- DL manuals

- Therma-Tru

- Door

- Fiber-Classic

- Assembly & Installation

Therma-Tru Fiber-Classic Assembly & Installation

PATIODOORSYSTEMS

Therma-Tru

Fiber-Classic

and

Smooth-Star

Sliding Patio

Door System

®

®

®

Double Unit

Assembly & Installation

Read all instructions before starting.

The applicable standards for these products are governed by

the International Residential Code.

Copies of performance ratings and testing are available on our website

www.thermatru.com and our product manual.

Summary of Fiber-Classic

Page 1

Patiodoorsystems therma-tru fiber-classic and smooth-star sliding patio door system ® ® ® double unit assembly & installation read all instructions before starting. The applicable standards for these products are governed by the international residential code. Copies of performance ratings and testi...

Page 2

1 the following packages are needed to complete the installation of your sliding patio door system. Therma-tru ® check all components for correct size and color. Tools and materials needed for assembly and installation: " phillips head i rubber mallet • gloves • safety glasses • partial roll of nsul...

Page 3

2 #10 x 3" flat head screw #8 x 3" pan head screw #10 x 2 pan head screw ½ #10 x 1 pan head screw ½" #8 x 1 s.S. Pan head screw ½" #8 x 1 3/8 flat head screw " #8 x 9/16" s.S. Pan head screw #8 x 1" s.S. Pan head screw screw chart.

Page 4: Frame Assembly

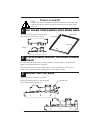

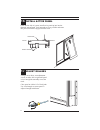

3 note: a large work area is needed to assemble the frame kit. Cover area with cardboard from one or more door panel cartons to protect frame parts and floor. Lay parts on floor and position sill, head, and side jambs with exterior side up. Side jamb sill head jamb side jamb exterior frame assembly ...

Page 5

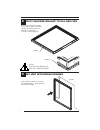

Attach sill to jambs attach head to jambs 4 5 note: be sure that foam pads are in place before assembling frame. Apply sealant to sill and side jambs as shown. Fasten side jambs to sill through pre-drilled holes using (3) #10 x 3 flat head screws. (starting with center screw is recommended.) repeat ...

Page 6

5 place drip cap on top of head jamb. Place head sealing fin on top of drip cap, engaging slot in sealing fin with flange on drip cap. Staple head sealing fin to each of the anchor blocks in head jamb using 1/2" staples, nails or screws (not provided). Drip cap installation apply corner pads to seal...

Page 7: Frame Installation

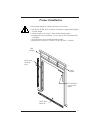

6 check rough opening as follows and correct if necessary: • sub-floor to be flat, level, and clean. Sill must be supported throughout its entire length. • all four corners to be square. Check with a framing square. • framing and walls to be plumb. Use a 6-foot level to check both sides of opening. ...

Page 8

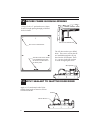

7 apply silicone sealant to sill and fins set unit into rough opening 8 9 note: continuous beads of sealant are required. Run continuous beads of sealant across entire length of sill bottom and around entire perimeter of backside of sealing fin to provide a weather-tight seal. Sealant sealant exteri...

Page 9

8 level sill plumb side jambs 10 11 sill be flat and level. Check and make any necessary adjustments. If necessary, add temporary blocking under projecting exterior edge of sill to serve as support during construction. Must interior jambs must be plumb and straight. Shim as necessary at screw locati...

Page 10

9 12 13 #8 x 3 pan head screws " the sill's center screw needs to be installed three inches off center in the direction of the active panel. Using (12) #8 x 3 pan head screws, fasten frame to rough opening through pre-drilled holes in frame. " apply a 1/4 continuous bead of clear sealant along lengt...

Page 11

10 install stationary panel install anchor blocks 14 15 12 from exterior side of system, install stationary panel by inserting top of panel up into exterior channel in head jamb. Rotate bottom of panel in until inactive door riser leg sets into groove. Slide panel tightly against side jamb wipe off ...

Page 12

Adjust rollers 17 using a screw driver, turn adjustment screws in rollers left or right until panel is level and glides smoothly across the track. Close panel to within 1/4 of lock jamb. Use visual margin to assure panel is adjusted straight with frame. " 11 install active panel 16 head jamb exterio...

Page 13

12 install active interlock 19 active interlock kerfs butt active interlock up against head jamb leaving a slight gap of approximately 1/64” between head jamb and interlock. Starting at top, insert barbs into kerfs in door edge. Working your way down, tap in place with a hammer and wood block or rub...

Page 14

Handle installation 21 refer to instructions supplied with handle set kit. Attach strike plate 22 align slots in strike plate to pre-drilled holes in active side jamb and fasten with (3) #8 x 1 3/8 flat head screws. Close door and adjust strike plate for proper latch engagement. Latch throw can be a...

Page 15

Prep door for foot bolt 23 tear out template on page 16 to locate and drill holes for foot bolt. Locate template on interior side of active panel towards inactive panel side. Align line on template with edge of active door panel and tape into place. Drill 1/8 dia. X 1 deep holes at hole locations sh...

Page 16

15 install foot bolt keeper insert plugs attach jamb cover sliding screen door 26 27 28 29 close the active door completely. Align notch in keeper with foot bolt as shown. Only the two exposed holes will be used for installation. Pre-drill using a 1/8" drill bit to drill two holes through the holes ...

Page 17

16 active panel edge bottom door edge 1/8” dia holes 1” deep bottom corner of active panel towards inactive panel towards inactive panel.

Page 18

17.

Page 19

18 1. Sand the surface to be re-coated with 180 grit sandpaper to abrade and make porous. 2. Remove all sanding dust from the surface. This can be accomplished by using a damp cloth. 3. Optional: wipe the surface with a solvent paint deglosser applied with a clean cloth followed by a final wipe with...

Page 20

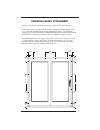

19 jamb extension information the following images are intended to help clarify how a patio door is installed in different frame openings. The jamb extensions are made of standard wood trim materials, readily available from lumber yards and building material retail stores. Attach the jamb extensions...

Page 21

31” 31” 5” 5” 5” 5” 13” 6 1/4” 6 1/4” 1” 1” 20 interior casing attachment interior casing may be attached to the frame in either of the following ways: an air nailer can be used to fasten the interior casing to the frame using 0.050 x 1- wire brad nails through the casing and fiberglass frame. For m...

Page 22

21 sizing information grids width height width height # of lites 5/0 x r.H. Xo or ox 59 1/4 79 1/2 60 80 10 or 15 6/0 x r.H. Xo or ox 71 1/4 79 1/2 72 80 10 or 15 5/0 x f.H. Xo or ox 59 1/4 82 60 82 1/2 10 or 15 6/0 x f.H. Xo or ox 71 1/4 82 72 82 1/2 10 or 15 5/0 x 8/0 xo or ox 59 1/4 95 1/2 60 96 ...

Page 23

22 door handing guide left hand right hand viewed from exterior.

Page 24

1687 woodlands dr. Maumee, oh 43537 1-800-thermatru (843-7628) www.Thermatru.Com patiodoorsystems © 2005 therma-tru corp. Therma-tru doors is an operating company of fortune brands, inc. Part # fcssspdbl 09/12/05.