- DL manuals

- U.S. Boiler Company

- Boiler

- MegaSteam MST

- Installation, Operating And Service Instructions

U.S. Boiler Company MegaSteam MST Installation, Operating And Service Instructions

103536-01 - 3/11

As an ENERGY STAR

®

Partner,

U.S. Boiler Company

has determined that the

MST288, MST396, MST513 and

MST629 meet the

ENERGY STAR

®

guidelines for Energy

efficiency established by the

United States Environmental

Protection Agency (EPA).

Price - $5.00

D

N

A

G

N

I

T

A

R

E

P

O

,

N

O

I

T

A

L

L

A

T

S

N

I

R

O

F

S

N

O

I

T

C

U

R

T

S

N

I

E

C

I

V

R

E

S

™

m

a

e

t

S

a

g

e

M

R

E

L

I

O

B

L

I

O

S

S

A

P

-

3

g

n

i

k

e

e

s

n

e

h

W

.

r

e

il

p

p

u

s

li

o

r

o

r

o

t

c

a

r

t

n

o

c

g

n

it

a

e

h

r

u

o

y

ll

a

c

,r

e

li

o

b

o

t

s

r

i

a

p

e

r

r

o

e

c

i

v

r

e

s

r

o

F

g

n

it

a

R

n

o

n

w

o

h

s

s

a

r

e

b

m

u

N

l

a

i

r

e

S

d

n

a

r

e

b

m

u

N

l

e

d

o

M

r

e

li

o

B

e

d

i

v

o

r

p

,

r

e

li

o

b

n

o

n

o

it

a

m

r

o

f

n

i

.

r

e

li

o

b

e

h

t

f

o

p

o

t

n

o

d

e

t

a

c

o

l

l

e

b

a

L

r

e

b

m

u

N

l

e

d

o

M

r

e

li

o

B

r

e

b

m

u

N

l

a

i

r

e

S

r

e

li

o

B

e

t

a

D

n

o

it

a

ll

a

t

s

n

I

T

S

M

r

o

t

c

a

r

t

n

o

C

g

n

it

a

e

H

r

e

b

m

u

N

e

n

o

h

P

s

s

e

r

d

d

A

9700609

Summary of MegaSteam MST

Page 1

103536-01 - 3/11 as an energy star ® partner, u.S. Boiler company has determined that the mst288, mst396, mst513 and mst629 meet the energy star ® guidelines for energy efficiency established by the united states environmental protection agency (epa). Price - $5.00 d n a g n i t a r e p o , n o i t ...

Page 2

Important information - read carefully the following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels, or to important information concerning product life. Danger indicates an imminently hazardous situation which, if not avoided, will result ...

Page 3

3 danger do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance. Warning improper installation, adjustment, alteration, service or maintenance can cause property damage, personal injury or loss of life. Failure to follow all instructions in t...

Page 4

Warning this boiler contains very hot water under high pressure. Do not unscrew any pipe fittings nor attempt to disconnect any components of this boiler without positively assuring the water is cool and has no pressure. Always wear protective clothing and equipment when installing, starting up or s...

Page 5

5 figure 1: mst 88 thru mst6 9 steam boiler with and without t ankless heater (beckett burner shown).

Page 6

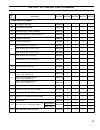

6 table 1a: dimensional data (see figure 1) table 1b: rating data boiler model no. Dimensions (see figure 1) water content (to normal water line) - gallons heat transfer surface area - sq. Ft. Actual shipping weight (lb.) "a" "b" "c" with tankless heater non-heater mst288 22-5/8" 24" 6" 15.3 14.9 20...

Page 7

Figure : minimum installation clearances to combustible materials (inches) a. Inspect shipment carefully for any signs of damage. 1. All equipment is carefully manufactured, inspected and packed. Our responsibility ceases upon delivery of crated boiler to the carrier in good condition. 2. Any claims...

Page 8

8 notice clearance to venting is for single wall vent pipe. If type l vent is used, clearance may be reduced to the minimum required by the vent pipe manufacturer. C. Provide combustion and ventilation air. Local and national codes may apply and should be referenced. Warning adequate combustion and ...

Page 9

9 section ii: unit-pak boiler assembly megasteam™ unit-pak boiler assembly shipment content check list (see figure 3) 1. ___ cast iron section/burner swing door/smoke box assembly mounted on shipping skid: ____ mst3 (rear section, heater) – part # 100566-03 / 100045-01 / 100021-01 ____ mst4 (rear se...

Page 10

10 a. Cast iron section assembly tappings refer to table 3 "purpose of tappings and bosses" and figure 7. 1. All tappings have factory installed thread protectors. The thread protectors must be removed prior to jacket and piping installation. 2. Depending of installation specifics and boiler build o...

Page 11

11 figure : boiler removal from skid se c t io n i i: u n it -p a k b o il er a ss em bl y ( co nt in ue d).

Page 12

1 figure 5a: partial front view - burner swing door mounted to boiler - fully closed and secured d. Jacket front panel installation. In order to install front jacket panel burner swing door and door mounting bracket need to be removed. As shipped, the door would open to the left side. 1. To open/rem...

Page 13

13 figure 5b: top view - burner swing door mounted to cast iron block assembly (jacket removed for clarity) 10. Inspect burner swing door insulation for damage and proper type. By design, for all models, cast bars on front section between the combustion chamber, and, between the left and right side ...

Page 14

1 11. Upon inspection completion, lift door and place integral cast hinge pins into door mounting bracket slotted holes. Do not close and secure door at this time, proceed to installing stainless steel flueway baffles. 12. Locate/remove four #8 x ½” shoulder sheet metal screws from hardware bag, the...

Page 15

15 figure 6: flueway baffle positioning/orientation in flueways flueway on right side of boiler, hold baffle with word "right" readable at the top. Slide baffle in flueway until position tab touches fins on left side of 2 nd pass flueway. F. Closing / securing burner swing door. 1. To close and secu...

Page 16

16 figure : purpose of tappings and bosses table 3: purpose of tappings & bosses tapping location size, npt boss location thread size unc steam boiler less heater with heater a ¼" - 18 pressure gauge b ¼" - 18 pressure limit c ¾" - 1 probe lwco - std. Plugged (float lwco) d ½" - 1 water gauge glass ...

Page 17

1 7. Secure panel bottom to studs with acorn nuts hand tight. 8. Align upper panel attachment holes with smokebox upper attachment bosses and install 5/16”-18 x ½” phillips pan head machine screws hand tight. 9. Securely tighten rear jacket panel mounting hardware. 10. Locate/remove four #8 x ½” sho...

Page 18

18 9. Place the panel between side panels upper inside flanges and slide it forward, until top panel front flange u-bend locks over front panel top flange, and, top panel rear flange is positioned over rear jacket panel. 10. Locate/remove two #8 x ½” sheet metal screws from hardware bag. 11. Install...

Page 19

19 figure 9: float-t ype l wco and pressure limit installation se c t io n i i: u n it -p a k b o il er a ss em bl y ( co nt in ue d).

Page 20

0 4. Pick-up the lwco harness molex end and feed it into the enclosure, thru external electrical enclosure top flange front left 7/8” hole; then, snap-in harness bx connector into the hole, and, plug-in molex connector into dedicated lwco receptacle inside the enclosure (middle left off transformer/...

Page 21

1 figure 10: oil burner installation (beckett burner shown) 3. Thread safety valve into the ¾” npt black coupling. Pipe the safety valve discharge as shown in figure 12 “ recommended boiler piping for gravity return steam boiler” shown in section iii of this manual. Installation of the safety valve ...

Page 22

G. Align holes and install two (2) remaining cap screws. Level burner and fully tighten all three (3) screws. H. Plug burner power cord into power outlet receptacle located in lower right corner of front panel. 2. Install riello oil burner, refer to figure 10. A. Loosen burner cover holding screws a...

Page 23

3 figure 11d: turbulator setting figure 11e: pump connections and port identification warning: do not operate a single line system with the by-pass plug installed. Operating a single line system with the by-pass plug installed will result in damage to the pump shaft seal. Note: pump pressure was fac...

Page 24

A. Evaluate the existing steam system. The single most important factor in determining the expected life cycle of a steam boiler, is the amount of fresh water added to the boiler during operation. Fresh water brings minerals and oxygen into the boiler. These contaminants greatly accelerate corrosion...

Page 25

5 figure 1 : recommended boiler piping for gravity return steam boiler section iii: steam b oiler piping & trim ( continued ).

Page 26

6 section iv: tankless & indirect water heater piping a. Connect tankless heater piping as shown in figure 13. See table 4 for tankless heater rating. Warning install automatic mixing valve at tankless heater outlet to avoid risk of burns or scalding due to excessively hot water at fixtures. Adjust ...

Page 27

Table : tankless heater data: figure 13: schematic tankless water heater piping boiler model heater no. Heater rating (gpm) pressure drop thru heater (psi) mst288 222a 3.00 22.0 mst396 3.25 24.3 mst513 3.50 26.5 mst629 4.00 31.0 section iv: tankless & indirect water heater piping (cont'd).

Page 28

8 figure 1: alliance sl™ water heater piping with megasteam™ boiler b. Connect alliance sl™ indirect water heater piping as shown in figure 14. 1. Refer to alliance sl™ manual for additional information. Section iv: tankless & indirect water heater piping (cont'd).

Page 29

9 a. Chimney venting 1. Chimney venting is an important part of a safe and efficient oil fired appliance system. Contact your local fire and building officials on specific requirements for restrictions and the installation of fuel oil burning equipment. In addition, consult with a professional knowl...

Page 30

30 figure 15: recommended vent pipe arrangement and chimney requirements figure 16: proper and improper locations of draft regulator section v: venting & air intake piping (continued).

Page 31

31 2. Type b chimney connector - a type b chimney connector can be used to transmit the flue gases provided flue gas temperature entering the chimney connector is greater than 310°f. 3. Type l chimney connector - a type l vent or other suitable material shall be used for a chimney connector if the t...

Page 32

3 a minimum, remove the baffles to increase the stack temperature. See tables 8 thru 8b for temperature differential (∆t) with baffles in and out. In addition, the lower the co 2 level the higher the stack temperature. Warning remove the baffles if there are any signs of condensation in the chimney ...

Page 33

33 a. General 1. Install wiring and electrically ground boiler in accordance with requirements of the authority having jurisdiction, or in absence of such requirements the national electrical code, ansi/ nfpa 70. 2. Refer to national electric code or local electric codes for proper size and type of ...

Page 34

3 figure 18: w iring diagram, steam, hydrolevel cg 50 probe l wco section vi: electrical (continued ).

Page 35

35 figure 18a: w iring diagram, riello 0 series burner , steam, hydrolevel cg 50 probe l wco section vi: electrical (continued ).

Page 36

36 figure 19: w iring diagram, steam, mcdonnell & miller ps-801 probe l wco section vi: electrical (continued ).

Page 37

3 figure 19a: w iring diagram, riello 0 series burner , steam, mcdonnell & miller ps-801 probe l wco section vi: electrical (continued ).

Page 38

38 figure 0: w iring diagram, steam, mcdonnell & miller #6 float l wco section vi: electrical (continued ).

Page 39

39 figure 0a: w iring diagram, riello 0 series burner , steam, mcdonnell & miller #6 float l wco section vi: electrical (continued ).

Page 40

0 boiler sequence of operation with probe lwco (see figure 18) when the thermostat calls for heat, it energizes the r8285c control center relay which in turn energizes the cad cell primary control, bringing on the burner. The burner will operate in the following sequence: prepurge for the first 10 s...

Page 41

1 figure 1: single pipe oil line section vii: oil piping a. General 1. Use flexible oil line(s) so the burner swing door can be opened without disconnecting the oil supply piping. 2. A supply line fuel oil filter is recommended as a minimum for all firing rates but a pleated paper fuel oil filter is...

Page 42

Figure : two pipe oil lines c. Two pipe oil lines 1. For two piped systems, where more lift is required, the two-stage fuel unit is recommended. Table 5 (two-stage) and table 6 (single-stage) show allowable lift and lengths of 3/8 inch and 1/2 inch od tubing for both suction and return lines. Refer ...

Page 43

3 section viii: system start-up 1. Set room thermostat about 10° above room temperature. 2. Press red reset button on front of burner cover, hold for one (1) second and release to reset primary control. 3. On steam boilers: a. With an l404f1367 - set cut-out pressure (main scale) on the pressure lim...

Page 44

5. Adjust oil pressure. A. When checking a fuel unit's operating pressure, a reliable pressure gauge may be installed in either the bleeder port or the nozzle port. See figure 23. B. Locate oil pressure adjusting screw and turn screw to obtain proper pump pressure, refer to tables 8 thru 8b at rear ...

Page 45

5 figure : "l1" and "v1" head electrode positioning and gun setting (beckett afg) section viii: system st ar t-up (continued ).

Page 46

6 2. If nozzle continues to drip, repeat paragraph h, no. 1. If this does not stop the dripping, remove cut-off valve and seat, and wipe both with a clean cloth until clean, then replace and readjust oil pressure. If dripping or after burn persist replace fuel pump. I. Test controls. 1. Check thermo...

Page 47

• check the piping to the oil tank. • check the oil nozzle, oil supply and oil filter. Ii. Check safety features safe start: • place a jumper across cad cell terminals. • follow procedure to turn on burner. Burner must not start, indicator light turns on and control remains in idle mode. • remove ju...

Page 48

8 important product safety information refractory ceramic fiber product warning: the repair parts list designates parts that contain refractory ceramic fibers (rcf). Rcf has been classified as a possible human carcinogen. When exposed to temperatures about 1805°f, such as during direct flame contact...

Page 49

9 section ix: maintenance and service instructions a. Maintenance of low water cut- off devices warning probe and float type low water cut-off devices require annual inspection and maintenance. 1. Probe type low water cut-off although these devices are solid state in their operation, the probe is ex...

Page 50

50 operate the boiler with steam in the entire system for a few days allowing the condensate to return to the boiler. If the condensate can temporarily be wasted, operate boiler only for the length of time it takes for condensate to run clear. If the latter cannot be achieved or if the condensate is...

Page 51

51 open gate valve in hartford loop, then repeat step 1 above. E. Make ph or alkalinity test. After boiler and system have been cleaned and refilled as previously described, test the ph of the water in the system. This can easily be done by drawing a small sample of boiler water and testing with hyd...

Page 52

5 section x: boiler cleaning a. Clean the flueways (see figure 27). 1. For access to the combustion chamberremove the two (2) 3/8" - 16 cap screws. If boiler is equipped with flexible fuel line(s), swing door open. 2. Remove the two smoke box clean-out covers from the rear smoke box by removing the ...

Page 53

53 figure : cleaning boiler flueways and combustion chamber surfaces warning the boiler must be connected to an approved chimney in good condition. Serious property damage could result if the boiler is connected to a dirty or inadequate chimney. The interior of the chimney flue must be inspected and...

Page 54

5 a. Combustion 1. Nozzles — although the nozzle is a relatively inexpensive device, its function is critical to the successful operation of the oil burner. The selection of the nozzle supplied with the megasteam™ boiler is the result of extensive testing to obtain the best flame shape and efficient...

Page 55

55 d. Excessive airflow or draft causing flame to leave burner head. E. Excessive back pressure causing flame to be erratic. 3. Control locks out after trial for ignition (tfi). A. No oil to burner. B. Shorted electrodes. C. Nozzle clogged. D. Airflow too high. E. Ignitor module defective. F. Cad ce...

Page 56

56 section xii: repair parts all megasteam™ boiler repair parts may be obtained through your local burnham product distributor. Should you require assistance in locating a burnham product distributor in your area, or have questions regarding the availability of burnham brand products or repair parts...

Page 57

5 item no. Description part no. Mst288 mst396 mst513 mst629 1. Bare boiler assembly 1a front section, machined 100569-01 1 1 1 1 1b center section, machined 100571-01 1 1 2 3 1c1 rear section (htr.), steam, machined 100573-01 1 1 1 1 1c2 rear section (non-htr.), steam, machined 100676-01 1 1 1 1 1d1...

Page 58

58 bare boiler assembly section x ii: r ep air p ar ts (continued ).

Page 59

59 item no. Description part no. Mst288 mst396 mst513 mst629 1. Bare boiler assembly (continued) 1s burner swing door insulation (less pockets) 100039-01 1 1 1 --- burner swing door insulation (with pockets) 100039-02 --- --- --- 1 1t 5/8" dia. Rope gasket - burner swing door 100097-01 1 1 1 1 1u 1/...

Page 60

60 jacket assembly section x ii: r ep air p ar ts (continued ).

Page 61

61 item no. Description part no. Mst288 mst396 mst513 mst629 . Jacket assembly 2a jacket front panel assembly w/insulation 100575-01 1 1 1 1 2b power outlet receptacle, w/harness 100605-01 1 1 1 1 2c #8 x 1/2" type ab truss head w/shoulder, sheet metal screw, plated 100038-01 10 10 10 10 2d jacket r...

Page 62

6 mst 88 thru mst6 9 steam boilers - t rim and controls section x ii: r ep air p ar ts (continued ).

Page 63

63 item no. Description part no. Mst288 mst396 mst513 mst629 3. Mst - trim and controls 3a 6" rc-std draft regulator 8116288 1 1 1 --- 7" rc-std draft regulator 8116289 --- --- --- 1 3b pressure gauge 100325-01 1 1 1 1 3c probe, hydrolevel el-1214 (for hydrolevel cg450) 80160629 1 1 1 1 3d low water...

Page 64

6 beckett afg burner section x ii: r ep air p ar ts (continued ).

Page 65

65 beckett oil burner part nos. For megasteam™ series boilers note: when ordering parts always give the serial and model numbers shown on the boiler and burner. Also provide the name of the part(s) and part number as listed below. Boiler model mst288 mst396 mst513 mst629 air tube combination afg70mm...

Page 66

66 note: when ordering parts always give the serial and model numbers shown on the boiler and burner. Refer to models f3 & f5 installation manual, riello 40 series residential oil burners (c6501010) for an exploded view of the burner and a list of spare parts. Riello oil burner part numbers for mega...

Page 67

6 table 8: beckett afg b u r n e r s p e c if ic a ti o n s boiler model burner input (gph) head type (setting) air shutter (setting) air band (setting) nozzle pump pressure (psi) approx. Shipped co 2 (%) baf fle location (pass) approx. Stack temp. Increase without baf fles (f) 2 baf fles in minimum...

Page 68

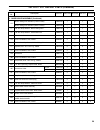

68 boiler model burner input (gph) burner model nozzle head setting air se tti ng pump pressure (psi) air tube type insertion depth (inch) approx. Shipped co 2 (%) baf fle location (pass) approx. Stack temp. Increase without baf fles °f (2) approx. Breech pressure (" w .C.) (3) baf fles in approx. O...

Page 69

69 appendix a - figures figure number page number description figure 1 5 mst288 thru mst629 steam boiler with and without tankless heater (beckett burner shown) section i - pre-installation figure 2 7 minimum installation clearances to combustible materials (inches) section ii - unit-pak boiler asse...

Page 70

0 appendix a - figures (continued) figure number page number description section viii - system start-up figure 23 44 adjusting fuel pump pressure figure 24 45 "l1" and "v1" head electrode positioning and gun setting (beckett afg) figure 25 46 r7184 terminals, led and reset button figure 26 47 cad ce...

Page 71

1 appendix b - tables table number page number description table 1a 6 dimensional data (see figure 1) table 1b 6 rating data section ii - unit-pak boiler assembly table 2 14 baffle usage table 3 16 purpose of tappings and bosses section iv - tankless & indirect water heater piping table 4 27 tankles...

Page 72

U.S. Boiler company, inc. P.O. Box 3020 lancaster, pa 17604 (717) 397-4701 www.Usboiler.Burnham.Com.