- DL manuals

- U-Line

- Refrigerator

- Echelon CLRCO2175B40

- Use And Care Manual

U-Line Echelon CLRCO2175B40 Use And Care Manual

Summary of Echelon CLRCO2175B40

Page 1

Clear ice maker model: clr2160 clear combo ® ice maker/refrigerator model: clrco2175 use and care guide clr2160 clrco2175.

Page 2

Clr2160, clrco2175 introduction congratulations on your purchase of a u-line refrigeration product. A pioneer in the field for more than 40 years, u-line corporation is the world’s number one manufacturer of built-in, under-counter, specialty refrigeration and ice making products. U-line dedicates 1...

Page 3

Clr2160, clrco2175 1 table of contents introduction .................................................................................................. Inside front cover warranty registration .................................................................................. Inside front cover please...

Page 4

2 clr2160, clrco2175 important important please read all instructions completely before attempting to install operate or service your unit. • proper installation procedures must be followed if this unit is being initially installed, or is moved to a new location after being in service. An installati...

Page 5

Clr2160, clrco2175 3 clr2160 clear ice maker • this model produces up to 60 lbs (27.2 kg) of ice per day, will store 30 lbs (13.6 kg). • stainless steel model is deemed suitable for outdoor use by ul. • an electronic control panel with digital display allows you to control all operating functions. C...

Page 6

4 clr2160, clrco2175 prepare plumbing caution plumbing installation must observe all state and local codes. All water and drain connections must be made by a licensed/qualified plumbing contractor. Failure to follow recommendations and instructions may result in damage and/or harm. Water supply conn...

Page 7

Clr2160, clrco2175 5 drain connection important important drain can not be located directly below unit. Unit has a solid base that will not allow unit to drain below itself. The clr2160 or clrco2175 can be installed using a gravity drain, a factory-installed drain pump (u-line p60) or a locally-inst...

Page 8

6 clr2160, clrco2175 factory-installed drain pump if your drain line will run up to a stand pipe, disposal assembly or spigot assembly or does not otherwise meet the requirements for a gravity drain, you may have ordered the clr2160 or clrco2175 with a u-line p60 drain pump. See figures 8, 9 and 10 ...

Page 9

Clr2160, clrco2175 7 • it must have a check valve in the discharge line to prevent waste water return to the pump. • it must have an overflow protection control which will shut off power to the ice maker in the event of a pump failure. • it must have an operating temperature range of 50°f to 110°f (...

Page 10

8 clr2160, clrco2175 final water/drain connection 1. Connect the water supply fitting by screwing the brass garden hose fitting to the watervalve in the rear of the unit. 2. Tighten this fitting with pliers. Note:do not use teflon tape or joint compound on this fitting. The rubber washer provides an...

Page 11

Clr2160, clrco2175 9 caution electrical installation must observe all state and local codes. This unit requires connection to a grounded (three-prong), polarized receptacle that has been placed by a qualified electrician. The unit requires a grounded and polarized 115 vac, 60 hz, 15a power supply (n...

Page 12

10 clr2160, clrco2175 and will correct itself within the first 24 hours of operation. 3. Re-install the evaporator cover. Note: on clrco2175 model, after the first slab of ice is produced, ice production will stop until the refrigerator side reaches the setpoint temperature, then ice production will...

Page 13

Clr2160, clrco2175 11 figure 17 all models incorporate rigid foam insulated cabinets to proved high thermal efficiency and maximum sound reduction for the internal working components. In spite of this technology, the unit may make sounds that are unfamiliar. Normal operating sounds may be more notic...

Page 14

12 clr2160, clrco2175 5. Reconnect power to the unit and allow it to run for one hour (minimum) until any remaining ice has been ejected from the ice maker assembly. 6. Disconnect power to the unit, dry any remaining water from the ice maker assembly, and reconnect any lines removed from the water s...

Page 15

Clr2160, clrco2175 13 warning do not use any type of electrical heating device, ice pick, knife or other sharp instrument to defrost; this could damage the inner lining or refrigeration system and void the warranty. Important important the drain pan was not designed to capture the water created when...

Page 16

14 clr2160, clrco2175 plumber to test the water quality and recommend appropriate treatment. Warning wear rubber gloves and safety goggles and/or face shield when handling ice machine cleaner. Caution use only u-line ice machine cleaner (part no. 41978, available from your dealer or direct from your...

Page 17

Clr2160, clrco2175 15 8. When water begins flowing over the evaporator (approximately 3 minutes), pour 1 packet of clr cleaner into the water trough. The cleaning process will last approximately 45 minutes. Figure 23 9. Following the cleaning process, sanitize the ice bin with a bleach solution. Dil...

Page 18

16 clr2160, clrco2175 figure 25 leveling important important it is extremely important that clear ice models are level. If not level, the ice mold will not fill evenly. Figure 26 a unit that is not level can cause a reduction in ice rate, uneven sized cubes or water spilling into the storage area, w...

Page 19

Clr2160, clrco2175 17 door alignment check and adjustment important important when properly aligned: • the door will not be flush with the top of the cabinet. The top edge of the door will be 1/8” (3.175 mm) below the cabinet top. • the door gasket will be firmly in contact with the perimeter of the...

Page 20

18 clr2160, clrco2175 door reversal - black and white models only figure 33 black and white units may be left- or right-hand opening. Stainless steel unit doors cannot be reversed. The doors are easily reversed by moving the hinge hardware to the opposite side. The top hinge hardware will be used on...

Page 21

Clr2160, clrco2175 19 5. Remove the two door closer inserts (figure 37) from the existing bottom hinge and install as shown on the new bottom hinge (figure 36). 6. Remove existing bottom hinge (three screws) and remount on opposite side top. Remove hinge screw pin. 7. Remove the plastic hole plug fr...

Page 22

20 clr2160, clrco2175 1. Grasp the edges of the light housing lens opposite the exposed tab, and gently push the lens towards the tab (figure 41). 2. Pull the edge of the lens down and swing it out of the light housing. Important important always use a genuine u-line replacement bulb (part no. 31317...

Page 23

Clr2160, clrco2175 21 fresh food section too cold (model clrco2175) temperature control set too cold use the temperature controller to set temperature warmer. Unit runs but no ice is produced. No water being supplied to the unit check to see that water is connected and turned on to the unit. Unit ru...

Page 24

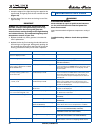

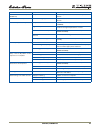

22 clr2160, clrco2175 note: 38°f is an example; the display will vary with actual set-point. Important factory recommended set-point is 38°f for refrigerators and beverage centers, and 50°f for wine coolers. 15 electronic control quick guide all models task touch touch display comment turn on/off ho...

Page 25

Clr2160, clrco2175 23 this page intentionally left blank..

Page 26

24 clr2160, clrco2175 this page intentionally left blank..

Page 27

Clr2160, clrco2175 u-line corporation limited warranty u-line corporation warrants each u-line product to be free from defects in materials and workmanship for a period of one year from the date of purchase; and warrants the sealed system (consisting of the compressor, the condenser, the evaporator,...

Page 28

For general inquiries: p.O. Box 245040 milwaukee, wisconsin 53224-9540 u.S.A. Phone (800) 779-2547 fax (414) 354-5696 www.U-line.Com for service and parts assistance: phone (800) 779-2547 (414) 354-0300 fax (414) 354-5696 email: onlineservice@u-line.Com www.U-lineservice.Com e-mail: onlineparts@u-li...