1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com

LOC B

408-2823

TETRA-CRIMP*

Hand Crimping Tool 59824-1

12 JUN 14 Rev Z

PROPER USE GUIDELINES

Cumulative Trauma Disorders can result from the prolonged use of manually powered hand tools. Hand tools are intended for occasional use

and low volume applications. A wide selection of powered application equipment for extended-use, production operations is available.

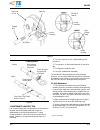

Figure 1

1. INTRODUCTION

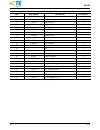

TETRA-CRIMP Hand Crimping Tool 59824-1 (shown

in Figure 1) is designed to crimp the terminals and

splices listed in Figure 2 onto stranded wire sizes 22

through 10 AWG. Refer to Catalog 82042 for product

part numbers. Read these instructions thoroughly

before using the hand tool.

Dimensions in this instruction sheet are in

millimeters [with inches in brackets]. Figures and

illustrations are for reference only and are not

drawn to scale.

Reasons for reissue are provided in Section 8,

REVISION SUMMARY.

2. DESCRIPTION

Each hand tool features two crimping dies, a spring-

loaded locator assembly, and a ratchet handle with a

ratchet pawl. See Figure 1.When closed, the dies form

three crimping chambers each labeled by color on the

BACK side of the tool. The color indicates the wire

size and must match the insulation color of the

terminal or splice: yellow (12-10), blue (16-14), red

(22-16), black heavy duty (16-14 HD), and green

(20-16 HD).

The locator assembly positions the terminal or splice

between the crimping dies. The ratchet handle

assures full crimping. Once engaged, the ratchet will

not release until the tool handles have been FULLY

closed, unless the ratchet pawl is depressed to

manually release the ratchet. This feature, when

depressed, prevents crimping of an improperly

positioned terminal or splice.

The crimping dies bottom before the ratchet

releases. This feature assures maximum electrical

and tensile performance of the crimp. Do NOT

re-adjust the ratchet.

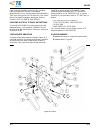

3. CRIMPING PROCEDURE

Select the appropriate wire size and terminal or splice

for the hand tool. The wire size and insulation

diameter must be within the specified range for the

terminal or splice. Strip the wire to the dimension

provided in Figure 2. Do NOT nick or cut the wire

strands. Then, proceed as follows:

1. Open the crimping dies by squeezing the tool

handles together until the ratchet releases.

2. Push the locator assembly away from the upper

crimping die slightly and hold.

a. If crimping a terminal, position the wire

barrel in the appropriate crimping chamber

between the locator assembly and the upper

die. Make sure that the flat side of the terminal

faces up. See Figure 3, Detail A.

b. If crimping a splice, position the wire barrel

in the appropriate crimping chamber. Seat the

splice window indent on the locator assembly.

Refer to Figure 3, Detail B.

3. Holding the wire barrel in place, release the

locator assembly.

4. Hold the tool so that the BACK side is facing you,

and insert the stripped wire into wire barrel until the

wire bottoms. Refer to Figure 3.

Crimping

Chamber Label

Crimping Chamber

(3 Places)

Back Side of Tool

Locator

Assembly

Crimping

Dies

Ratchet

Pawl

Ratchet

Handle

NOTE

i

CAUTION

!

O

R

IG

INAL

INST

RUCTIONS