Summary of FI4

Page 1

Vacon nxi inverters fi4-fi8 user manual ®.

Page 3

Vacon • 1 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com at least the 10 following steps of the start-up quick guide must be performed during the installation and commissioning. If any problems occur, please contact your local distributor. Start-up quick guide 1. Check that the delive...

Page 4

2 • vacon tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 contents vacon nxi user’s manual index 1 safety 2 eu directive 3 receipt of delivery 4 technical data 5 installation 6 cabling and connections 7 control keypad 8 commissioning 9 fault tracing.

Page 5

Vacon • 3 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com about the vacon nxi user's manual and the ”all in one” application manual congratulations for choosing vacon nx inverters! The user's manual will provide you with the necessary information about the installation, commissioning a...

Page 6

4 • vacon tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 vacon nx user's manual document code: dpd00908b date: 11.12.2015 index 1. Safety ........................................................................................................................ 6 1.1 warnings ..........................

Page 7

Vacon • 5 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 6.1.3 cable installation and the ul standards ......................................................................... 36 6.1.4 cable and motor insulation checks ....................................................................

Page 8

6 • vacon safety tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 1 1. Safety 1.1 warnings 1 the components of the power unit of the inverter are live when the vacon nx is connected to dc supply. Coming into contact with this voltage is extremely dangerous and may cause death or severe injury. The ...

Page 9

Safety vacon • 7 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 1 1.3 earthing and earth fault protection the vacon nx inverter must always be earthed with an earthing conductor connected to the earthing terminal. The earth fault protection inside the inverter only protects the invert...

Page 10

8 • vacon eu directive tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 2 2. Eu directive 2.1 ce marking the ce marking on the product guarantees the free movement of the product within the eea (european economic area). It also guarantees that the product complies with applicable directives (for ex...

Page 11

Receipt of delivery vacon • 9 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 3 3. Receipt of delivery vacon nx inverters have undergone scrupulous tests and quality checks at the factory before they are delivered to the customer. However, after unpacking the product, check that no sig...

Page 12

10 • vacon receipt of delivery tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 3 3.1.2 the standard features of nx inverters inu sales code nxi_aaaa 5/6 standard features fr4, fr6 and fr7 dc connection ip21 air cooling integrated charging alphanumeric control panel (in the front of the module) i/o...

Page 13

Receipt of delivery vacon • 11 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.2 storage if the inverter is to be stored before use, make sure that the ambient conditions are acceptable: storage temperature –40…+70 c relative humidity if the inverter is stored for over 12 months, c...

Page 14

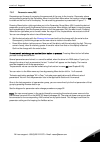

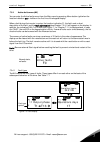

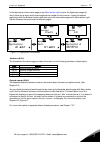

12 • vacon technical data tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 4 4. Technical data 4.1 introduction the figure below presents the block diagram of the vacon nx inverter. The inverter mechanically consists of two units, the power unit and the control unit. The power unit contains an inve...

Page 15

Technical data vacon • 13 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 4 the control keypad constitutes a link between the user and the inverter. The control keypad is used for parameter setting, reading status data and giving control commands. It is detachable and can be operated e...

Page 16

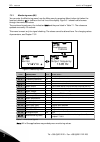

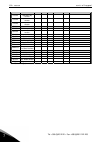

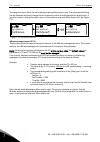

14 • vacon technical data tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 4 4.2 power ratings 4.2.1 vacon nxi_xxxx 5 – supply voltage 465-800 vdc, motor voltage 380—500 vac high overload = max current is, 2 sec/20 sec, 150% overloadability, 1 min/10 min following continuous operation at rated outp...

Page 17

Technical data vacon • 15 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 4 4.2.2 vacon nxi_xxxx 6 – supply voltage 640-1100 vdc, motor voltage 525—690 vac high overload = max current is, 2 sec/20 sec, 150% overloadability, 1 min/10 min following continuous operation at rated output cu...

Page 18

16 • vacon technical data tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 4 4.3 technical information dc connection input voltage u in 465...800vdc; 640...1100vdc; –0%…+0% , the ripple voltage of the inverter supply voltage generated during the rectification of the fundamental frequency ac voltage...

Page 19

Technical data vacon • 17 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 4 control connections analogue input voltage 0…+10v, r i = 200k , (–10v…+10v joystick control) resolution 0.1%, accuracy ±1% analogue input current 0(4)…20 ma, r i = 250 differential digital inputs (6) positive o...

Page 20

18 • vacon technical data tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 4 structure inom (output) motor cos idc (input) fr6 4.5 0.81 4.7 5.5 0.82 5.9 7.5 0.83 8.1 10.0 0.84 10.9 13.5 0.85 14.9 18.0 0.85 19.9 22.0 0.86 24.6 27.0 0.86 30.2 34.0 0.86 38.1 fr7 41.0 0.87 46 52.0 0.87 59 fr8 62.0 0.87...

Page 21

Installation vacon • 19 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 5 5. Installation 5.1 mounting the inverter can be mounted in either a vertical or horizontal position on a wall or on the back plane of a cubicle. Enough space must be reserved around the inverter to ensure suffic...

Page 22

20 • vacon installation tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 5 figure 5-1. The dimensions of vacon nx, ip21 type dimensions [mm] w1 w2 h1 h2 h3 d1 e1 nxi_0004—0012 5 128 100 327 313 292 190 7 3 x 28.3 nxi_0016—0045 5 nxi_0004—0034 6 195 148 558 541 519 237 9 3 x 37 nxi_0061—0105 5 nxi_0...

Page 23

Installation vacon • 21 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 5 figure 5-2. Vacon nx dimensions, ip21 with flange, fr4 and fr6 type dimensions [mm] w1 w2 h1 h2 h3 h4 h5 d1 d2 nxi_0004—0012 5 128 113 337 325 327 30 22 190 77 7 nxi_0016—0045 5 nxi_0004—0034 6 195 170 560 549 55...

Page 24

22 • vacon installation tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 5 figure 5-3. The opening needed for flange mounting, fr4 and fr6 type dimensions [mm] w1 w2 w3 h1 h2 h3 h4 nxi_0004—0012 5 123 113 – 315 325 – 5 6.5 nxi_0016—0045 5 nxi_0004—0034 6 185 170 157 539 549 7 5 6.5 table 5-3. Dimen...

Page 25

Installation vacon • 23 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 5 figure 5-4. Vacon nx dimensions, ip21 with flange, fr4 and fr6 type dimensions [mm] w1 w2 w3 w4 h1 h2 h3 h4 h5 h6 h7 d1 d2 nxi_0061—0105 5 nxi_0041—0052 6 237 175 270 253 652 632 630 188.5 188.5 23 20 257 117 5.5...

Page 26

24 • vacon installation tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 5 figure 5-5. The opening needed for flange mounting, fr7/fr8 type dimensions [mm] w1 w2 w3 h1 h2 h3 h4 h5 h6 nxi_50061—0105 nxi_0041—0052 6 233 175 253 619 188.5 188.5 34.5 32 7 5.5 nxi_0140 5 nxi_0062—0100 6 301 – 330 810 25...

Page 27

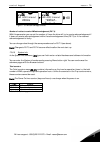

Installation vacon • 25 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 5 c a nk5_2 a 2 a 2 d b a b 5.2 fan cooling 5.2.1 frames fr4 to fr8 enough free space must be left around the inverter to ensure sufficient air circulation and cooling. You will find the required dimensions for fre...

Page 28

26 • vacon installation tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 5 5.2.2 power losses as function of switching frequency raising the switching frequency of the drive, to reduce motor noise for example, inevitably affects the power losses and cooling requirements as shown in the figure below...

Page 29

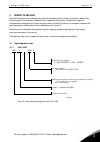

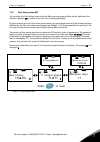

Cabling and connections vacon • 27 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 6 6. Cabling and connections 6.1 power unit the following wiring diagrams show the supply and motor connections. Figure 6-1. The basic wiring diagram pe u v w m b+ b- dc+ dc- b+.

Page 30

28 • vacon cabling and connections tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 6 6.1.1 power connections 6.1.1.1 dc supply and motor cables the power cables are connected to terminals dc+ and dc- (r+/b+ and dc terminals when using an external charging circuit) and the motor cables to terminals...

Page 31

Cabling and connections vacon • 29 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 6 6.1.1.3 fuses, nxi_xxxx 5 frame type i l [a] bussman ar fuse type fuse size fuse u n [v] fuse i n [a] no. Of fuses fr4 nxi_0004 4.3 170m1560 000 690 20 2 fr4 nxi_0009 9 170m1565 000 690 63 2 fr4 nxi_00...

Page 32

30 • vacon cabling and connections tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 6 6.1.1.5 cable sizes, nxi_xxxx 5 frame type i l [a] supply cable cu [mm 2 ] motor cable cu [mm 2 ] terminal cable size main terminal [mm 2 ] earth terminal [mm 2 ] fr4 nxi_0004 5—0009 5 3—9 2*1.5 3*1.5+1.5 1—4 1—2....

Page 33

Cabling and connections vacon • 31 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 6 6.1.2 installation instructions 1 before starting the installation, check that none of the components of the inverter are live. 2 if the inverter is installed outside the cubicle, cabinet or device spa...

Page 34

32 • vacon cabling and connections tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 6 5 connect the cables: strip the motor and dc supply cables as advised in figure 6-2 and table 6-6. Remove the screws of the cable protection plate. Do not open the cover of the power unit! Make holes into and pass...

Page 35

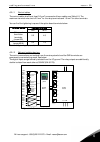

Cabling and connections vacon • 33 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 6 6.1.2.1 stripping lengths of motor and dc supply cables figure 6-2. Stripping of cables frame size c1 d1 a2 b2 c2 d2 fr4 10 20/70 7 50 7 35 fr6 15 60/80 20 90 15 60 fr7 25 120/140 25 120 25 120 fr8 014...

Page 36

34 • vacon cabling and connections tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 6 6.1.2.2 vacon nx frames figure 6-3. Vacon nxi, fr4 figure 6-4. Vacon nxi, fr6, protection class ip21.

Page 37

Cabling and connections vacon • 35 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 6 figure 6-5. Vacon nxi, fr7. Protection class ip21 figure 6-6. Vacon nxi, fr8. Protection class ip00

Page 38

36 • vacon cabling and connections tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 6 6.1.3 cable installation and the ul standards to meet the ul (underwriters laboratories) regulations, a ul-approved copper cable with a minimum heat-resistance of +60/75 c must be used. The tightening torques of t...

Page 39

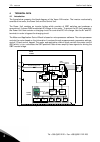

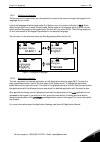

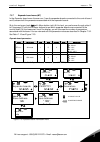

Cabling and connections vacon • 37 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 6 6.2 control unit the control unit of the inverter consists of the control board and option boards (see figure 6-7 and figure 6-20) connected to the five slot connectors (a to e) on the control board. T...

Page 40

38 • vacon cabling and connections tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 6 dotted line indicates the connection with inverted signal levels 24 v g nd 24 v gnd u i + 0(4) /2 0ma rl basic i/o board nxopta1 +10vref aia1+ gnd aia2+ aia2- 24vout gnd dia1 dia2 dia3 cma 24vout gnd dib4 dib5 dib...

Page 41

Cabling and connections vacon • 39 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 6 6.2.1.1 control cables the control cables shall be at least 0.5 mm 2 screened multicore cables, see table 6-8. The maximum terminal wire size is 2.5 mm 2 for the relay terminals and 1.5 mm 2 for other ...

Page 42

40 • vacon cabling and connections tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 6 6.2.2 control terminal signals terminal signal technical information 1 +10 vref reference voltage maximum current 10 ma 2 ai1+ analogue input, voltage or current selection v or ma with jumper block x1 (see page 43...

Page 43

Cabling and connections vacon • 41 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 6 nxopta2 21 ro1/1 relay output 1 switching capacity 24vdc/8a 250vac/8a 125vdc/0.4a min.Switching load 5v/10ma 22 ro1/2 23 ro1/3 24 ro2/1 relay output 2 switching capacity 24vdc/8a 250vac/8a 125vdc/0.4a ...

Page 44

42 • vacon cabling and connections tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 6 6.2.2.2 jumper selections on the nxopta1 basic board the user can customise the functions of the inverter to better suit his needs by selecting certain positions for the jumpers on the nxopta1 board. The positions...

Page 45

Cabling and connections vacon • 43 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 6 figure 6-15. Jumper selection for nxopta1 ensure that the jumper positions are correct. Running the motor with signal settings that differ from the jumper positions will not harm the inverter but may h...

Page 46

44 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 7. Control keypad the control keypad is the link between the vacon inverter and the user. The vacon nx control keypad features an alphanumeric display with seven indicators for the run status (run, , ready, stop, alarm, fa...

Page 47

Control keypad vacon • 45 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 alarm = indicates that the drive is running outside a certain limit and a warning is given. Fault = indicates that unsafe operating conditions were encountered due to which the drive was stopped. 7.1.2 control ...

Page 48

46 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 7.1.4 text lines the three text lines ( , , ) provide the users with information on their present location in the keypad menu structure as well as with information related to the operation of the drive. = location indicato...

Page 49

Control keypad vacon • 47 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 7.2 keypad push-buttons the vacon alphanumeric control keypad has 9 push-buttons that are used for controlling the inverter (and motor), setting parameters, and monitoring values. Figure 7-1 keypad push-buttons...

Page 50

48 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 = menu button right move forward in menu. Move cursor right (in parameter menu). Enter edit mode. = start button pressing this button starts the motor if the keypad is the active control place. See chapter 7.3.3. = stop bu...

Page 51

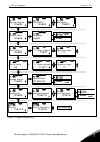

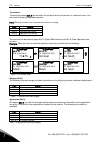

Control keypad vacon • 49 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 figure 7-2 keypad navigation chart f t1 t7 stop fault i/ote rm stop i/ote rm fault h1 h3 ready i/oterm t1 t7 i/ote rm ready i/oterm ready s1 s9 stop r eady i/oterm stop r eady i/ote rm enter g1 g5 ready i/oterm...

Page 52

50 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 7.3.1 monitoring menu (m1) you can enter the monitoring menu from the main menu by pressing menu button right when the location indication m1 is visible on the first line of the display. Figure 3-1 shows how to browse thro...

Page 53

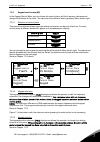

Control keypad vacon • 51 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 7.3.2 parameter menu (m2) parameters are the way of conveying the commands of the user to the inverter. Parameter values can be edited by entering the parameter menu from the main menu when the location indicat...

Page 54

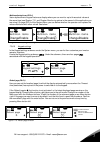

52 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 figure 7-1. Parameter value change procedure g1 g8 ready ke ypad p1 p18 ready ke ypad 13.95 hz ready keypad g1 g8 keypa d ready keypad 13.95 hz enter ready keypad 14.45 hz parameters basic parameters min frequency input si...

Page 55

Control keypad vacon • 53 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 7.3.3 keypad control menu (m3) in the keypad control menu , you can choose the control place, edit the frequency reference and change the direction of the motor. You can enter the submenu level by pressing menu...

Page 56

54 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 7.3.3.4 stop button activated by default, pushing the stop button will always stop the motor regardless of the selected control place. You can disable this function by giving parameter 3.4 the value 0. If the value of this...

Page 57

Control keypad vacon • 55 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 7.3.4 active faults menu (m4) you can enter the active faults menu from the main menu by pressing menu button right when the location indication m4 is visible on the first line of the keypad display. When a fau...

Page 58

56 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 fault type symbol meaning a (alarm) this type of fault is a sign of an unusual operating condition. It does not cause the drive to stop, nor does it require any special actions. The 'a fault' remains in the display for abo...

Page 59

Control keypad vacon • 57 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 7.3.4.2 fault codes the fault codes, their causes and correcting actions are presented in the table below. The shadowed faults are a faults only. The items in white on black background are faults for which you ...

Page 60

58 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 fault code fault possible cause correcting measures 14 inverter overtemperature heatsink temperature is over 90 c or 77ºc (nx_6, fr6). Overtemperature warning is issued when the heatsink temperature exceeds 85 c (72ºc). Ch...

Page 61

Control keypad vacon • 59 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 fault code fault possible cause correcting measures 43 encoder fault note the exceptional fault data record. See 7.3.4.3. Additional codes: 1 = encoder 1 channel a is missing 2 = encoder 1 channel b is missing ...

Page 62

60 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 7.3.4.3 fault time data record when a fault occurs, the information described in chapter 7.3.3.4 is displayed. By pressing menu button right, you will enter the fault time data record menu indicated by t.1 t.#. In this men...

Page 63

Control keypad vacon • 61 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 7.3.5 fault history menu (m5) you can enter the fault history menu from the main menu by pressing menu button right when the location indication m5 is visible on the first line of the keypad display. All faults...

Page 64

62 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 7.3.6 system menu (m6) you can enter the system menu from the main menu by pressing menu button right when the location indication m6 is visible on the first line of the keypad display . The controls associated with the ge...

Page 65

Control keypad vacon • 63 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 system menu functions code function min max unit default cust selections s6.1 selection of language english english deutsch suomi svenska italiano s6.2 application selection basic application basic application ...

Page 66

64 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 code function min max unit default cust selections t6.8.2.3 operation day counter t6.8.2.4 operation hour counter t6.8.2.5 clear operation hour counter s6.8.3 software information s6.8.3.1 software package s6.8.3.2 system ...

Page 67

Control keypad vacon • 65 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 7.3.6.1 selection of language the vacon control keypad offers you the possibility to control the inverter through the keypad in the language of your choice. Locate the language selection page under the system m...

Page 68

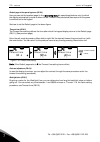

66 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 figure 7-6. Change of application 7.3.6.3 copy parameters the parameter copy function is used when the operator wants to copy one or all parameter groups from one drive to another. All the parameter groups are first upload...

Page 69

Control keypad vacon • 67 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 figure 7-7. Storing and loading of parameter sets upload parameters to keypad (to keypad, s6.3.2) this function uploads all existing parameter groups to the keypad provided that the drive is stopped. Enter the ...

Page 70

68 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 automatic parameter backup (p6.3.4) on this page you can activate or inactivate the parameter backup function. Enter the edit mode by pressing menu button right. Select yes or no with the browser buttons . When the paramet...

Page 71

Control keypad vacon • 69 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 figure 7-9. Parameter comparison 7.3.6.5 safety note: the security submenu is protected with a password. Store the password in a safe place! Password (s6.5.1) the application selection can be protected against ...

Page 72

70 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 this function allows the user to prohibit changes to the parameters. If the parameter lock is activated, the text *locked* will appear on the display if you try to edit a parameter value. Note: this function does not preve...

Page 73

Control keypad vacon • 71 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 multimonitoring items (p6.5.4) vacon alphanumeric keypad features a display where you can monitor up to three actual values at the same time (see chapter 7.3.1 and chapter monitoring values in the manual of the...

Page 74

72 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 default page in the operating menu (p6.6.2) here you can set the location (page) in the operating menu (in special applications only) to which the display automatically moves to when the set timeout time (see below) has ex...

Page 75

Control keypad vacon • 73 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 7.3.6.7 hardware settings note: the hardware settings submenu is protected with a password. Store the password in a safe place! In the hardware settings submenu (s6.7) under the system menu, you can further con...

Page 76

74 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 to change the value: enter the edit mode by pressing menu button right . The value starts blinking. Use the browser buttons to change the fan mode and confirm the change with the enter button. If you do not want to change ...

Page 77

Control keypad vacon • 75 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 figure 7-19. Hmi acknowledge timeout number of retries to receive hmi acknowledgement (p6.7.4) with this parameter you can set the number of times the drive will try to receive acknowledgement if it does not re...

Page 78

76 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 trip counters trip counters (menu s6.8.2) are counters the values of which can be reset i.E. Restored to zero. You can use the following resettable counters: note! The trip counters run only when the motor is running. Page...

Page 79

Control keypad vacon • 77 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 in the applications information page, press menu button right to enter the application pages of which there are as many as there are applications loaded into the inverter. Locate the desired application with th...

Page 80

78 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 figure 7-22. Expander board information menus e1 e5 ready i/o term a:nxopta1 i/o term ready b:nxopta2 i/oterm e1 e2 i/o term ready i/oterm e1 e2 10001.0 expander boards software version state run.

Page 81

Control keypad vacon • 79 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 7 7.3.7 expander board menu (m7) in the expander board menu the user can 1) see the expander boards connected to the control board and 2) see and edit the parameters associated with the expander boards. Go to the...

Page 82

80 • vacon control keypad tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 7 7.4 further keypad functions the vacon nx control keypad contains additional application-related functions. See vacon nx application package for more information..

Page 83

Commissioning vacon • 81 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 8 8. Commissioning 8.1 safety before commissioning, note the following directions and warnings: 1 internal components and circuit boards of the inverter (except for the galvanically isolated i/o terminals) are liv...

Page 84

82 • vacon commissioning tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 8 6 connect the inverter to dc supply. 7 set the parameters of group 1 according to the requirements of your application (see vacon all in one application manual). At least the following parameters should be set: motor nomina...

Page 85

Commissioning vacon • 83 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 8 9 run the start-up tests without the motor being connected to the process. If this is not possible, make sure that running each test is safe prior to running it. Inform your co- workers of the tests. A) switch o...

Page 86

84 • vacon fault tracing tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 9 9. Fault tracing when a fault is detected by the inverter control electronics, the drive is stopped and the symbol f together with the ordinal number of the fault, the fault code and a short fault description appear on the ...

Page 87

Fault tracing vacon • 85 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 9 fault code fault possible cause correcting measures 12 brake chopper supervision no brake resistor installed brake resistor is broken brake chopper failure check brake resistor. If the resistor is ok, the choppe...

Page 88

86 • vacon fault tracing tel. +358 (0)201 2121 • fax: +358 (0)201 2121 205 9 fault code fault possible cause correcting measures 37 device changed (same type) option board or control unit changed. Same type of board or same power rating of drive. Reset note: no fault time data record! 38 device adde...

Page 89

Fault tracing vacon • 87 24-hour support: +358 (0)201 212 575 • email: vacon@vacon.Com 9 fault code fault possible cause correcting measures 59 follower communication systembus is broken between master and follower. Check option board parameters. Check optical fibre cable. 60 cooling coolant circula...

Page 90

Document id: rev. B sales code: doc-userfi4fi8+dluk vacon ltd member of the danfoss group runsorintie 7 65380 vaasa finland www.Danfoss.Com.