- DL manuals

- U.S. Boiler Company

- Boiler

- PVG

- Installation, Operating And Service Instructions

U.S. Boiler Company PVG Installation, Operating And Service Instructions

103997-06 - 1/14

As an ENERGY STAR

®

Partner, U.S. Boiler Company has determined that the PVG-3, PVG-4, PVG-5, PVG-6 and

PVG-7 meet the ENERGY STAR

®

guidelines for energy efficiency established by the United States Environmental

Protection Agency (EPA).

Price - $5.00

9700609

INSTALLATION, OPERATING AND

SERVICE INSTRUCTIONS FOR

PVG

™

Gas - Fired Boiler

For service or repairs to boiler, call your heating contractor. When seeking information on boiler, provide

Boiler Model Number and Serial Number as shown on Rating Label.

Model Number

Boiler Serial Number

Installation Date

Heating Contractor

Phone Number

Address

Summary of PVG

Page 1

103997-06 - 1/14 as an energy star ® partner, u.S. Boiler company has determined that the pvg-3, pvg-4, pvg-5, pvg-6 and pvg-7 meet the energy star ® guidelines for energy efficiency established by the united states environmental protection agency (epa). Price - $5.00 9700609 installation, operating...

Page 2

2 important information - read carefully note: the equipment shall be installed in accordance with those installation regulations enforced in the area where the installation is to be made. These regulations shall be carefully followed in all cases. Authorities having jurisdiction shall be consulted ...

Page 3

3 special installation requirements for massachusetts a. For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential purposes and where the side wall exhaust vent termination is less than seven (7) feet above ...

Page 4

4 warning this boiler requires regular maintenance and service to operate safely. Follow the instructions contained in this manual. Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal injury or loss of life. Read and understand the entire manual ...

Page 5

5 table of contents figure 1: minimum clearances to combustibles i. Pre-installation ............................... 7 ii. Unpack boiler ................................ 8 iii. Venting ........................................... 9 iv. Water piping and trim ................. 19 v. Gas piping ...........

Page 6

6 figure 2: dimensions pvg connection sizes(dimensions in inches) model supply return vent relief v alve pvg3 1¼ npt 1¼ npt 3 ¾ npt pvg4 pvg5 pvg6 pvg7 pvg8 4 pvg9 pvg dimensional da ta model ‘a’ pvg3 11.65 pvg4 14.72 pvg5 17.78 pvg6 20.84 pvg7 23.90 pvg8 26.97 pvg9 30.03.

Page 7

7 warning if you do not follow these instructions exactly, a fire or explosion may result causing property damage or personal injury. Danger do not install boiler where gasoline or other flammable vapors or liquids, or sources of hydrocarbons (i.E. Bleaches, cleaners, chemicals, sprays, paint remove...

Page 8

8 confined space. Use indoor air if two permanent openings communicate directly with additional space(s) of sufficient volume such that combined volume of all spaces meet criteria for unconfined space. Size each opening for minimum free area of one (1) square inch per 1,000 btu per hour input of all...

Page 9

9 iii. Venting table 1: vent system options table 2: vent system components included with boiler warning do not use this boiler with galvanized, type 304 or type 316 stainless steel, non metallic or any other non al29-4c ® based vent systems. Do not use a barometric damper or draft hood with this ap...

Page 10

10 table 3: vent system components vent system component part number equivalent feet of pipe 3” dia. Pipe x 1 ft 8116296u 1 4” dia. Pipe x 1 ft 100176-01 3” dia. Pipe x 3 ft 8116298u 3 4” dia. Pipe x 3 ft 100177-01 3” dia. Pipe x 5 ft 8116300u 5 4” dia. Pipe x 5 ft 100178-01 3” dia. Pipe x adjustabl...

Page 11

11 b. General guidelines 1. Vent system installation must be in accordance with national fuel gas code, ansi z223.1/nfpa 54, natural gas and propane installation code, can/csa b149.1 or applicable provisions of local building codes. Contact local building or fire officials about restrictions and ins...

Page 12

12 g. Minimum 10 feet (2 m) horizontally from an operable opening in an adjacent building. This does not apply to vent terminals 2 feet (0.6 m) or more above or 25 feet (7.6 m) or more below operable openings. 9. Enclose vent passing through occupied or unoccupied spaces above the boiler with materi...

Page 13

13 c. Install vent pipe, u.S. Boiler gasketed vent system. 1. Procedure for joining u.S. Boiler gasketed vent pipe and fittings. See figure 3. A. Wipe the male end of each joint using an alcohol pad to remove any dirt and grease. B. Align weld seams in pipes and use a slight twisting motion to fully...

Page 14

14 figure 4: horizontal – v ent installation iii. V enting (continued).

Page 15

15 figure 5: horizontal – vent terminal configuration (3” or 4” vent) vertical venting – 1. See figure 28 for blower vent connector assembly. Do not exceed maximum vent lengths. Refer to table 4. 2. Installation of a vertical vent drain tee 8116304u is required on all vertical vent applications. See...

Page 16

16 figure 7: attic offset figure 6: v ertical v ent installation iii. V enting (continued).

Page 17

17 figure 8: v ertical v ent t ermination united states: extend v ent piping to maintain minimum vertical (“x”) and minimum horizontal (“y”) distance of twelve (12) inches from roof surface. Allow additional vertical (“x”) distance for expected snow accumulation. Canada: extend at least 18 inch (450...

Page 18

18 1. See figure 28 for blower vent connector assembly. Do not exceed maximum vent lengths. Refer to table 4. 2. This installation will allow a maximum of seven (7) feet vertical exterior run of the vent piping to be installed . Notice exterior run to be included in equivalent vent lengths. F. Optio...

Page 19

19 a. Design and install boiler and system piping to prevent oxygen contamination of boiler water and frequent water additions. 1. There are many possible causes of oxygen contamination such as: a. Addition of excessive make-up water as a result of system leaks. B. Absorption through open tanks and ...

Page 20

20 5. When constructing a piping tree to install lwco select fittings (tees, elbows etc) and nipples to have the same size (npt) as boiler supply connection. At minimum, 1-1/4” tee with ¾” branch outlet is required to connect the probe lwco to the supply piping. See figure 10. Do not reduce the size...

Page 21

21 figure 13: recommended piping for combination heating & cooling (refrigeration) system notice u.S. Boiler recommends sizing the system circulator to supply sufficient flow (gpm) to allow a 20°f temperature differential in the system. When sizing the system circulator, the pressure drop of all rad...

Page 22

22 iv. Water piping and trim (continued) bring the ph between 7 and 11. L. If it is required to perform a long term pressure test of the hydronic system, the boiler should first be isolated to avoid a pressure loss due to the escape of air trapped in the boiler. To perform a long term pressure test ...

Page 23

23 figure 14: recommended boiler piping for circulator zoned heating systems iv . W ater p iping and t rim (continued ).

Page 24

24 figure 15: recommended w ater piping for zone v alve zoned heating systems iv . W ater p iping and t rim (continued ).

Page 25

25 v. Gas piping table 5: gas ratings for materials or conditions other than those listed above, refer to national fuel gas code, ansi z223.1 / nfpa54, can/csa b149.1 natural gas and propane installation code or size system using standard engineering methods acceptable to authority having jurisdicti...

Page 26

26 figure 16: recommended gas piping table 8: equivalent lengths of standard pipe fittings & valves b. Connect boiler gas valve to gas supply system. Warning failure to use proper thread compounds on all gas connectors may result in leaks of flammable gas. Warning gas supply to boiler and system mus...

Page 27

27 c. Pressure test. The boiler and its gas connection must be leak tested before placing boiler in operation. 1. Protect boiler gas control valve. For all testing over ½ psig, boiler and its individual shutoff valve must be disconnected from gas supply piping. For testing at ½ psig (3.5kpa) or less...

Page 28

28 vi. Electrical a. General. Install wiring and electrically ground boiler in accordance with authority having jurisdiction or, in the absence of such requirements, follow the national electrical code, ansi/nfpa 70, and/or the canadian electrical code part 1, csa c22.1, electrical code. B. A separa...

Page 29

29 figure 17: wiring connection diagram vi. Electrical (continued).

Page 30

30 figure 18: wiring ladder diagram vi. Electrical (continued) notice all wire, wire nuts, controls etc. Are installer supplied unless otherwise noted. If an additional system limit is used, install in series with the auxiliary limit jumper shown in the drawing below..

Page 31

31 figure 19: circulator zoned system w iring diagram vi. E lectrical (continued).

Page 32

32 figure 20: zone v alve zoned system w iring schematic vi. E lectrical (continued).

Page 33

33 a. General guidelines 1. Read and follow all venting, combustion air, water piping, gas piping and electrical instructions contained in this manual unless otherwise instructed in this section. 2. Consult local building codes or national fuel gas code, nfpa 54/ansi z222.3 for restrictions and inst...

Page 34

34 figure 21: modular boiler piping vii. M odular inst alla tion (continued).

Page 35

35 a. Verify that the venting, water piping, gas piping and electrical system are installed properly. Refer to installation instructions contained in this manual. B. Confirm all electrical, water and gas supplies are turned off at the source and that vent is clear of obstructions. C. Confirm that al...

Page 36

36 figure 22: operating instructions viii. System start-up (continued).

Page 37

37 h. Check pilot burner flame. See figure 24. Flame should be steady, medium hard blue enveloping 3/8 to ½ inch of sensing probe. I. Check main burner flame. See figure 23. Flame should have clearly defined inner cone with no yellow tipping. Orange-yellow streaks should not be confused with true ye...

Page 38

38 warning failure to properly adjust gas input rate will result in over firing or under firing of the appliance. Improper and unsafe boiler operation may result. 4. Determine input rate. Multiply gas flow rate by gas heating value. 5. Compare measured input rate to input rate stated on rating plate...

Page 39

39 ix. Operation a. Boiler sequence of operation normal operation 1. The pvg boilers are equipped with an intelligent hydronic control (control). This control replaces the traditional separate ignition control, high limit switch, blower relay and circulator relay and adds energy saving thermal purge...

Page 40

40 figure 26: boiler display ix. Operation (continued) the control display, along with up ñ, down ò, and “ i ” keys may be used to view boiler operating status (figure 26). D. Viewing the operating mode options in operating mode the user may view (but not change) boiler operating status, settings an...

Page 41

41 ix. Operation (continued) e. Changing the adjustable parameters to adjust parameters such as high limit setpoint and high limit differential: 1. Access the adjustment mode by pressing and holding the up ñ, down ò, and “ i ” keys simultaneously for three (3) seconds. This procedure is intended to ...

Page 42

42 7. Domestic hot water (dhw) terminal function (dh_) the control allows configuration of the dhw circulator output functionality to help the pvg integrate into each installation more effectively. The dhw circulator output can be connected to a domestic hot water circulator or a second heating zone...

Page 43

43 x. Troubleshooting a. Before troubleshooting the following pages contain trouble shooting tables for use in diagnosing control problems. When using these tables the following should be kept in mind: 1. This information is only meant to be used by a professional heating technician as an aid in dia...

Page 44

44 x. Troubleshooting (continued) iq boiler control error codes (when "err" is flashing) display status boiler / control action(s) blank boiler and circulator off no 120 vac power at boiler, check breaker and wiring between breaker panel and boiler. Err 2 pressure switch failed to open while the blo...

Page 45

45 x. Troubleshooting (continued) 2. Circulator is on, but boiler is off display / status recommended corrective action sta1 circulator pre-purge burner off circulator on the boiler is warm and circulator is providing residual boiler heat to building: check boiler temperature - the boiler will not s...

Page 46

46 x. Troubleshooting (continued) 5. Circulator is on, blower is on but boiler fails to start display / status description sta 10 retry / recycle delay the boiler is in “retry delay”: - the burner failed to light (no flame signal). After a 5 minute delay, control will attempt to light the burner aga...

Page 47

47 x. Troubleshooting (continued) display / status recommended corrective action sta 10 retry / recycle delay sta 13 soft lockout 1. No spark a. Can you hear sparking while sta 6 is displayed? - if there is no spark noise replace the control. B. If you can hear spark noise check the following: - loo...

Page 48

48 xi. Service danger this boiler uses flammable gas, high voltage electricity, moving parts, and very hot water under high pressure. Assure that all gas and electric power supplies are off and that the water temperature is cool before attempting any disassembly or service. Do not attempt any servic...

Page 49

49 a. General. Inspection and service should be conducted annually. Turn off electrical power and gas supply while conducting service or maintenance. Follow instructions to turn off gas to appliance. See figure 22. Caution label all wires prior to disconnection when servicing controls. Wiring errors...

Page 50

50 figure 27: silicone tubing assembly figure 28: blower vent connector assembly 5. Disconnect wiring harness from blower motor. 6. Remove canopy/blower assembly. A. Loosen the (4) screws from canopy. 7. Remove flue gas baffles. Inspect flue gas baffles for deterioration. 8. Inspect flue passages. C...

Page 51

51 figure 29: flue and burner cleanout, 1” burner xi. S er vice (continued ).

Page 52

52 table 16: pilot burner location figure 30: differential pressure measurement table 17: differential pressure switch settings model main burner with pilot bracket pilot burner located between main burners * pvg3 2 2 & 3 pvg4 3 3 & 4 pvg5 4 4 & 5 pvg6 5 5 & 6 pvg7 6 6 & 7 pvg8 7 7 & 8 pvg9 8 8 & 9 ...

Page 53

53 xii. Repair parts all pvg repair parts may be obtained through your local u.S. Boiler wholesale distributor. Should you require assistance in locating a u.S. Boiler distributor in your area, or have questions regarding the availability of u.S. Boiler products or repair parts, please contact u.S. ...

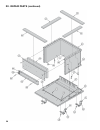

Page 54

54 xii. Repair parts (continued).

Page 55

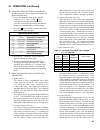

55 key no. Description [quantity] part number pvg3 pvg4 pvg5 pvg6 pvg7 pvg8 pvg9 1. Casting assembly 1 section assembly 61707031 61707041 61707051 61707061 61707071 61707081 61707091 1a left end section 71707001 1b center section [1] 71707003 [2] 71707003 [3] 71707003 [4] 71707003 [6] 71707003 [6] 7...

Page 56

56 xii. Repair parts (continued).

Page 57

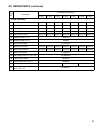

57 key no. Description [quantity] part number pvg3 pvg4 pvg5 pvg6 pvg7 pvg8 pvg9 2. Base assembly 2a base wrapper 71807031 71807041 71807051 71807061 71807071 71807081 71807091 2b base tray 71807032 71807042 71807052 71807062 71807072 71807082 71807092 2c burner tray assembly 61807031 61807041 61807...

Page 58

58 key no. Description [quantity] part number pvg3 pvg4 pvg5 pvg6 pvg7 pvg8 pvg9 3. Base assembly 3a burner cover (natural gas only) 102033-03 102033-04 102033-05 102033-06 102033-07 102033-08 102033-09 3b manifold support bracket 718070001 3c sheet metal screw, #8 x 1/2” [2] 80860000 3d self tappin...

Page 59

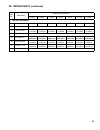

59 key no. Description [quantity] part number pvg3 pvg4 pvg5 pvg6 pvg7 pvg8 pvg9 4. Fan/canopy assembly 4a canopy assembly - sea level 61107031 61107041 61107051 61107061 61107071 61107081 61107091 canopy assembly - high altitude 61107032 61107042 61107052 61107062 61107072 61107082 61107092 4b cera...

Page 60

60 xii. R ep air p arts (continued).

Page 61

61 key no. Description [quantity] part number pvg3 pvg4 pvg5 pvg6 pvg7 pvg8 pvg9 5. Burner assembly 5a gas valve (natural gas), honeywell vr8204p1171 81660282 n/a gas valve (natural gas), honeywell vr8304p4496 n/a 81660283 gas valve (lp gas), honeywell vr8204c3015 81660146 n/a gas valve (lp gas), ho...

Page 62

62 key no. Description [quantity] part number pvg3 pvg4 pvg5 pvg6 pvg7 pvg8 pvg9 6. Control panel assembly 6a limit rated temperature sensor, 12”, honeywell 50001464-001 103195-01 6b transformer, honeywell at140b1297 102516-01 6c boiler control, induced draft, honeywell s9361a2075 103661-01 6d contr...

Page 63

63 key no. Description [quantity] part number pvg3 pvg4 pvg5 pvg6 pvg7 pvg8 pvg9 7. Jacket parts 7a left side panel 60407002 7b right side panel 60407001 7c rear panel 60407033 60407043 60407053 60407063 60407073 60407083 60407093 7d vestibule panel 60407034 60407044 60407054 60407064 60407074 60407...

Page 64

64 key no. Description [quantity] part number pvg3 pvg4 pvg5 pvg6 pvg7 pvg8 pvg9 8. Miscellaneous parts carton 8a water manifold 80607001 8b temperature/pressure gauge 100282-01 8c circulator wiring harness 6130701 8d safety relief valve 81660363 8e boiler drain valve 806603061 8f vent terminal 8110...

Page 65

65 figure number page number description figure 1 5 minimum clearances to combustibles figure 2 6 dimensions section iii - venting figure 3 13 u.S. Boiler gasketed vent joint detail figure 4 14 horizontal - vent installation figure 5 15 horizontal - vent terminal configuration (3” or 4” vent) figure...

Page 66

66 table number page number description section iii - venting table 1 9 vent system options table 2 9 vent system components included with boiler table 3 10 vent system components table 4 10 vent length section v - gas piping table 5 25 gas ratings table 6 25 specific gravity correction factors for ...

Page 67

67 service record date service performed.

Page 68

68 u.S. Boiler company, inc. P.O. Box 3020 lancaster, pa 17604 1-888-432-8887 www.Usboiler.Net.