- DL manuals

- Vacon

- Controller

- NXP 0650 6

- User Manual

Vacon NXP 0650 6 User Manual

Summary of NXP 0650 6

Page 1

Vacon nx ac drives user manual ® phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 2

2 • vacon at least the 10 following steps of the start-up quick guide must be performed during the installation and commissioning. If any problems occur, please contact your local distributor. Start-up quick guide 1. Check that the delivery corresponds to your order, see chapter 1. 2. Before taking ...

Page 3

Vacon • 3 contents vacon nxs/p user’s manual index 1 safety 2 eu directive 3 receipt of delivery 4 technical data 5 installation 6 cabling and connections 7 control keypad 8 commissioning 9 fault tracing phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 4

4 • vacon about the vacon nxs/p user's manual the user's manual will provide you with the necessary information about the installation, commissioning and operation of vacon nx ac drives. We recommend that you carefully study these instructions before powering up the ac drive for the first time. This...

Page 5

Vacon • 5 vacon nxs/p user's manual index document code: dpd01241a date: 6.3.2013 1. Safety .......................................................................................................................... 7 1.1 warnings .........................................................................

Page 6

6 • vacon 6.1.3 changing the emc protection class .................................................................................... 49 6.1.4 mounting of cable accessories ............................................................................................ 51 6.1.5 installation instruction...

Page 7

Safety vacon • 7 1 1. Safety 1.1 warnings 1 the vacon nx_ ac drive is meant for fixed installations only. 2 do not perform any measurements when the ac drive is connected to the mains. 3 do not perform any voltage withstand tests on any part of vacon nx_. There is a certain procedure according to wh...

Page 8

8 • vacon safety 1 1.3 earthing and earth fault protection the vacon nx_ ac drive must always be earthed with an earthing conductor connected to the earthing terminal . The earth leakage current of vacon nx_ exceeds 3.5ma ac. According to en61800-5-1, one or more of the following conditions for the ...

Page 9

Eu directive vacon • 9 2. Eu directive 2.1 ce marking the ce marking on the product guarantees the free movement of the product within the eea (european economic area). Vacon nx_ ac drives carry the ce label as a proof of compliance with the low voltage directive (lvd) and the electro magnetic compa...

Page 10

10 • vacon eu directive 2 vacon emc class l (protection classes nema1 and nema12: nx_5 fr10 and greater, nx_6 fr6 and greater): ac drives of this class comply with the requirements of category c3 of the product standard en 61800-3 (2004). Category c3 includes converters the rated voltage of which is...

Page 11

Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 12

Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 13

Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 14

14 • vacon receipt of delivery 3 3. Receipt of delivery vacon nx_ ac drives have undergone scrupulous tests and quality checks at the factory before they are delivered to the customer. However, after unpacking the product, check that no signs of transport damages are to be found on the product and t...

Page 15

Receipt of delivery vacon • 15 3 3.2 storage if the ac drive is to be kept in store before use make sure that the ambient conditions are acceptable: storing temperature -40…+158 f (–40…+70 c) relative humidity if the converter is to be stored during longer periods power should be connected to the co...

Page 16

16 • vacon receipt of delivery 3 3.4 warranty only manufacturing defects are covered by the warranty. The manufacturer assumes no responsibility for damages caused during or resulting from transport, receipt of the delivery, installation, commissioning or use. The manufacturer shall in no event and ...

Page 17

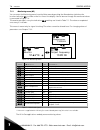

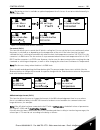

Technical data vacon • 17 4 4. Technical data 4.1 introduction figure 4-1 presents the block diagram of the vacon nx_ ac drive. The ac drive mechanically consists of two units, the power unit and the control unit. Pictures of the mechanical assemblage on pages 55 to 63. The three-phase ac-choke (1) ...

Page 18

18 • vacon technical data 4 the control keypad constitutes a link between the user and the ac drive. The control keypad is used for parameter setting, reading status data and giving control commands. It is detachable and can be operated externally and connected via a cable to the ac drive. Instead o...

Page 19

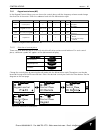

Technical data vacon • 19 4 4.2 power ratings 4.2.1 vacon nx_5 – mains voltage 380—500 v high overload = max current is, 2 sec/20 sec, 150% overloadability, 1 min/10 min following continuous operation at rated output current, 150 % rated output current (ih) for 1 min, followed by a period of load cu...

Page 20

20 • vacon technical data 4 4.2.2 vacon nx_6 – mains voltage 525—690 v high overload = max current is, 2 sec/20 sec, 150% overloadability, 1 min/10 min following continuous operation at rated output current, 150 % rated output current (ih) for 1 min, followed by a period of load current less than ra...

Page 21

Technical data vacon • 21 4 4.2.3 vacon nx_2 – mains voltage 208—240 v high overload = max current is, 2 sec/20 sec, 150% overloadability, 1 min/10 min following continuous operation at rated output current, 150 % rated output current (ih) for 1 min, followed by a period of load current less than ra...

Page 22

22 • vacon technical data 4 4.3 brake resistor ratings mains voltage 380-500 v, 50/60 hz, 3~ converter type max. Brake current [i] resistor nom [ohm] converter type max. Brake current [i] resistor nom. [ohm] nx_ 0003 5 12 63 nx_ 0105 5 111 6.5 nx_ 0004 5 12 63 nx_ 0140 5 222 3.3 nx_ 0005 5 12 63 nx_...

Page 23

Technical data vacon • 23 4 mains voltage 208-240 v, 50/60 hz, 3~ converter type max. Brake current [i] resistor nom [ohm] converter type max. Brake current [i] resistor nom. [ohm] nx_ 0004 2 15 30 nx_ 0061 2 46 10 nx_ 0007 2 15 30 nx_ 0075 2 148 3.3 nx_ 0008 2 15 30 nx_ 0088 2 148 3.3 nx_ 0011 2 15...

Page 24

24 • vacon technical data 4 4.4 technical data mains connection input voltage u in 208…240v; 380…500v; 525…690v; –15%…+10% input frequency 45…66 hz connection to mains once per minute or less starting delay 2 s (fr4 to fr8); 5 s (fr9) motor connection output voltage 0—u in continuous output current ...

Page 25

Technical data vacon • 25 4 shock en50178, en60068-2-27 ups drop test (for applicable ups weights) storage and shipping: max 15 g, 11 ms (in package) enclosure class ip21/nema1 standard in entire kw/hp range ip54/nema12 option in fr4 to fr10 note! Keypad required for ip54/nema12 emc (at default sett...

Page 26

26 • vacon installation 5 5. Installation 5.1 mounting the ac drive can be mounted in either vertical or horizontal position on the wall or on the back plane of a cubicle. However, if the drive is mounted in a horizontal position, it is not protected against vertically falling drops of water. Enough...

Page 27

Installation vacon • 27 5 figure 5-1. Vacon nx_ dimensions type dimensions [inch] w1 w2 h1 h2 h3 d1 e1 e2 * 0004—0012 nxs2 0003—0012 nx_5 5.04 3.94 12.87 12.32 11.5 7.48 0.3 0.1 x 1.11 0017—0031 nxs2 0016—0031 nx_5 5.67 3.94 16.5 15.98 15.39 8.43 0.3 0.1 x 1.46 0.04 x 1.11 0048—0061 nxs2 0038—0061 n...

Page 28

28 • vacon installation 5 figure 5-2. Vacon nx_ dimensions, fr4 to fr6; flange mounting type dimensions [inch] w1 w2 h1 h2 h3 h4 h5 d1 d2 0004—0012 nxs2 0003—0012 nx_5 5.03 4.45 13.27 12.8 12.9 1.18 0.87 7.48 3.03 0.3 0017—0031 nxs2 0016—0031 nx_5 5.67 4.72 17.09 16.54 16.5 1.42 0.71 8.43 3.94 0.3 0...

Page 29

Installation vacon • 29 5 figure 5-3. The opening needed for the flange mounting, fr4 to fr6 type dimensions [inch] w1 w2 w3 h1 h2 h3 h4 0004—0012 nxs2 0003—0012 nx_5 4.84 4.45 – 12.40 12.8 – 0.2 0.3 0017—0031 nxs2 0016—0031 nx_5 5.31 4.72 – 16.14 16.54 – 0.2 0.3 0048—0061 nxs2 0038—0061 nx_5 0004—0...

Page 30

30 • vacon installation 5 figure 5-4. Vacon nx_ dimensions, fr7 and fr8, flange mounting type dimensions [inch] w1 w2 w3 w4 h1 h2 h3 h4 h5 h6 h7 d1 d2 0075—0114 nxs2 0072—0105 nx_5 0041—0052 nx_6 9.33 6.89 10.62 9.96 25.67 24.9 24.8 188.5 7.42 0.91 0.79 10.11 4.61 0.2 0140—0205 nxs2 0140—0205 nx_5 0...

Page 31

Installation vacon • 31 5 figure 5-5. The opening needed for the flange mounting, fr7 type dimensions [inch] w1 w2 w3 h1 h2 h3 h4 h5 h6 0075—0114 nxs2 0072—0105 nx_5 0041—0052 nx_6 9.17 6.89 9.96 24.4 7.42 7.42 1.36 1.26 0.28 0.2 table 5-5. Dimensions for the opening for flange mounting, fr7 figure ...

Page 32

32 • vacon installation 5 figure 5-7. The dimensions vacon nx_, fr9 type dimensions [inch] w1 w2 w3 w4 w5 h1 h2 h3 h 4 h5 h6 d1 d2 d3 0261—0300 nxs2 0261—0300 nx_5 0125—0208 nx_6 18.9 400 15.74 0.4 2.13 45.28* 44.09 28.39 8.07 0.63 7.40 14.25 13.39 11.22 0.83 table 5-7. The dimensions vacon nx_, fr9...

Page 33

Installation vacon • 33 5 figure 5-8. Vacon nx_ dimensions. Fr9 flange mounting type dimensions [inch] w1 w2 w3 w4 w5 h1 h2 h3 h4 h5 h6 h7 d1 d2 d3 0261-0300 nxs2 0261-0300 nx_5 0125-0208 nx_6 20.87 20.08 19.09 7.87 0.2 51.65 45.28 16.5 3.94 1.38 0.4 0.08 14.25 13.39 4.29 0.83 table 5-8. Vacon nx_ d...

Page 34

34 • vacon installation 5 figure 5-9. Vacon nx_ dimensions, fr10 and fr11 (floorstanding units) type dimensions [inch] w1 w2 w3 w4 h1 h2 h3 h4 h5 d1 0385…0520 nx_5 0261…0416 nx_6 23.43 11.46 5.16 0.59 79.45 74.8 56.5 20.161.57 23.70 0590…0730 nx_5 0460…0590 nx_6 31.26 15.35 9.06 0.6 79.45 74.8 56.5 ...

Page 35

Installation vacon • 35 5 figure 5-10. Vacon nxp dimensions, fr12 (floorstanding units) type plate detail y, 1:5 15 y x warning plate detail x, 1:5 1197 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 36

36 • vacon installation 5 c a nk5_2 a 2 a 2 d b a b 5.2 cooling enough free space shall be left around the ac drive to ensure sufficient air circulation, cooling as well as maintenance. You will find the required dimensions for free space in the tables below. If several units are mounted above each ...

Page 37

Installation vacon • 37 5 type cooling air required cfm (cubic feet per minute, ft 3 /min) 0004—0012 nxs2 0003—0012 nx_5 41.2 0017—0031 nxs2 0016—0031 nx_5 0004—0013 nx_6 112 0048—0061 nxs2 0038—0061 nx_5 0018—0034 nx_6 112 0075—0114 nxs2 0072—0105 nx_5 0041—0052 nx_6 250 0140—0205 nxs2 0140—0205 nx...

Page 38

38 • vacon installation 5 5.2.2 standalone units (fr10 to fr12) a a c d b type dimensions [in] a b c d 0385—0520 nx_5 0261—0416 nx_6 1.97 3.94 0590—0730 nx_5 0460—0590 nx_6 1.97 3.94 2.76 5.91 0820—1030 nx_5 0650—0820 nx_6 1.97 3.94 a = minimum distance to the side walls or adjacent components. B = ...

Page 39

Installation vacon • 39 5 a b c table 5-12. Mounting space dimensions type cooling air required cubic yard/hour [yd 3 /h] 0385—0520 5 0261—0416 6 3400.7 0650—0730 5 0460—0590 6 5101.01 0820—1030 5 0650—0820 6 6801.3 table 5-13. Required cooling air figure 5-12. Cabinet installation space mounting sp...

Page 40

40 • vacon installation 5 5.3 power losses 5.3.1 power losses as function of switching frequency if the operator wants to raise the switching frequency of the drive for some reason (typically e.G. In order to reduce the motor noise), this inevitably affects the power losses and cooling requirements ...

Page 41

Installation vacon • 41 5 figure 5-15. Power loss as function of switching frequency; nx_5 0038…0061 figure 5-16. Power loss as function of switching frequency; nx_5 0072…0105 0,00 500,00 1000,00 1500,00 2000,00 2500,00 0,00 2,00 4,00 6,00 8,00 10,00 12,00 switching frequency [khz] p[ w] 0072nx5 400...

Page 42

42 • vacon installation 5 figure 5-17. Power loss as function of switching frequency; nx_5 0140…0205 figure 5-18. Power loss as function of switching frequency; nx_5 0261…0300 0,00 500,00 1000,00 1500,00 2000,00 2500,00 3000,00 3500,00 4000,00 0,00 2,00 4,00 6,00 8,00 10,00 12,00 switching frequency...

Page 43

Installation vacon • 43 5 figure 5-19. Power loss as function of switching frequency; nx_5 0385…0520 0,00 1000,00 2000,00 3000,00 4000,00 5000,00 6000,00 7000,00 8000,00 1 2 3 4 switching frequency [khz] p[w] 0385nx 400v 0385nx 500v 0460nx 400v 0460nx 500v 0520nx 400v 0520nx 500v phone: 800.894.0412...

Page 44

44 • vacon cabling and connections 6 6. Cabling and connections 6.1 power unit 6.1.1 power connections 6.1.1.1 mains and motor cables the mains cables are connected to terminals l1, l2 and l3 and the motor cables to terminals marked with u, v and w. A cable entry gland should be used when installing...

Page 45

Cabling and connections vacon • 45 6 6.1.1.2 dc supply and brake resistor cables vacon ac drives are equipped with terminals for the dc supply and an optional external brake resistor. These terminals are marked with b–, b+/r+ and r–. The dc bus connection is made to terminals b– and b+ and the brake...

Page 46

46 • vacon cabling and connections 6 6.1.1.5 cable and fuse sizes, nx_6, fr6 to fr9 the table below shows typical cable sizes and types that can be used with the converter. The final selection should be made according to local regulations, cable installation conditions and cable specification. Frame...

Page 47

Cabling and connections vacon • 47 6 6.1.1.6 cable and fuse sizes, nx_5, fr10 to fr12 the table below shows typical cable sizes and types that can be used with the converter. The final selection should be made according to local regulations, cable installation conditions and cable specification. Fra...

Page 48

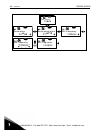

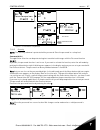

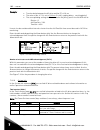

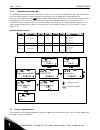

48 • vacon cabling and connections 6 6.1.2 understanding the power unit topology figure 6-1 shows the principles for mains and motor connections of the basic 6-pulse drive in frame sizes fr4 to fr12. Figure 6-1. Topology of mechanical sizes fr4 – fr12 m m m nk6_18.Fh8 fr4-9/fr10 single input single ...

Page 49

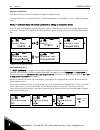

Cabling and connections vacon • 49 6 6.1.3 changing the emc protection class the emc protection level of vacon nx_ ac drives can be changed from class h to class t (and from class l to t in nx_6 fr6) with a simple procedure presented in the following figures. Note! After having performed the change ...

Page 50

50 • vacon cabling and connections 6 fr7: figure 6-4. Changing of emc protection class, fr7 note! Only a vacon service person may change the emc protection class of vacon nxs/p, fr8 and fr9. Remove this screw remove this screw and replace with plastic screw m4 phone: 800.894.0412 - fax: 888.723.4773...

Page 51

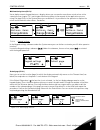

Cabling and connections vacon • 51 6 6.1.4 mounting of cable accessories enclosed to your vacon nxs/p ac drive you have received a plastic bag containing components that are needed for the installation of the mains and motor cables in the ac drive. Figure 6-5. Cable accessories components: 1 groundi...

Page 52

52 • vacon cabling and connections 6 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 53

Cabling and connections vacon • 53 6 6.1.5 installation instructions 1 before starting the installation, check that none of the components of the ac drive is live. 2 place the motor cables sufficiently far from other cables: avoid placing the motor cables in long parallel lines with other cables if ...

Page 54

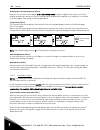

54 • vacon cabling and connections 6 6.1.5.1 stripping lengths of motor and mains cables figure 6-6. Stripping of cables frame a1 b1 c1 d1 a2 b2 c2 d2 fr4 0.59 1.4 0.4 0.79 0.3 2 0.3 1.4 fr5 0.79 1.6 0.4 1.2 0.79 2.4 0.4 1.6 fr6 0.79 3.5 0.59 2.4 0.79 3.5 0.59 2.4 fr7 0.98 4.7 0.98 4.7 0.98 4.7 0.98...

Page 55

Cabling and connections vacon • 55 6 6.1.5.2 vacon nx_ frames and installation of cables note: in case you want to connect an external brake resistor, see separate brake resistor manual. See also chapter 'internal brake resistor connection (p6.7.1)' on page 100 in this manual. Figure 6-7. Vacon nxs/...

Page 56

56 • vacon cabling and connections 6 figure 6-9. Additional grounding connector for fr4 phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 57

Cabling and connections vacon • 57 6 figure 6-10. Vacon nxs/p, fr5. Figure 6-11. Cable installation in vacon nxs/p, fr5 note: see chapter 1.3. Mains cable motor cable earth terminals brake resistor terminals dc terminals phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clr...

Page 58

58 • vacon cabling and connections 6 figure 6-12. Vacon nxs/p, fr6. Figure 6-13. Cable installation in vacon nxs/p, fr6 note: see chapter 1.3. Mains cable motor cable earth terminals brake resistor terminals brake resistor terminals mains cable motor cable earth terminals dc terminals phone: 800.894...

Page 59

Cabling and connections vacon • 59 6 figure 6-14. Vacon nxs/p, fr7. Figure 6-15. Cable installation in vacon nxs/p, fr7 note: see chapter 1.3. Mains cable motor cable earth terminals brake resistor terminals dc terminals phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clr...

Page 60

60 • vacon cabling and connections 6 figure 6-16. Vacon nxs/p, fr8 (with optional dc/brake resistor connection box on top) phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 61

Cabling and connections vacon • 61 6 figure 6-17. Cable installation in vacon nxs/p, fr8 figure 6-18. Brake resistor terminal box on top of fr8 mains cable motor cable earth terminal dc terminals brake resistor terminals phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clr...

Page 62

62 • vacon cabling and connections 6 figure 6-19. Vacon nxs/p, fr9 figure 6-20. Cable installation in vacon nxs/p, fr9 mains cable motor cables earth terminals phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 63

Cabling and connections vacon • 63 6 figure 6-21. Dc and brake resistor terminals on fr9; dc terminals marked with b– and b+, brake resistor terminals marked with r+ and r– b– b+/r+ r– phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 64

64 • vacon cabling and connections 6 figure 6-22. Example of nxs/p standalone drives (fr11) note: more information on cabling for frames fr10 and greater you will find in vacon nxp/c user’s manual. Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.

Page 65

Cabling and connections vacon • 65 6 6.1.6 cable selection and unit installation in accordance with the ul standards to meet the ul (underwriters laboratories) regulations, use a ul-approved copper cable with a minimum heat-resistance of +140/167 f (+60/75 c). Use class 1 wire only. The units are su...

Page 66

66 • vacon cabling and connections 6 6.2 control unit the control unit of the ac drive consists roughly of the control board and additional boards (see figure 6-23 and figure 6-24) connected to the five slot connectors (a to e) of the control board. The control board is connected to the power unit t...

Page 67

Cabling and connections vacon • 67 6 6.2.1 control connections the basic control connections for boards a1 and a2/a3 are shown in chapter 6.2.2. The signal descriptions are presented in the all in one application manual. Figure 6-25. The i/o terminals of the two basic boards figure 6-26. General wir...

Page 68

68 • vacon cabling and connections 6 6.2.1.1 control cables the control cables shall be at least 0.0008 in 2 screened multicore cables, see table 6-1. The maximum terminal wire size is 0.004 in 2 for the relay terminals and 0.002 in 2 for other terminals. Find the tightening torques of the option bo...

Page 69

Cabling and connections vacon • 69 6 6.2.2 control terminal signals opt-a1 terminal signal technical information 1 +10 vref reference voltage maximum current 10 ma 2 ai1+ analogue input, voltage or current selection v or ma with jumper block x1 (see page 72): default: 0– +10v (ri = 200 k ) (-10v…..+...

Page 70

70 • vacon cabling and connections 6 opt-a2 terminal signal technical information 21 ro1/1 relay output 1 switching capacity 24vdc/8a 250vac/8a 125vdc/0.4a min.Switching load 5v/10ma 22 ro1/2 23 ro1/3 24 ro2/1 relay output 2 switching capacity 24vdc/8a 250vac/8a 125vdc/0.4a min.Switching load 5v/10m...

Page 71

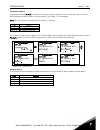

Cabling and connections vacon • 71 6 6.2.2.2 jumper selections on the opt-a1 basic board the user is able to customise the functions of the ac drive to better suit his needs by selecting certain positions for the jumpers on the opt-a1 board. The positions of the jumpers determine the signal type of ...

Page 72

72 • vacon cabling and connections 6 figure 6-31. Jumper selection for opt-a1 ! Note if you change the ai/ao signal content also remember to change the corresponding board parameter in menu m7. A b c d a b c d a b c d a b c d a b c d a b c d a b c d a b c d a b c d a b c d jum per b lock x 1 : ai1 m...

Page 73

Control keypad vacon • 73 7 7. Control keypad the control keypad is the link between the vacon ac drive and the user. The vacon nx control keypad features an alphanumeric display with seven indicators for the run status (run, , ready, stop, alarm, fault) and three indicators for the control place (i...

Page 74

74 • vacon control keypad 7 7.1.2 control place indications the symbols i/o term, keypad and bus/comm (see figure 7-1) indicate the choice of control place made in the keypad control menu (m3) (see chapter 7.3.3). I/o term = i/o terminals are the selected control place; i.E. Start/stop commands or r...

Page 75

Control keypad vacon • 75 7 7.2 keypad push-buttons the vacon alphanumeric control keypad features 9 push-buttons that are used for the control of the ac drive (and motor), parameter setting and value monitoring. Figure 7-2. Keypad push-buttons 7.2.1 button descriptions reset = this button is used t...

Page 76

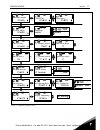

76 • vacon control keypad 7 7.3 navigation on the control keypad the data on the control keypad are arranged in menus and submenus. The menus are used for example for the display and editing of measurement and control signals, parameter settings (chapter 7.3.2), reference values and fault displays (...

Page 77

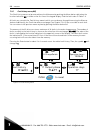

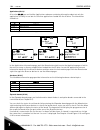

Control keypad vacon • 77 7 figure 7-3. Keypad navigation chart f t1 t7 stop fault i/ote rm stop i/ote rm fault h1 h3 ready i/oterm t1 t7 i/ote rm ready i/oterm ready s1 s9 stop r eady i/oterm stop r eady i/ote rm enter g1 g5 ready i/oterm a:nxopta1 r eady i/ote rm g1 g1 r eady i/oterm v1 v15 r eady...

Page 78

78 • vacon control keypad 7 7.3.1 monitoring menu (m1) you can enter the monitoring menu from the main menu by pushing the menu button right when the location indication m1 is visible on the first line of the display. How to browse through the monitored values is presented in figure 7-4. The monitor...

Page 79

Control keypad vacon • 79 7 7.3.2 parameter menu (m2) parameters are the way of conveying the commands of the user to the ac drive. The parameter values can be edited by entering the parameter menu from the main menu when the location indication m2 is visible on the first line of the display. The va...

Page 80

80 • vacon control keypad 7 figure 7-5. Parameter value change procedure g1 g8 ready ke ypad p1 p18 ready ke ypad 13.95 hz ready keypad g1 g8 keypa d ready keypad 13.95 hz enter ready keypad 14.45 hz parameters basic parameters min frequency input signals min frequency min frequency phone: 800.894.0...

Page 81

Control keypad vacon • 81 7 7.3.3 keypad control menu (m3) in the keypad controls menu, you can choose the control place, edit the frequency reference and change the direction of the motor. Enter the submenu level with the menu button right. Code parameter min max unit default cust id note p3.1 cont...

Page 82

82 • vacon control keypad 7 7.3.3.2 keypad reference the keypad reference submenu (p3.2) displays and allows the operator to edit the frequency reference. The changes will take place immediately. This reference value will not, however, influence the rotation speed of the motor unless the keypad has ...

Page 83

Control keypad vacon • 83 7 7.3.4 active faults menu (m4) the active faults menu can be entered from the main menu by pushing the menu button right when the location indication m4 is visible on the first line of the keypad display. When a fault brings the ac drive to a stop, the location indication ...

Page 84

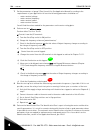

84 • vacon control keypad 7 7.3.4.1 fault types in the nx_ ac drive, there are four different types of faults. These types differ from each other on the basis of the subsequent behaviour of the drive. See table 7-3. Figure 7-7. Fault display fault type symbol meaning a (alarm) this type of fault is ...

Page 85

Control keypad vacon • 85 7 7.3.4.2 fault codes the fault codes, their causes and correcting actions are presented in the table below. The shadowed faults are a faults only. The items written in white on black background present faults for which you can program different responses in the application...

Page 86

86 • vacon control keypad 7 fault code fault possible cause correcting measures 9 undervoltage dc-link voltage is under the voltage limits defined. Most probable cause: too low a supply voltage ac drive internal fault defect input fuse external charge switch not closed subcode in t.14: s1 = dc-link ...

Page 87

Control keypad vacon • 87 7 fault code fault possible cause correcting measures 30 safe disable the input on opt-af board has opened cancel safe disable if this can be done safely. 31 igbt temperature (hardware) igbt inverter bridge overtemperature protection has detected too high a short term overl...

Page 88

88 • vacon control keypad 7 fault code fault possible cause correcting measures 52 keypad communication fault the connection between the control keypad (or ncdrive) and the ac drive is broken. Check keypad connection and possible keypad cable. 53 fieldbus fault the data connection between the fieldb...

Page 89

Control keypad vacon • 89 7 7.3.4.3 fault time data record when a fault occurs the information described above in 7.3.4 is displayed. By pushing the menu button right here you will enter the fault time data record menu indicated by t.1 t.13. In this menu, some selected important data valid at the ti...

Page 90

90 • vacon control keypad 7 7.3.5 fault history menu (m5) the fault history menu can be entered from the main menu by pushing the menu button right when the location indication m5 is visible on the first line of the keypad display. Find the fault codes in table 7-4. All faults are stored in the faul...

Page 91

Control keypad vacon • 91 7 7.3.6 system menu (m6) the system menu can be entered from the main menu by pushing the menu button right when the location indication m6 is visible on the display. The controls associated with the general use of the ac drive, such as application selection, customised par...

Page 92

92 • vacon control keypad 7 p6.7.2 fan control continuous continuous temperature p6.7.3 hmi acknowledg. Timeout 200 5000 ms 200 p6.7.4 hmi number of retries 1 10 5 s6.8 system information s6.8.1 total counters c6.8.1.1 mwh counter kwh c6.8.1.2 power on day counter c6.8.1.3 power on hours counter hh:...

Page 93

Control keypad vacon • 93 7 7.3.6.1 language selection the vacon control keypad offers you the possibility to control the ac drive through the keypad in the language of your choice. Locate the language selection page under the system menu. Its location indication is s6.1. Press the menu button right...

Page 94

94 • vacon control keypad 7 figure 7-10. Change of application 7.3.6.3 copy parameters the parameter copy function is used when the operator wants to copy one or all parameter groups from one drive to another or to store parameter sets in the internal memory of the converter. All the parameter group...

Page 95

Control keypad vacon • 95 7 figure 7-11. Storing and loading of parameter sets upload parameters to keypad (to keypad, s6.3.2) this function uploads all existing parameter groups to the keypad provided that the drive is stopped. Enter the to keypad page (s6.3.2) from the parameter copy menu. Push th...

Page 96

96 • vacon control keypad 7 automatic parameter backup (p6.3.4) on this page you can activate or inactivate the parameter backup function. Enter the edit mode by pressing the menu button right. Choose yes or no with the browser buttons. When the parameter backup function is activated vacon nx contro...

Page 97

Control keypad vacon • 97 7 figure 7-13. Parameter comparison 7.3.6.5 security note: the security submenu is protected with a password. Store the password in a safe place! Password (s6.5.1) the application selection can be protected against unauthorised changes with the password function (s6.5.1). B...

Page 98

98 • vacon control keypad 7 parameter lock (p6.5.2) this function allows the user to prohibit changes to the parameters. If the parameter lock is activated the text *locked* will appear on the display if you try to edit a parameter value. Note: this function does not prevent unauthorised editing of ...

Page 99

Control keypad vacon • 99 7 multimonitoring items (p6.5.4) vacon alpha-numeric keypad features a display where you can monitor even three actual values at the same time (see chapter 7.3.1 and chapter monitoring values in the manual of the application you are using). On page p6.5.4 of the system menu...

Page 100

100 • vacon control keypad 7 default page in the operating menu (p6.6.2) here you can set the location (page) in the operating menu (in special applications only) to which the display automatically moves as the set timeout time (see below) has expired or as the power is switched on to the keypad. Se...

Page 101

Control keypad vacon • 101 7 note! The brake resistor is available as optional equipment for all classes. It can be installed internally in classes fr4 to fr6. Figure 7-21. Internal brake resistor connection fan control (p6.7.2) this function allows you to control the ac drive’s cooling fan. You can...

Page 102

102 • vacon control keypad 7 example: transfer delay between the ac drive and the pc = 600 ms the value of par. 6.7.3 is set to 1200 ms (2 x 600, sending delay + receiving delay) the corresponding setting shall be entered in the misc -part of the file ncdrive.Ini: retries = 5 acktimeout = 1200 timeo...

Page 103

Control keypad vacon • 103 7 trip counters (s6.8.2) trip counters (menu s6.8.2) are counters the values of which can be reset i.E. Restored to zero. You have the following resettable counters at your disposal. See table 7-7 for examples. Note! The trip counters run only when the motor is running. Pa...

Page 104

104 • vacon control keypad 7 applications (s6.8.4) at location s6.8.4 you can find the applications submenu containing information about not only the application currently in use but also all other applications loaded into the ac drive. The information available is: page content 6.8.4.# name of appl...

Page 105

Control keypad vacon • 105 7 for more information on the expander board-related parameters, see chapter 7.3.7. Figure 7-26. Expander board information menus debug menu (s6.8.7) this menu is meant for advanced users and application designers. Contact factory for any assistance needed. E1 e5 ready i/o...

Page 106

106 • vacon control keypad 7 7.3.7 expander board menu (m7) the expander board menu makes it possible for the user 1) to see what expander boards are connected to the control board and 2) to reach and edit the parameters associated with the expander board. Enter the following menu level (g#) with th...

Page 107

Commissioning vacon • 107 8 8. Commissioning 8.1 safety before commissioning, note the following directions and warnings: 1 internal components and circuit boards of the ac drive (except for the galvanically isolated i/o terminals) are live when vacon nx_ is connected to mains potential. Coming into...

Page 108

108 • vacon commissioning 8 7 set the parameters of group 1 (see vacon all in one application manual) according to the requirements of your application. At least the following parameters should be set: - motor nominal voltage - motor nominal frequency - motor nominal speed - motor nominal current yo...

Page 109

Commissioning vacon • 109 8 11 connect the motor to the process (if the startup test was run without the motor being connected) a) before running the tests, make sure that this can be done safely. B) inform your co-workers of the tests. C) repeat test 8a or 8b. Phone: 800.894.0412 - fax: 888.723.477...

Page 110

110 • vacon fault tracing 9 9. Fault tracing when a fault is detected by the ac drive control electronics, the drive is stopped and the symbol f together with the ordinal number of the fault, the fault code and a short fault description appear on the display. The fault can be reset with the reset bu...

Page 111

Fault tracing vacon • 111 9 fault code fault possible cause correcting measures 8 system fault - component failure - faulty operation note exceptional fault data record. S1 = reserved s2 = reserved s3 = reserved s4 = reserved s5 = reserved s6 = reserved s7 = charging switch s8 = no power to driver c...

Page 112

112 • vacon fault tracing 9 fault code fault possible cause correcting measures 24 counter fault values displayed on counters are incorrect 25 microprocessor watchdog fault faulty operation component failure reset the fault and restart. Should the fault re-occur, contact the distributor near to you....

Page 113

Fault tracing vacon • 113 9 fault code fault possible cause correcting measures 49 division by zero in application division by zero has occurred in application program. Contact your distributor if the fault re- occurs while the converter is in run state. If you are application programmer check the a...

Page 114

Document id: rev. A finland subject to change without prior notice © 2013 vacon plc. Phone: 800.894.0412 - fax: 888.723.4773 - web: www.Clrwtr.Com - email: info@clrwtr.Com.