- DL manuals

- Vacon

- Controller

- 20 SERIES

- Applications Manual

Vacon 20 SERIES Applications Manual

Summary of 20 SERIES

Page 1

Vacon ® 20 x ac drives bh application manual.

Page 3

Vacon • 0 service support: find your nearest vacon service center at www.Vacon.Com index document id: dpd01381b rev. B version release date: 5.12.13 corresponds to application package acit1124v101.Vcx 1. Bh application ....................................................................................

Page 4

Vacon • 1 4. Fault tracing .................................................................................................. 64.

Page 5

Bh application vacon • 2 service support: find your nearest vacon service center at www.Vacon.Com 1 1. Bh a pplication the vacon ® 20 cp/x drive with +d option contains a preloaded application for instant use. The parameters of this application are listed in chapter 2.2 of this manual and explained ...

Page 6

Vacon • 3 bh application 1 1.2 asi board diagnostic this information is valid only for vacon ® 20x with +d option and as-interface connection. Monitor v1.3 shows the state of asi board, as numeric code. Visual information is provided by red fault led on the drive's cover. Off: no anomaly on: cumulat...

Page 7

Bh application vacon • 4 service support: find your nearest vacon service center at www.Vacon.Com 1 1.3 description of the terminals (d-option with as-interface) the following pictures describe the power and m12 terminals in vacon 20x drives with d-option and as-interface connection. 1.3.1 mu2 conne...

Page 8

Vacon • 5 bh application 1 x1 digital input / type m12 a-coding – 5 pole (female) pin function 1 +24v (25ma max.) 2 d input 1 3 gnd 4 d input 2 5 functional earth table 3. X1 connector, mu2. X2 digital input / type m12 a-coding – 5 pole (female) pin function 1 +24v (25ma max.) 2 d input 3 3 gnd 4 d ...

Page 9

Bh application vacon • 6 service support: find your nearest vacon service center at www.Vacon.Com 1 1.3.2 mu3 connections figure 2. Power and control terminals in mu3. Mains supply / type han q4/2 (male) pin function 1 l1 2 l2 3 l3 4 - 11 - 12 - pe protective earth table 6. Mains supply connector, m...

Page 10

Vacon • 7 bh application 1 x1 digital input / type m12 a-coding – 5 pole (female) pin function 1 +24v (25ma max.) 2 d input 1 3 gnd 4 d input 2 5 functional earth table 8. X1 connector, mu3. X2 digital input / type m12 a-coding – 5 pole (female) pin function 1 +24v (25ma max.) 2 d input 3 3 gnd 4 d ...

Page 11

Bh application vacon • 8 service support: find your nearest vacon service center at www.Vacon.Com 1 1.4 description of the terminals (d-option with profibus) the following pictures describe the power and m12 terminals in vacon 20x drives with d-option and profibus connection. 1.4.1 mu2 connections f...

Page 12

Vacon • 9 bh application 1 x1 digital input / type m12 a-coding – 5 pole (female) pin function 1 +24v (25ma max.) 2 d input 1 3 gnd 4 d input 2 5 functional earth table 13. X1 connector, mu2. X2 digital input / type m12 a-coding – 5 pole (female) pin function 1 +24v (25ma max.) 2 d input 3 3 gnd 4 d...

Page 13

Bh application vacon • 10 service support: find your nearest vacon service center at www.Vacon.Com 1 1.4.2 mu3 connections figure 4. Power and control terminals in mu3. Mains supply / type han q4/2 (male) pin function 1 l1 2 l2 3 l3 4 - 11 - 12 - pe protective earth table 18. Mains supply connector,...

Page 14

Vacon • 11 bh application 1 x1 digital input / type m12 a-coding – 5 pole (female) pin function 1 +24v (25ma max.) 2 d input 1 3 gnd 4 d input 2 5 functional earth table 20. X1 connector, mu3. X2 digital input / type m12 a-coding – 5 pole (female) pin function 1 +24v (25ma max.) 2 d input 3 3 gnd 4 ...

Page 15

Description of groups vacon • 12 service support: find your nearest vacon service center at www.Vacon.Com 2 2. D escription of g roups 2.1 monitor group: menu mon vacon ® 20 cp/x ac drive provides you with a possibility to monitor the actual values of pa- rameters and signals as well as statuses and...

Page 16

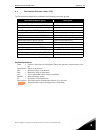

Vacon • 13 description of groups 2 2.1.4 drive table 28: drive monitoring items. Code monitoring value unit id level description v4.1 dc link voltage v 7 advanced v4.2 unit temperature °c 8 advanced heatsink temperature v4.3 board temperature °c 1825 service power board temperature v4.4 actual outpu...

Page 17

Description of groups vacon • 14 service support: find your nearest vacon service center at www.Vacon.Com 2 2.2 parameter groups: menu par the decentralized application embodies the following parameter groups: table 29: parameter groups column explanations: code = location indication on the keypad; ...

Page 18

Vacon • 15 description of groups 2 2.2.1 group motor settings: menu par g1 code parameter min max unit default id level description p1.1 motor nominal voltage 120 500 v 400 110 basic find this value u n on the rating plate of the motor. This parame- ter sets the voltage at the field weakening point ...

Page 19

Description of groups vacon • 16 service support: find your nearest vacon service center at www.Vacon.Com 2 2.2.2 group start/stop settings: menu par g2 code parameter min max unit default id level description p2.1 auto start/stop logic 0 3 0 300 basic logic = 0: start sgn 1 = start forward start sg...

Page 20

Vacon • 17 description of groups 2 2.2.3 group references: menu par g3 code parameter min max unit default id level description p3.1 minimum frequency 0.00 p3.2 hz 0.00 101 basic minimum allowed frequency reference p3.2 maximum frequency p3.1 320.00 hz 50.00 102 basic maximum allowed frequency refer...

Page 21

Description of groups vacon • 18 service support: find your nearest vacon service center at www.Vacon.Com 2 p3.19 manual reference selection 0 2 1 3) 1820 advanced selection of manual reference source: 0 = manual preset speed 1 = panel potentiom- eter 2 = manual preset speed + panel poten- tiometer ...

Page 22

Vacon • 19 description of groups 2 2.2.4 group ramps: menu par g4 code parameter min max unit default id level description p4.1 acceleration time 1 0.1 3000.0 s 3.0 103 basic defines the time required for the output frequency to increase from zero fre- quency to maximum fre- quency p4.2 deceleration...

Page 23

Description of groups vacon • 20 service support: find your nearest vacon service center at www.Vacon.Com 2 2.2.5 group input functions: menu par g5 code parameter min max unit default id level description p5.1 start signal 1 0 8 1 403 basic start signal 1 when control place is i/o 1 (fwd) see p2.1 ...

Page 24

Vacon • 21 description of groups 2 2.2.6 group output functions: menu par g6 code parameter min max unit default id level description p6.1 asi input 1 0 17 5 1881 basic bit0 transmitted on asi bus 0: not used 1: sensor 1 2: sensor 2 3: sensor 3 4: sensor 4 5: ready + auto 6: run 7: fault 8: fault or...

Page 25

Description of groups vacon • 22 service support: find your nearest vacon service center at www.Vacon.Com 2 2.2.7 group mechanical brake: menu par g7 note! 1) when automatic mode is not assigned to any input, running feedback includes also information about automatic. 2) relay terminals are not acce...

Page 26

Vacon • 23 description of groups 2 2.2.8 group supervisions: menu par g8 code parameter min max unit default id level description p8.1 running ok speed tolerance 0.0 100.0 % 90.0 1880 advanced p8.2 output frequency supervision 0 2 2 315 advanced 0 = not used 1 = low limit 2 = high limit p8.3 frequen...

Page 27

Description of groups vacon • 24 service support: find your nearest vacon service center at www.Vacon.Com 2 2.2.9 group motor control: menu par g9 code parameter min max unit default id level description p9.1 field weakening point frequency 8.00 320.00 hz 50.00 602 advanced field weakening point fre...

Page 28

Vacon • 25 description of groups 2 2.2.10 group protections: menu par g10 parameters of motor thermal protection (p10.9 to p10.12 and p10.18-p10.19) the motor thermal protection is to protect the motor from overheating. The drive is capable of supplying higher than nominal current to the motor. If t...

Page 29

Description of groups vacon • 26 service support: find your nearest vacon service center at www.Vacon.Com 2 the torque values for setting the underload curve are set in percentage which refers to the nominal torque of the motor. The motor's name plate data, parameter motor nominal current and the dr...

Page 30

Vacon • 27 description of groups 2 2.2.11 group automatic reset: menu par g11 p10.12 motor thermal time constant 1 200 min 45 707 advanced the time constant is the time within which the calculated thermal stage has reached 63% of its final value. P10.13 fieldbus communica- tion fault 0 2 1 733 advan...

Page 31

Description of groups vacon • 28 service support: find your nearest vacon service center at www.Vacon.Com 2 2.2.12 group non-asi fieldbus: menu par g12 code parameter min max unit default id level description p12.1 fieldbus data out 1 selection 0 10 0 852 basic / service 2) variable mapped on pd1: 0...

Page 32

Vacon • 29 description of groups 2 2.2.13 group analogue output: menu par g13 2.2.14 group user interface: menu par g14 code parameter min max unit default id level description p13.1 ao1 function 0 6 2 307 service 0 = not used (fixed 100%) 1 = freq. Reference (0-fmax) 2 = output freq. (0 -fmax) 3 = ...

Page 33

Description of groups vacon • 30 service support: find your nearest vacon service center at www.Vacon.Com 2 2.3 system parameters, faults and history faults: menu flt code parameter min max unit defa ult id description v1.1 api system sw id 2314 v1.2 api system sw version 835 v1.3 power sw id 2315 v...

Page 34

Vacon • 31 description of groups 2 p2.5 input assembly type 70 117 71 14013 when opte3/e5(profibus) option board has been installed, the following values are visible: v2.1 profibus communication sta- tus 14022 p2.2 fieldbus protocol 14023 p2.3 active protocol 14024 p2.4 active baud rate 14025 p2.5 t...

Page 35

Description of groups vacon • 32 service support: find your nearest vacon service center at www.Vacon.Com 2 2.4 keypad reference: menu ref this menu is not used even if it is automatically entered when pressing the loc/rem keypad and shows the frequency reference in local control mode. The reference...

Page 36

Vacon • 33 description of groups 2.

Page 37

Parameter description vacon • 34 service support: find your nearest vacon service center at www.Vacon.Com 3 3. P arameter description due to its user-friendliness and simplicity of use, the most parameters only require a basic de- scription which is given in the parameter tables in chapter 2.2. In t...

Page 38

Vacon • 35 parameter description 3 the parameter sets the speed variation (as % of nominal speed) when the motor is at 100% load. Normally droop action is decreased when the motor is running at low speed. Parameter p9.9 allows to set a speed independent droop. P1.10 m otor identification this proced...

Page 39

Parameter description vacon • 36 service support: find your nearest vacon service center at www.Vacon.Com 3 3.2 start/stop settings p2.1 s tart /d irection logic auto start/direction logic these logics are based on start1 and start2 signals (defined with p5.1 and p5.2), which allow the control of ru...

Page 40

Vacon • 37 parameter description 3 p2.5 q uick stop mode quick stop is activated through the input signal defined in p5.14 (or p5.15). Signal low (or high) forces the drive to stop, ramping down with the time defined in p4.9. The ramp to zero is continued also in case the signal returns high (or low...

Page 41

Parameter description vacon • 38 service support: find your nearest vacon service center at www.Vacon.Com 3 3.3 references p3.1 m in frequency minimum frequency reference, for automatic control. Manual control allows a different mini- mum. Note: if motor current limit is reached, actual output frequ...

Page 42

Vacon • 39 parameter description 3 p3.14 m ot p ot s tep down variation of reference at any inc/dec signals edge, when drive is in run state. Reference is anyway limited between p 3.1 and p 3.2 values. P3.15 m ot p ot in r everse 0: same reference used in forward 1: different reference p3.16 m ot p ...

Page 43

Parameter description vacon • 40 service support: find your nearest vacon service center at www.Vacon.Com 3 p3.23 p anel p otentiometer min correction p3.24 p anel p otentiometer max correction define the minimum and maximum correction on preset reference, controlled with potentiom- eter on panel. 3...

Page 44

Vacon • 41 parameter description 3 p4.4 a cceleration time 2 p4.5 d eceleration time 2 p4.6 r amp 2 s shape ramp 2 is available only in automatic mode, and is activated through digital signal defined in p5.11. Automatic activation based on output frequency is also available. P4.7 t hreshold a cceler...

Page 45

Parameter description vacon • 42 service support: find your nearest vacon service center at www.Vacon.Com 3 3.5 input functions p5.1 s tart signal 1 p5.2 s tart signal 2 signals for start and direction. Logic is selected with p2.1. 0: function not used 1: asi output 1 2: asi output 2 3: asi output 3...

Page 46

Vacon • 43 parameter description 3 p5.8 e xternal fault , close fault is triggered by high signal. P5.9 e xternal fault , open fault is triggered by low signal. P5.10 r un e nable motor stops by coasting if the signal is missing. Note: the drive is not in ready state when enable is low. P5.11 r amp ...

Page 47

Parameter description vacon • 44 service support: find your nearest vacon service center at www.Vacon.Com 3 3.6 output functions p6.1 as i i nput 1 p6.2 as i i nput 2 p6.3 as i i nput 3 p6.4 as i i nput 4 meaning of asi input bit. 0: not used 1: sensor 1 2: sensor 2 3: sensor 3 4: sensor 4 5: ready ...

Page 48

Vacon • 45 parameter description 3 p6.5 ro1 signal selection p6.6 ro2 signal selection function for internal relays. 0: not used 1: ready 2: run 3: fault 4: fault inverted 5: fault or warning 6: reverse 7: at speed (motor control feedback) 8: output freq superv 9: output current superv 10: asi outpu...

Page 49

Parameter description vacon • 46 service support: find your nearest vacon service center at www.Vacon.Com 3 3.7 mechanical brake p7.1 b rake open frequency p7.2 b rake open current thresholds that must be reached for external brake open at start. If p7.1 > 0hz, frequency reference is internally limi...

Page 50

Vacon • 47 parameter description 3 3.8 supervisions p8.1 r unning feedback tolerance when output frequency has reached this percentage of reference, running feedback is set high. P8.2 f requency supervision function 0: no supervision 1: low limit 2: high limit p8.3 f requency supervision limit thres...

Page 51

Parameter description vacon • 48 service support: find your nearest vacon service center at www.Vacon.Com 3 3.9 motor control p9.1 f ield weakening point output frequency corresponding to max voltage. Note: if p1.2 nominal frequency is changed, p9.1 will be set at same value. P9.2 f ield weakening p...

Page 52

Vacon • 49 parameter description 3 2: programmable the u/f curve can be programmed with three different points: zero frequency voltage (p1), midpoint voltage/frequency (p2) and field weakening point (p3). Programmable u/f curve can be used if more torque is needed at low frequencies. The optimal set...

Page 53

Parameter description vacon • 50 service support: find your nearest vacon service center at www.Vacon.Com 3 note: it is suggested not to program manually the value, but to perform motor identification procedure that automatically sets the value. P9.8 s witching frequency pwm frequency. Values above ...

Page 54

Vacon • 51 parameter description 3 p9.18 undervoltage regulator undervoltage regulator automatically decelerates the motor if the internal dc link voltage is too low. 0: enabled 1: disabled p9.19 switching frequency regulator switching frequency regulator automatically decreases the pwm frequency if...

Page 55

Parameter description vacon • 52 service support: find your nearest vacon service center at www.Vacon.Com 3 3.10 protections p10.1 e arth fault 0: no action 1: warning 2: fault output currents sum not zero. P10.2 m otor s tall fault 0: no action 1: warning 2: fault this is an overload protection. St...

Page 56

Vacon • 53 parameter description 3 figure 9. Stall time count. P10.4 s tall frequency limit stall is recognized when the current limiter has reduced the output frequency below p10.4, for the time in p10.3. P10.5 u nderload fault 0: no action 1: warning 2: fault underload is recognized when torque is...

Page 57

Parameter description vacon • 54 service support: find your nearest vacon service center at www.Vacon.Com 3 figure 10. Underload characteristic settings. P10.7 u nderload fault : zero frequency load p10.8 u nderload fault : time limit definition of minimum load at nominal and zero speed zero. Fault ...

Page 58

Vacon • 55 parameter description 3 p10.9 m otor thermal fault 0: no action 1: warning 2: fault this is a software protection, based on time integral of current. P10.10 m otor ambient temperature factor change if environment is not standard. P10.11 m otor thermal zero speed cooling defines the coolin...

Page 59

Parameter description vacon • 56 service support: find your nearest vacon service center at www.Vacon.Com 3 p10.12 m otor thermal time constant time at nominal current, to reach nominal temperature. The time constant is the time within which the calculated thermal stage has reached 63% of its final ...

Page 60

Vacon • 57 parameter description 3 p10.15 r esponse to s afe t orque o ff 0: no action 1: warning 2: fault, not stored in history 3: fault, stored in history safe torque off disabled. P10.16 i nput phase fault 0: no action 1: warning 2: fault input phase missing. P10.17 i nput phase fault ripple lim...

Page 61

Parameter description vacon • 58 service support: find your nearest vacon service center at www.Vacon.Com 3 3.11 automatic reset p11.1 automatic reset 0: disabled 1: enabled the automatic reset function deletes fault state when the fault cause has been eliminated and the wait time p11.2 has elapsed....

Page 62

Vacon • 59 parameter description 3 3.12 non-asi fieldbus p12.1 to p12.8 f ieldbus d ata out 1 - 8 sel parameter couples read only variables to output process data 1. 0: not used 1: output frequency 2: motor speed 3: motor current 4: motor voltage 5: motor torque 6: motor power 7: dc link voltage 8: ...

Page 63

Parameter description vacon • 60 service support: find your nearest vacon service center at www.Vacon.Com 3 3.12.1 modbus fieldbus mapping 3.12.1.1 fieldbus data in: master -> slave notes: • cw b0 run is acquired on edge, only if the drive is in ready state (see status word b0) and actual control pl...

Page 64

Vacon • 61 parameter description 3 3.12.1.2 fieldbus data out: slave ->master notes: • fieldbus different from modbus have their own status word (see manual of the specific fieldbus board). Modbus register name description range 2101 status word drive state binary coded: b0: ready b1: run b2: revers...

Page 65

Parameter description vacon • 62 service support: find your nearest vacon service center at www.Vacon.Com 3 3.13 analogue output p13.1 a nalogue output function signal coupled to analogue output. P13.2 a nalogue output minimum signal 0: 0v 1: 2v p13.3 a nalogue output scaling scaling factor. P13.4 a...

Page 66

Vacon • 63 parameter description 3.

Page 67

Fault tracing vacon • 64 service support: find your nearest vacon service center at www.Vacon.Com 4 4. F ault tracing fault code fault name possible cause remedy 1 overcurrent ac drive has detected too high a cur- rent (>4*i h ) in the motor cable: • sudden heavy load increase • short circuit in mot...

Page 68

Vacon • 65 fault tracing 4 16 motor overtem- perature motor is overloaded. Decrease motor load. If no motor overload exists, check the temperature model parame- ters. 17 motor under- load motor is under loaded check load. 19 power overload supervision for drive power drive power is to high: decrease...

Page 69

Fault tracing vacon • 66 service support: find your nearest vacon service center at www.Vacon.Com 4 63 quick stop quick stop activated the drive has been stopped with quick stop digital input or quick stop command by fieldbus 64 asi communi- cation not ok asi board is not working properly. Check the...

Page 72

Document id: rev. B manual authoring: documentation@vacon.Com vacon plc. Runsorintie 7 65380 vaasa finland subject to change without prior notice © 2013 vacon plc. Find your nearest vacon office on the internet at: www.Vacon.Com.