- DL manuals

- Triple S

- Floor Machine

- Ace 26BA1

- User Manual

Triple S Ace 26BA1 User Manual

Page 1 of 35

Ace 26BA1

Auto Scrubber

The contents of this manual are based on the

latest product information available at the

time of publication. Triple S reserves the

right to make changes or improvements to its

machines without notice.

Carefully inspect all components to ensure

that there is no concealed freight damage. If

such damage is discovered, file a

“CONCEALED DAMAGE REPORT”

immediately with the delivering carrier.

FOR YOUR CONVENIENCE, RECORD

THE FOLLOWING IMPORTANT

INFORMATION:

For new manuals write to:

Triple S

2 Executive Park Drive

Billerica, MA 01862

or download the most recent version of the

manuals from our website:

www.triple-s.com

SERIAL NUMBER

DATE PURCHASED

Summary of Ace 26BA1

Page 1

Page 1 of 35 ace 26ba1 auto scrubber the contents of this manual are based on the latest product information available at the time of publication. Triple s reserves the right to make changes or improvements to its machines without notice. Carefully inspect all components to ensure that there is no c...

Page 2: Safety Instructions

Page 2 of 35 safety instructions 1) you must have training in the operation of the machine before using it. Read the instruction book. If you do not understand any instruction, ask your supervisor. 2) make sure all labels, decals, warnings, cautions and instructions are fastened to the machine. 3) r...

Page 3

Page 3 of 35 symbols used on the automatic scrubber water valve indicator brush drive motor control switch vacuum motor control switch battery charge indicator main machine power key switch squeegee lift control lever solution flow rate adjusting lever.

Page 4: Machine Preparation

Page 4 of 35 machine preparation 1) unpacking the machine a) take off the outer packaging. B) the machine is fastened to the pallet with wooden wedges that block the wheels. Remove tie down straps. C) using a ramp, pull the machine off the pallet. 2) battery installation a) remove the squeegee hose ...

Page 5: Machine Preparation

Page 5 of 35 machine preparation battery installation (cont.) d) place the batteries in the battery compartment. E) connect the battery connector to the machine connector f) replace the recovery tank and reassemble the vacuum cover and squeegee hose. 3) battery charge level indicator the battery ind...

Page 6: Machine Preparation

Page 6 of 35 machine preparation 4) squeegee assembly installation the squeegee is assembled to the machine by lifting the locking latches and sliding the squeegee assembly onto the 2 posts at the rear of the squeegee swing arm. Push on the locking latches down. Lower the squeegee and install vacuum...

Page 7: Machine Preparation

Page 7 of 35 machine preparation 7) recovery tank open the lid and confirm the following connections are secure: a) the vacuum cover is securely attached. Align the notches and rotate the cover clockwise to close. The vacuum hose must also be attached. B) confirm that the squeegee hose is properly c...

Page 8: Machine Operation

Page 8 of 35 machine operation 1) connect machine connector to the battery connector. 2) turn on the main power key switch. Battery charge indicator will illuminate indicating the charge level of the batteries. If the indicator is flashing the batteries need to be charged. 3) turn on the brush motor...

Page 9: Machine Operation

Page 9 of 35 machine operation 10) scrubbing this machine is equipped with brush assist propulsion. Depress the handle switch lever. The scrub brush will begin to rotate and solution will begin to flow. During the first few yards of operation, check that the quantity of the cleaning solution is suff...

Page 10

Page 10 of 35 upon completion of machine use after finishing your work and before any type of maintenance is done, it is necessary to do the following : 1) close the water valve by raising the solution flow control lever. 2) raise the brush base by stepping down locking the brush base lift lever. To...

Page 11: Daily Machine Maintenance

Page 11 of 35 daily machine maintenance cleaning the recovery tank 1) empty the recovery tank by removing the drain plug from the drain hose. Warning: use gloves for protection from contact with dangerous solution. 2) lift the cover of the recovery tank. 3) take off the vacuum cover by rotating it c...

Page 12: Daily Machine Maintenance

Page 12 of 35 daily machine maintenance cleaning the squeegee to obtain the best drying results, keep the squeegee clean. To clean the squeegee it is necessary to: 13) remove the vacuum hose from the squeegee. 14) lift locking latches. Remove the squeegee assembly by pulling rearward. 15) clean the ...

Page 13: Daily Machine Maintenance

Page 13 of 35 daily machine maintenance brush / pad driver removal 24) lift the brush base by depressing the foot level at the rear of the machine. 25) the photo shows the directions to rotate the brushes to unlock them from the auto scrubber. Clean the brushes with clear water..

Page 14: Weekly Machine Maintenance

Page 14 of 35 weekly machine maintenance cleaning the squeegee hose to obtain the best drying results, keep the squeegee hose clean. To clean the squeegee hose it is necessary to: 1) take off the vacuum hose from its vacuum port on the squeegee. 2) remove the other end of the vacuum hose from the re...

Page 15: Water Solenoid Maintenance

Page 15 of 35 water solenoid maintenance in the event that the water solenoid begins to leak when turned off debris must be cleared at the valve seat. To gain access the water solenoid the scrub deck most be disassembled from the lifting arms. Remove the 4 bolts shown in the photo to release the scr...

Page 16: Trouble Shooting Guide

Page 16 of 35 trouble shooting guide 1) insufficient water to the brushes a) make sure the solution flow control valve is open. B) confirm that there is water in the solution tank. C) make sure solution dispensing tubes are not clogged or obstructed. 2) the machine does not clean satisfactorily a) c...

Page 17

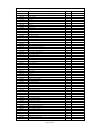

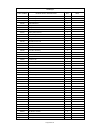

Page 17 of 35 brush deck assembly drawing 1.

Page 18

Page 18 of 35 drawing 1 part number description & specification qty note 840502 adjuster bolt 6 840901 brush 2 optional 840904 carbon brush 4 841102 wheel bushing 2 841110 bushing 2 841111 bushing 4 841308 brush drive belt 2 841309 bearing 6 842312 base cover 1 842706 brush deck 1 843302 fitting bar...

Page 19

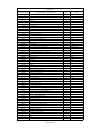

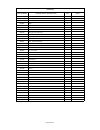

Page 19 of 35 main frame assembly drawing 2.

Page 20

Page 20 of 35 drawing 2 part number description & specification qty note 840308 brake lever arm weldment 1 zinc 840310 brush deck idle arm weldment 1 zinc 840311 brush desk lift arm weldment asm 1 zinc 841108 bushing 2 841112 bushing 2 842003 hose clamp 2 ss 842008 clamp bar 1 842306 pedal cover 1 8...

Page 21

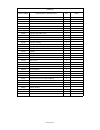

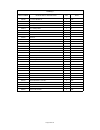

Page 21 of 35 squeegee arm assembly drawing 3.

Page 22

Page 22 of 35 drawing 3 part number description & specification qty note 840304 squeegee link arm weldment 1 840501 squeegee adjuster bolt rod 1 841103 wheel bushing 2 842405 squeegee lift cable 2 842407 squeegee lift cable 1 845001 knob handle 3 845601 squeegee mount base 1 845602 squeegee mount ba...

Page 23

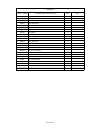

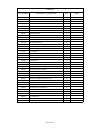

Page 23 of 35 squeegee assembly drawing 4.

Page 24

Page 24 of 35 drawing 4 part number description & specification qty note 840703 squeegee blade front 1 840704 squeegee blade rear 1 841304 squeegee attachment block 2 842012 band clamp-rear 1 842013 band clamp-front 1 843205 squeegee frame weldment 1 843317 filler - squeegee 2 845104 latch asm 2 845...

Page 25

Page 25 of 35 solution tank assembly drawing 5.

Page 26

Page 26 of 35 drawing 5 part number description & specification qty note 841300 rear battery bracket 1 841303 side battery bracket 1 842003 hose clamp 2 842705 sound deadener 1 843308 fitting barbed 1 843309 fitting barbed 1 843310 filter basket 1 843401 battery plastic gasket 1 843402 side battery ...

Page 27

Page 27 of 35 recovery tank assembly drawing 6.

Page 28

Page 28 of 35 drawing 6 part number description & specification qty note 842007 hose clamp 1 842305 solution tank cover 1 842308 recovery tank cover 1 842403 chain 2 842411 chain for lift 1 843405 tank gasket 1 844101 recovery tank vacuum hose 1 844102 squeegee vacuum hose 1 844103 drain hose 1 8451...

Page 29

Page 29 of 35 vacuum assembly drawing 7.

Page 30

Page 30 of 35 drawing 7 part number description & specification qty note 840305 lever arm weldment 1 zinc 840805 bracket-weldment 1 epoxy paint 841104 bushing 2 brass 841305 lever bracket 1 zinc 842014 hose clamp 50mm 1 ss 842702 vacuum motor sound deadener 1 842703 vacuum motor sound deadener 1 842...

Page 31

Page 31 of 35 switch box assembly drawing 8.

Page 32

Page 32 of 35 drawing 8 part number description & specification qty note 841306 bezel - rocker switch 5 842302 cover lower switch box 1 842307 cover - rocker switch 5 843801 grommet 1 844001 fuse holder 1 844703 insulator 1 845101 scrubber lever - switch box 2 845120 switch box label 1 845122 switch...

Page 33

Page 33 of 35 electrical schematic drawing 9.

Page 34

Page 34 of 35 drawing 9 part number description & specification qty note 844506 wire harness 1 844507 wire harness 1 844509 wire harness 1 844513 wire harness 1 844514 wire harness 1 844515 wire harness 1 844516 wire harness 1 844518 wire harness 1 844519 wire harness 1 844520 wire harness 1 844521 ...

Page 35

04/2008 page 35 of 35 pn 845612 warranty policy triple s limited warranty the triple s 26ba1 has been manufactured, tested and inspected in accordance with specific engineering requirements. This machine is warranted to be free from defects in workmanship and materials for periods as follows from th...