- DL manuals

- U.S. Boiler Company

- Boiler

- K2

- Operating Instructions Manual

U.S. Boiler Company K2 Operating Instructions Manual

1

105337-03 - 5/15

Price - $5.00

Warning:

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury, or loss of life. For assistance or additional information, consult a qualified installer, service agency or the

gas supplier. This boiler requires a special venting system. Read these instructions carefully before installing.

9700609

as an EnErgY STar

®

Partner, U.S. Boiler Company has determined that the K2™ Series meets the EnErgY

STar

®

guidelines for energy efficiency established by the United States Environmental Protection Agency (EPA).

OPEraTing inSTrUCTiOnS

FOr

K2™

CONDENSING HIGH EFFICIENCY

DIRECT VENT

GAS - FIRED HOT WATER BOILER

Summary of K2

Page 1

1 105337-03 - 5/15 price - $5.00 warning: improper installation, adjustment, alteration, service or maintenance can cause property damage, injury, or loss of life. For assistance or additional information, consult a qualified installer, service agency or the gas supplier. This boiler requires a spec...

Page 2

2 105337-03 - 5/15 important information - read carefully note: the equipment shall be installed in accordance with those installation regulations enforced in the area where the installation is to be made. These regulations shall be carefully followed in all cases. Authorities having jurisdiction sh...

Page 3

3 105337-03 - 5/15 warning asphyxiation hazard. This boiler requires regular maintenance and service to operate safely. Follow the instructions contained in this manual. Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal injury or loss of life. ...

Page 4

4 105337-03 - 5/15 table of contents i. Operation 5 ii. Troubleshooting 33.

Page 5

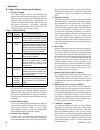

5 105337-03 - 5/15 5. Built-in safety control the control includes safety controls designed to ensure safe and reliable operation. In addition to flame safety controls the control includes supply water temperature, differential water temperature, and stack temperature safety limits and stepped modul...

Page 6

6 105337-03 - 5/15 i. Operation b. Supply water temperature regulation 1. Priority demand the control accepts a call for heat (demand) from multiple places and responds according to it’s “priority”. When more than 1 demand is present the higher priority demand is used to determine active boiler sett...

Page 7

7 105337-03 - 5/15 i. Operation table 2: frost protection c. Boiler protection features 1. Supply water temperature high limit the control is equipped with internal operating control and high limit features. The control monitors a dual element temperature sensor that is mounted in the supply water m...

Page 8

8 105337-03 - 5/15 i. Operation d. Multiple boiler control sequencer 1. “plug & play” multiple boiler control sequencer when multiple boilers are installed, the control’s sequencer may be used to coordinate and optimize the operation of up to eight (8) boilers. Boilers are connected into a “network”...

Page 9

9 105337-03 - 5/15 x. Operation e. Boiler sequence of operation 1. Normal operation table 3: boiler sequence of operation status screen display description priority: standby status: standby (burner off, circulator(s) off) boiler is not firing and there is no call for heat, priority equals standby. T...

Page 10

10 105337-03 - 5/15 i. Operation e. Boiler sequence of operation (continued) 2. Using the display the control includes a touch screen lcd display. The user monitors and adjusts boiler operation by selecting screen navigation “buttons” and symbols. The “home screen” and menu selections are shown belo...

Page 11

11 105337-03 - 5/15 figure 3: status screen overview 3. Status screens boiler status screens are the primary boiler monitoring screens. The user may simply “walk” though boiler operation by repeatedly selecting the right or left “arrow” symbol. These screens are accessed by selected the “status” but...

Page 12

12 105337-03 - 5/15 3. Status screens (continued) bargraph screen bargraph screen the bargraph screen presents measured values for easy comparison. Data logging real time graphic trends allow users to observe process changes over time providing valuable diagnostic information. For example, flame cur...

Page 13

13 105337-03 - 5/15 i. Operation e. Boiler sequence of operation (continued) pumping is a major part of any hydronic system. This screen provides the status of the boiler’s demand to connected pumps as well as the status of frost protection and pump exercise functions. This screen provides the statu...

Page 14

14 105337-03 - 5/15 5. Multiple boiler sequencer screens when the sequence master is enabled the following screens are available : i. Operation e. Boiler sequence of operation (continued) header: measured header water temperature. This is the temperature being used to start, stop and fire boiler whe...

Page 15

15 105337-03 - 5/15 i. Operation 1. Entering adjust mode the control is factory programmed to include basic modulating boiler functionality. These settings are password protected to discourage unauthorized or accidental changes to settings. User login is required to view or adjust these settings: - ...

Page 16

16 105337-03 - 5/15 i. Operation f. Changing adjustable parameters (continued) 2. Adjusting parameters (continued) the following pages describe the control’s adjustable parameters. Parameters are presented in the order they appear on the control’s display, from top to bottom and, left to right. From...

Page 17

17 105337-03 - 5/15 2. Adjusting parameters (continued) warning asphyxiation hazard. Boiler type is factory set and must match the boiler model. Only change the boiler type setting if you are installing a new or replacement control. The boiler type setting determines minimum and maximum blower speed...

Page 18

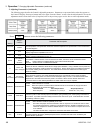

18 105337-03 - 5/15 i. Operation f. Changing adjustable parameters (continued) control repair part kit part number 106194-01 altitude 0 - 2000 ft. Parameter k2-80-02 k2-100-02 k2-120-02 k2-150-02 k2-180-02 maximum heat rate (rpm) 5100 5500 5100 5400 6000 minimum heat rate (rpm) 1600 1650 1600 2000 1...

Page 19

19 105337-03 - 5/15 i. Operation f. Changing adjustable parameters (continued) the control is shipped with defaults that will provide improved operation. Adjustment is only required to optimize setup. The expected heat rate adjustment is used to better match boiler output to the home heating needs. ...

Page 20

20 105337-03 - 5/15 “press” pump setup button to access the following parameters: factory setting range / choices parameter and description central heat, optional priority never, any demand, central heat, no priority, central heat, optional priority system pump run pump for: activates the system pum...

Page 21

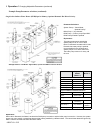

21 105337-03 - 5/15 parameter selections: system pump = “central heat, optional priority” boiler pump = “any demand” dhw pump = “primary loop piped iwh” dhw priority enable is optional explanation: this piping arrangement permits the system pump to run or not run when there is a domestic hot water c...

Page 22

22 105337-03 - 5/15 multiple boilers iwh piped to primary, optional domestic hot water priority sequencer master (boiler 1) boiler 2 wiring locations: thermostat x dhw call for heat x system pump x dhw pump x boiler pump x x sequencer master parameter selections: sequencer master enabled indirect wa...

Page 23

23 105337-03 - 5/15 “press” contractor setup button to access the following parameters: i. Operation f. Changing adjustable parameters (continued) factory setting range / choices parameter and description contractor name user defined contractor name address line 1 user defined contractor address lin...

Page 24

24 105337-03 - 5/15 i. Operation f. Changing adjustable parameters (continued) “press” central heat button to access the following parameters: factory setting range / choices parameter and description 180°f (82.2°c) 60°f to 190°f (16°c to 87.8°c) central heat setpoint target temperature for the cent...

Page 25

25 105337-03 - 5/15 i. Operation f. Changing adjustable parameters (continued) “press” button to access the following parameters: factory setting range / choices parameter and description 180°f (82.2°c) 60°f to 190°f (16°c to 87.8°c) auxiliary heat setpoint target temperature for the auxiliary heat ...

Page 26

26 105337-03 - 5/15 “press” domestic hot water button to access the following parameters: factory setting range / choices parameter and description tank tank, tankless domestic hot water heater type tank selected when boiler is piped to an indirect water heater. Tankless selected when a k2 combi kit...

Page 27

27 105337-03 - 5/15 i. Operation f. Changing adjustable parameters (continued) “press” button to access the following parameters: factory setting range / choices parameter and description enabled enable disable central heat outdoor reset enable if an outdoor sensor is installed and outdoor reset is ...

Page 28

28 105337-03 - 5/15 x. Operation f. Changing adjustable parameters (continued) “press” button to access the following parameters: factory setting range / choices parameter and description enabled enable disable auxiliary heat outdoor reset enable if an outdoor sensor is installed and outdoor reset i...

Page 29

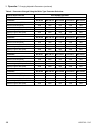

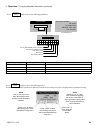

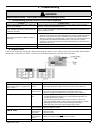

29 105337-03 - 5/15 figure 8: outdoor reset curve central heat setpoint heating element type central heat setpoint heating element type 180°f to 190°f (82.2°c to 87.8°c) fan coil 100°f to 140°f (37.8°c to 60°c) in slab radiant high mass radiant 160°f to 190°f (71.1°c to 87.8°c) convection baseboard ...

Page 30

30 105337-03 - 5/15 i. Operation f. Changing adjustable parameters (continued) “press” sequence master button to access the following parameters: factory setting range / choices parameter and description disable enable, disable master enable/disable the sequencer master enable/disable is used to “tu...

Page 31

31 105337-03 - 5/15 i. Operation f. Changing adjustable parameters (continued) “press” button to access the following parameters: factory setting range / choices parameter and description central heat 1 user defined zone control 1 zone 1 central heat 2 user defined zone control 1 zone 2 central heat...

Page 32

32 105337-03 - 5/15 i. Operation f. Changing adjustable parameters (continued) factory setting range / choices parameter and description local local, 4-20ma central heat modulation source this parameter enables the 4-20ma input to control firing rate and the thermostat input to control boiler on/off...

Page 33

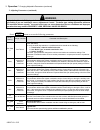

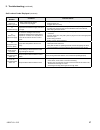

33 105337-03 - 5/15 ii. Troubleshooting a. Troubleshooting problems where no error code is displayed. Warning electrical shock hazard. Turn off power to boiler before working on wiring. Condition possible cause boiler not responding to call for heat, “status” and “priority” show “standby”. Boiler is...

Page 34

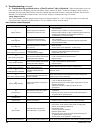

34 105337-03 - 5/15 ii. Troubleshooting (continued) c. Help screen faults d. Help screen diagnostic features indication possible cause lockout history is stored in a first-in, first-out basis. Each history file is stored with boiler run hour of when the lockout occurred. The “when happened” and “cur...

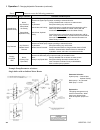

Page 35

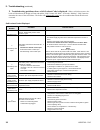

35 105337-03 - 5/15 indication condition possible cause limit string status limit string status i air proving switch limits flow switch limit string fault the limit string status screen shows the safety limit status. A contact icon, either “open” or “closed”, graphically represents each safety limit...

Page 36

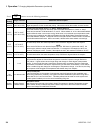

36 105337-03 - 5/15 soft lockout codes displayed f. Troubleshooting problems where a soft lockout code is displayed. When a soft lockout occurs, the boiler will shut down, the display will turn red and the “help” button will “blink”. Select the “blinking” “help” button to determine the cause of the ...

Page 37

37 105337-03 - 5/15 ii. Troubleshooting (continued) lockout number condition possible cause 13 flame rod shorted to ground • flame rod shorted to ground • condensate trap plugged. • shorted or mis-wired flame rode wiring. • defective flame rod. • plugged drain line in trap. 14 dt inlet/outlet high t...

Page 38

38 105337-03 - 5/15 ii. Troubleshooting (continued) g. Troubleshooting problems where a hard lockout code is displayed. When a hard lockout occurs, the boiler will shut down, the display will turn red and the “help” button will “blink”. Select the “blinking” “help” button to determine the cause of t...

Page 39

39 105337-03 - 5/15.

Page 40

40 105337-03 - 5/15 u.S. Boiler company, inc. P.O. Box 3020 lancaster, pa 17604 1-888-432-8887 www.Usboiler.Net.