- DL manuals

- U.S. Boiler Company

- Boiler

- SERIES 3

- Installation, Operating And Service Instructions

U.S. Boiler Company SERIES 3 Installation, Operating And Service Instructions

103796-07 - 12/14

9700609

Price - $5.00

For service or repairs to boiler, call your heating contractor. When seeking information on boiler, provide

Boiler Model Number and Serial Number as shown on Rating Label.

Boiler Model Number

30__B

Boiler Serial Number

Installation Date

Heating Contractor

Phone Number

Address

INSTALLATION, OPERATING AND

SERVICE INSTRUCTIONS FOR

SERIES 3™

Gas - Fired Boiler

Summary of SERIES 3

Page 1

103796-07 - 12/14 9700609 price - $5.00 for service or repairs to boiler, call your heating contractor. When seeking information on boiler, provide boiler model number and serial number as shown on rating label. Boiler model number 30__b boiler serial number installation date heating contractor phon...

Page 2

2 follow all instructions and warnings printed in this manual and posted on the boiler. Inspect the boiler annually. To keep your boiler safe and efficient, have a service technician follow the service checklist near the end of this manual. If you are not qualified to install or service boilers, do ...

Page 3

3 read this entire manual before attempting installation, start-up, or service. Improper installation, adjustment, alteration, service, or maintenance may cause serious property damage, personal injury, or death. Do not disconnect pipe fittings on the boiler or in the heating system without first ve...

Page 4

4 congratulations on your purchase of a new series 3 boiler—designed and constructed to provide you with years of reliable service. • cast iron heat exchanger – for reliability and durability, nothing beats a cast iron heat exchanger. • iq control™ – the most advanced and easiest to use control avai...

Page 5

5 series 3 boiler model input (mbh) (1) doe heating capacity (mbh) net ahri rating, water (mbh) (2) afue (%) 303b 70 59 51 84.0 304b 105 88 77 84.0 305b 140 117 102 84.0 306b 175 146 127 84.0 307b 210 176 153 84.0 308b 245 205 178 84.0 309b 280 234 203 84.0 ratings specifications boiler model depth ...

Page 6

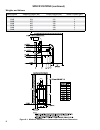

6 boiler model shipping weight (lbs) empty weight (lbs) water content (gal) 303b 254 180 2 304b 304 231 3 305b 357 284 4 306b 405 332 5 307b 462 382 5 308b 518 438 6 309b 564 484 7 weights and volume figure s-1: minimum clearances to combustibles and alcove dimensions specifications (continued).

Page 7

7 installation: 1. Unpack the crate ............................................................................................. 8 2. Position the boiler ............................................................................................ 9 3. Provide combustion air ...........................

Page 8

8 the boiler is top-heavy. Do not allow it to tip over. 1. Remove the sleeve. 2. Remove the contents from the skid, except the boiler. 3. Remove the four (4) hex-drive lag screws holding the boiler to the skid (figure 1-a). Do not damage front air dam. It is required for proper operation of the boil...

Page 9

9 2. Position the boiler warnings 1. Slide the boiler into desired location. 2. Meet the minimum clearances to combustible construction per the specification section of this manual. 3. Allow 24" (610 mm) service clearance in front and on the left side of the boiler. Observe minimum clearances to com...

Page 10

10 3. Provide combustion air insufficient combustion air supply may result in the production and release of deadly carbon monoxide (co) into the home which can cause severe personal injury or death. Provide combustion and ventilation air in accordance with the section "air for combustion and ventila...

Page 11

11 5. Connect gas piping size gas piping according to appendix c – gas piping shut off gas supply before servicing the boiler. All gas piping must be gas tight. Use gas rated thread compound on all threaded joints to avoid leaks, which may result in fire or explosion. Size gas piping, regulators, va...

Page 12

12 4. Screw the relief valve into manifold tapping “rv”. I this installation is not complete until the relief valve is installed. Pipe the relief valve discharge to a location where it will not harm people or damage property. The relief valve may discharge scalding hot water or steam. Blocking the r...

Page 13

13 6. Connect boiler water piping (continued) 6-b item description part number 1 1¼ x 1¼ x ½ tee 806601021 2 immersion well, ½ npt 80160456 3 1¼ x 6 nipple 806600029 4 1¼ tee 806601030 5 1¼ x ¾ bushing 806600504 6 lwco sensor, ¾ npt 102305-01 7 1¼ x 3 nipple 806600005 8 1¼ elbow 806601528.

Page 14

14 disconnect electrical power to the boiler and heating system before servicing. Positively assure that no voltage is present. Lock electrical boxes to prevent someone from inadvertently restoring power before the heating system is safe to operate. Never defeat or jump out safety devices. Protect e...

Page 15

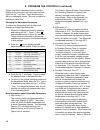

15 8. Program the controls intelligent hydronic control 8-b iq option panel 8-a using intelligent hydronic control display the intelligent hydronic control (control) is located inside the boiler front door, just above the iq option panel (figure 8-a). Intelligent hydronic control the control display...

Page 16

16 8. Program the controls (continued) please note that in operating mode to hold the display on the value the user can press and hold either the up ñ or down ò keys and the value will be continuously shown. This may be helpful in watching a value “live”. Changing the adjustable parameters to adjust...

Page 17

17 8. Program the controls (continued) table 8a: circulator pre-purge time example, (pp_ = 2 minutes) call for heat source dhw terminal selection boiler temperature burner status tt = on - start with no delay tt = on - >140 start after 2 minute delay dhw = on tt2 start with no delay dhw = on tt2 >14...

Page 18

18 b. When dh_ is set equal to second heating zone (tt2) when there is no iwh the “dhw circulator” output may be configured to control a second heating zone. This is particularly helpful when the home uses only two heating zones. The control replaces the need for a two circulator zone panel. When dh...

Page 19

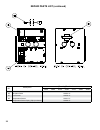

19 10-b 10. Perform startup checks and adjustments failure to perform these checks of the boiler's combustion and safety systems may result in serious property damage, injury, or death. If you smell gas, stop and repair the leak. Lighting the boiler when gas is leaking may cause explosion or fire. F...

Page 20

20 10. Perform startup checks and adjustments (continued) 12. Return high limit to the desired setting (see "programming high limit" in section 8). 13. Check draft. See appendix g – checking draft and combustion. Q no spillage observed. 14. Check combustion in the vent stack and record results in th...

Page 21

21 equipment you will need: q soft bristle brush q bristle flue brush q vacuum with brush attachment perform these tasks each year: 1. Clean low water cutoff probe (if applicable). Flush float-type low water cutoff (if applicable). 2. Inspect vent for obstruction and signs of condensation, distortio...

Page 22

22 annual maintenance checklist (continued) operating instructions, vr8204 and vr8304 gas valves am-2.

Page 23

23 before troubleshooting the following pages contain trouble shooting tables for use in diagnosing control problems. When using these tables the following should be kept in mind: 1. This information is only meant to be used by a professional heating technician as an aid in diagnosing boiler problem...

Page 24

24 troubleshooting (continued) use control display err (error) number to direct troubleshooting efforts if the control detects an error it will flash “err” (error) followed by a number. Use this number to identify the boiler problem and corrective action in the table below. If there is no err displa...

Page 25

25 troubleshooting (continued) use sta (status) number to guide troubleshooting the control will flash “sta” followed by a number. Use this number to identify the boiler problem in the table below: 1. Boiler and circulator off display / status recommended corrective action sta1 standby burner off ci...

Page 26

26 6. Circulator is on, damper is open but boiler fails to start display / status description sta 10 retry / recycle delay the boiler is in “retry delay”: - the burner failed to light (no flame signal). After a 5 minute delay, control will attempt to light the burner again. There is no limit to the ...

Page 27

27 display / status recommended corrective action sta 10 retry / recycle delay sta 13 soft lockout 1. No spark a. Can you hear sparking while sta 6 is displayed? - if there is no spark noise replace the control. B. If you can hear spark noise check the following: - loose connection in ignition cable...

Page 28

28 troubleshooting (continued) if control shows status code “sta 15": the control is “waiting for limit to close” and the display on the iq option panel should be the first place to check. The iq option panel display (lower display) will show one of the following status codes: if iq option panel dis...

Page 29

29 repair parts list key no. Description [quantity] part number 303b 304b 305b 306b 307b 308b 309b 1a block assembly 102287-03 102287-04 102287-05 102287-06 102287-07 102287-08 102287-09 1b canopy gasket kit 6206001 1c canopy assembly 102554-03 102554-04 102554-05 102554-06 102554-07 103860-08 10255...

Page 30

30 repair parts list (continued) key no. Description [quantity] part number 303b 304b 305b 306b 307b 308b 309b 2a base wrapper 71807031 71807041 71807051 71807061 71807071 71807081 71807091 2b base tray 102543-03 102543-04 102543-05 102543-06 102543-07 102543-08 102543-09 2c burner tray assembly 618...

Page 31

31 repair parts list (continued) key no. Description [quantity] part number 303b 304b 305b 306b 307b 308b 309b 3a gas valve (natural gas), honeywell vr8204p1171 81660282 n/a gas valve (natural gas), honeywell vr8304p4496 n/a 81660283 gas valve (lp gas), honeywell vr8204c3015 81660146 n/a gas valve (...

Page 32

32 repair parts list (continued) key no. Description [quantity] part number 303b 304b 305b 306b 307b 308b 309b 4a control 103660-01 4b iq option panel 102291-01 4c transformer 102516-01 4d temperature sensor 102411-01 temperature sensor spring clip (not shown) 102422-01.

Page 33

33 key no. Description [quantity] part number 303b 304b 305b 306b 307b 308b 309b 5a jacket left side panel 102566-01 5b jacket right side panel 102567-01 5c jacket rear panel 102569-03 102569-04 102569-05 102569-06 102569-07 102569-08 102569-09 5d jacket vestibule panel 102565-03 102565-04 102565-05...

Page 34

34 repair parts list (continued) key no. Description [quantity] part number 303b 304b 305b 306b 307b 308b 309b 6a supply water manifold 80607001 6b temperature/pressure gauge 100282-01 6c 30 psi relief valve 81660363 6d drain valve 102802-01 6e vent damper 102284-01 102284-02 102284-03 102284-04 102...

Page 35

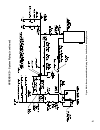

35 internal wiring figure iw-1: wiring diagram.

Page 36

36 internal wiring (continued) figure iw-2: wiring schematic.

Page 37

37 internal wiring (continued) figure iw-3: multiple zone system with zone circulators figure iw-4: multiple zone system with zone valves.

Page 38

38 internal wiring (continued) figure iw-5: multiple zone system with zone circulator panel t stat 1 valve 1 t stat 2 valve 2 t stat 3 off on zone 4 priority taco zvc 404 (or eqiv.) four zone zone valve control with optional priority thermostat boiler jacket panel 1 2 3 t t 1 1 4 2 3 5 6 7 8 2 3 lin...

Page 39

39 appendix a – combustion air provide enough air to ventilate the boiler room, dilute the flue gases, and sustain combustion. Ignition failure, overheating, fire, carbon monoxide, and spillage of flue gases may result from poor air supply. If the boiler is a direct vent boiler and exchanges all com...

Page 40

40 appendix b – venting vent this boiler according to the instructions. Failure to do so may cause products of combustion to enter the building resulting in severe property damage, personal injury or death. I install this boiler according to this manual and the national fuel gas code, ansi z223.1/nf...

Page 41

41 au moment du retrait d’une chaudière existante, les mesures suivantes doivent être prises pour chaque appareil toujours raccordé au système d’evacuation commun et qui fonctionne alors que d’autres appareils toujours raccordés au système d’évacuation ne fonctionnent pas: (1) sceller toutes les ouv...

Page 42

42 appendix b1 – atmospheric venting general warnings for atmospheric venting systems use atmospheric venting only with boilers approved for atmospheric venting as noted in the specifications section of this manual. Inspect existing chimney for obstructions and deterioration and repair or line the c...

Page 43

43 figure b-1: typical atmospheric vent installation install vent and vent connector (figure b-1). Vent installation shall be in accordance with "venting of equipment," of the national fuel gas code, ansi z223.1/nfpa 54, or "venting systems and air supply for appliances," of the natural gas and prop...

Page 44

44 appendix c – gas piping assure gas piping is leak free and of proper size and type for the connected load. Shut off main gas supply prior to installing or servicing boiler gas piping. 1. Determine the boiler’s maximum gas demand and minimum gas supply pressure (printed on the boiler’s rating labe...

Page 45

45 5. Bond all above-ground gas piping to a grounding electrode and ensure the piping is electrically continuous. Do not use gas piping as a grounding electrode. Refer to national electrical code, nfpa 70. 6. Install sediment trap, ground-joint union and manual shut-off valve upstream of boiler gas ...

Page 46

46 3. Overpressure (1) install a properly sized expansion tank. (2) do not exceed the boiler’s specific requirements for maximum allowable working pressure. (3) do not plug or block the relief valve. 4. Freezing (1) run all portions of the system piping inside a heated space unless the system is pro...

Page 47

47 appendix d – system piping (continued) figure d-w2: recommended w ater piping for zone v alve zoned h eating systems.

Page 48

48 appendix d – system piping (continued) figure d-w3: recommended w ater piping for circulator zoned h eating systems.

Page 49

49 appendix e – filling the system and checking for leaks fill entire heating system with water and vent air from system. Use the following procedure on a series loop or multi-zoned system installed as per the figure below. Remove air from system when filling. 1. Close full port ball valve located b...

Page 50

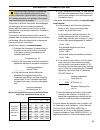

50 appendix f – adjusting gas input rate f-1 f-2 input ratings shown on boiler rating label can be used for elevations up to 2000 ft (600 m). United states. For elevations 2000 ft (600 m) or higher, reduce input rate 4 percent per 1000 ft (300 m) above sea level. Do not install at elevations above 1...

Page 51

51 appendix f – adjusting gas input rate (continued) do not force the adjustment screw. 4. Liquefiedpetroleumgases(lp/propane). Adjustgasvalvepressureregulatorto provideoutletpressureof10incheswater column. Or naturalgas.Adjustgasvalvepressure regulatortoprovideoutletpressureof3.5 incheswatercolumn....

Page 52

52 appendix g – checking draft and combustion check draft (gas boilers with draft hoods) 1. Insofar as is practical, close all doors and windows in the building. 2. Turn on all appliances not connected to the same venting system as the boiler being checked. 3. Turn on all exhaust fans (such as range...

Page 53

53 appendix h – operation boiler sequence of operation normal operation 1. The boiler is equipped with an intelligent hydronic control (control). This control replaces the traditional separate ignition control, high limit switch and circulator relay and adds energy saving thermal purge features. Ene...

Page 54

54 appendix i – iq control system iq control system overview the “iq control system” consists of a control and an iq option panel with optional “plug in” cards: • fully integrates both factory and field installed components, simplifying installation and troubleshooting. • efficiently operates the en...

Page 55

55 appendix i – iq control system (continued) iq outdoor reset option card: p/n 105648-01 installing the iq outdoor reset option card is the simplest way to maximize the efficiency of any boiler. The iq outdoor reset card is a microprocessor- based control that regulates the water temperature of the...

Page 56

56 appendix i – iq control system (continued) iq high limit option cards add auxiliary temperature limit-rated controls to boilers. High limit option cards plug into the iq option panel and connect to a system-mounted probe with a single molex connection. Iq high limit option cards feature an adjust...

Page 57

57 appendix i – iq control system (continued) part number item description 105648-01 outside reset iq option card, domestic hot water priority, for use with option control panel, with outside air temperature sensor with 60 inch lead, instructions, unit pack. No additional pipe fittings required. Con...

Page 58

58.

Page 59

59.

Page 60

60 u.S. Boiler company, inc. P.O. Box 3020 lancaster, pa 17604 1-888-432-8887 www.Usboiler.Net.