- DL manuals

- V2

- Gate Opener

- FORTECO

- Owner's Manual

V2 FORTECO Owner's Manual

ATTUATORE ELETTROMECCANICO 230V IRREVERSIBILE A

CREMAGLIERA PER CANCELLI SCORREVOLI FINO A 2200 KG

DI PESO

230V ELECTRO-MECHANICAL IRREVERSIBLE RACK

ACTUATOR FOR SLIDING GATES UP TO 2200 KG

OPERATEUR ELECTROMECANIQUE 230V IRREVERSIBLE A

CREMAILLERE POUR PORTAILS COULISSANTS JUSQU'A

2200 KG DE POIDS

MOTOR ELECTROMECANICO 230V IRREVERSIBLES A

CREMALLERA PARA PUERTAS CORREDERAS HASTA

2200 KG DE PESO

I

GB

F

E

FORTECO

IL n. 284-1

EDIZ. 04/07/2012

V2 S.p.A.

Corso Principi di Piemonte, 65/67

12035 RACCONIGI (CN) ITALY

tel. +39 01 72 81 24 11 - fax +39 01 72 84 050

info@

gatestore.co.uk

- www.

remotecontrolgates.co.uk

Summary of FORTECO

Page 1

Attuatore elettromeccanico 230v irreversibile a cremagliera per cancelli scorrevoli fino a 2200 kg di peso 230v electro-mechanical irreversible rack actuator for sliding gates up to 2200 kg operateur electromecanique 230v irreversible a cremaillere pour portails coulissants jusqu'a 2200 kg de poids ...

Page 3: Index

English 29 index important remarks..................................................................................................................................................30 conformity to regulations ..............................................................................................

Page 4: Important Remarks

English 30 important remarks for any installation problems please contact v2 s.P.A. Tel. (+39) 01 72 81 24 11 v2 s.P.A. Has the right to modify the product without previous notice; it also declines any responsibility to damage or injury to people or things caused by improper use or wrong installatio...

Page 5

English 31 technical specifications forteco 1200-230v forteco 1800-230v forteco 2200-230v gate maximum weight 1200 kg 1800 kg 2200 kg power supply 230vac / 50hz 230vac / 50hz 230vac / 50hz maximum power 600 w 650 w 800 w idling current 1.9 a 1,4 a 2 a full load current 3 a 3,2 a 4 a running capacito...

Page 6: Installation Of The Motor

English 32 installation of the motor preparatory steps carefully observe european regulations en12445 and en12453 (which replace uni 8612). Always check the following: • your gate should have a strong and suitable build; no wickets should be present on the sliding gate. • the sliding gate should not...

Page 7

English 33 fixing of the motor check the following points: 1. The motor must be on a levelled surface and perfectly parallel to the gate 2. The distance between pinion and rack must be 1 or 2 mm. If needed, adjust the 4 grains 3. The rack must be trued up with the pinion of the motor 4. The minimum ...

Page 8: Installation Layout

English 34 installation layout motor overriding system in case of absence of current, the gate can be released by operating on the motor: 1. Open the hatch of the lock j in front of the motor 2. Insert the key k in the lock and turn clockwise to open the hatch of the release on the side 3. Insert th...

Page 9: Unit

English 35 description of the control unit the digital control unit pd18 is an innovative v2 s.P.A. Product that guarantees a safe and reliable automation of sliding gates. The pd18 has been designed to realize a product that meets all kind of requirements, with a highly versatile control unit that ...

Page 10

English 36 safety ribbons the control unit considers two kinds of safety ribbons, depending on the terminal to which they are connected: • type 1 (fixed): they are mounted on walls or on other fixed obstacles that are approached by the gate doors during the opening phase. When type 1 safety ribbons ...

Page 11

English 37 stop for a better safety, you can fit a stop switch that will cause the immediate gate stop when activated. This switch must have a normally close contact that will get open in case of operation. In case the stop switch is operated while the gate is open, the automatic closing function wi...

Page 12: Electric Connections Table

English 38 p1 antenna p2 antenna shield p3 opening control for the connection of control devices with n.O. Contact p4 opening controls for pedestrian access for the connection of control devices with n.O. Contact p5 stop command. N.C. Contact p6 common (-) p7 photocells type 1. N.C. Contact p8 photo...

Page 13

English 39 programming wheel f1 = 10a.

Page 14: Control Panel

English 40 control panel when power is on, the control unit checks that display correctly operates by switching on all segments for 1.5 sec. 8.8.8.8 . Firmware version, e.G. Pr i.6 , will be viewed in the following 1.5 sec. Panel will be viewed upon completion of this test. The control panel represe...

Page 15: Loading Of Default

English 41 loading of default parameters if necessary, it is possible to restore all the parameters to their standard or default value (see table at the end) m warning: this procedure causes the loss of all the customized parameters, therefore it has been put outside the configuration menu, to reduc...

Page 16: Obstacle Sensor

English 42 obstacle sensor the pd18 control unit has two independent systems allowing detection of whether gate movement is impeded by obstacles. The first system is based on measurement of the current absorbed by the motor, and is available on all control units: an unexpected increase in current ab...

Page 17

English 43 opening time the motor will be operated for the setup time in the opening phase; in case there is an obstacle or the end of stroke operates, the control unit can stop the opening phase before the relevant time expires. Partial opening time (pedestrian access) when the control unit receive...

Page 18

English 44 gate direction this menu allows to invert the opening direction of the gate without swapping motor wires and limit switch ones. Dx the gate opens rightwards sx the gate opens leftwards m warning: “opening direction of gate” means the direction you see from the inside. Motor power this men...

Page 19

English 45 start command during the opening phase this menu allows fixing the control unit conduct in case it receives a start command during the opening phase. Paus the gate stops and goes to pause chiu the gate immediately starts closing no the gate go on with the opening phase (command is ignored...

Page 20

English 46 automatic closing during the automatic operation, the control unit will automatically close the gate when a set-up time expires. The start command, if enabled by st.Pa menu, allows closing the gate before the set up time expires. In semi-automatic operation, that is to say, if the automat...

Page 21

English 47 closing after transit during the automatic operation, the pause count down starts from the set up value each time a photocell operates during the pause. If the photocell operates during the opening time, this time will be immediately stored as pause time. This function allows having a fas...

Page 22

English 48 photocell 1 input this menu allows enabling the input for type 1 photocells, that is to say, photocells active both during the opening and closing phase (see paragraph “installation”). No input disabled (ignored by the control unit). No jumper with the common is required. Ap.Ch input enab...

Page 23

English 49 photocell 2 input this menu allows enabling the input for type 2 photocells, that is to say, photocells non active during the opening phase (see paragraph “installation”). No input disabled (ignored by the control unit). No jumper with the common is required. Cf.Ch input enabled even at s...

Page 24

English 50 end of stroke inputs pd18 control unit allows connecting magnetic limit switch which are activated by the door motion and showing to the control unit that each door reached its position of complete opening or closing. Si end of stroke inputs are enabled no end of stroke inputs are disable...

Page 25

English 51 anti-skid when an opening or closing operation is interrupted by a command or for the intervention of the photocell, the set-up time for the opposite movement would be excessive, so the control unit operates the motors only for the time necessary to recover the actually covered journey. T...

Page 26: Reading Of Cycle Counter

English 52 reading of cycle counter pd18 control unit counts the completed opening cycles of the gate and, if requested, it shows that service is required after a fixed number of cycles. There are two counters available: • a totalizing counter for completed opening cycles that cannot be zeroed (opti...

Page 27: Operation Defects

English 53 error 5 once given a start control, the gate does not open and the display shows err5 it means that the test of the safety edges failed. Check that the menu of the test of safety edges (co.Te) have been set correctly. Check that the safety edges enabled from the menu are installed. Error ...

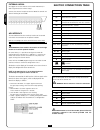

Page 28: Pd18 Function Table

English 54 pd18 function table display data description default memo data t.Ap 0.0" ÷ 5.0' gate opening time 22.5" t.App 0.0" ÷ t.Ap opening time of pedestrian gate 6.0" t.Ch 0.0" ÷ 5.0' gate closing time 23.5" t.Chp 0.0" ÷ t.Ch closing time of pedestrian gate 7.0" t.Pre 0.5" ÷ 1.0' pre-flashing tim...

Page 29: Pd18 Function Table

English display data description default memo data aus auxiliary channel tim - time working 1’00 bist - bistable working mon - monostable working lp.Pa no/si flashlight in pause no st.Rt operation modes stan stan - start inputs from terminal board are disabled no - standard operation ap.Ch - separat...